4 min read

From crisis to strength: How Komatsu is reinventing its supply chain

- Operational efficiency,Blog

2 min read

Did you know you can bring new life to your underground hard rock operations with an equipment retrofit of vital components? Komatsu retrofits are compatible with every major OEM. It’s an easy and cost-effective way to help improve operations and increase the value and efficiency of your underground hard rock fleet.

Komatsu offers four retrofit solutions: Montabert hydraulic rock drill drifters, Timberock feeds and bolting heads, and an innovative J-LOK P pumpable resin injection system. Choose any or all based on application and need.

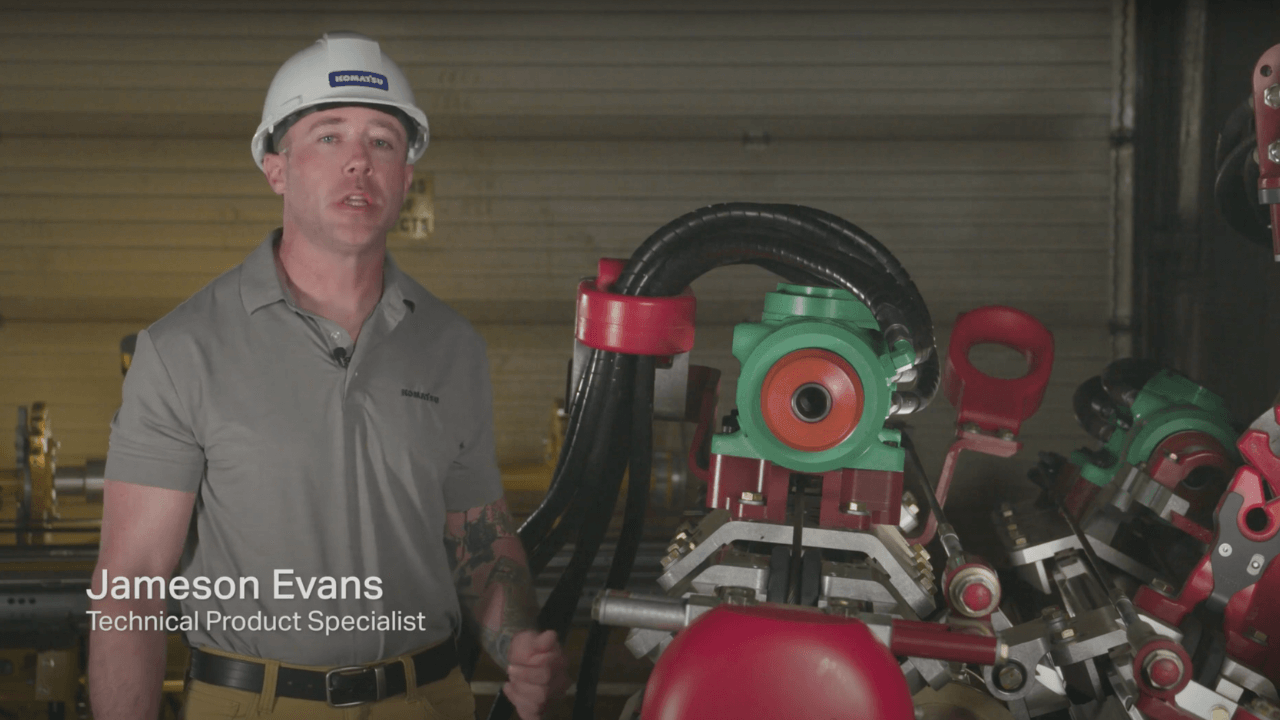

To help further illustrate the many advantages of a retrofit, we’ve put together a series of short videos that focuses on several key features of a bolting head retrofit. This multi-episode video series is hosted by Jameson Evans, Product Support Specialist. Each brief episode spotlights one important aspect of a bolting head retrofit from a competitor jumbo to a Komatsu TR-21, manufactured by Timberock.

In this first video, Jameson takes you through the all-important feeds, highlighting the benefits of the dual, independent feed design of the TR-21, the innovative and adjustable wear strips, and more.

Watch this brief video to get the whole story.

Interested in learning more? Click here to watch the remaining retrofit videos.