Seamless retrofits no matter the original manufacturer

Features and benefits

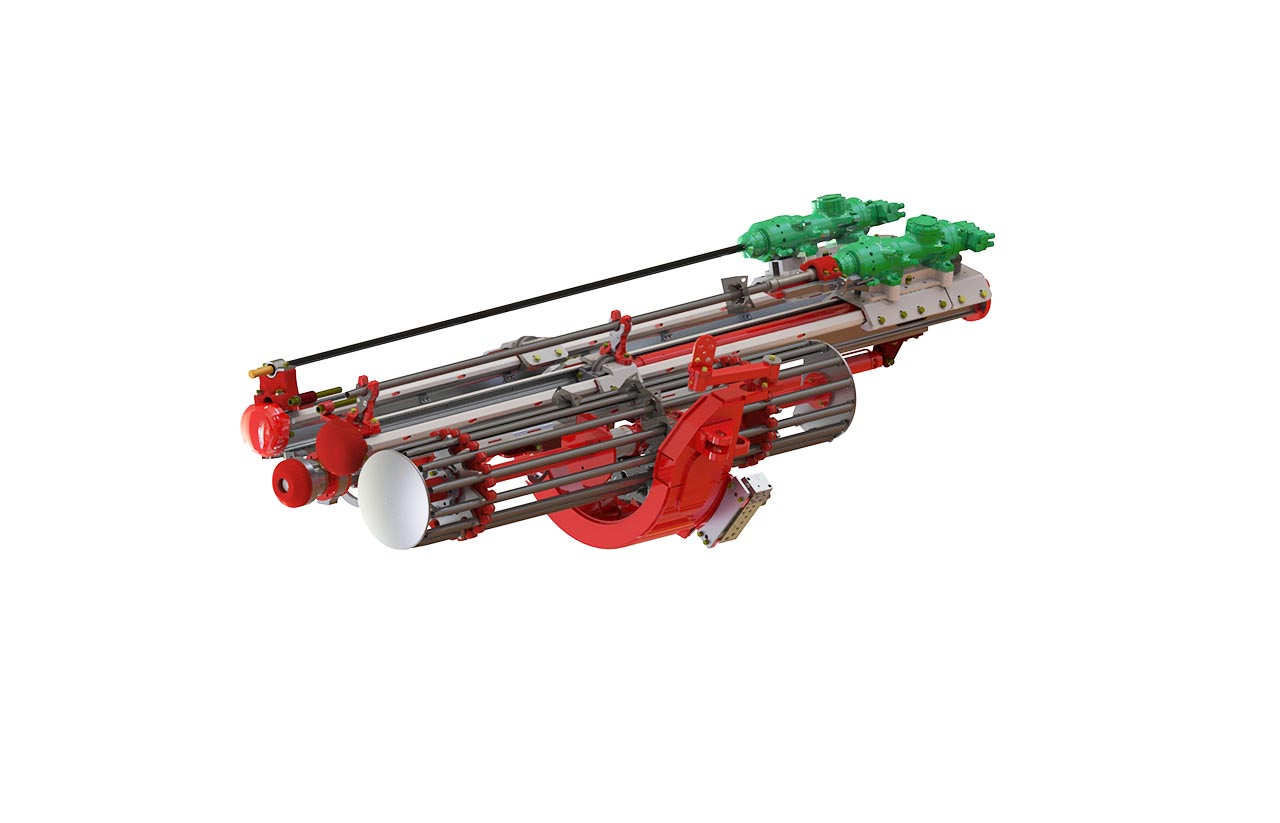

Key features of a Timberock bolting head retrofit

Video series

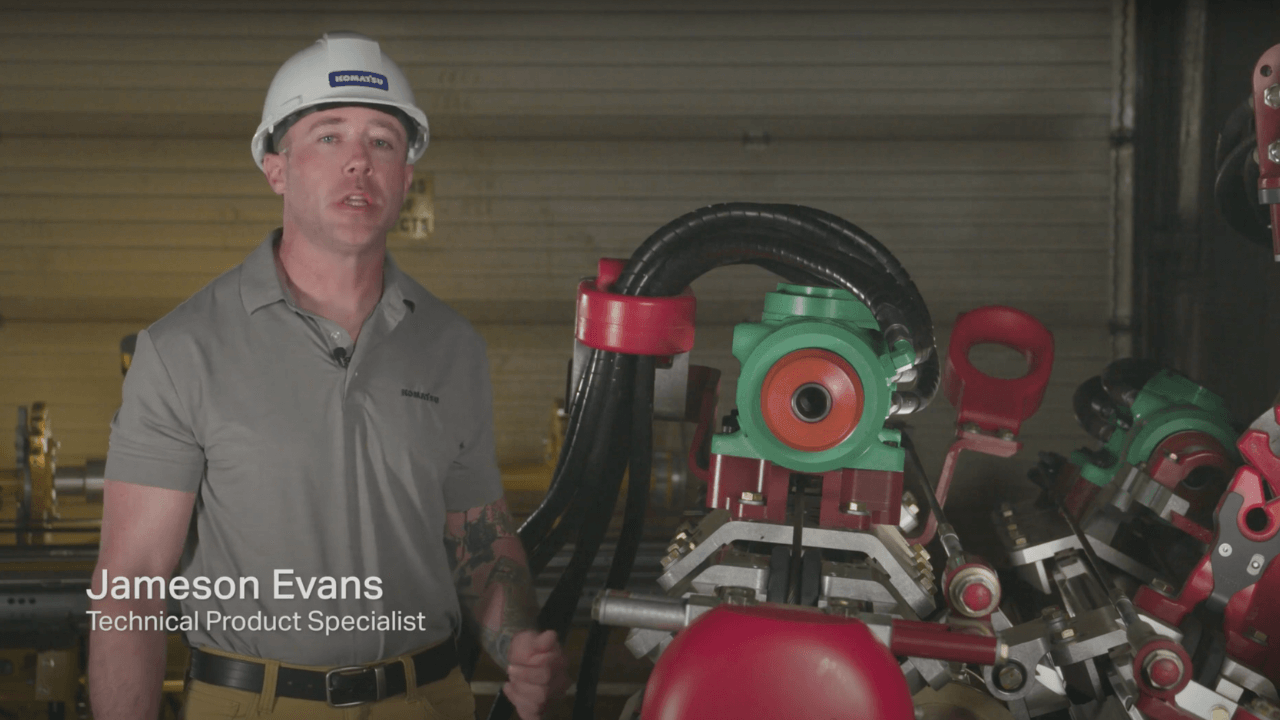

Episode 1: Feeds

Jameson Evans, Product Support Specialist, takes you through the all-important feeds, highlighting the benefits of the dual, independent feed design of the TR-21, the innovative and adjustable wear strips, and more.

