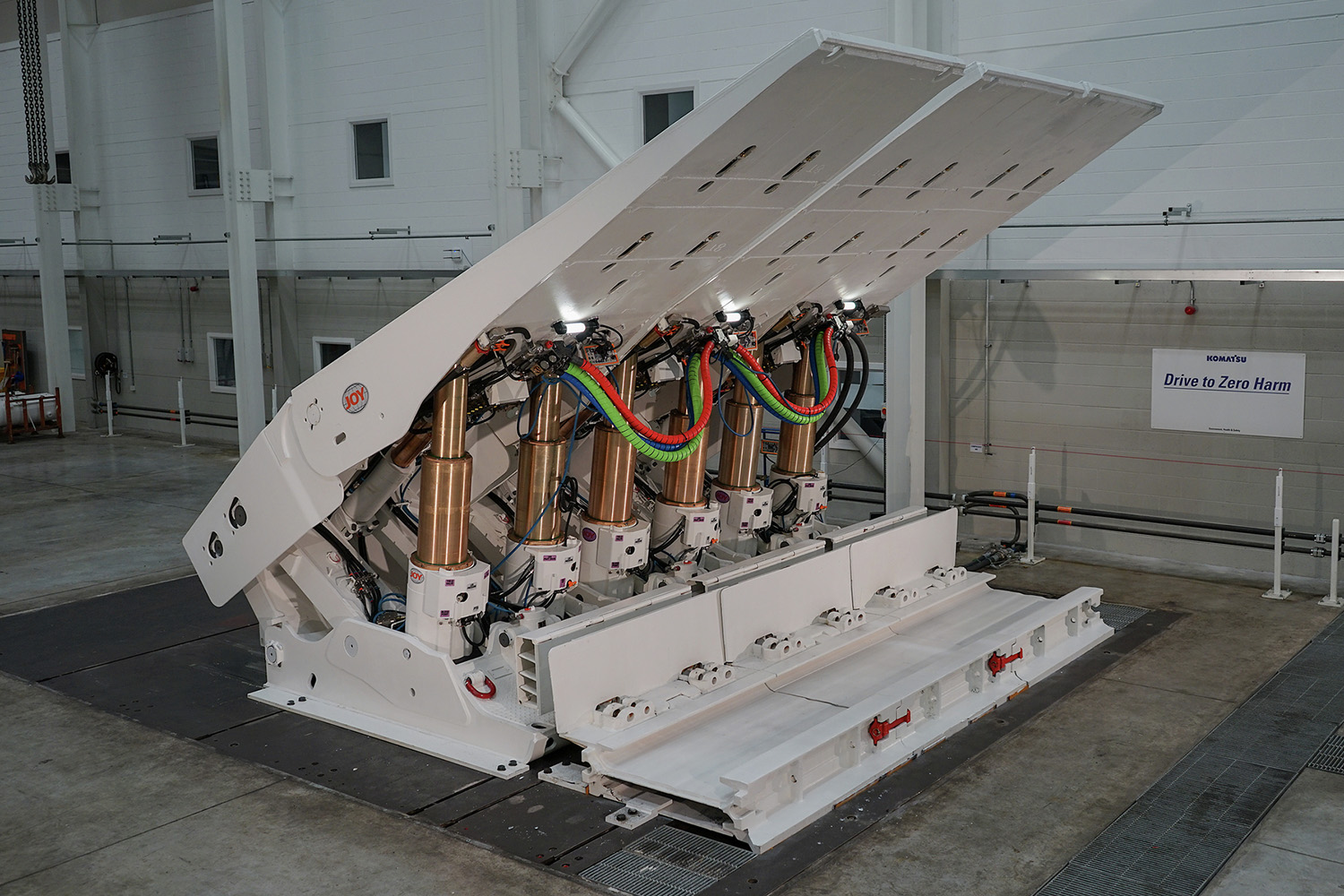

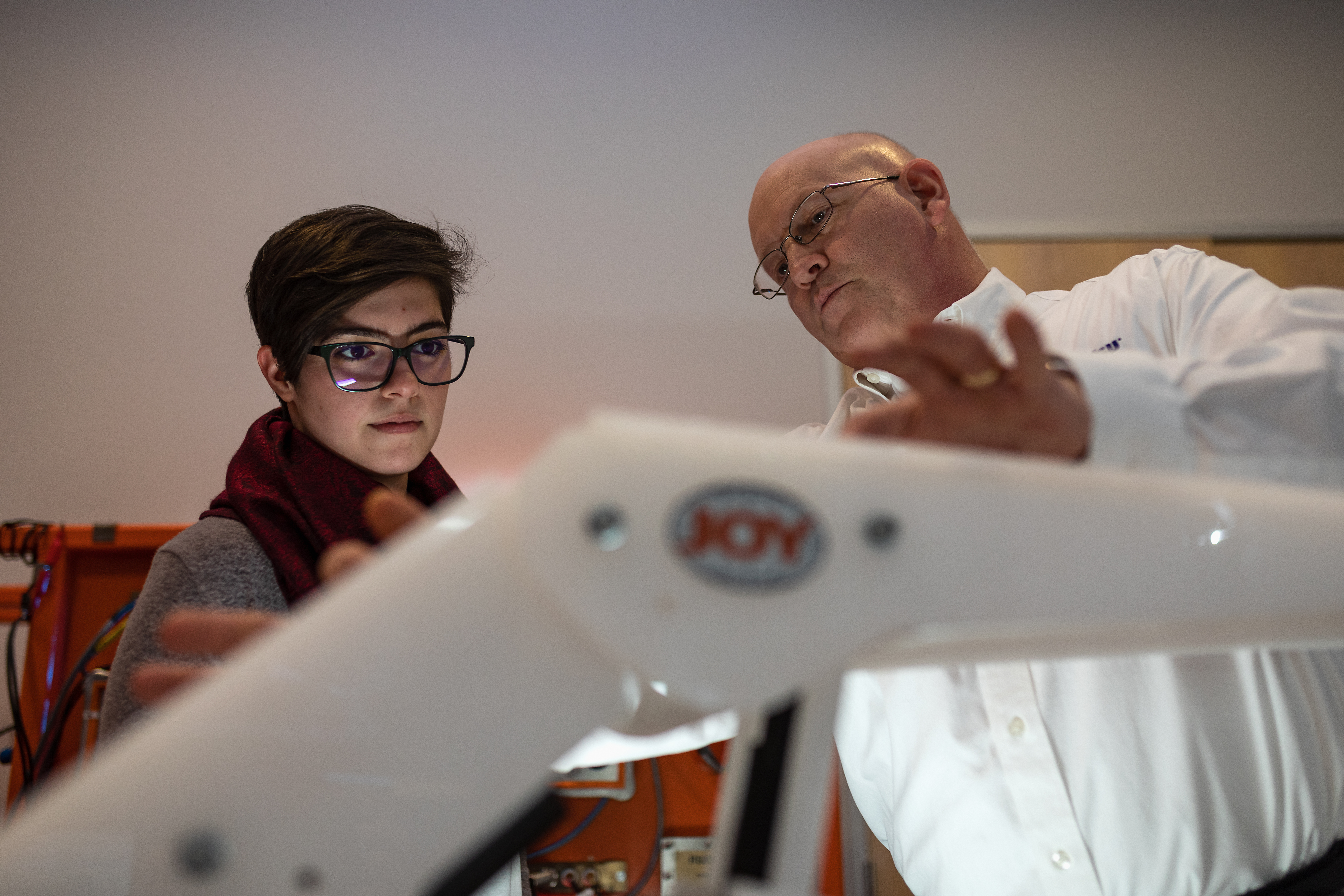

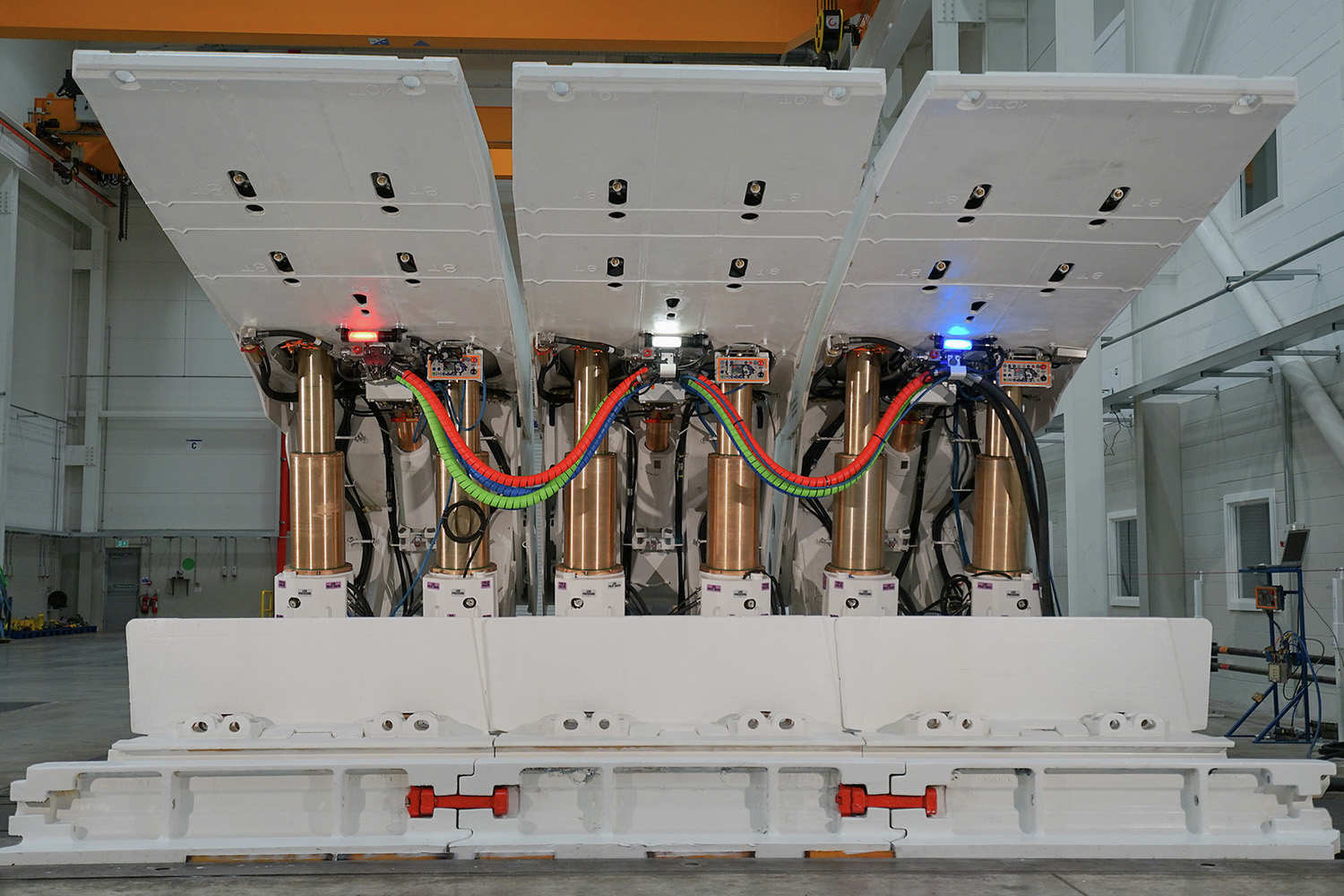

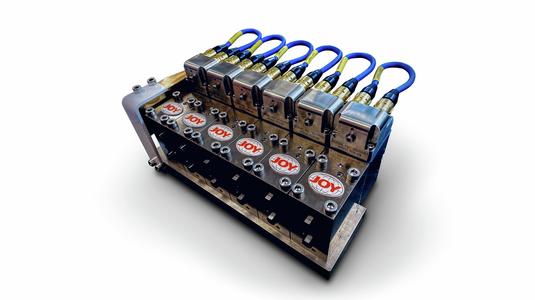

