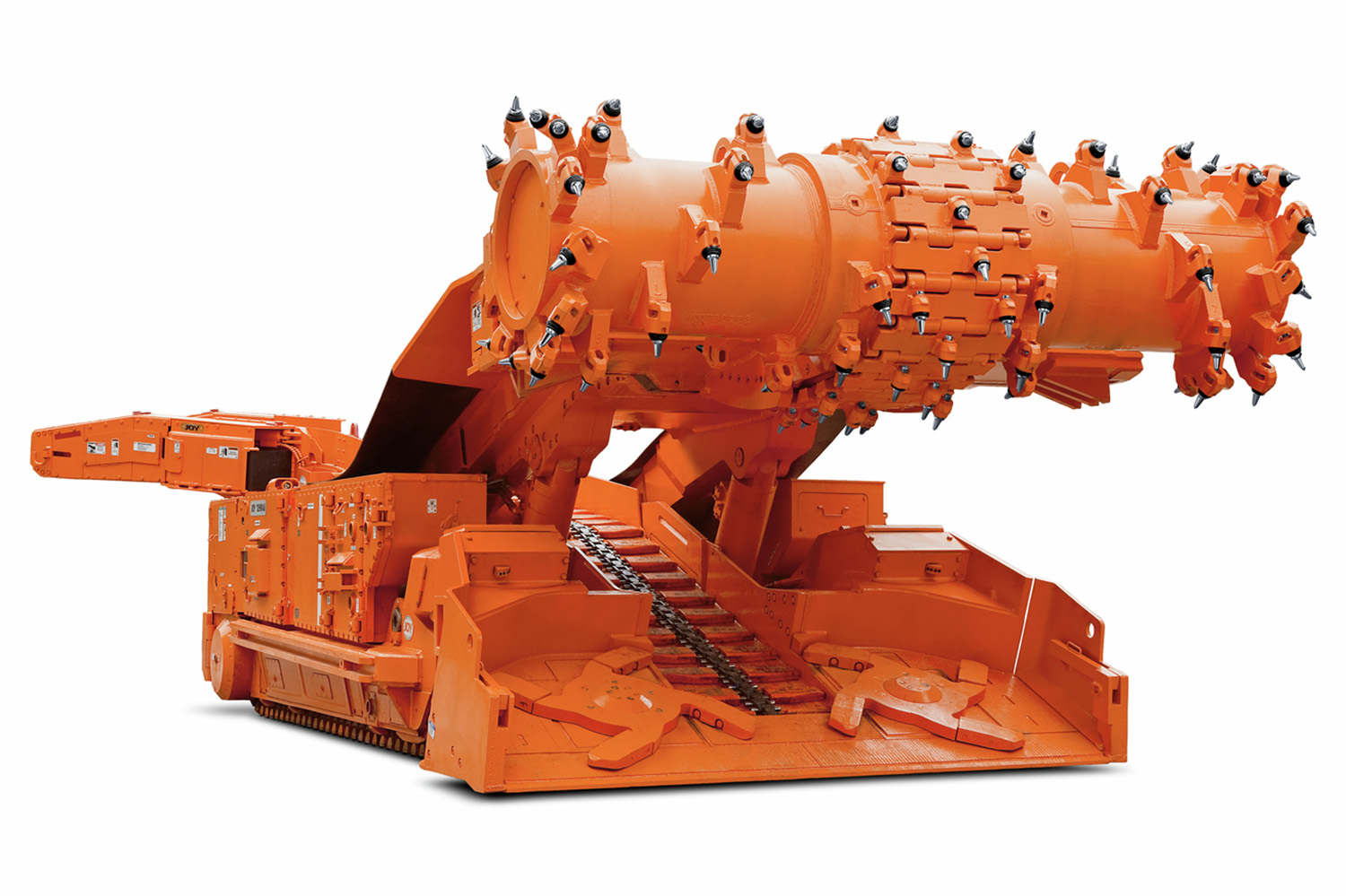

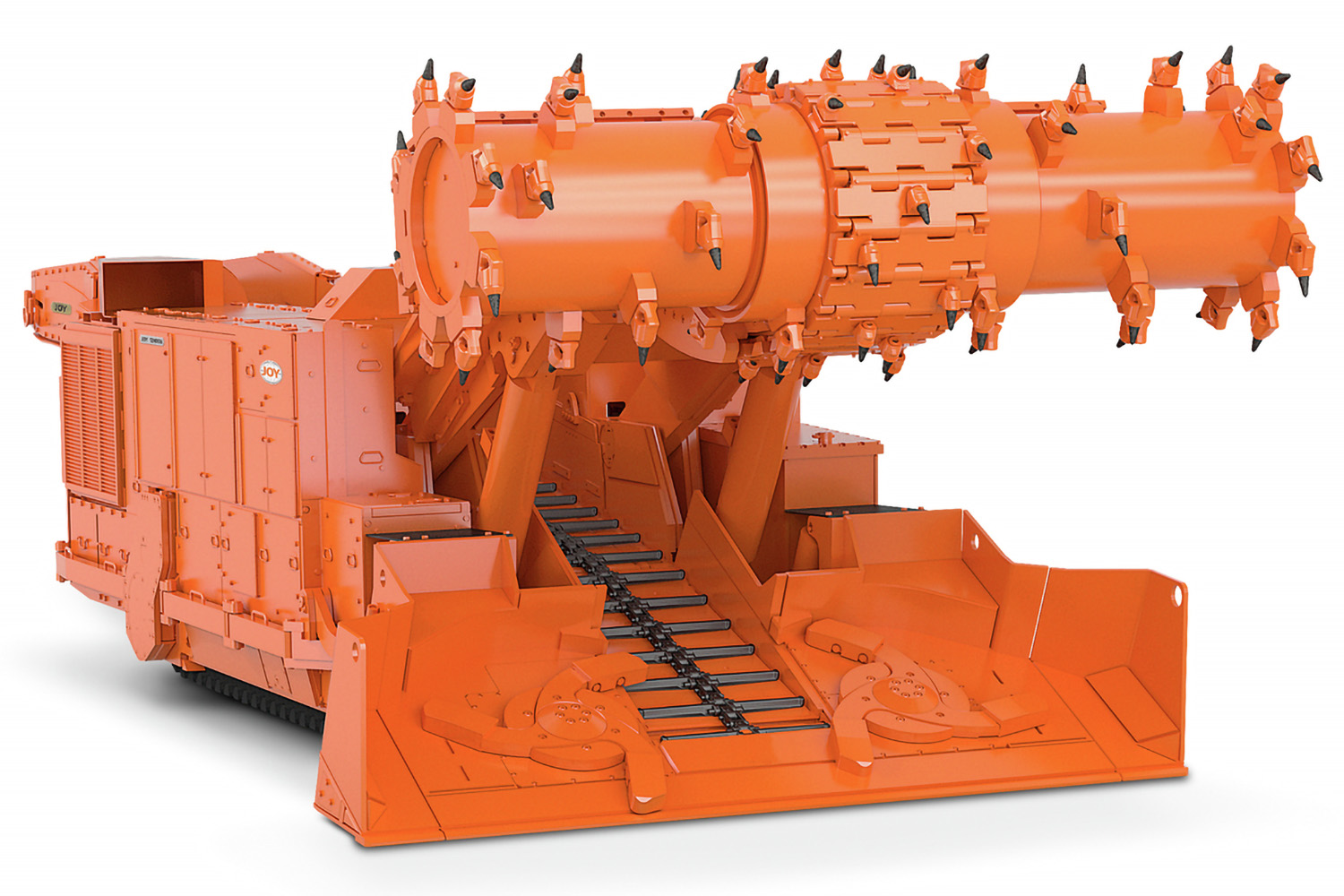

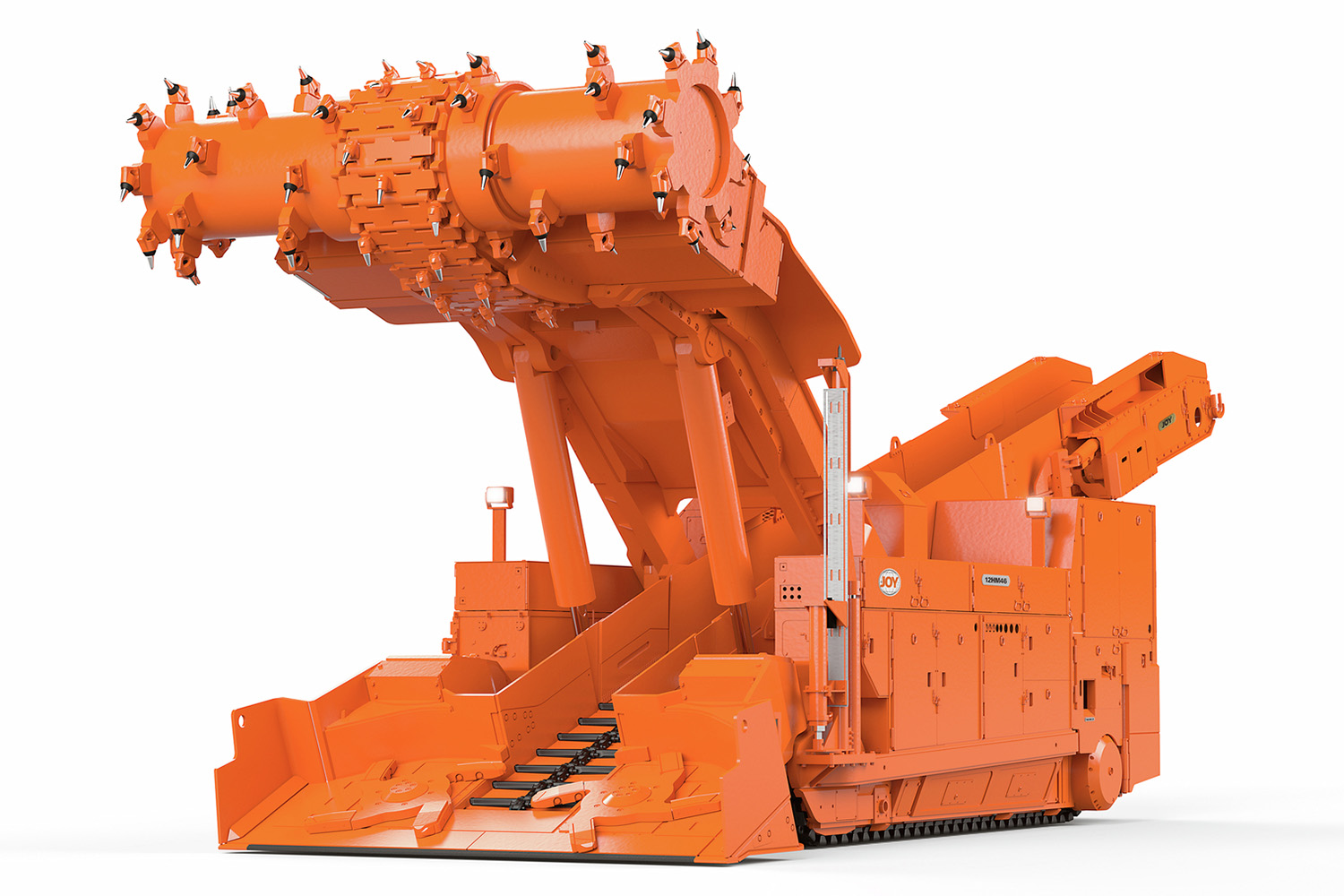

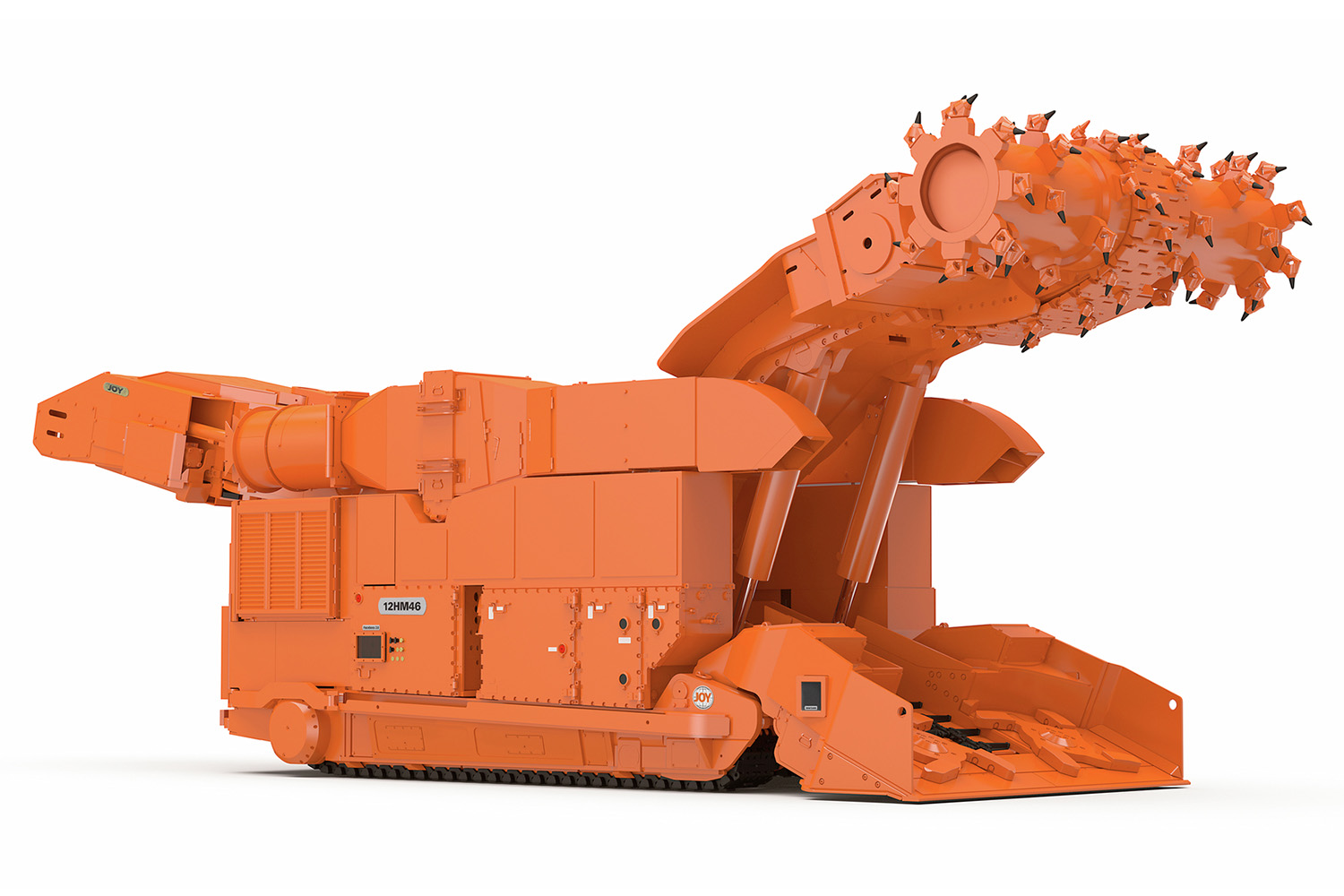

