4 min read

Barrick and Komatsu reach agreement on $440M equipment contract

- Press release,Company,Surface mining

May 27, 2019

Surface mining, Innovation and technology

12 min read

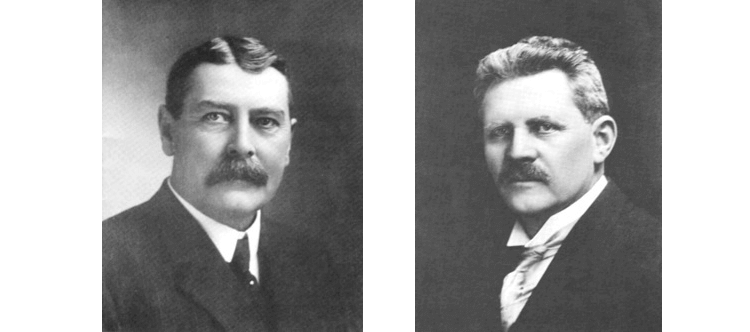

Near the turn of the century, Milwaukee drew innovators and toolmakers from across the country, including young but experienced innovators Alonzo Pawling and Henry Harnischfeger.

Alonzo Pawling (left) and Henry Harnischfeger (right)

Alonzo Pawling (left) and Henry Harnischfeger (right)

Henry immigrated to the United States at the age of 17, already an experienced toolmaker journeyman. In New York, New Jersey and Rhode Island he continued to build upon his manufacturing experience, working on sewing machines, measuring instruments and other tooling machinery.

Henry came to Milwaukee to work at Whitehill Sewing Machine Company where Alonzo was already working as a patternmaker.

Alonzo left Whitehill because of business concerns; the manufacturing process was unsustainable. As Henry wrote in his autobiography, “Mr. Whitehill was an inventor but did not have any experience in manufacturing. He kept on changing designs constantly which required new tools and often necessitated shutting down manufacture. His capital was insufficient for this.”

Alonzo left and he and Maurice Weiss, a toolmaker from Whitehill, started the Milwaukee Tool & Pattern Shop in 1883, though they lacked capital and Henry’s machining expertise. In 1884, they discontinued the partnership and Alonzo was unable to pay Maurice for his share of the business, so he gave him a chattel mortgage.

Maurice wanted to return to New York but needed funds, so he borrowed money from Henry on the mortgage. When the mortgage came due in November, Alonzo was not able to raise enough money and realized he needed more expertise in the machining area, so he offered to take Henry in as a partner. Henry wrote, “As things at the Whitehill Sewing Machine Company were practically at an end, I accepted his offer and on December 1, 1884, we formed a partnership under the name of Pawling & Harnischfeger.”

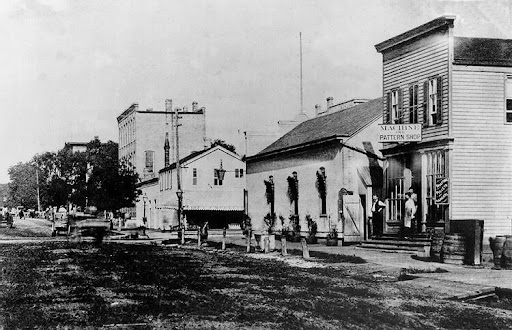

The Pawling & Harnischfeger Machine and Pattern Shop at 292 Florida Street in the Walker’s Point neighborhood of Milwaukee in the summer of 1885.

The Pawling & Harnischfeger Machine and Pattern Shop at 292 Florida Street in the Walker’s Point neighborhood of Milwaukee in the summer of 1885.

Alonzo, an experienced castings patternmaker and Henry, an experienced machinist, formed a partnership, striving to provide customers with the highest level of quality and service support. They secured work designing patterns for casting industrial components, carried out a variety of repair work, and brought new ideas for inventors to life.

A turning point for their business was in 1887 after the Edward P. Allis Company burned down. When the new foundry was erected, it was equipped with two rope-driven overhead traveling cranes. One of the cranes fell to the floor after a girder twisted, killing the operator and injuring others.

P&H replaced the rope-and-pulley mechanisms with a simpler system of motor-transmission sets applied to the crane’s hoist, trolley and bridge-drive functions. The crane produced immediate performance and reliability gains for the customer and soon after, other manufacturing firms, warehouse operations and railroad maintenance shops began to approach P&H for more such cranes. Pawling and Harnischfeger had a product of their own.

