4 min read

From crisis to strength: How Komatsu is reinventing its supply chain

- Operational efficiency,Blog

4 min read

The COVID-19 pandemic severely disrupted global supply chains, causing widespread production and distribution delays, demand and supply imbalances, and logistical challenges. These disruptions highlighted the critical need for more resilient and adaptable supply chains. In response, Komatsu has undertaken significant initiatives to strengthen its supply chain, investing in technology and infrastructure, enhancing risk mitigation strategies and renewing their focus on building stronger, more collaborative relationships with suppliers.

The following outlines the specific impact of the pandemic on Komatsu's supply chain, the initial response, strategic improvements and future resilience plans.

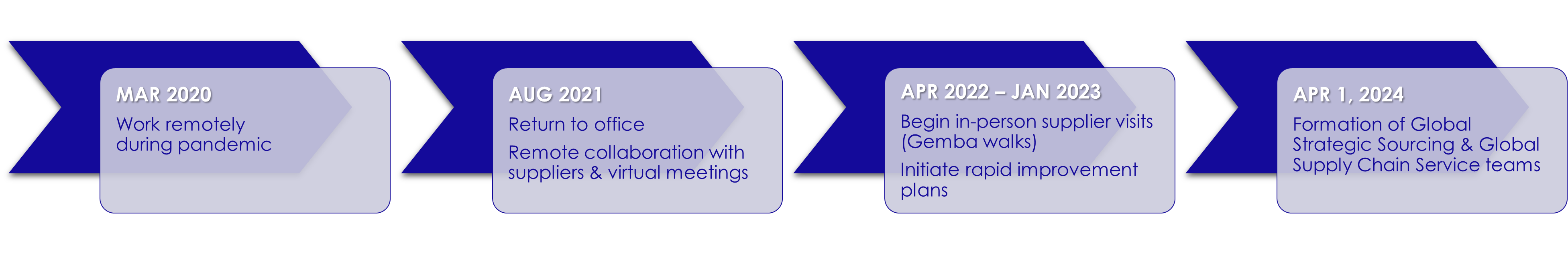

Global supply chain disruptions during the pandemic underscored the importance of building resilient supply networks and investing in advanced technology and infrastructure. For Komatsu's Supply Chain Team, the pandemic resulted in stopping in-person visits to suppliers, not traveling between facilities for team meetings and not going into the office. Despite adapting to remote work and virtual supplier management, the team still faced issues with on-time delivery, extended lead times and quality.

Komatsu quickly adapted to virtual work in the face of the pandemic, expanding IT infrastructure to support remote collaboration, engaging in virtual supplier summits, conducting video inspections with suppliers and eventually returning to the office on a hybrid basis. However, after three years, it became clear that this approach was not sufficient to address overall safety, legal, quality, delivery and cost (SLQDC) performance.

Recognizing the need for a more robust and resilient supply chain, Komatsu implemented a Rapid Improvement Plan. This initiative involved regular meetings, reviews and supplier visits to strengthen relationships and improve operational efficiency. Specific examples include:

These efforts helped improve on-time delivery, enhanced supplier focus on critical parts and strengthened communication to provide customers with accurate delivery dates.

Komatsu established a Global Strategic Sourcing group and a Global Supply Chain Services group to help unify and standardize systems, processes and the management of their core global supply chain. These teams are dedicated to globalizing the Komatsu supply chain while identifying and mitigating risks across key categories to better prepare for future business disruptions, such as those experienced during the Covid crisis. By managing planning, forecasting and inventory at a global level, along with strategic and tactical execution with respect to critical global suppliers and categories, Komatsu aims to improve supply chain efficiency. These efforts are designed to bring the supply chain closer to future customers, supported by globally distributed resources and a commitment to continuously improving SLQDC performance.

While Komatsu quickly adapted to ensure its continuous delivery of products during the pandemic, the company recognized the need for a more refined approach. By categorizing the supply base, creating globally resourced teams and focusing on key risk areas, Komatsu has built a more resilient supply chain for the future. The company will continue to diversify and strengthen its supply chain by prioritizing top-performing suppliers and leveraging the lowest cost markets to deliver exceptional quality to customers.