Ready for today’s industrial minerals challenges

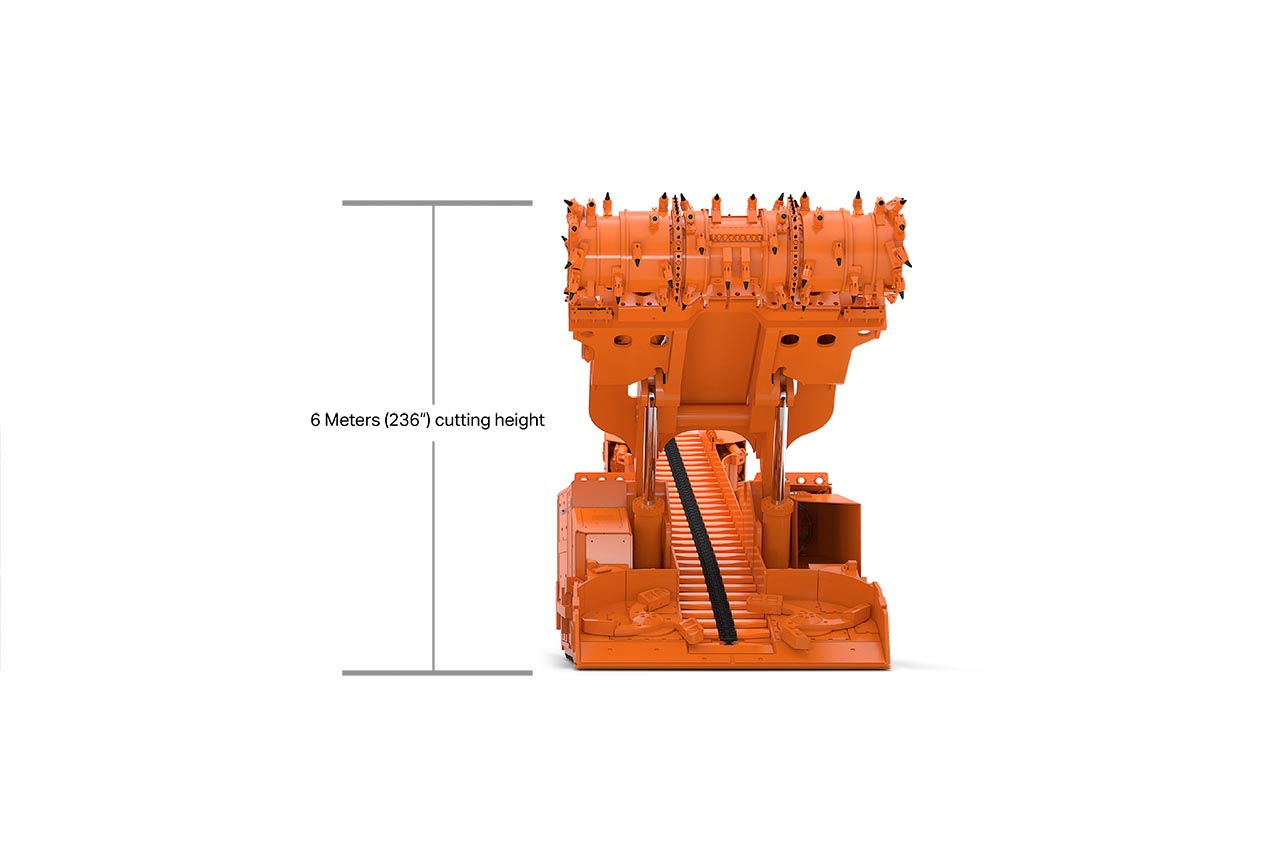

As society's demand for industrial minerals grows, so do your challenges. To support you, Komatsu offers the 12HM (Heavy-duty Miner) series continuous miner, that includes the 12HM26, 12HM27, 12HM36 and 12HM46. Engineered to help productively mine industrial minerals like trona, gypsum, potash and salt mines around the world. The flagship machine, the 12HM46, is the largest and most powerful continuous miner manufactured.

- 50% more cutting power*

- Up to 30% more mass*

- Production increase up to 70%*