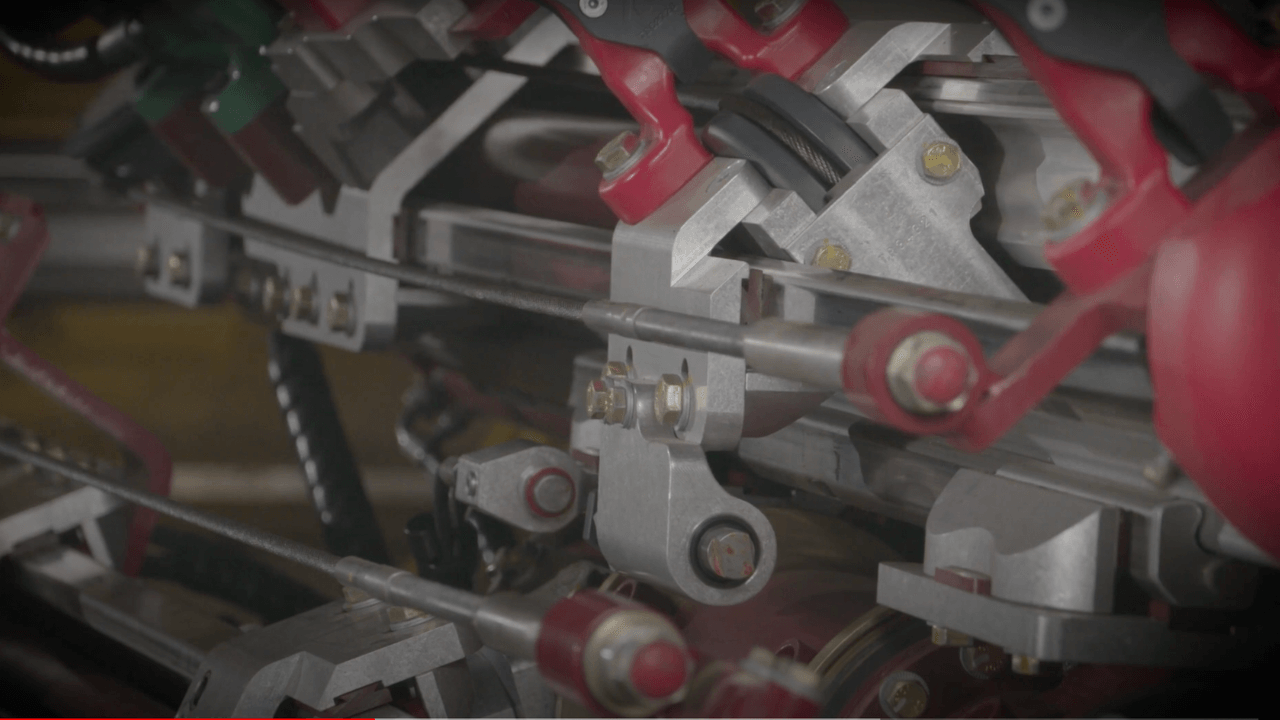

Episode 2: Pulley and cable system

Jameson Evans, Product Support Specialist, shows you how important the pully and cable system is to performance and longevity. Discover a unique and innovative design that can help deliver bolter maintenance and longevity benefits to your underground hard rock mining operation.

Episode 3: Drill mounts and cables

Discover how an intelligent and unique design manufactured with durable aluminum alloy and enhanced with adjustable wear piece holders reduces weight and helps minimize corrosion.

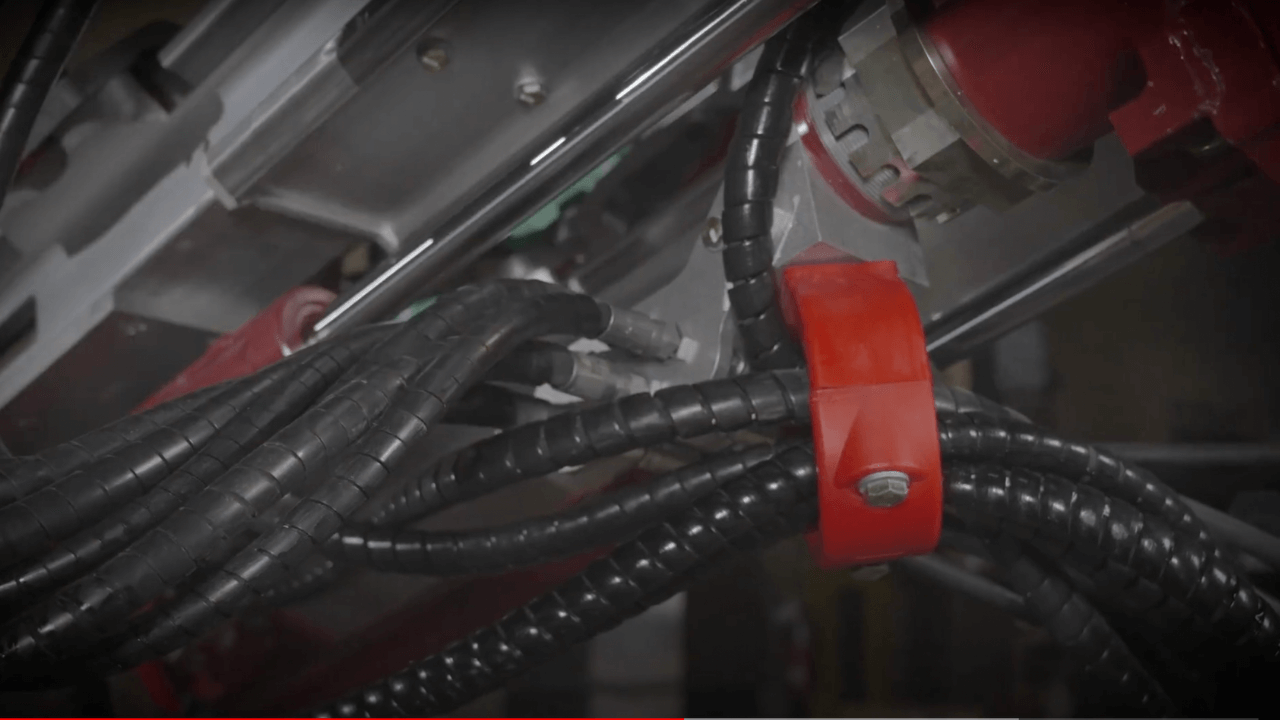

Episode 4: Hose management

Jameson Evans, Product Support Specialist, demonstrates how a smart hose management system design can help you minimize downtime and maximize uptime.