Soon after Pawling & Harnischfeger secured the order for their first innovative three-motor electric crane, railroad repair shops and other manufacturing firms turned to them for more cranes and they expanded their facility, a three-story 50x90 brick building equipped with a 10-ton, 25-foot hand crane.

Soon after Pawling & Harnischfeger secured the order for their first innovative three-motor electric crane, railroad repair shops and other manufacturing firms turned to them for more cranes and they expanded their facility, a three-story 50x90 brick building equipped with a 10-ton, 25-foot hand crane.

As they expanded their business in making cranes, they began making the electric motors and controllers that were required for the cranes they were building, as well as severe-duty industrial applications. P&H AC and DC motors continue to be the prime motors on virtually all P&H manufactured equipment today.

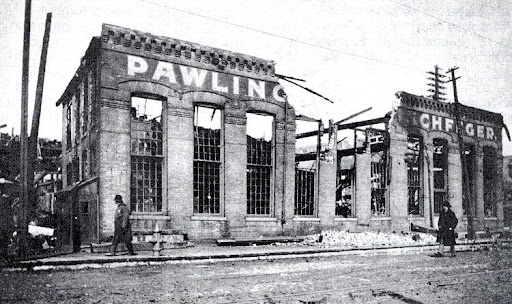

A fire at the Pawling & Harnischfeger foundry destroyed the entire shop with hours on February 15, 1903.

A fire at the Pawling & Harnischfeger foundry destroyed the entire shop with hours on February 15, 1903.

On February 15, 1903, a disastrous fire swept through the building. Within a few hours, the entire shop was burnt nearly to the ground.

“While the fire seemed a great calamity to us at that time, it was nevertheless a blessing in disguise,” wrote Henry. The insurance money provided funds to build new shops at 38th and National Avenue, where the business would reside for more than 115 years.

The Pawling & Harnischfeger facility at 38th and National Avenue, circa 1905.

The Pawling & Harnischfeger facility at 38th and National Avenue, circa 1905.

Between 1905 to 1910, Pawling and Harnischfeger manufactured mainly electric cranes, hoists and hand cranes. “Those were years of either feast or famine because the crane business was one of the first to suffer when business conditions in the country were bad,” wrote Henry. To prevent their business from becoming over-reliant on one product line, they began to explore earth-moving machinery as a potential counter-balance to their overhead cranes business.

In 1914 Alonzo Pawling died following a long illness. Before selling his interest in the firm to Henry, he asked Henry to consider always displaying the “P&H” trademark on the equipment the firm might market in the future. It was evident that the “P&H” trademark had already acquired a strong reputation for quality and service excellence, and Henry agreed to that idea.

It was also in 1914 that the first P&H earthmoving machines appeared. A P&H Model T-1 gravel tamper and pavement-cutting machine (pictured) was the very first.

It was also in 1914 that the first P&H earthmoving machines appeared. A P&H Model T-1 gravel tamper and pavement-cutting machine (pictured) was the very first.

A P&H Model 205 power shovel with a dipper capacity of about 1/4 cubic meters appeared in 1919. Customers liked the shovels and requested various improvements that P&H quickly applied to a successor machine, the P&H Model 206.

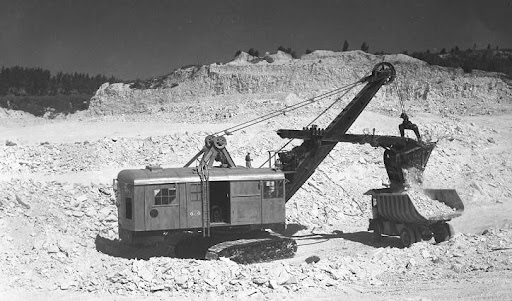

The P&H 208 excavator introduced in 1920 would be the first in a long line of high-performance digging machines

The P&H 208 excavator introduced in 1920 would be the first in a long line of high-performance digging machines

As regions around North America and the world were rapidly developing roads, pipelines, airports and other infrastructure, the push was on for highly productive and versatile construction and mining machinery. P&H responded during the Roaring ‘20s with the P&H Model 300 8-in-1 Convertibles — a sturdy crawler-mounted platform upon which the customer could specify attachments ranging from a front shovel, backhoe, “skim-scoop,” or dragline to a construction hook crane, construction clamshell crane, scrap yard magnet attachment, or pile-driver configuration.

In 1927, P&H 206 Convertibles joined the P&H product line.

In 1927, P&H 206 Convertibles joined the P&H product line.

