Drilling and bolting retrofits

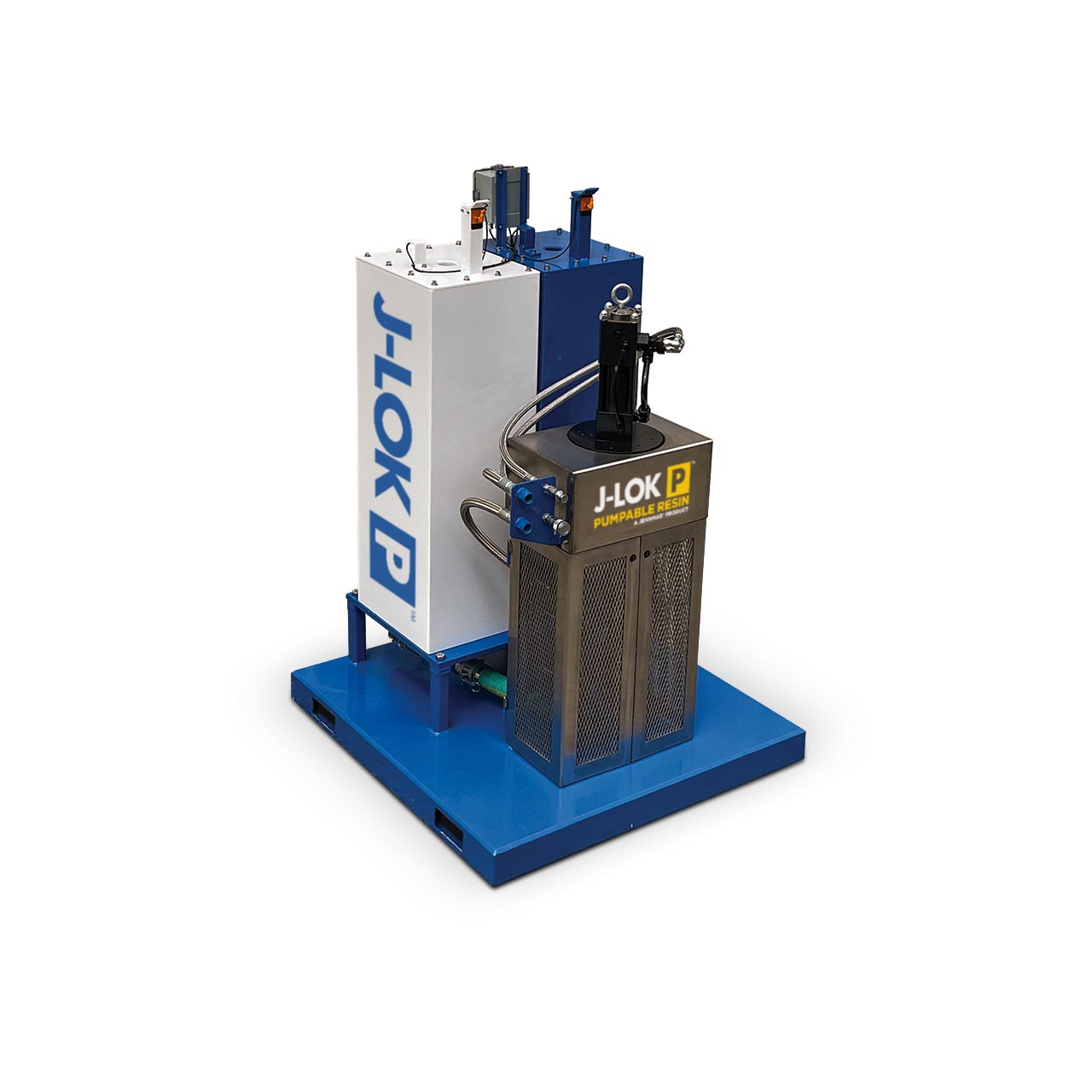

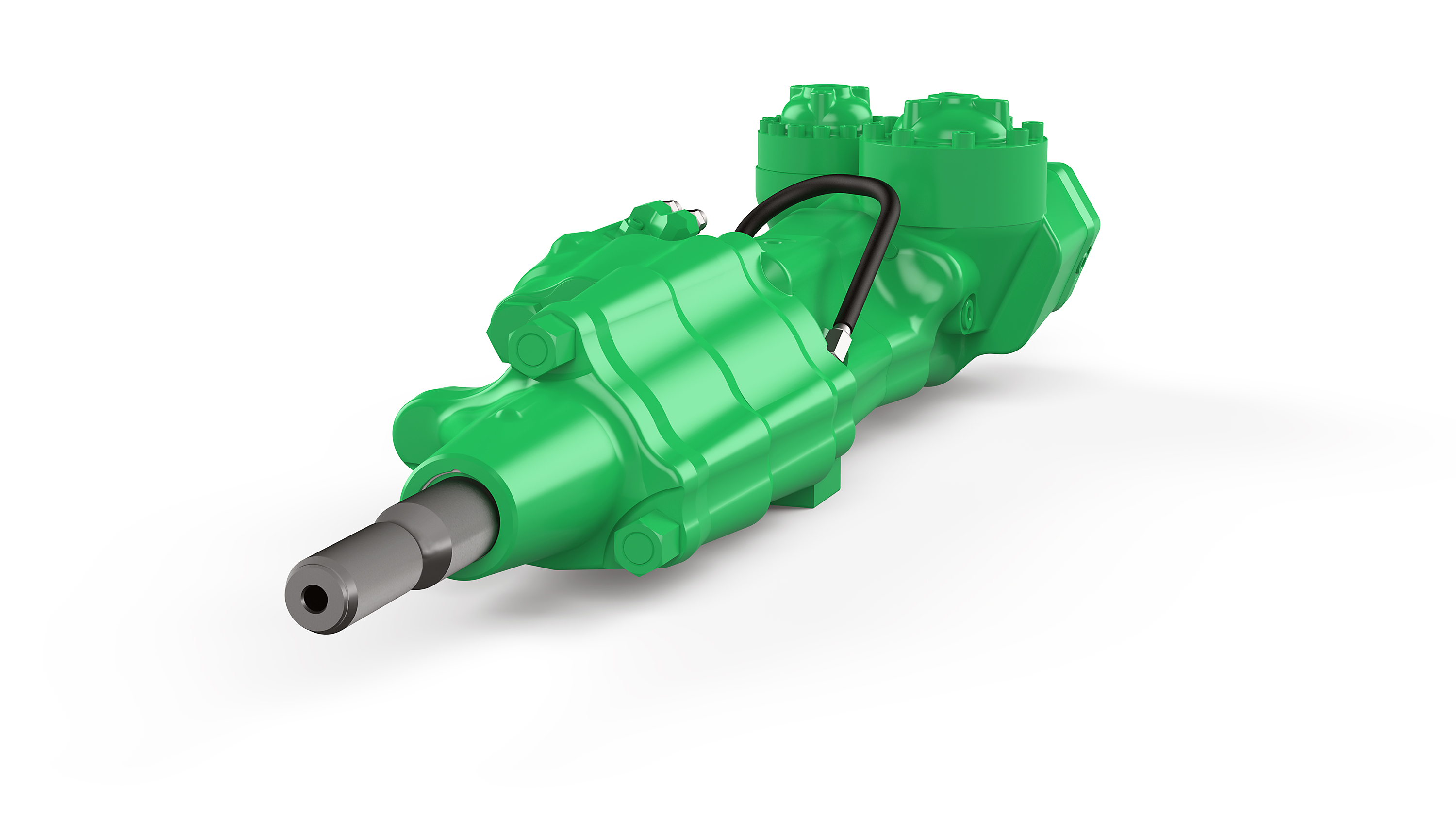

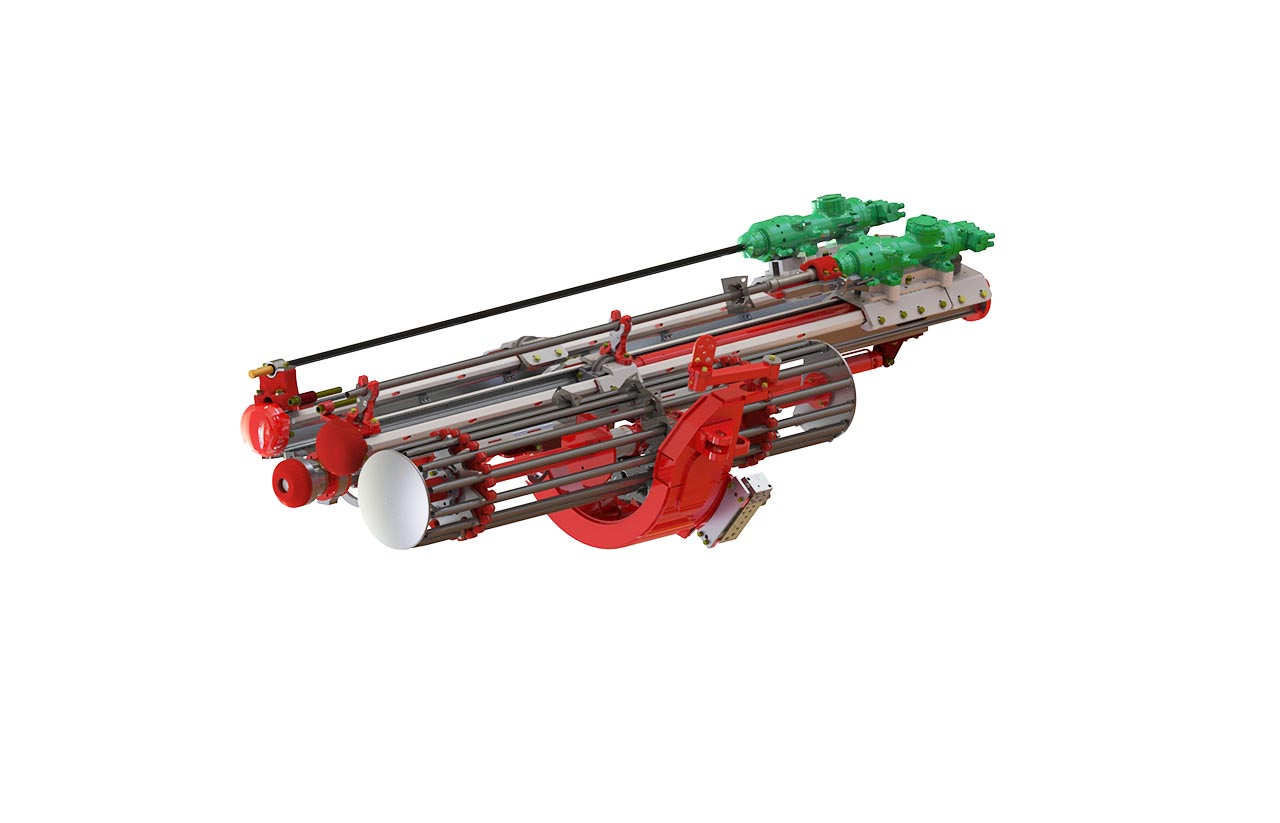

You have the power to revitalize your underground hard rock mining drilling and bolting operations when it’s time for drill rig repair and maintenance by just retrofitting some of the vital components. Komatsu offers four retrofit solutions compatible with every major OEM: Montabert hydraulic rock drill drifters, Timberock feeds and bolting heads, and an innovative J-LOK P pumpable resin injection system. Choose any or all based on application and need.

Top 5 benefits of retrofits

Retrofits in action

See Komatsu retrofits solutions in action with a hands-on view of these vital components. Our hard rock expert walks you through what retrofits can do for your mining operations.

Reimagine your drilling and bolting fleet

Revitalize your underground hard rock machines by retrofitting vital components.