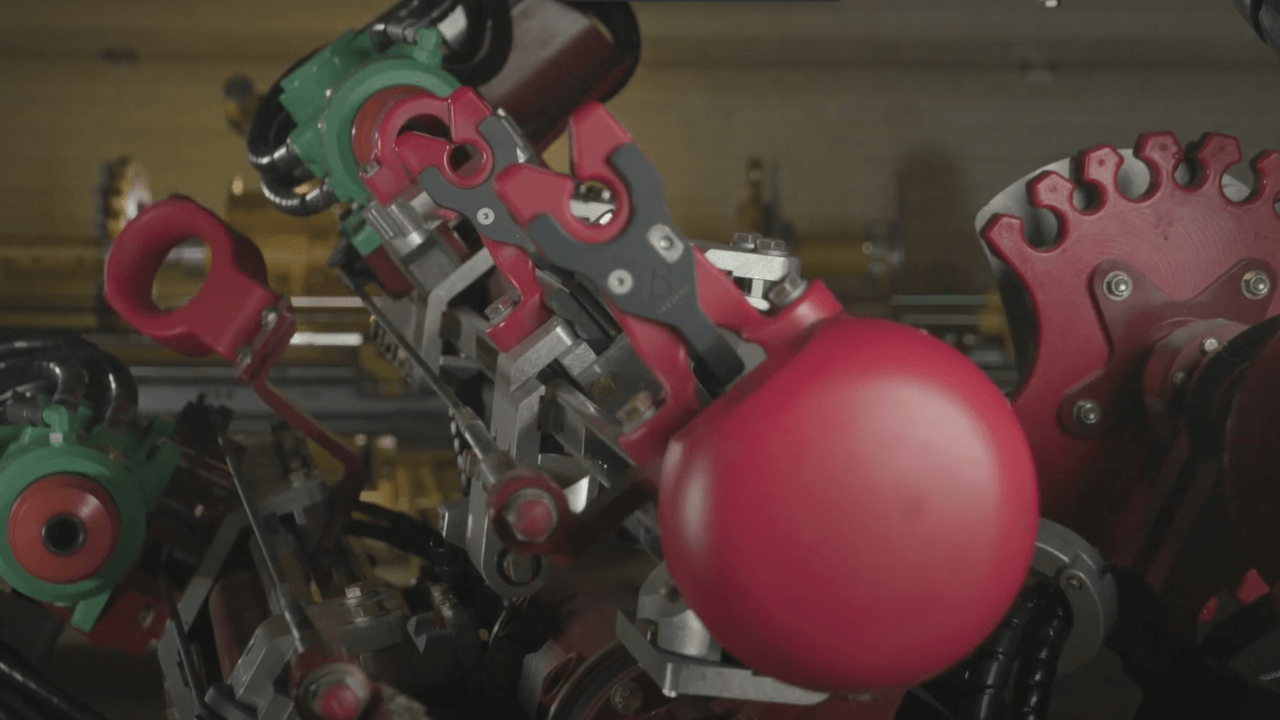

Episode 5: Indexing protection

A common operator error can result in the driver contacting the carousel and causing costly damage to your machine, along with productivity-sapping downtime for your underground hard rock operation. See how unique indexing protection features can help avoid this costly mishap.

Episode 6: Flexible bolt centralizers

Jameson Evans, Product Support Specialist, demonstrates how the flexible and unique design of the TR-21 bolt centralizer works and offers some significant advantages to underground hard rock mining operations. This innovative component has no moving parts, which can help reduce operating costs and downtime.