To differentiate its products from the competition, engineering and manufacturing managers insisted upon applying state-of-the-art materials and processes to P&H equipment to provide their customers with optimum performance value. When the Great Depression began to impact the global economy in 1929, P&H absorbed that impact through a hard focus on cost management and limited, but continuing, efforts to advance product technology.

It was in 1930 that P&H began to replace riveted-construction machinery with all-welded design for increased machine strength and payload capacity. In fact, P&H was so well versed in welding technology, and eager to supplant lost business volume due to the severity of the recession, that it began to develop and manufacture its own line of P&H welding machines and welding consumables.

To meet the demands for greater machine productivity, P&H looked at improving operator comfort to reduce the required effort and to improve alertness. They applied the Ward-Leonard DC control system to its excavators and draglines, which freed machine operators from the exertion of tired hands and arms to push and pull excavator mechanical levers, resulting in increased machine responsiveness, speed, power and productivity.

For increased strength, reduced working weight and bigger payloads, P&H began applying all-welded design to its product line starting around 1932. P&H 1300WL shovels equipped with Ward-Leonard DC drive controls were among the first P&H all-welded digging machines.

For increased strength, reduced working weight and bigger payloads, P&H began applying all-welded design to its product line starting around 1932. P&H 1300WL shovels equipped with Ward-Leonard DC drive controls were among the first P&H all-welded digging machines.

To reduce over-reliance on cranes and digging machines during the Depression era, P&H experimented with an expanded product line, including diesel engines and pre-fabricated homes. However, in the long run, the firm would find its core market to be the construction and mining industries.

During World War II, P&H concentrated on building cranes and digging machines for industry in support of the war effort. Demand was strong for P&H mining shovels applied to copper, iron ore and other mining operations in North America and South America. P&H met and passed strict government requirements affecting cost management and production efficiency as the factory ran at full-bore over four years.

Post-war reconstruction and a resumption of global economic growth enabled P&H to resume research and development efforts toward bigger, more efficient digging machines in the 1950s. Several excavator models during this time featured a new friction-free Magnetorque electromagnetic clutch drive on the hoist. It made possible smooth, rapid dipper passage through the bank without stalling and with increased dipper fill factor performance.

In terms of mechanical systems, during the 1960s P&H replaced machinery deck-mounted propel drive with propel motor-transmission sets mounted direct to the shovel lower works for more direct and efficient propel performance. Dig attachment worm gear crowd was replaced by a more efficient power band crowd system that was later refined. Dual-motor hoist drive for increased power and productivity also emerged during the late 1960s.

The P&H 2800 Mark I electric shovel.

The P&H 2800 Mark I electric shovel.

It was in February of 1969 that P&H placed into service the first of a long line of P&H 2800-class electric shovels. The first four P&H 2800 Mark II machines were deployed to a metallurgical coal mine in Western Canada and quickly established a reputation for exceptional toughness and productivity in a rugged, often cold and harsh place, 1800 meters above sea level.

P&H is believed to have introduced the first gasoline engine-powered dragline back in 1920. However, credit for the first practical dragline belongs to John W. Page, founder of the Page Engineering Company based near Chicago, Illinois, back in 1903.

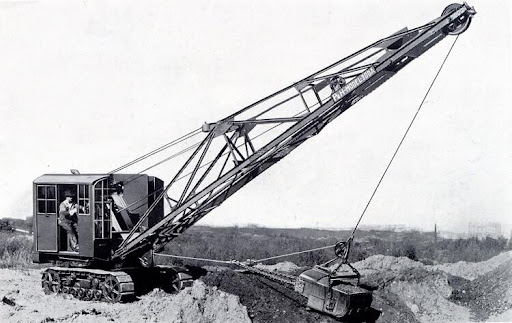

P&H has been designing and manufacturing various types of draglines since 1912. One of the earliest was the Model 300 Series Excavator, sold and fitted with a dragline configuration.

P&H has been designing and manufacturing various types of draglines since 1912. One of the earliest was the Model 300 Series Excavator, sold and fitted with a dragline configuration.

While P&H designed and built a well-regarded line of crawler-mounted draglines ranging from the P&H 300 in the 1920s through the P&H 2355 starting in 1980, the firm recognized an opportunity to expand its presence in the mining industry by acquiring the Page Engineering walking dragline product line in 1988. In so doing, P&H positioned itself to offer a wider range of high-capacity, cost-efficient earthmoving options to solve any pit challenge.

