4 min read

Barrick and Komatsu reach agreement on $440M equipment contract

- Press release,Company,Surface mining

4 min read

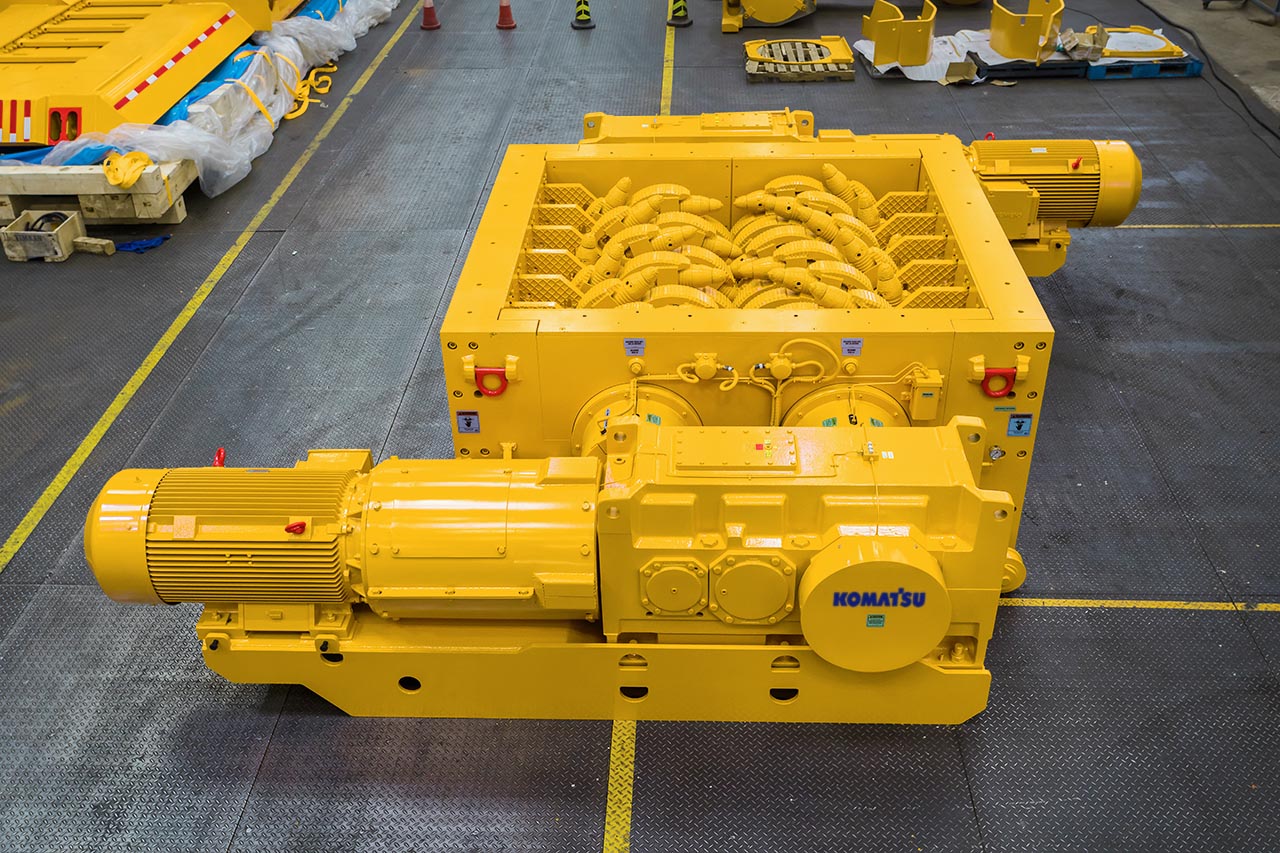

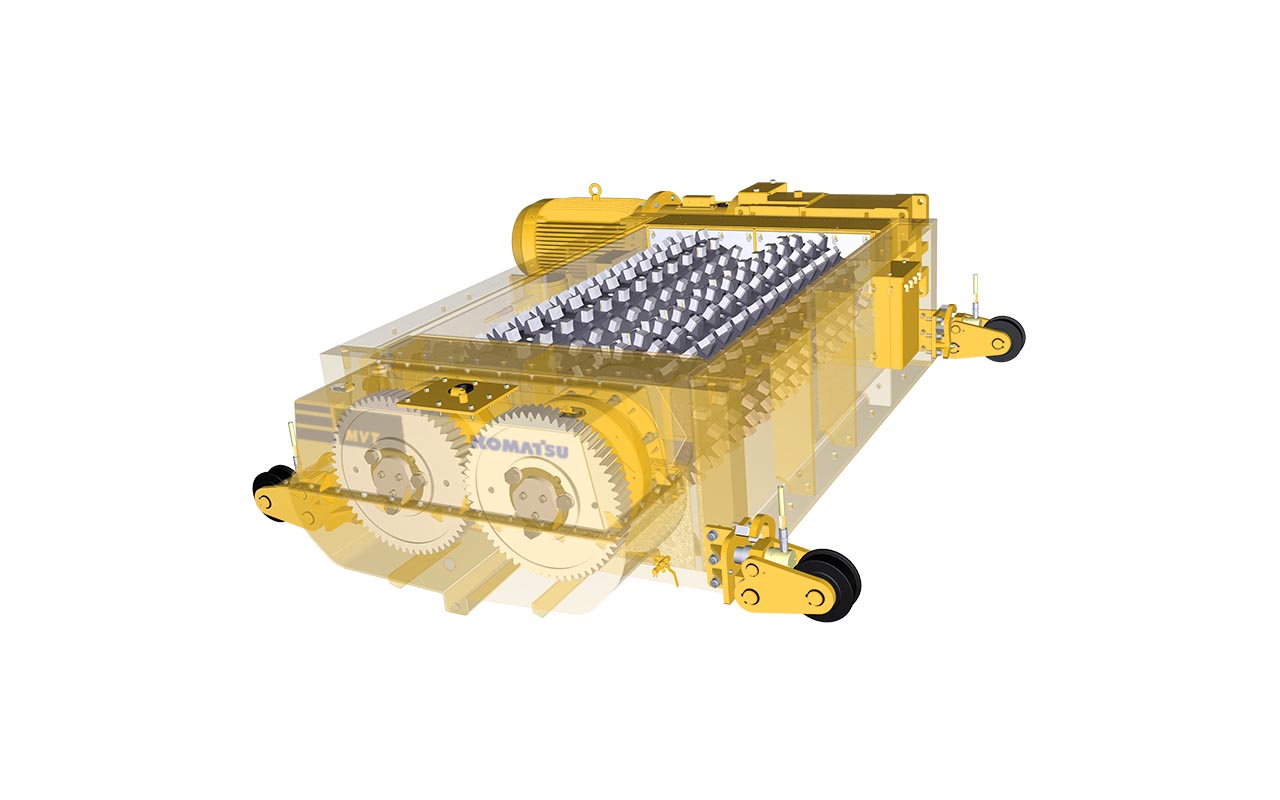

Komatsu sizers are high-performance double-roll crushers designed to excel in both hard and soft rock applications. With a capacity of up to 3,000 metric tons per hour, these versatile machines can be used as a primary or secondary crusher to reduce material size and prepare it for further processing. Equipped with crushing blocks or picks, depending on the specific application, Komatsu sizers are engineered to efficiently crush material using compression, tension and shear forces. Their compact design helps minimize installation requirements, making them a practical choice for a variety of mining operations.

In the competitive world of mining and material processing, efficiency, reliability and cost-effectiveness are paramount. Komatsu sizers offer a robust solution that’s designed to handle a variety of materials with high efficiency and minimal operational downtime. This article will explore the key advantages of Komatsu sizers, showcasing how they redefine performance standards and expand the boundaries of where sizers can be applied for maximum impact.

Komatsu sizers are designed for exceptional crushing performance, offering high-capacity production while efficiently processing a wide range of materials — from high-moisture minerals and clay to hard, abrasive rocks. Proven to manage even the toughest materials, they operate effectively in mine sites with compressive strengths exceeding 260 MPa. The primary sizers incorporate wear-resistant pick technology, built from Komatsu's extensive experience with feeder breakers, shearers and continuous miners. Material is processed using a combination of gravity and rotational downforce from the heavy-duty center sizing shafts. Additionally, the sizers feature a breaker bar beneath the rolls to control product sizing in three dimensions. A key benefit of this technology is its ability to efficiently screen undersized material through the rolls, preventing over-crushing, reducing fines generation and minimizing waste.

Komatsu offers a range of primary and secondary sizers tailored to meet the specific needs of your operation. Primary sizers are designed to handle large lumps and produce a consistent product size that can be easily transported. These machines are particularly effective with wet, sticky materials that often cause problems for other types of crushers. Secondary sizers are optimized for reducing fines while maintaining high throughput, due to their matched velocity technology (MVT) and replaceable teeth segments, helping to extend the machine's lifespan.

