4 min read

Barrick and Komatsu reach agreement on $440M equipment contract

- Press release,Company,Surface mining

4 min read

There’s no question that moving dirt, digging mines and mining activity in general is messy and dust is part of the process. To help keep operators safer, several regulations have been enacted to limit operator exposure to dust (particularly dust with silica).

The main standards are ISO 23875, RS20 Queensland standards and U.S. Mine Safety and Health Administration (MSHA) revised silica standards (Rule 6920). They all create measurable standards and require proof of meeting and maintaining these standards.

Studies by reputable health organizations have concluded that long-term exposure to respirable crystalline silica can cause several serious, irreversible, potentially disabling and possibly fatal conditions and disorders.

While the ISO standard is a voluntary one, many international miners have used it to make their cab interior air cleaner. However, in the US, MSHA has released a revised silica standard that refers to this ISO standard that alters some of the numbers and defines a reporting structure; it is now a published legal requirement in the U.S. Both standards are less prescriptive in method and more results-based than prior standards. Let’s take a look at the core of the MSHA revised silica standard, published April 18, 2024:

“Effective April 14th, 2025, for coal mines, and April 8th, 2026, for metal and non-metal (MNM) mines, mine operators will need to monitor miners’ exposure to respirable crystalline silica with a uniform permissible exposure limit (PEL) of 50 micrograms per cubic meter of air (µg/m3) and an action level of 25 µg/m3 over a full shift, calculated as an 8-hour TWA for all mines. Existing exposure levels remain in effect up to these dates.”

This new rule halves the previous MSHA rule, which was roughly 100 micrograms per cubic meter of air (100 µg/m3) over a full shift calculated as an eight-hour TWA.

Under the final rule, the mine operator must install, use and maintain engineering controls, supplemented by administrative controls when necessary, to keep each miner’s exposure at or below the PEL. They also must monitor and report these conditions.

MSHA determined that this new rule is technologically feasible. Many mine operators already maintain respirable crystalline silica exposures at or below the final rule’s PEL of 50 µg/m3, and at mines where there are elevated exposures, operators are able to reduce exposures to at or below the PEL by properly maintaining existing engineering controls and/or by implementing new engineering and administrative controls that are currently available.

A consultant working for Komatsu found that 82% of samples captured by studies done leading up to the rule clearly met the limits imposed by the new rule.

The MSHA rule specifically cites:

Komatsu can help you make sense of these new regulations and help you meet them in your operation. Many Joy machines have available process preventative equipment, and we are expanding automation capabilities at a rapid pace.

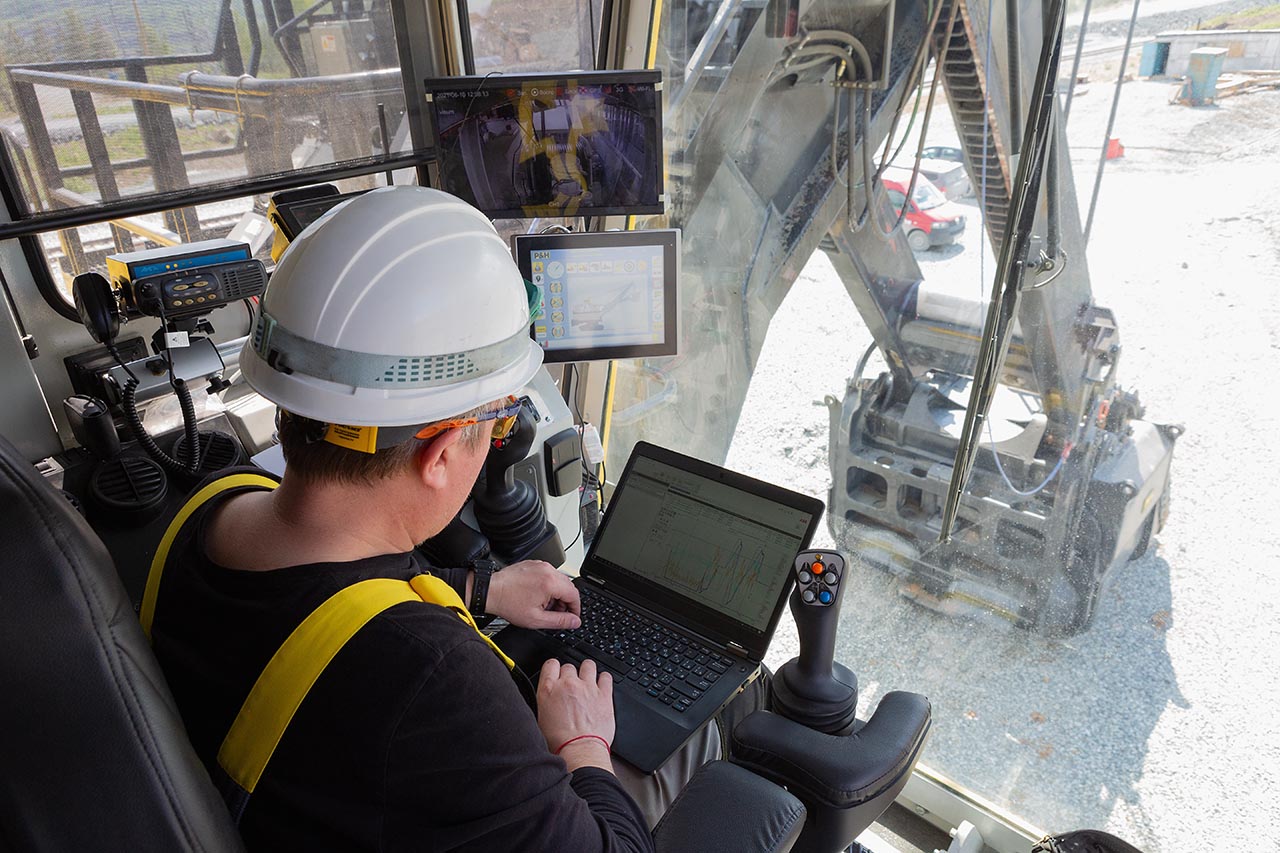

Adding a Komatsu Mine Air Clean Cab filtration system to your equipment may get you to the standards, but you may also need further mitigations, such as tighter cab sealing, modifying return air filters and more. Model-specific and generic kits are available and in stock and include the measurement and record-keeping functions the regulations require. We will even train you how to use it, how to validate it and how to maintain it for the long term.

This is not a topic to avoid or be fearful of. Simply reach out to the Komatsu Mine Air team or a local Komatsu representative and we can help you with it.