The year 1991 was significant for P&H Mining Equipment as it introduced a new electric shovel model, the P&H 4100-class machine, and acquired the Gardner-Denver line of rotary blasthole drilling rigs. Based on the needs of the customers, P&H upgraded and modernized the largest Gardner-Denver drills, the GD 120. By 1994, the P&H 120A blasthole drill was being placed into iron ore, copper and metallurgical coal mines and demonstrating strong productivity, reliability and ease-of-maintenance performance.

The P&H 2800 Mark I electric shovel.

The P&H 2800 Mark I electric shovel.

With the arrival of new 240-ton haul trucks around 1990, the customer need for larger shovels capable of three-pass loading capacity prompted development of the P&H 4100 with a 45-cubic-meter nominal dipper capacity rating. P&H engineers and manufacturing specialists applied planetary propel and swing transmissions, modular hoist drive, a sealed electrical room, modular crowd case and other state-of-art technology to make the new shovel highly productive and easy to maintain for reduced operating cost.

Ongoing refinements would transform the 4100 into the 4100A, a higher-performance 4100XPB and the 90-metric-ton capacity AC-drive P&H 4100BOSS or oil sand application, as well as the AC-drive P&H 4100XPC. Driven by the need to meeting increasing production demands, the 4800XPC leverages Adaptive Controls 2 technology with optimized machine structures to enable larger payload and increased efficiencies.

The next chapter for manufacturing in mining

Meitaro Takeuchi founded Komatsu in 1921 and over the course of its history, it has always faced challenges to overcome them, which made it stronger, just as the P&H brand.

In 2017 Komatsu acquired the P&H brand, which had, throughout the years, continued to apply the strong focus on quality and service that it inherited from co-founders Pawling and Harnischfeger back in 1884.

The challenges of mining today are driving advanced technology and automation to improve safety, sustainability and increased production while reducing costs. To ensure customers are equipped to meet those demands, Komatsu is moving toward the future.

The site of a new state-of-the-art facility will be the South Harbor Campus, located in the Harbor District, near the original site of Pawling and Harnischfeger’s original Machine and Pattern Shop.

A rendering of a possible design for the South Harbor Campus, which will be a resource for all of Komatsu worldwide, with modern conference and training facilities.

A rendering of a possible design for the South Harbor Campus, which will be a resource for all of Komatsu worldwide, with modern conference and training facilities.

The South Harbor Campus will be the new home for the design, large gearing and heavy fabrication of P&H mining shovels, as well as engineering and test manufacturing for surface drills. It will be a space to innovate and collaborate, host training and customer visits and proudly display our manufacturing and technological capabilities.

The new campus will be purpose-built to support Milwaukee’s role as a large machining, heavy fabrication and engineering center of excellence for P&H mining shovels and drills.

Henry Harnischfeger ended his autobiography: “As I write this sketch, in March, 1929, it is with a feeling of satisfaction that my many years of struggling and hard labor have been rewarded with a business and an organization that any man can well be proud of.” Through Komatsu and its guiding principles, his brand’s legacy continues.

To commemorate 135 years of P&H, employees reflect on the legacy of the brand while looking forward to its future.

Alonzo, an experienced castings patternmaker and Henry, an experienced machinist, formed a partnership, striving to provide customers with the highest level of quality and service support. They secured work designing patterns for casting industrial components, carried out a variety of repair work, and brought new ideas for inventors to life.

A turning point for their business was in 1887 after the Edward P. Allis Company burned down. When the new foundry was erected, it was equipped with two rope-driven overhead traveling cranes. One of the cranes fell to the floor after a girder twisted, killing the operator and injuring others.

P&H replaced the rope-and-pulley mechanisms with a simpler system of motor-transmission sets applied to the crane’s hoist, trolley and bridge-drive functions. The crane produced immediate performance and reliability gains for the customer and soon after, other manufacturing firms, warehouse operations and railroad maintenance shops began to approach P&H for more such cranes. Pawling and Harnischfeger had a product of their own.

As they expanded their business in making cranes, they began making the electric motors and controllers that were required for the cranes they were building, as well as severe-duty industrial applications. P&H AC and DC motors continue to be the prime motors on virtually all P&H manufactured equipment today.

On February 15, 1903, a disastrous fire swept through the building. Within a few hours, the entire shop was burnt nearly to the ground.

“While the fire seemed a great calamity to us at that time, it was nevertheless a blessing in disguise,” wrote Henry. The insurance money provided funds to build new shops at 38th and National Avenue, where the business would reside for more than 115 years.