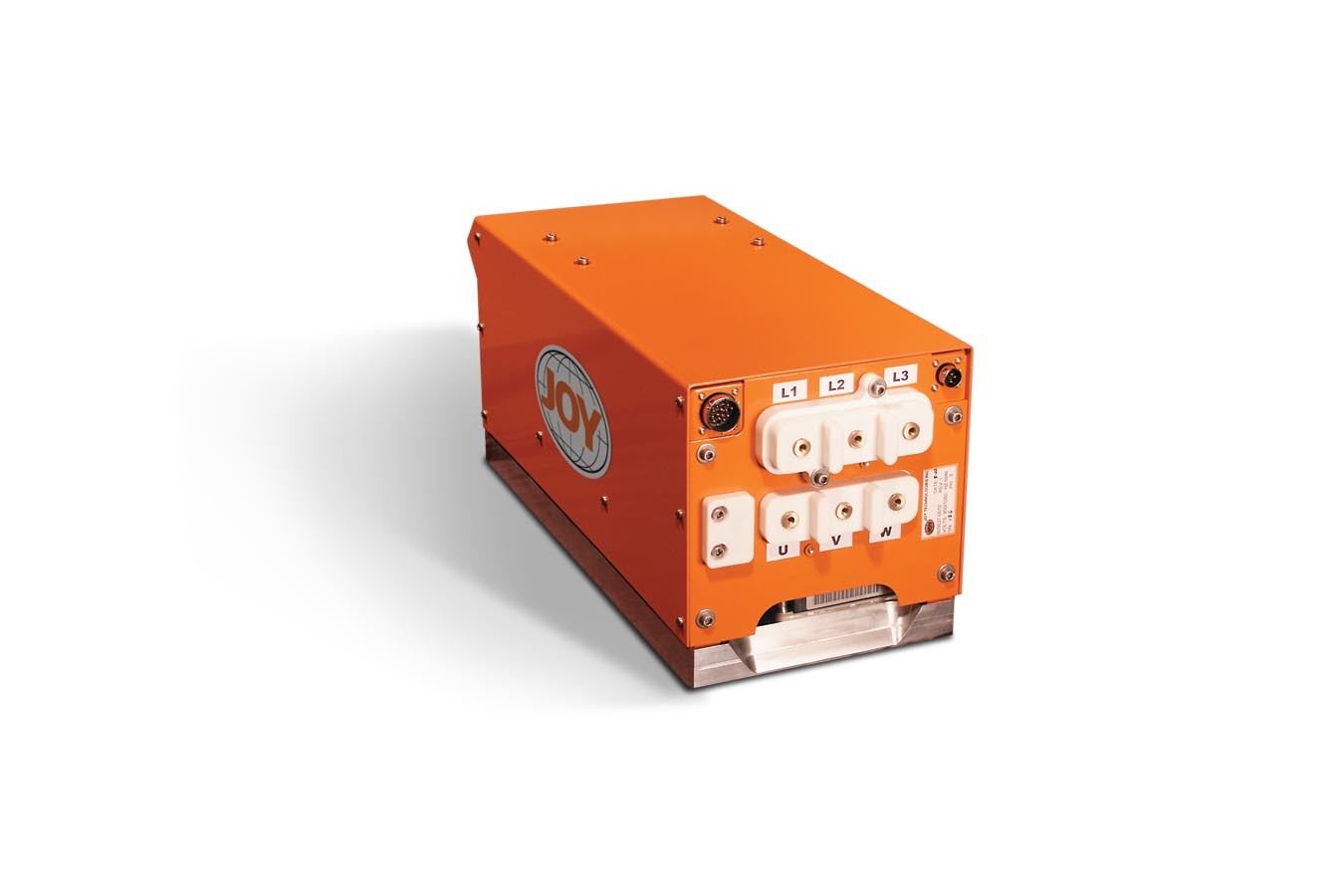

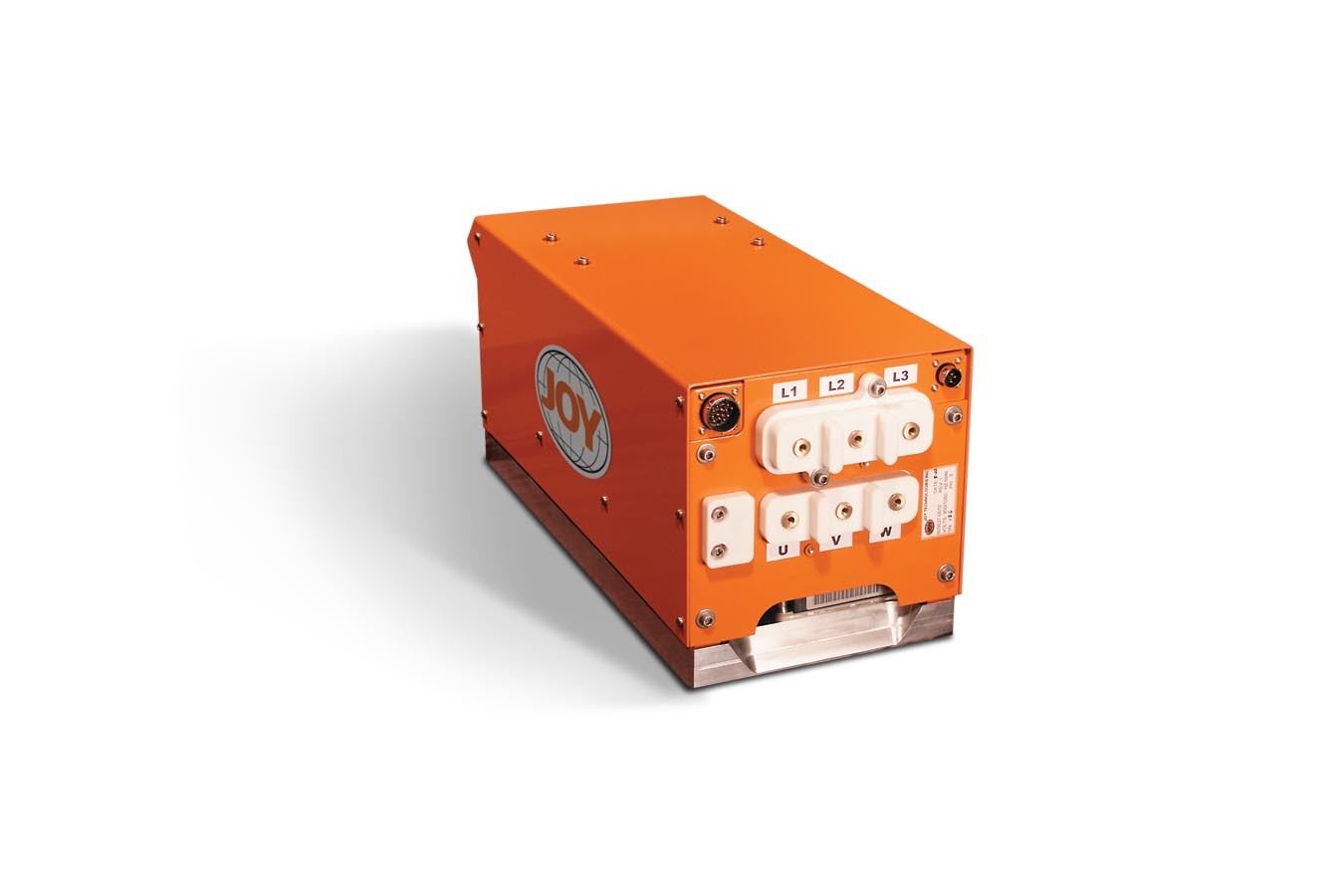

OptiDrive AC

Patented Joy OptiDrive AC system integrates software with the electronic and mechanical systems to provide a durable, maneuverable machine.

Purchase options

Request a quotePatented Joy OptiDrive AC system integrates software with the electronic and mechanical systems to provide a durable, maneuverable machine.

Operators can perform more quickly and safely when they can easily see what’s in front of and behind the hauler. Optional forward and rearward FLIR cameras, mated to monitors in operator compartment, help operators be sure of their surroundings.

Find what works for you