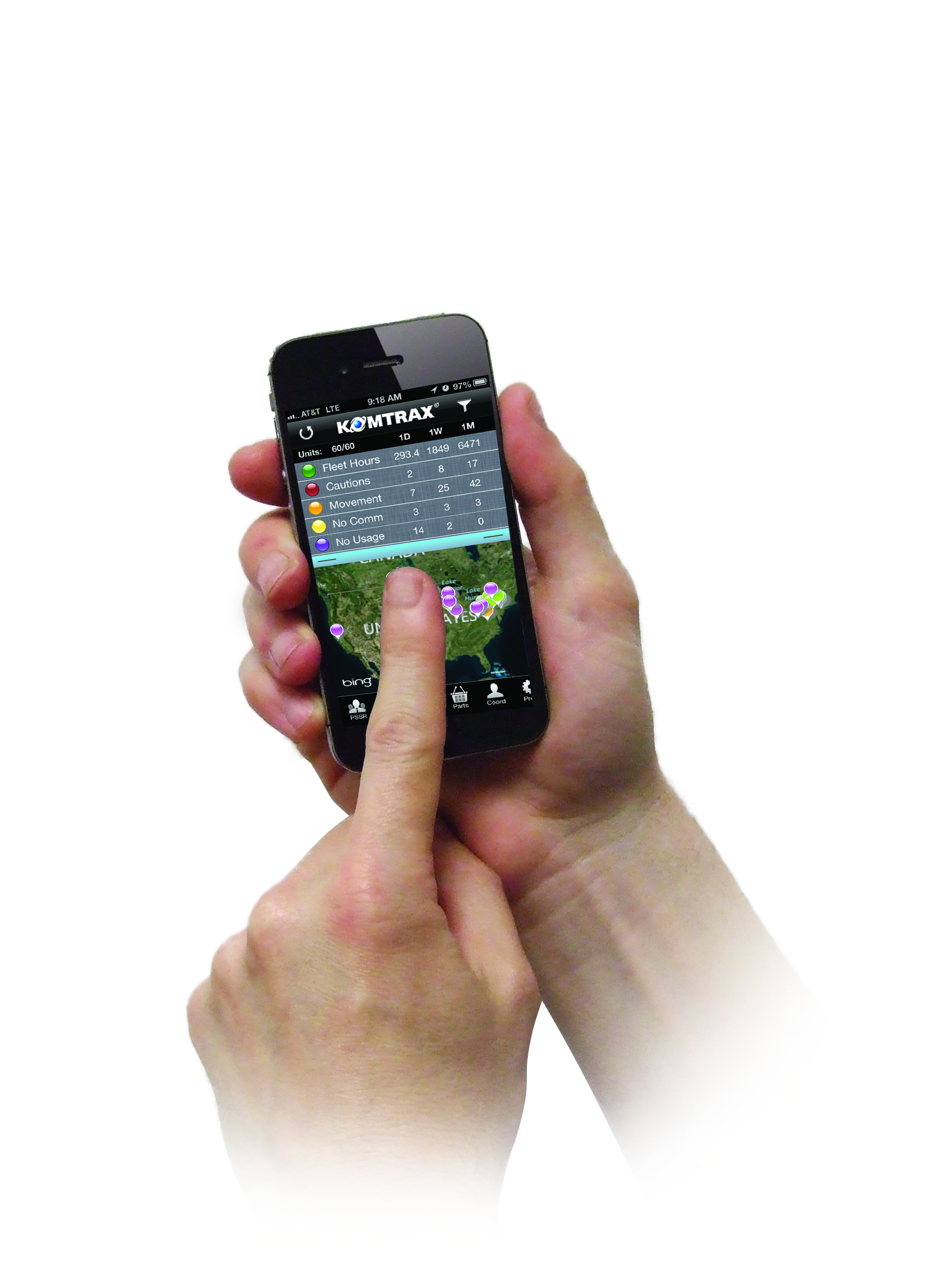

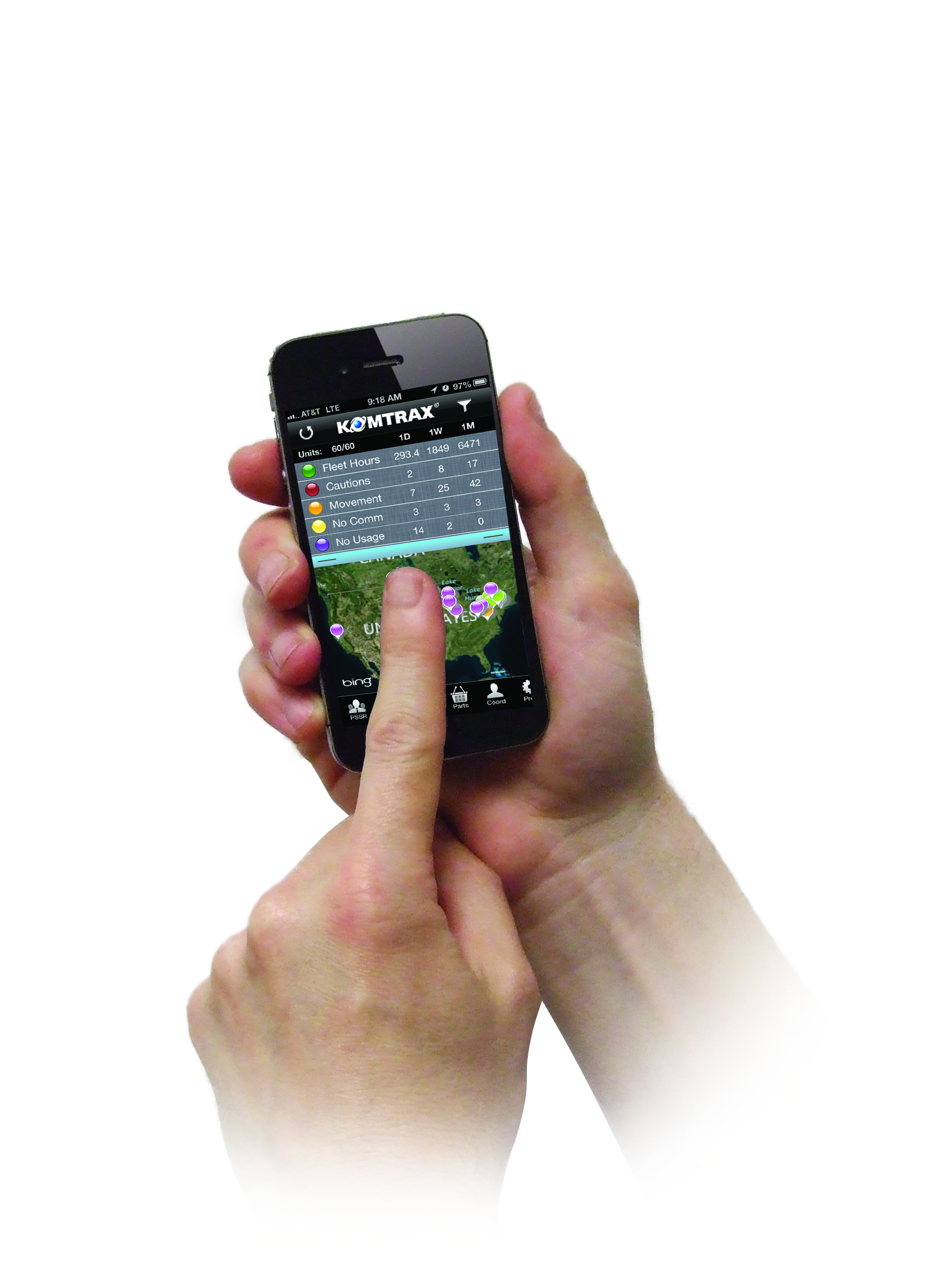

Komtrax monitoring system

Helps manage owning and operating costs by continuously monitoring and recording machine health and operational data such as fuel consumption and utilization. Tracks when maintenance is due so you can plan ahead.

Your crews need equipment that can deliver exceptional performance in difficult environments. With its rugged design, high and wide undercarriage, powerful swing motor and ability to withstand high-debris conditions, the PC230F-11 processor is built specifically for the job. A comfortable and quiet cab, too.

Move large trees around easily thanks to a powerful swing system and a large swing circle. Achieve exceptional reach, as well — up to 29 feet (8,951 mm). Superior maneuverability helps you drive productivity.

