4 min read

4LD mining loader and on-site support drives efficiency with a total solution

Case Study

- Overview

- Challenge

- Solution

- Results

Select continent

New Horus, a small contractor working on development and exploration since 2009, was moving away from conventional operation to a trackless loading and hauling system. While working at the Poderosa Mine in Peru, they wanted to increase productivity by 25% and reduce costs by 15%. Poderosa is a gold mine located 572 miles (920 kilometers) northeast of Lima with an altitude between 0.78 and 1.86 miles (1,250 to 3,000 meters).

To meet their goals, New Horus needed a total solution, including technicians and procedures. They also needed to capitalize on the flexibility of the equipment available to them. Komatsu suggested a 4LD loader, whose efficiency would help improve production, along with a package that would allow New Horus to gain better control of operations to optimize efficiency, reliability and safety.

The 4LD was commissioned May 2017. Komatsu’s technicians started studying existing maintenance practices and worked with New Horus to create a preventive and corrective maintenance plan that could improve cost and mechanical availability. Soon afterward, the mine began to expand its operations and, due to the 4LD’s performance, New Horus decided to purchase two more 4LD loaders, commissioned November 2017 and May 2018.

Throughout this process, Komatsu helped support New Horus with technicians, an operator trainer and field engineers. To ensure the achievement of the company’s targets, they designed a three-stage approach: (1) Review and measure logistics, technical support needs, tools, infrastructure and safety standards. (2) Implement solutions in safety, logistics, tools, technical support and infrastructure. (3) Commission equipment; train operators; establish a maintenance schedule; follow up on safety conditions; and conduct targeted data collection, including hours, costs, operator schedule and productivity.

A combination of equipment with high mechanical availability, on-site technical support and the best logistic solution helped New Horus surpass its targets.

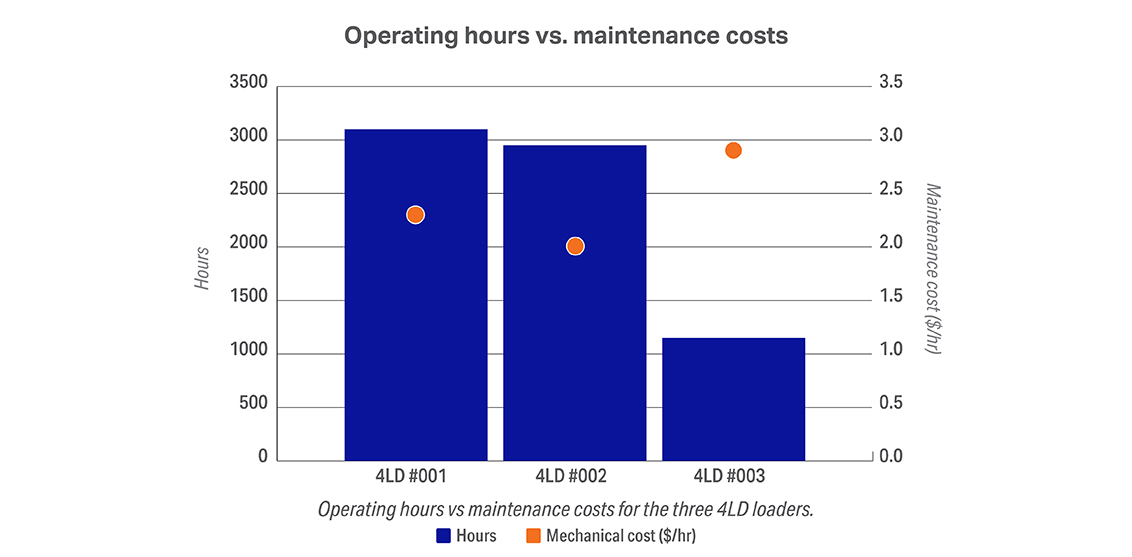

New Horus increased the tons produced per month by 35% from an average of 2,560 tons/month to an average of 3,456 tons/month. Maintenance costs dropped by 25% from $3.20/hour to $2.40/hour. The average mechanical availability increased from 50% for competitor equipment on-site to more than 90% for the three 4LD units. The increase in mechanical availability increased the monthly development meters and material moved by 40%, with an additional value of $64,000.

With the data collected, on-site technicians could give more feedback about how operators were working in order to prevent premature failures and adjust the maintenance plan according to the conditions of the mine.