One of the standout benefits of Komatsu sizers is their low total cost of ownership (TCO). The robust design and durable wear components are designed to help extend operational productivity between scheduled maintenance periods, resulting in lower running costs and longer machine life. Komatsu sizers feature replaceable teeth and segmented wear parts, allowing you to replace the worn components instead of the entire unit. Customers can also rotate high-wear areas with low-wear areas within the crushing chamber, an innovation that’s designed to help reduce TCO.

Komatsu sizers are equipped with smart machine LINCS technology that provides real-time monitoring and proactive maintenance capabilities. Features like resistance temperature detectors, vibration sensors and torque-limiting clutch slip detection are designed to help protect the machine from damage and reduce downtime, so your operations remain efficient and productive.

Minimizing environmental impact and reducing maintenance for operators are critical considerations in modern mining operations. Komatsu sizers incorporate features that are engineered to address these concerns effectively. The innovative design of sealed outboard bearings helps minimize water and dust ingress, reducing the need for water sprays and helping to maintain a cleaner work environment. The no-clog performance of Komatsu’s primary sizers, even with challenging materials, helps enable consistent production and reduces the risk of operational delays.

Every mining operation has unique requirements. Komatsu sizers offer the flexibility needed to meet these demands with options like mechanically adjustable roll gaps, various pick designs and metallurgical cladding. These machines can be customized to handle different material sizes and consistencies so you can optimize your crushing processes. The sizers can also be rail-mounted with wheels for a maintenance rollout feature. Configurable motor options are available for either singular or dual drives to suit a range of space configurations and power requirements. Whether you are working in a large-scale open pit, an underground mine, tunneling/civil aggregates or cement applications, Komatsu sizers provide a flexible solution to help enhance your operation.

Komatsu’s range of sizers is a testament to the company's commitment to innovation, efficiency and sustainability in the mining industry. By offering superior crushing performance, cost-effective operation and integrated smart technology, they provide a competitive edge that can help your operation thrive. For more information on how Komatsu sizers can help benefit your business, visit Komatsu.com or contact your local Komatsu representative today.

Enhance your crushing operations with Komatsu — your trusted partner in mining technology.