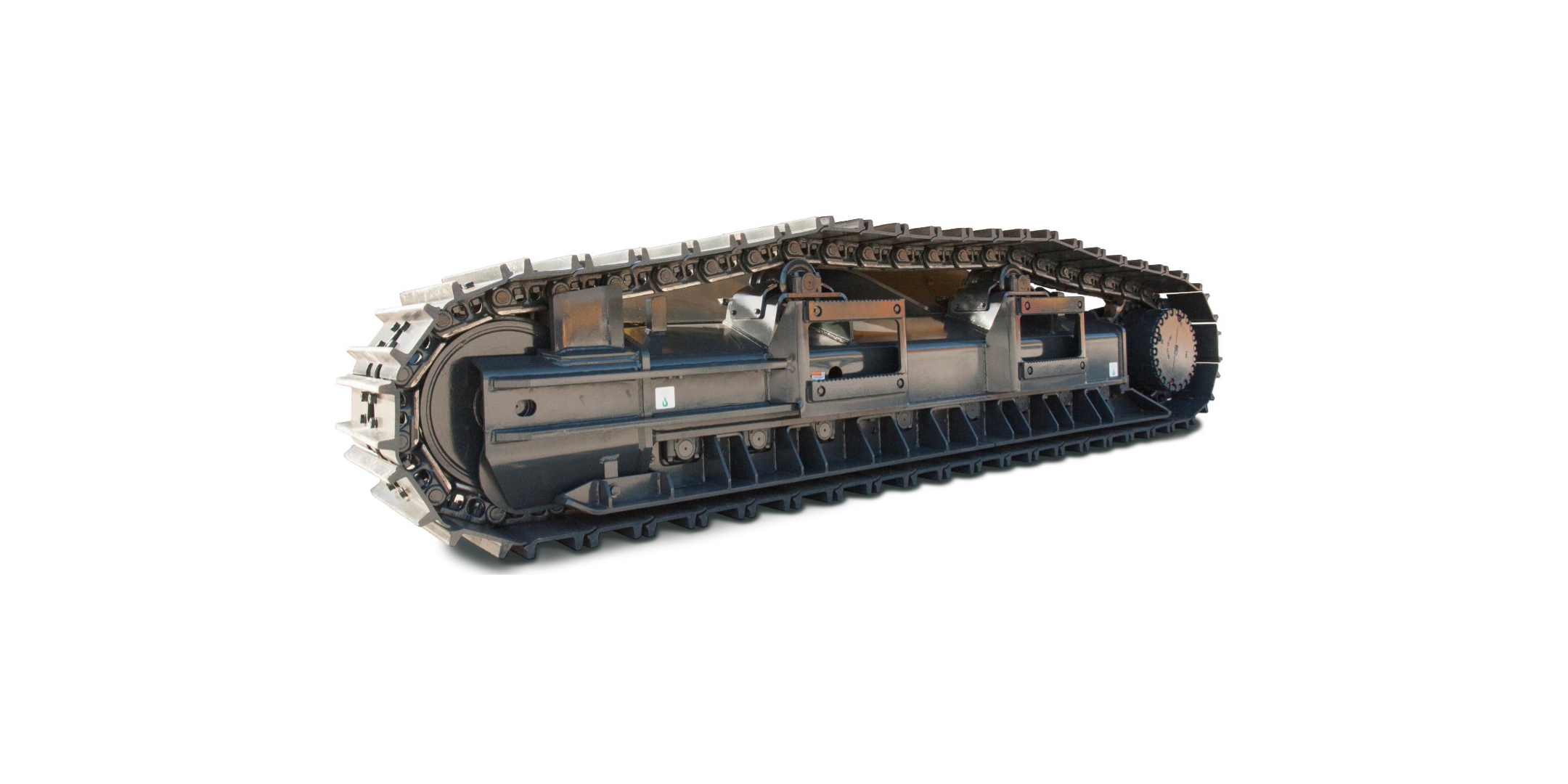

Maneuvers reliably in tough forestry environments thanks to a high and wide undercarriage designed with larger class-size components.

Reduce fatigue and support productivity by giving your operators a quiet, comfortable work environment. Cabs are climate-controlled and equipped with Bluetooth technology. The cushioned air-suspension seat can be heated or cooled.

An extra-rugged exterior protects your investment by guarding against falling limbs, with glass and metal are thick enough withstand demanding environments. Thicker service undercover guards, thicker rear compartment doors, right corner guard with tree deflector and much more.

Minimize worries when working in high-debris conditions with a machine engineered to handle the situation. A robust wide-fin radiator design is protected by fine screens and a variable pitch reversing fan delivers improved airflow.

Engineered for processing with Komatsu-designed setups to help you maximize productivity.

