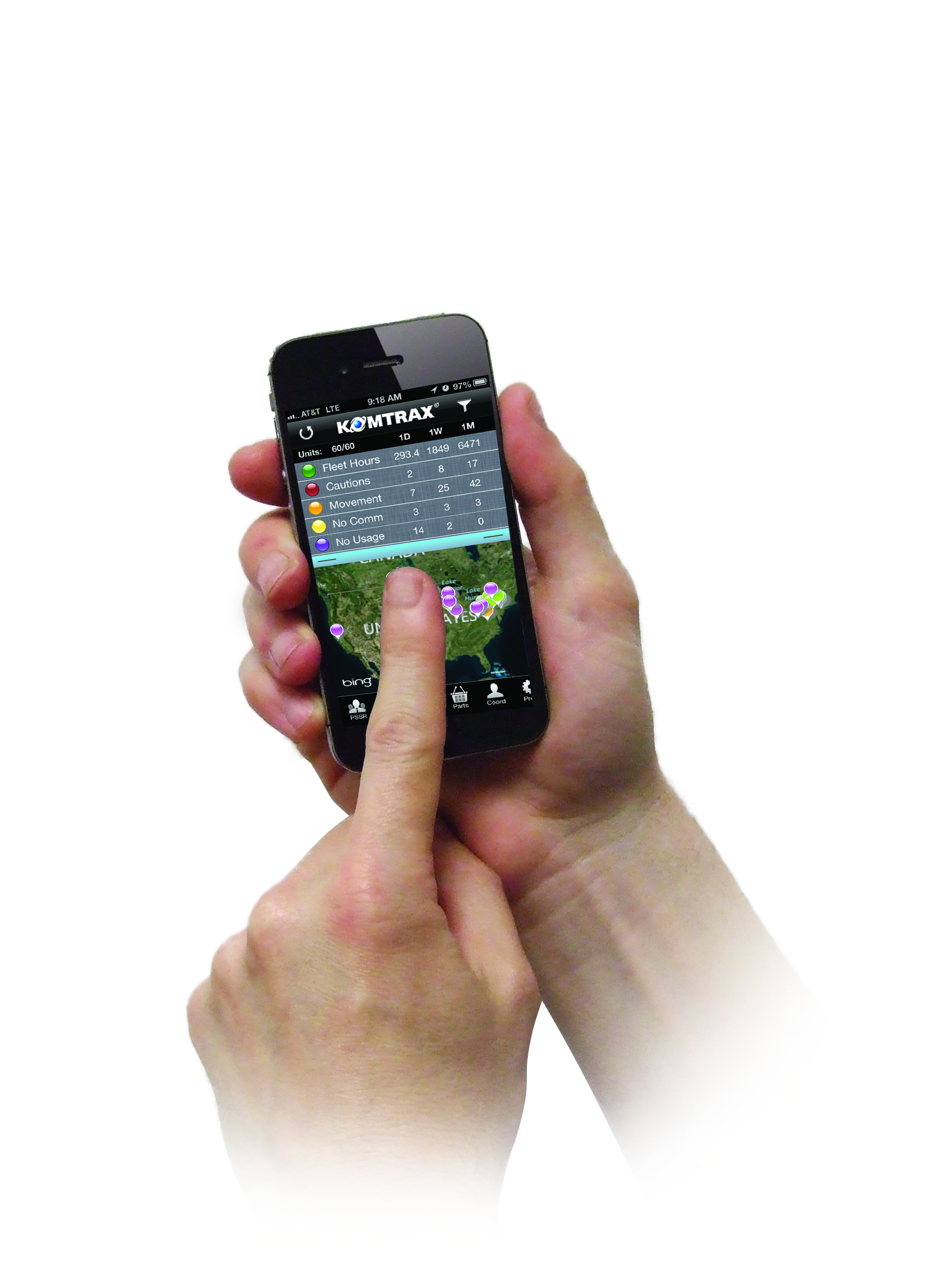

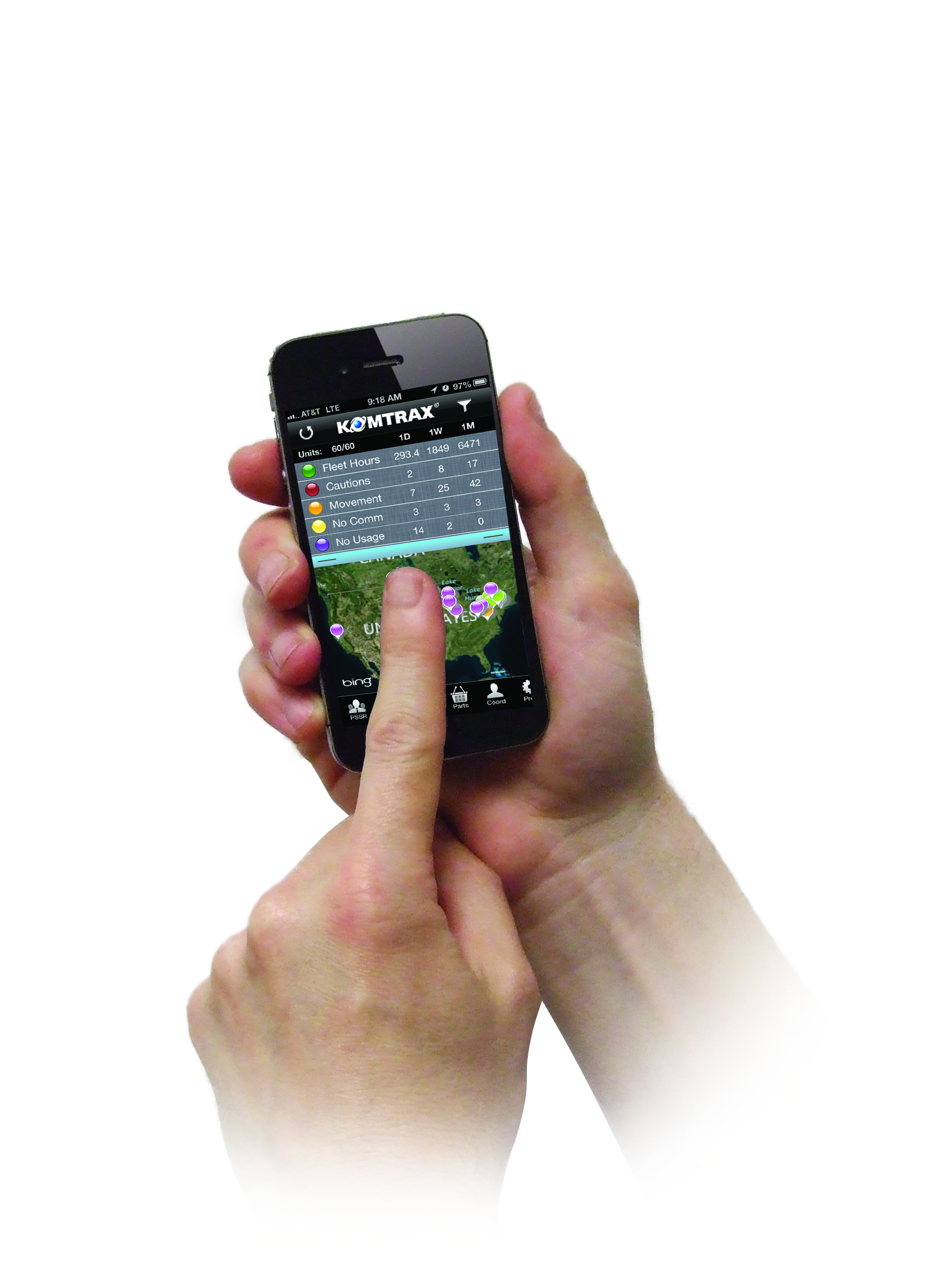

Komtrax monitoring system

Helps manage owning and operating costs by continuously monitoring and recording machine health and operational data such as fuel consumption and utilization. Tracks when maintenance is due so you can plan ahead.

We developed the TN230D from the ground up with one goal — merging quality components with the latest technology. Your forestry operation will benefit from increased horsepower and faster cycle times.* Operators will appreciate the wide views, rear-entry cab design and large cooling package.

*Increased power, faster cycle times and improved service access compared to the PC210LL-10 Komatsu truck loader (a similar class machine).

Total ground-up design for tough forestry jobs. Features and improvements were engineered by integrating customer feedback.

Electrically actuated left and right-side service platforms with repositioning of the main valve to allow better access. Also allows better entry to the engine through the large electronically powered engine hood.

Swing machine is designed to drive zero harm when the operator is entering the cab. Rear entry cab includes walkways and safety railings.

Built with proven, high-quality components. Hydraulic system, powertrain, control valve and interior components are designed and manufactured in-house to help ensure performance and quality control.

Elevated cabin with large windows and front view camera to optimize operator visibility. Large overhead skylight also allows better visibility and improves the operator experience.

Useful when your operators need a boost of power for forestry challenges. Power Max momentarily increases the engine horsepower and hydraulic flow to help accomplish a tough task.

Hydraulic motors

Relief valve setting

Main pump

Hydraulic cylinders (Bore x Stroke x Rod Diameter)

Maximum travel speed (auto-shift)

Maximum travel speed (auto-shift)

Horsepower

Helps manage owning and operating costs by continuously monitoring and recording machine health and operational data such as fuel consumption and utilization. Tracks when maintenance is due so you can plan ahead.

Find what works for you