Global dual solenoid

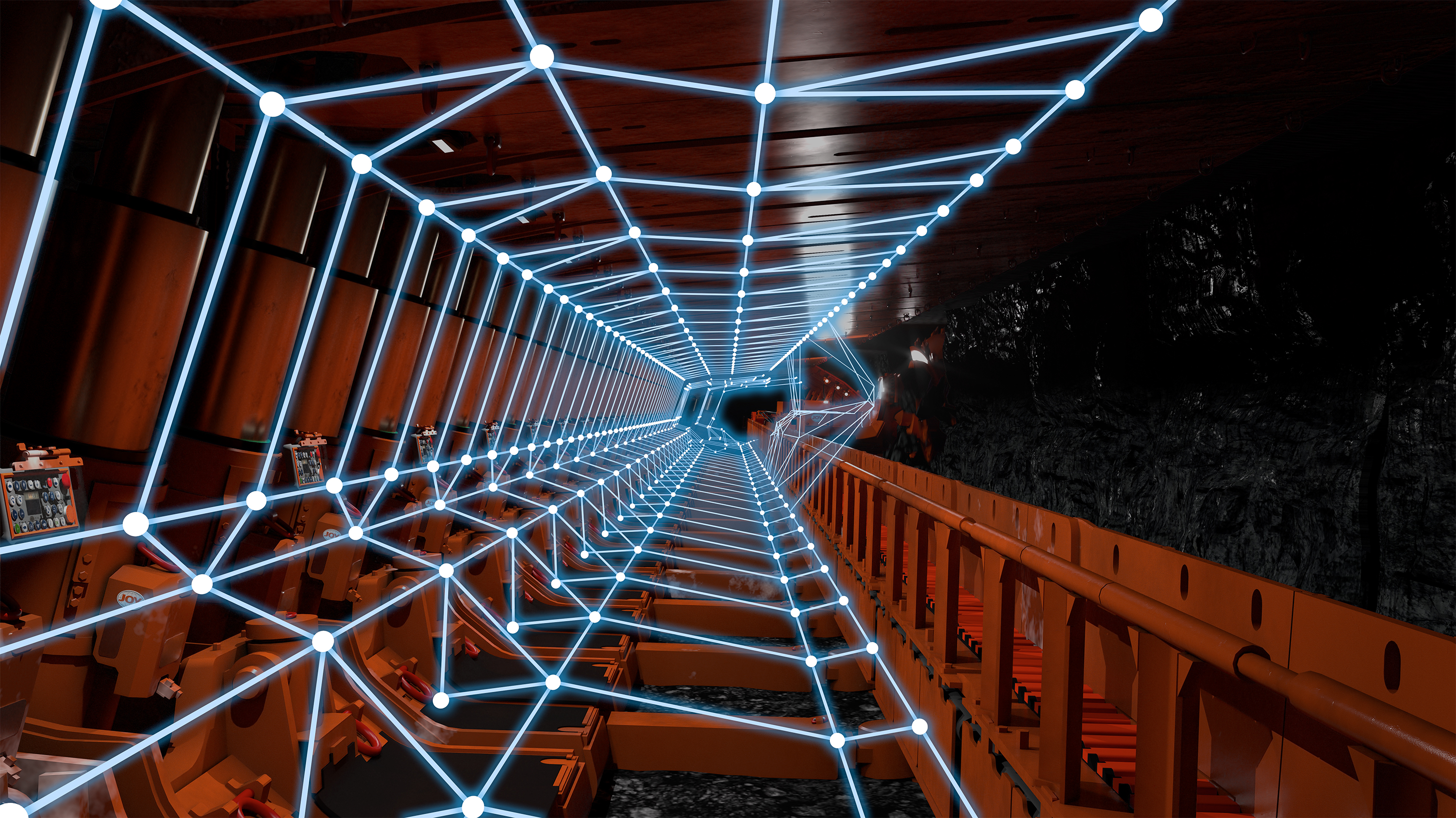

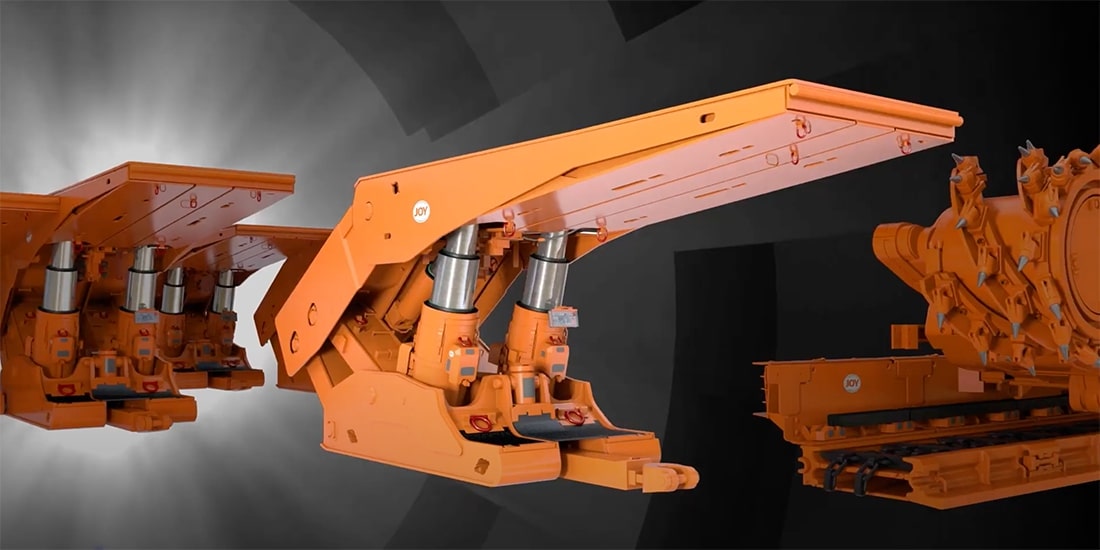

Unlock the power of automation for the journey to zero harm and increased productivity with the global dual solenoid valve for powered roof supports. Its serial connectivity enables a distributed system for fast response. Can be used with any PRS system; common control with shearer and AFC advances Komatsu remote operation capabilities.

-solution/445798_gpl9722-web.jpg)