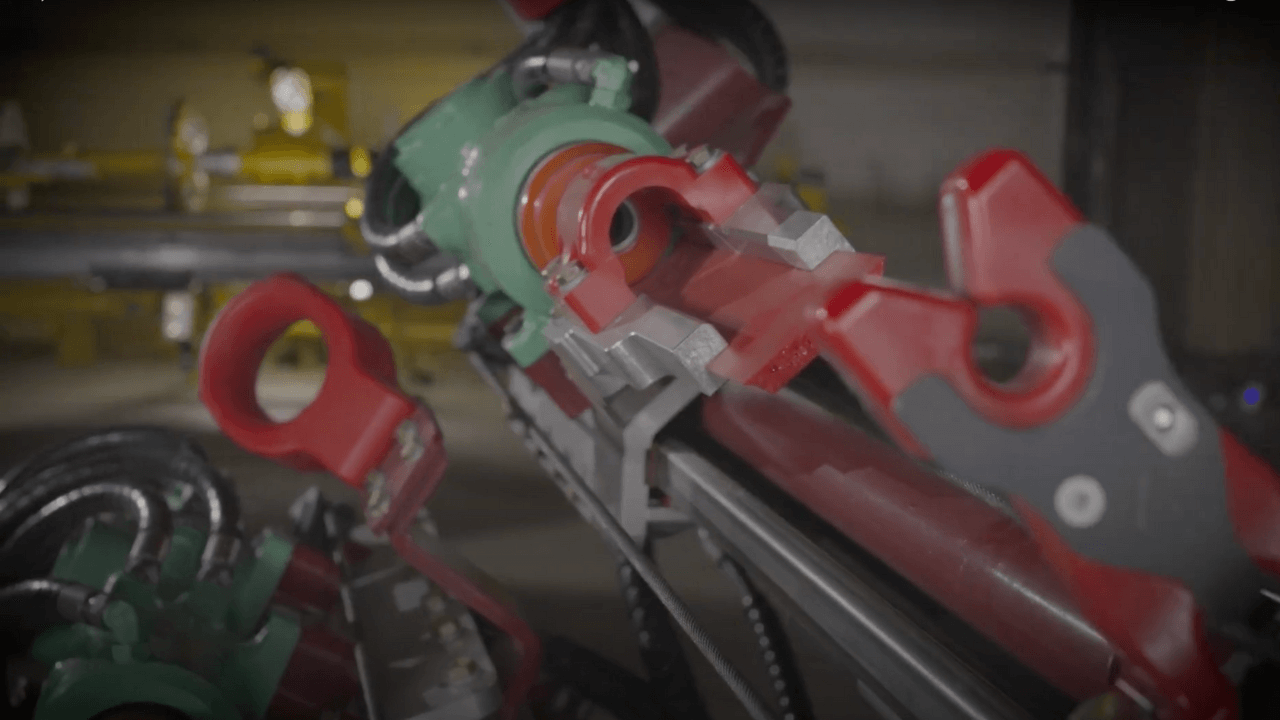

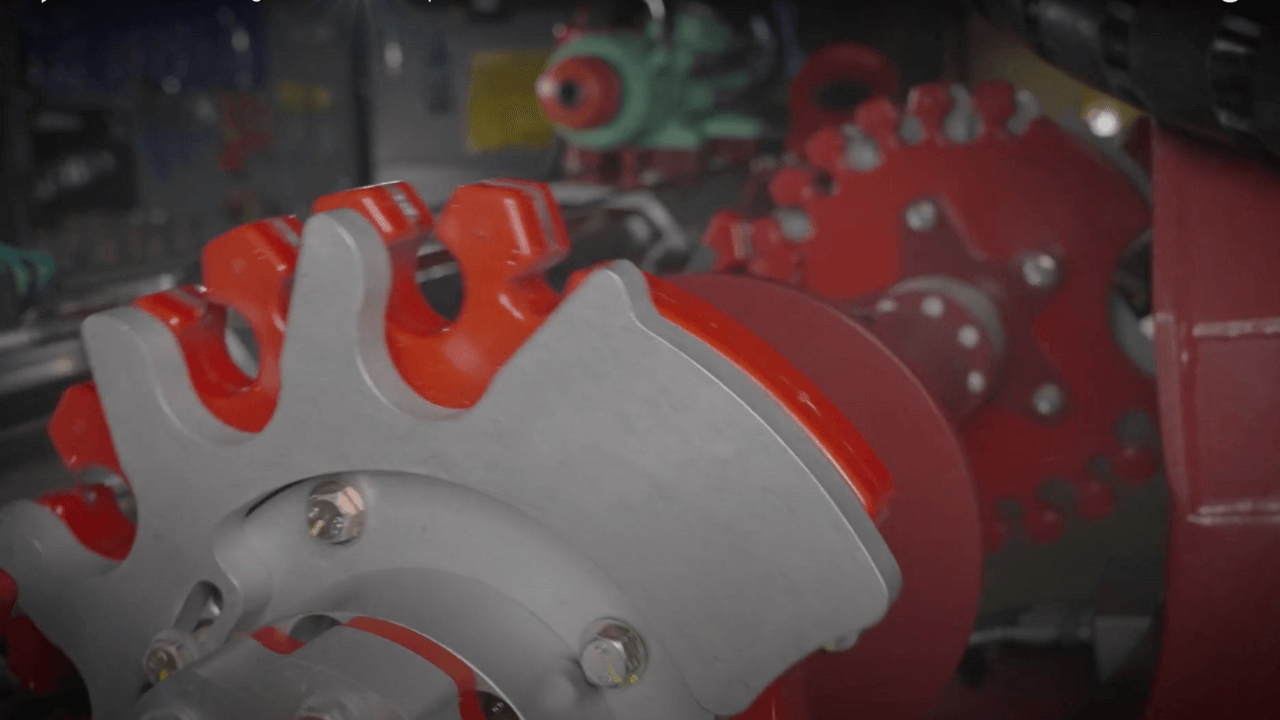

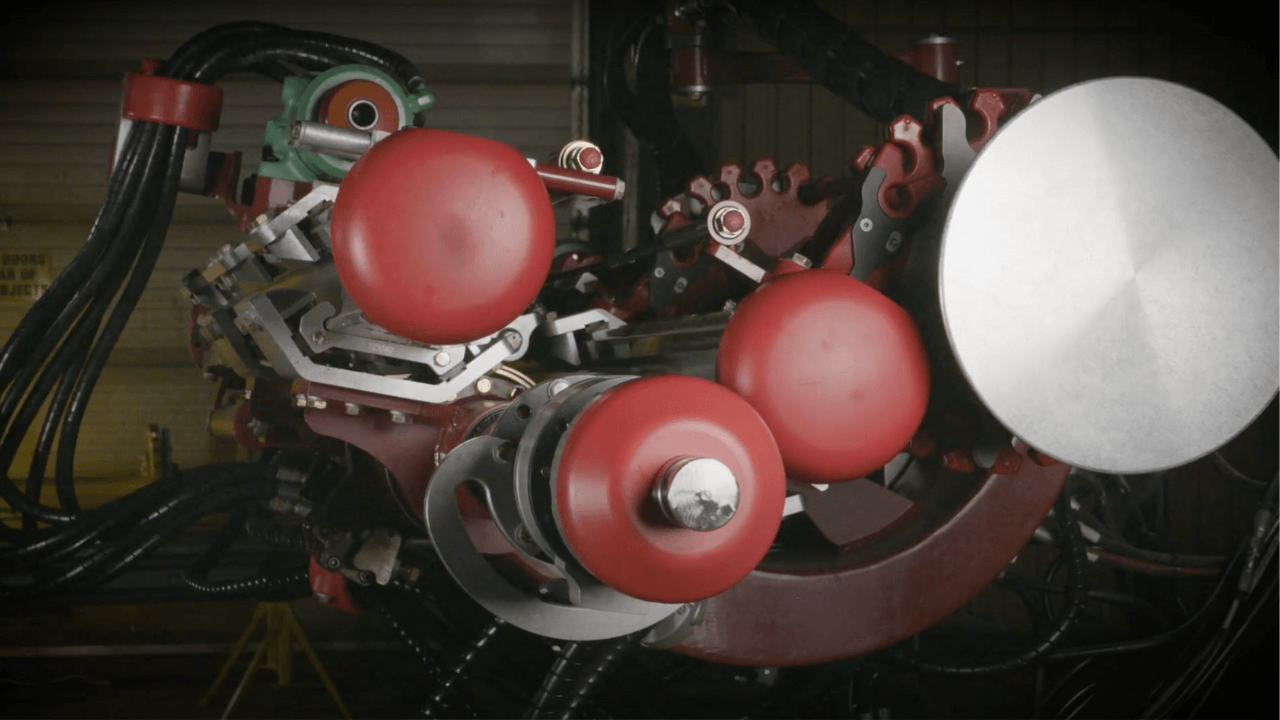

Episode 7: Bolt carousel

Versatility and the ability to change out different bolts quickly and easily during the bolting process are vital to efficiency and productivity in underground hard rock mining. See how simple and fast it is to change between two different bolt size options on the nine-bolt carousel of the TR-21.