New Horus’ maintenance costs dropped by 25% after Komatsu’s solutions were implemented.

New Horus’ maintenance costs dropped by 25% after Komatsu’s solutions were implemented.

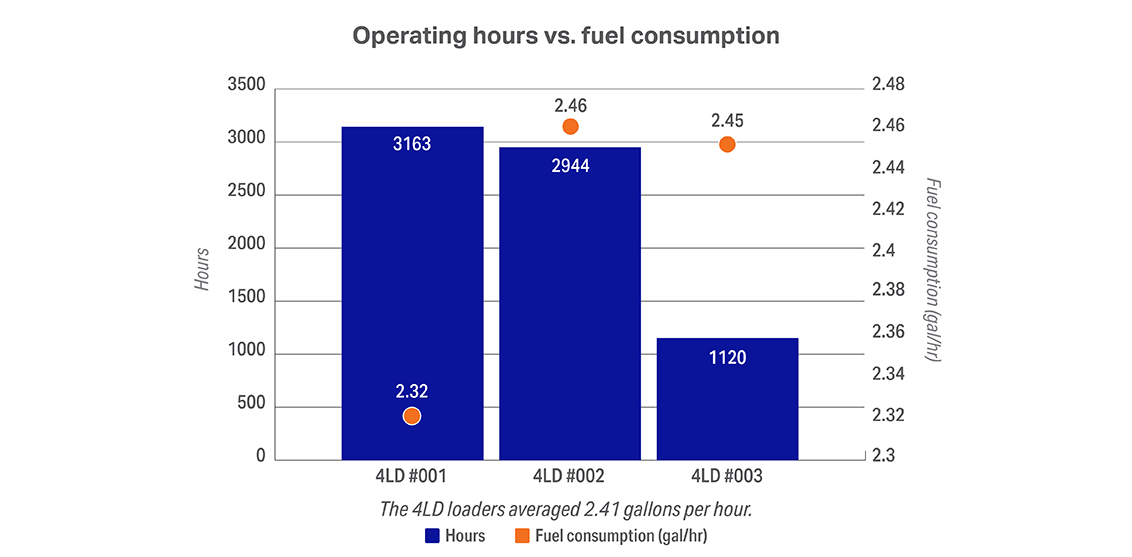

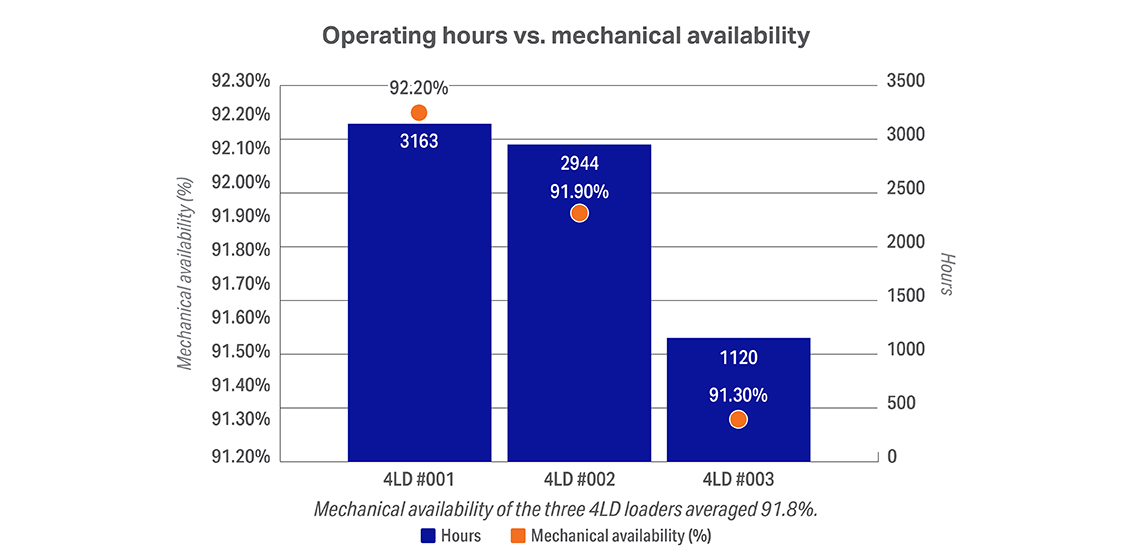

The two charts above contain data gathered from June 2017 to August 2018 showing total operating hours, average mechanical availability and fuel consumption.