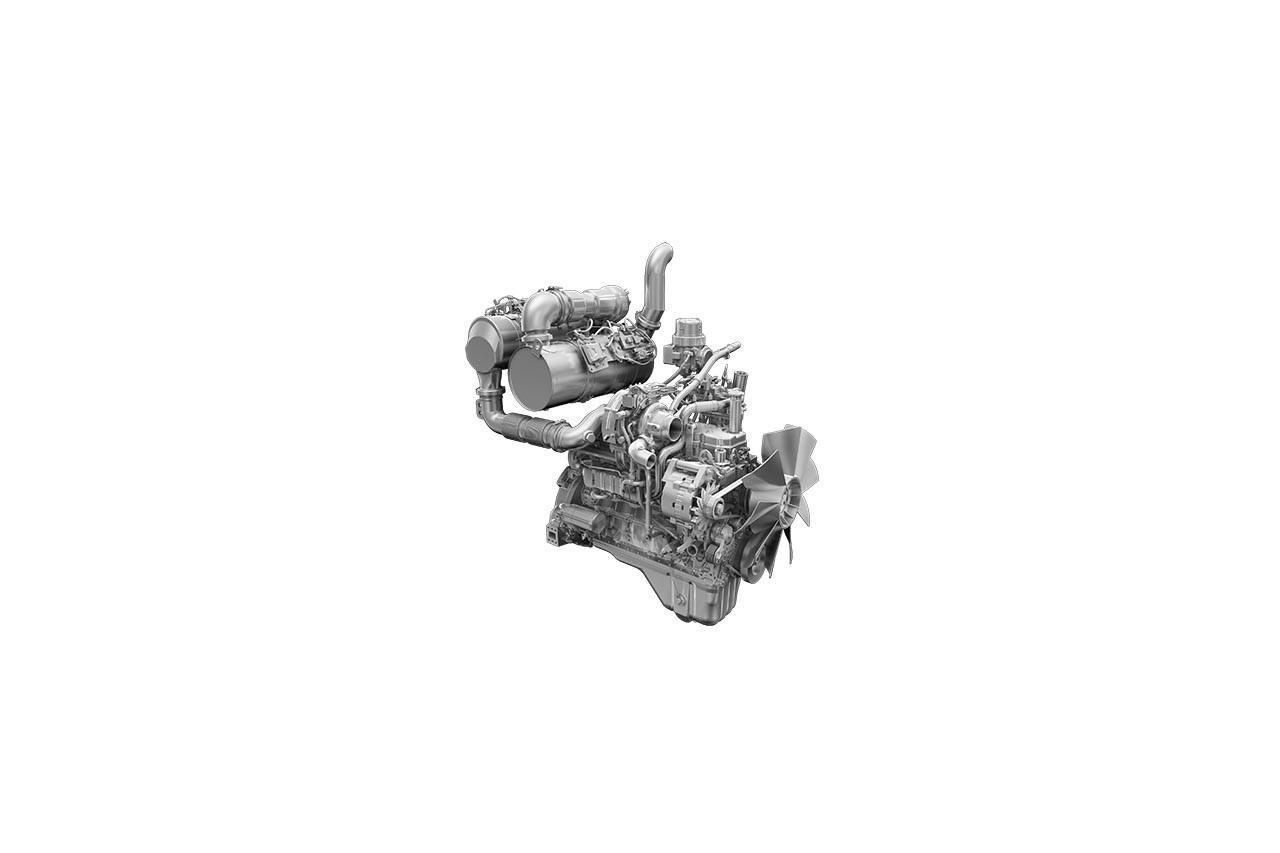

Adjust quickly to a sudden change in load weight without losing productivity. The Auto Power Max feature automatically senses the change and reacts with an 8.5-second burst of additional horsepower to help pull the trees through during the delimbing process of the wood.

Achieve exceptional performance with low fuel consumption thanks to a powerful PC290LL-11 Size Class engine from factory. Proprietary Komatsu technology delivers exceptional performance with high fuel efficiency.

Spend more time on the job and less time refueling with additional fuel storage. The tank is located in the rear of the carrier and built into the counterweight, delivering double the fuel capacity compared to the prior model. * * Comparison is to the PC210LL-10 (813 L)

Hydraulic motors

Relief valve setting

Main pump

Hydraulic cylinders (Bore x Stroke x Rod Diameter)

Maximum travel speed (auto-shift)

Maximum travel speed (auto-shift)

Horsepower

Helps manage owning and operating costs by continuously monitoring and recording machine health and operational data such as fuel consumption and utilization. Tracks when maintenance is due so you can plan ahead.

Forestry work sites are tough, so operators need a powerful, rugged processor built for the job. The Komatsu's PC230F-11 swing machine features a high and wide undercarriage for maneuverability and a powerful swing motor for exceptional performance.

Find what works for you