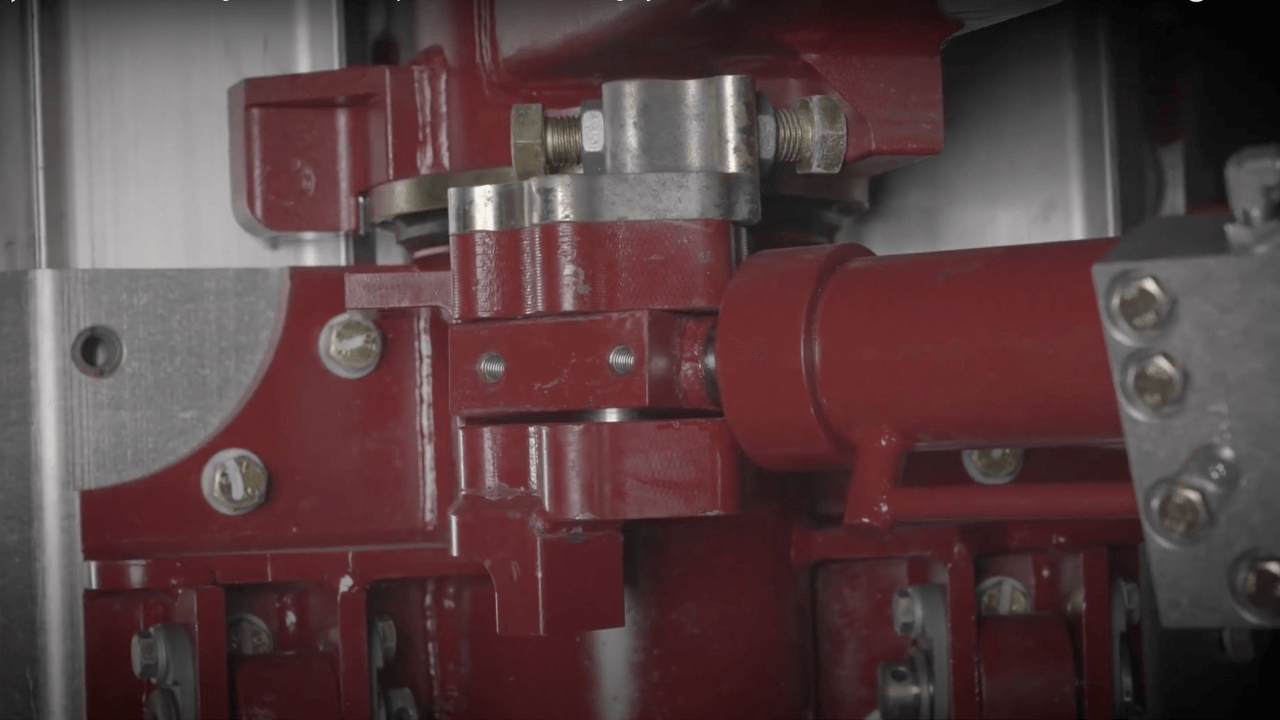

Episode 8: Indexing system

In this video, Jameson Evans, Product Support Specialist, demonstrates the features of the TR-21 indexing system. Explore how the unique features of this system make it easy to perform maintenance and repairs, helping your underground hard rock operation maximize uptime.

Episode 9: C-frame

A common issue for underground hard rock bolting heads is C-frame cracks after extended service. See how the design of the all-important C-frame can help your underground hard rock operation minimize downtime from C-frame failure.

