4 min read

From crisis to strength: How Komatsu is reinventing its supply chain

- Operational efficiency,Blog

4 min read

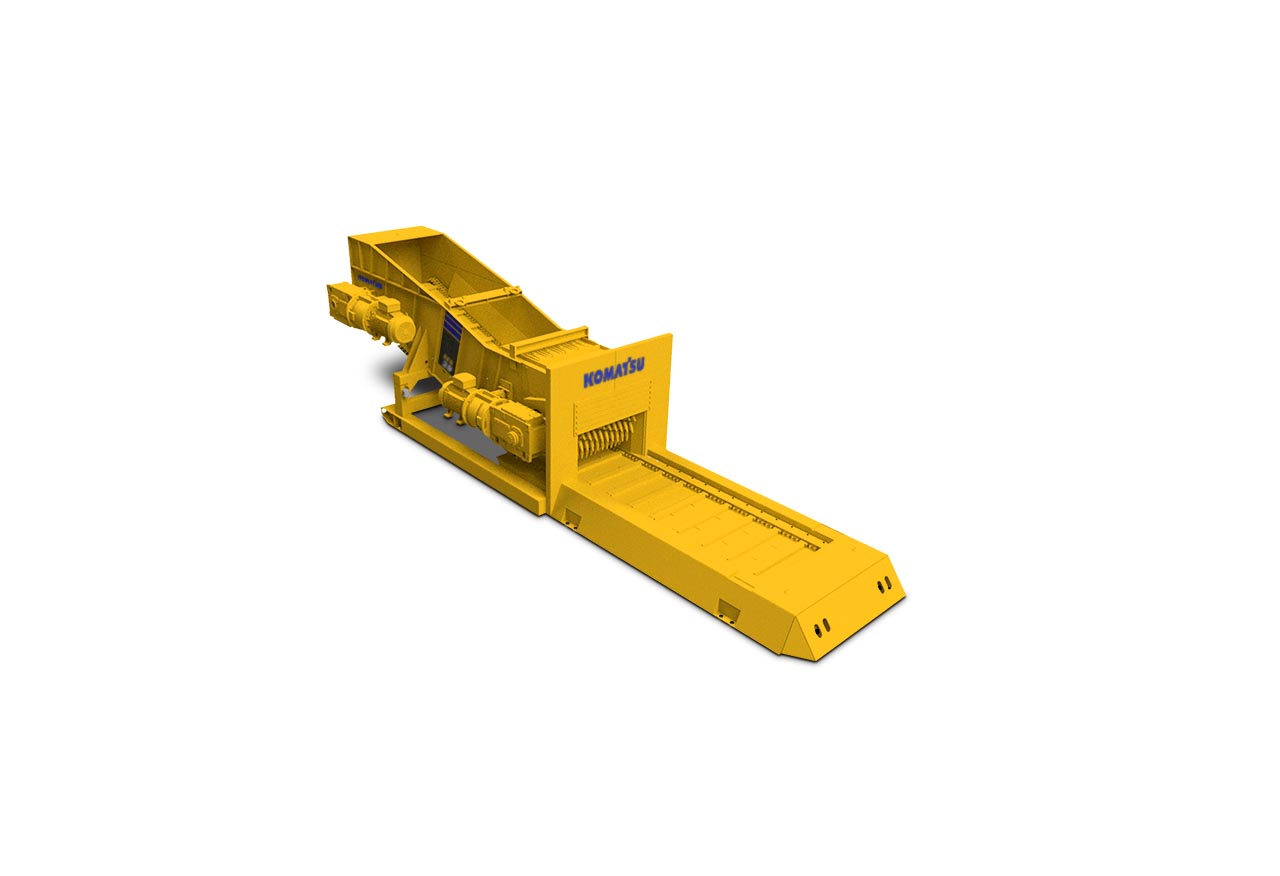

Surface feeder breakers offer substantial benefits to aggregate and cement operations. Surface feeder breakers feature a unique design that can help enhance operational efficiency, reduce downtime and provide exceptional reliability. If you’re unfamiliar with surface feeder breakers, we’ll explore what these innovative crushing machines can do and how they play a critical role in material handling and streamlining operations, particularly for the cement industry.

Understanding feeder breakers

A feeder breaker is an integral crushing solution for aggregate and cement operations, helping enable smooth material flow and size reduction.

This versatile equipment combines two functions: it feeds the material into the process and pre-screens and crushes it. Because of its innovative design, surface feeder breakers are ideal for handling bulky and hard-to-manage materials.

What makes surface feeder breakers unique is the combination of a chain feeder and primary crusher packaged in a common frame. The Stamler Corporation — now part of Komatsu — originally developed this technology. The chain conveyor moves material horizontally under the rotary breaker. Feeder breakers drive a replaceable pick into the mineral, splitting it in tension. The tensile strength of most minerals is less than 10% of its compressive strength, making feeder breakers highly effective and efficient in breaking down the size of materials.

Komatsu surface feeder breakers can handle clay and wet, sticky materials that clog many conventional crushing machines, such as jaw and cone crushers.

Komatsu surface feeder breakers can handle clay and wet, sticky materials that clog many conventional crushing machines, such as jaw and cone crushers.

Komatsu’s surface feeder breaker design

Komatsu offers a range of surface feeder breakers designed to meet the unique challenges of the cement industry. Our surface feeder breakers are engineered for durability and efficiency. They can handle high capacities, making them suitable for various aggregate processing and cement production.

Komatsu surface feeder breakers come with several key features:

Designed to crush challenging materials effectively — handles clay and wet, sticky materials that can clog many conventional crushing machines, such as jaw and cone crushers; helps avoid unscheduled production downtime from blockages

That last feature is important and relates to how conventional equipment is designed compared to Komatsu surface feeder breakers. For instance, jaw and cone crushers are gravity-fed machines with a top-down materials handling process, which makes clay and wet, sticky materials challenging to crush and can cause blockages. Blockages within crushers decrease cement production and increase operating costs. Komatsu feeder breakers are not gravity-fed and have an efficient chain and flight conveyor that keeps material moving. This design pulls material through the surface feeder breaker, helping to overcome potential blockages of clay or wet, sticky material.

Other surface feeder breaker features

Besides those top features, there are several other design elements of the Komatsu surface feeder breakers that bring advantages to aggregate and cement applications:

Choosing the right surface feeder breaker for cement plants

Komatsu surface feeder breakers are essential in sectors that require precise material handling and size reduction, such as the cement industry. Specific material output size is achieved and modified by adjusting the height of the rotary breaker above the conveyor deck and selecting the most efficient pick pattern.

These crushing machines are particularly valuable for aggregate and cement operations since surface feeder breakers facilitate the processing of minerals and other materials into manageable sizes with the added ability to handle the challenges of clay and wet, sticky materials.

Selecting the right Komatsu surface feeder breaker depends on several factors, including material characteristics, desired output size and overall capacity requirements. Komatsu’s team of experts within its dedicated applications and proposals team can help you choose the perfect surface feeder breaker for your operation, ensuring optimized performance and productivity.

Let us help you make your cement production more efficient

Surface feeder breakers are essential for efficient material handling and processing in aggregate and cement applications. Komatsu's range of surface feeder breakers embodies innovation, efficiency and durability, making them an excellent choice for businesses looking to enhance their operations.

Are you interested in learning more about Komatsu's surface feeder breakers for your cement production operation? Contact our team today.