4 min read

Barrick and Komatsu reach agreement on $440M equipment contract

- Press release,Company,Surface mining

4 min read

Ensuring you get the most from our technologies is a hallmark of Komatsu. So, when our mining customers recently hauled more than three billion metric tons of materials leveraging our FrontRunner Autonomous Haulage System (AHS)— it was about far more than a mining industry milestone.

Our mining customers’ prioritized investment in technology and equipment—to transition to autonomous haulage—underscores the value the system provides. It’s no wonder; AHS has helped them save hundreds of millions of dollars while autonomously moving billions of metric tons of essential minerals and driving for zero harm.

Customers deploying our autonomous haulage system appreciate the full value proposition that AHS delivers, and a key value driver is cost savings. Consider our recent milestone of moving three billion metric tons of materials autonomously. Based on 2020 estimated operating cost reductions of between $0.50 to $0.62 per ton (as noted by mining industry analyst GlobalData in mid-2018), Komatsu’s AHS customers have potentially saved as much as $600 million since we crossed the threshold of moving 2 billion tons autonomously in November 2018.

When discussing the impacts of digital innovation in mine safety at a recent webinar, experts concluded that mining companies are likely to continue to invest in the deliberate deployment of technology to work to keep workers out of harm’s way. Deploying autonomous systems is one important step toward achieving that goal.

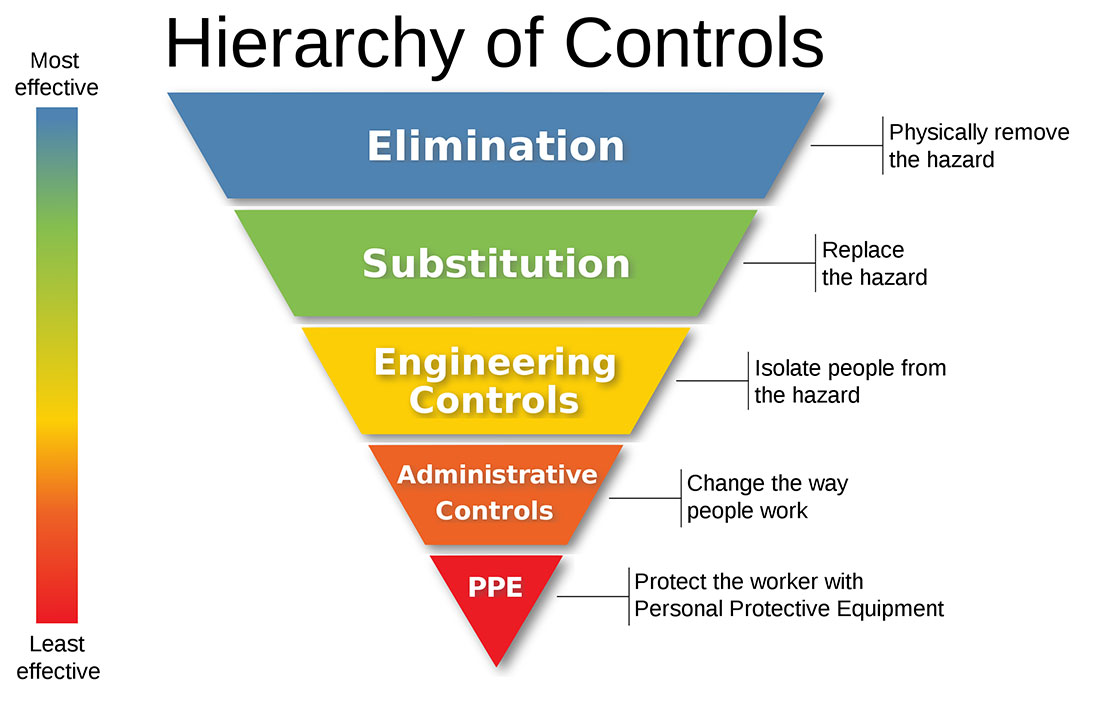

In the Hierarchy of Controls designed by the U.S. National Institute for Occupational Safety and Health (NIOSH), NIOSH defines the rungs as elimination, substitution, engineering controls, administrative controls and personal protective equipment. The hierarchy is arranged beginning with the most effective controls.

“You can’t eliminate every hazard, but the closer you can get to the top, the closer you can reach that ideal and make people healthier and safer,” said Jonathan Bach, director of NIOSH’s Prevention through Design Initiative.

AHS addresses the top four (most important) rungs:

We’ve learned during site visits that digger operators feel more secure working alongside autonomous trucks, especially during night shifts because they know the trucks will back into the same spot every time without conducting multiple sequences.

Conversely, truck operators who are physically absent from the mine site avoid the reckless behavior of colleagues. Those truck operators don’t have to be concerned about a loader operator dumping rocks too roughly into their haul truck, which can cause neck injury.

At fully manned mining sites, there can be over-reliance on drivers to report (or not report) near-misses or potential incidents. With Komatsu’s FrontRunner, the system records and plays back incidents, enabling the mine operator to continually review, refine and improve safety practices. As an OEM, our visibility into incidents at customer’s mine sites allows us to leverage that intelligence to enhance our products and processes globally.

Aside from reducing operators’ physical exposure, mental health benefits accrue from AHS usage. Autonomous systems have allowed mining operations to set up control centers in urban areas, such as Perth, Edmonton and Santiago. Because of these easier-to-reach locations, the number of people who have to fly in and out for two-week shifts in harsh, remote locations is reduced.

Control room workers have told us first-hand how much more enjoyable their lives are because they can return home every night to their families and not worry about long commutes. And, one of the unintended benefits of having operators sit next to each other in one control room is that if an incident does occur, they can all review it together.

While the world remains in the throes of a global pandemic, we’re all struggling to deal with our “new normal.” We’ve been gratified to hear from our customers that AHS proved to be a valuable resource in helping them mitigate some of the operational risks associated with COVID-19. But no one has a crystal ball.

Challenging times require innovation and creativity. Together let’s meet the needs of tomorrow by solving today's immediate challenges.