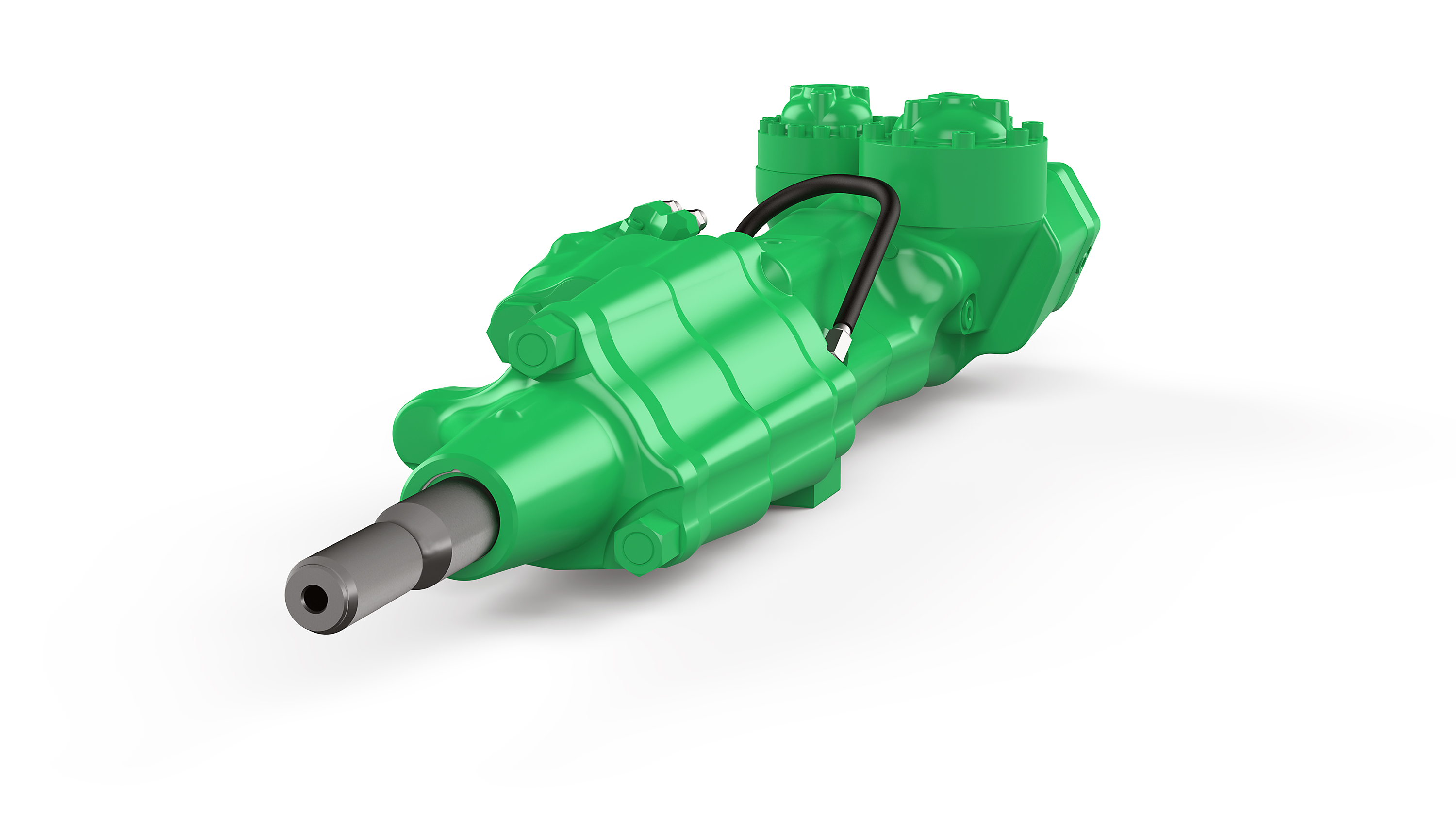

Episode 10: Hydraulic control manifold

The innovative design of the hydraulic control manifold allows for two independent feeds, an indexing lock safety function and control of several options. See how this innovation can enhance bolting operations for your underground hard rock mine.

Episode 11: Integrated screen handler

Jameson Evans, Product Support Specialist, demonstrates how the stinger cylinder and optional screen handler work. See how the intelligent design of the integrated screen handler inside the cylinder offers exceptional visibility and performance when installing protective screens.

- Episode 1: Feeds

- Episode 2: Pulley and cable system

- Episode 3: Drill mounts and cables

- Episode 4: Hose management

- Episode 5: Indexing protection

- Episode 6: Flexible bolt centralizers

- Episode 7: Bolt carousel

- Episode 8: Indexing system

- Episode 9: C-frame

- Episode 10: Hydraulic control manifold

- Episode 11: Integrated screen handler