4 min read

From crisis to strength: How Komatsu is reinventing its supply chain

- Operational efficiency,Blog

2 min read

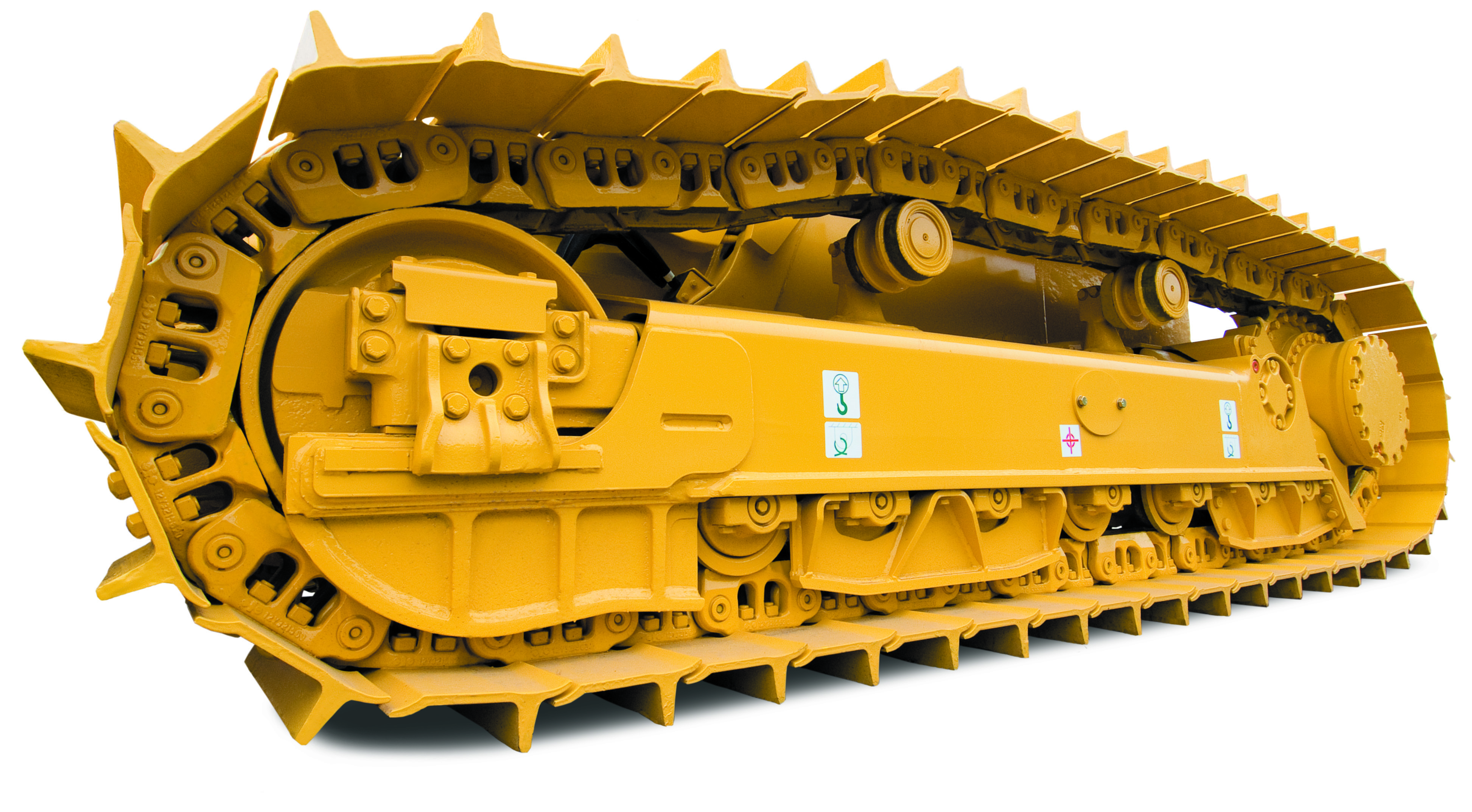

The number one maintenance issue for dozers is damage to the undercarriage due to the large quantity of relatively expensive parts involved, as well as high utilization every time the dozer travels.

While a crawler undercarriage typically accounts for 20 percent of a dozer’s purchase price, it racks up 50 percent (or more) of its lifetime repair tab because the undercarriage suffers more force, sliding and abrasion than any other piece of equipment.

That’s a lot of money tied to one component.

With such large potential repair expenses at stake, keeping the undercarriage in good working condition can significantly minimize repair expenses and lower per-hour operating costs. But, when you figure in 10-hour days, high duty-cycles, and unforgiving terrain, maintaining uptime gets trickier.

A few quick tips for proper undercarriage management:

To learn more about how to better manage your Undercarriage, find your local Komatsu Distributor.