The two charts above contain data gathered from June 2017 to August 2018 showing total operating hours, average mechanical availability and fuel consumption.

The units resulted in an average 2.41 gallons per hour and an average mechanical availability of 91.8%.

The units resulted in an average 2.41 gallons per hour and an average mechanical availability of 91.8%.

Driving efficiency with on-site support and teamwork

New Horus was a small contractor who had been working on development and exploration since 2009. They were moving away from conventional operation to a trackless loading and hauling system and looking for ways operate more efficiently. When New Horus contacted Komatsu, they were working at Poderosa Mine, a gold mine located 572 miles (920 kilometers) northeast of Lima with an altitude between 0.78 and 1.86 miles (1,250 to 3,000 meters).

New Horus had these goals:

- Increase productivity by 25%

- Reduce costs by 15%

- Improve mechanical availability and fuel consumption

- Replace its fleet, comprised of older, second-hand equipment including a 3.5-tonnes loader and a 15-tonnes haul truck

Refocusing on total cost of operation

New Horus was practicing conventional mining methods and was more focused on meeting monthly tonnage targets than on the total cost of the operation. Komatsu recommended its 4LD loader, whose efficiency would allow the company to improve current production, along with a total solution package that would help New Horus gain better control of operations to optimize efficiency, reliability and safety.

The 4LD was commissioned in May 2017 and, as part of the total solution, Komatsu technicians began to conduct studies to better understand New Horus’ challenges and identify solutions. The technicians studied existing maintenance practices and worked with the customer to develop a preventive and corrective maintenance plan to improve cost and mechanical availability.

Soon after, the mine began to expand operations and, due to 4LD’s performance, New Horus decided to purchase a second 4LD loader which was commissioned November 2017. A third was commissioned in May 2018.

A three-stage plan of attack

After review of the operations, the Komatsu team offered a total solution that involved equipment with high mechanical availability, good on-site technical support and the best logistic solution. Komatsu helped support New Horus with technicians, an operator trainer and field engineers to ensure the achievement of their targets. Working together, they developed a three-stage plan:

- Stage one: Review and measure logistics, technical support needs, tools, infrastructure and safety standards. This review took place over three months and was conducted by a technician, a trainer, an account manager and a service engineer

- Stage two: Implement solutions in safety, logistics, tools, technical support and infrastructure. This began after initial studies were conducted on the first 4LD and was progressive over the course of six months. Improvements continued after the study period, after New Horus contracted with Komatsu for two technicians to be on site seven days a week to provide the operator with ongoing support. Logistics processes were improved, and procedures to control the life of spare parts and safety procedures continued to evolve

- Stage three: Commission equipment; operator training; execution of a maintenance schedule; follow-up of safety conditions; and targeted data collection, including hours, costs, operator schedule, and productivity. Komatsu provided New Horus with a monthly report enabling the company to better handle its productivity rate for the mine. The monthly report included the following information for each unit about mechanical availability, fuel consumption, distribution of costs (preventive or corrective), total cost of spare parts for maintenance, record of life of spare parts, fulfillment of the programmed, and a preventive maintenance plan.

The plan was followed up by engineers and supervisors from Komatsu’s teams in Peru and Canada, who planned to periodically visit the operation to ensure optimum service. With the data collected, on-site technicians could give more feedback about how operators are working in order to prevent premature failures and adjust the maintenance plan according to the conditions of the mine.

Surpassing expectations for productivity and more

At the end of the study, the 4LD loaders allowed New Horus to surpass its targets of increasing productivity and reducing maintenance costs. After commissioning the 4LD units, New Horus increased the tons produced per month by 35% from an average of 2,560 tons/month to an average of 3,456 tons/month. Other results:

- Maintenance costs dropped by 25% from $3.20/hour to $2.40/hour

- The average mechanical availability increased from 50% for competitor equipment onsite to more than 90% for the three 4LD units. Onsite support by Komatsu technicians was key to this result

- The increase in mechanical availability increased the monthly development meters and material moved by 40%, with an additional value of $64,000

The excellent performance of the 4LDs and the high level of service and on-site support provided by Komatsu personnel encouraged New Horus to purchase two 16TD trucks, commissioned September 2018, replacing their existing haul truck. New Horus referred Komatsu to two other contractors operating at Poderosa Mine, who purchased two LT-270 hard rock loaders and a 4LD loader and engaged on-site Komatsu technicians to improve their operations.