4 min read

From crisis to strength: How Komatsu is reinventing its supply chain

- Operational efficiency,Blog

8 min read

Forklifts have evolved through more than 100 years of progress in innovative thinking and material handling. From the first hydraulic lift introduced in 1920 to the standardization of pallets in the 1930s to today’s advanced, high-tech machines, forklifts are more powerful, maneuverable and efficient than ever.

Among recent advancements in forklifts is the hydrostatic transmission. It’s a type of transmission that — although not suited for every kind of vehicle or machine — is ideal for the typical forklift tasks, environment and operators that are part of materials handling operations. And although it’s a relatively new advancement in forklifts, hydrostatic transmissions have a proven track record in much bigger construction and mining machines with similar high cycle/heavy load applications, such as wheel loaders, dozers and excavators.

What is a hydrostatic transmission?

When you think about how your typical vehicle transmission works, you might focus on the gearing —whether manual or automatic. With a hydrostatic transmission, there are no gears to be changed, which means there is no clutch. In this way, it’s more akin to an automatic transmission, although the design and operation of a hydrostatic transmission is much different.

The biggest difference from conventional transmissions is the introduction of a pump, which is based on a basic engineering concept of using fluid under pressure to convert to mechanical energy. With a hydrostatic transmission, power is generated and transmitted by pressurizing and releasing fluid through a pump — rather than with a drive belt or gears. The movement of the fluids through a hydraulic pump drives the train of the vehicle. In simple terms, the pump converts mechanical energy into pressure. The motor then transforms the pressure energy into mechanical energy.

This transmission design can deliver a lot of power fast — ideal capabilities for vehicles and machines that require impressive on-demand power in the mining, construction and material handling industries.

A hydrostatic transmission also changes how operators drive a vehicle offering greater control and precision. For instance, without a clutch, the operator must become accustomed to a different — but in many ways advantageous — way of driving and operating a vehicle like a forklift.

For instance, the accelerator controls the flow of oil through the transmission, so releasing it automatically slows down the vehicle, with the braking pedal used for inching. It’s a subtle but intuitive way of driving a vehicle. But, once the operator becomes accustomed to the unique nature of how acceleration works in a variable speed hydrostatic transmission, it’s a better overall experience. That’s just one of the benefits that material handling operators will appreciate.

Conventional versus hydrostatic systems

| Conventional | Hydrostatic |

| Transmission loss is created in the torque converter and the clutch | The power losses over the entire engine speed range are minimal |

| Clutches and gearing are used, which can cause interruption of power | No clutches and gearing are used for smoother, uninterrupted power, and no possibility of heat loss or slippage from inching operations |

| Mechanical power is generated by engine combustion | Mechanical energy is generated by fluid under pressure in a pump connected to a motor |

| Ideal for vehicles that require higher, constant speeds | Best for vehicles — such as forklifts — that require on-demand bursts of power, low speeds |

| Many moving parts that require maintenance and could wear out | Less moving parts than conventional transmissions, which may result in less maintenance and downtime |

| Fixed displacement gear pumps use more oil, leading to added loading on the engine and added fuel consumption | Hydrostatic drive products that use automatic load sensing with a variable displacement pump supply only the amount of hydraulic fluid needed to do the job |

| Requires the operator to perform demanding inching maneuvers and arduous cargo handling and dock work | Easy controls and improved operability, especially in non-creep travel, starting on slope, and switch-back situations |

Now that you know the basic design differences between conventional and hydrostatic transmissions, let’s explore some key benefits for material handling applications.

Lower fuel consumption and emissions: Forklifts often operate in a narrow place and are frequently required to accelerate and stop quickly (switching between forward and backward travel) or combine the operation of container handling and traveling. In particular, the higher the load or operation rate at the site (e.g., land transportation, container handling), the more these working conditions becomes prevalent.

Ease of operation is an essential advantage of a hydrostatic transmission.

Ease of operation is an essential advantage of a hydrostatic transmission.

Overall, forklift engines with hydrostatic transmission are extremely efficient for this stop-and-go operation. This ultra efficiency can be mostly attributed to the forklift engine operating at a lower RPM, driving power to the wheels using hydraulic fluid. No engine revving is needed either. Best of all, since the speed and power depend on the pressurized fluid, a forklift engine with a hydrostatic transmission can be left operating at its most efficient RPM, reducing fuel costs.

