1 min read

Early identification of failing head gaskets prevents US$250,000 in engine replacement and downtime cost

- Challenge

- Solution

- Results

Select continent

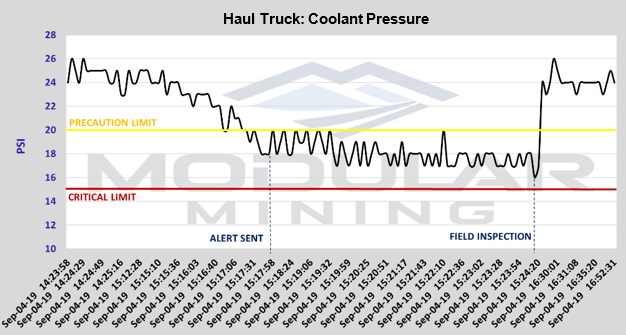

Figure 3. The RemoteCare analyst leveraged data from the MineCare system to generate a report for the site’s maintenance technicians, which identified a drop in the engine’s coolant pressure below the allowable and configurable threshold.

Figure 3. The RemoteCare analyst leveraged data from the MineCare system to generate a report for the site’s maintenance technicians, which identified a drop in the engine’s coolant pressure below the allowable and configurable threshold.

The mine’s maintenance team and RemoteCare personnel had previously worked together to establish precautionary and critical coolant pressure limits for the haul trucks and other equipment units. When the MineCare system detected a drop below this precautionary threshold, it sent an alert, in real time, to the RemoteCare team, who started troubleshooting its possible cause and monitoring the real-time condition of other potentially impacted components.

After verifying the alert’s validity, the analyst remotely leveraged the data from the MineCare system to identify a downward trend in coolant pressure, indicating a possible leak in a cylinder head gasket.

The analyst quickly generated a report (figure 3), which was immediately sent to the mine’s maintenance technicians in route to conduct a field inspection. To confirm the potential leaking head gasket diagnosis, the RemoteCare analyst also recommended the mine review the truck’s oil samples, looking specifically for an increase in glycol or sodium.

During inspection, the mine’s maintenance technician identified a critical leak in cylinder head gaskets 7 and 8 in the engine’s left bank.

Considering the potential for engine damage if additional leaky gaskets went undetected, the maintenance technician was then directed to inspect the engine’s remaining cylinders, and found slight leaks in cylinders 1 and 2, with additional head gasket damage to cylinder 4 (which was found to be caused by corrosion from coolant leakage). The technician added more coolant to the engine, which temporarily improved the pressure and allowed the truck enough time to get to the maintenance bay for a more permanent repair.

Had the truck continued running with low coolant levels, catastrophic engine failure would have likely occurred as a result of overheating. Leveraging the MineCare system’s real-time monitoring and user-defined alarms to identify potential issues early, in conjunction with the expertise of the RemoteCare service analysts, helped prevent approximately $250,000 (US) in parts and downtime to replace the engine. Typical mine sites experience alarms indicating potential head gasket issues at least once a month on average; extrapolated over the course of a year, this savings can equate to more than $3 million annually. For more information please view the following case study