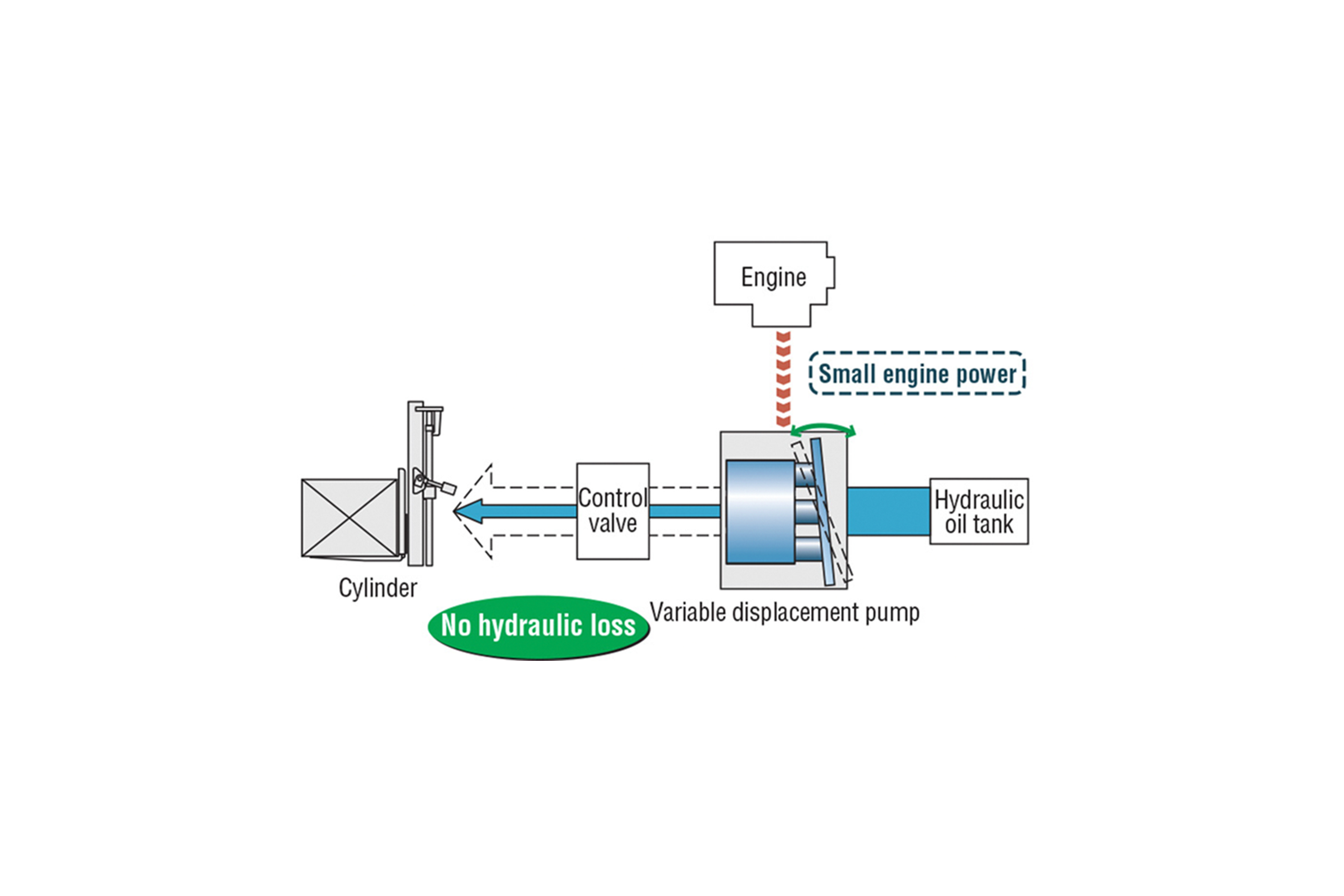

Also, how the hydrostatic transmission is designed can impact fuel consumption. For instance, Komatsu forklifts use a closed-center load sensing capability that automatically senses loading with a variable displacement pump that supplies only the amount of hydraulic fluid needed to do the job. This provides for much greater efficiency than conventional fixed displacement gear pumps, making good use of engine power to reduce overall fuel consumption. With this system, the operator also can lift the load with the engine running at slow speeds, further increasing efficiency with less need for fuel.

Lower emissions: The reduced use of carbon fuels with no engine revving needed also reduces CO2 emissions, providing environmental benefits and improving the air quality in confined indoor material handling environments.

Other technologies can be used with hydrostatic transmission to further reduce emissions, such as The Komatsu FH100-160’s Tier Final 4 engine — used in the FH series of forklifts — that employ multiple catalytic and gas recirculation systems. This technology decomposes NOx into water vapor and non-toxic gas.

Ease of operation: Simple controls (no clutch), smooth acceleration, variable speeds and fast on-demand power in short bursts all add up to an enhanced operator experience — once operators are acclimatized to the unique way that a hydrostatic transmission performs.

Here is a snapshot of some of the ways a forklift with a hydrostatic transmission is easier to operate:

Less wear and tear: With a hydrostatic transmission, there are fewer moving parts. Since a forklift with a hydrostatic transmission doesn’t have a clutch or gearbox, less could go wrong. Fewer components overall than a mechanical system could result in easier, faster and less costly servicing of a hydrostatic transmission. This could save any material handling operation money in repairs further down the line.

Also, there is virtually no wear on drive and brake components, meaning more uptime and reduced maintenance costs compared to traditional torque converter systems — even in the most demanding applications.

Exceptional braking: Materials handling tasks are made easier and more efficient with the advanced braking capabilities of a forklift with a hydrostatic transmission. The oil disc brakes with these forklifts will engage automatically once the accelerator is released. This capability translates into smoother braking and lessens the machine's overall wear.

Lower operating costs: When considering all the advantages of a forklift with a hydrostatic transmission, reduced operating costs are a valuable benefit. For instance, a highly efficient forklift with an electronically controlled hydrostatic transmission hydraulic pump and motor system increases operator control, minimizes power transmission loss, helps moderate fuel use and reduces environmental impact — all factors that can reduce operating costs.

Materials handling operations are under constant pressure to increase efficiencies, boost productivity and reduce total cost of ownership. Fortunately, hydrostatic transmissions use a different kind of pressure to produce performance benefits that materials handling managers can leverage to achieve their operational goals.

For more information on forklifts with hydrostatic transmissions, check out our FH series forklifts at https://www.komatsu.com/products/forklifts.