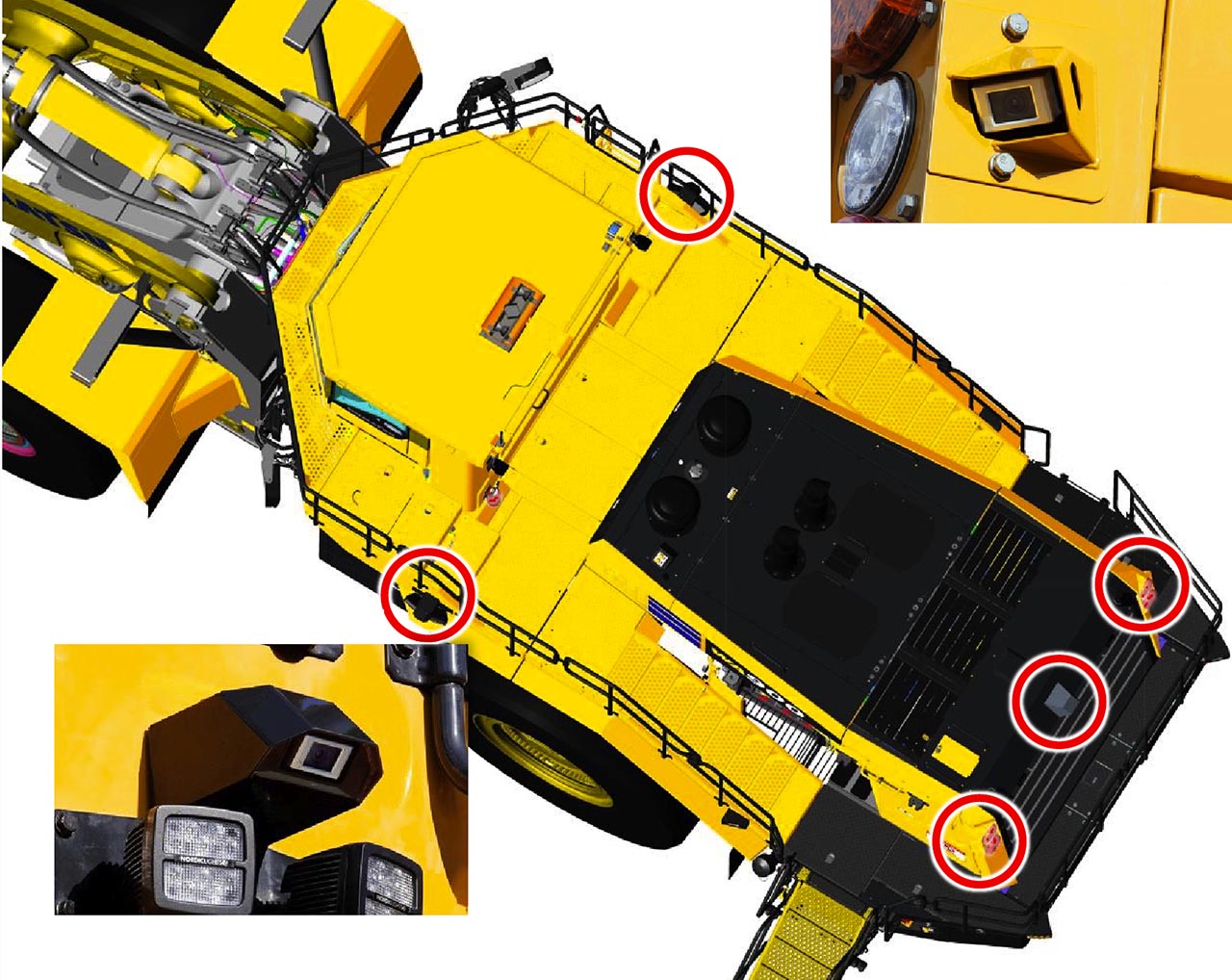

KomVision

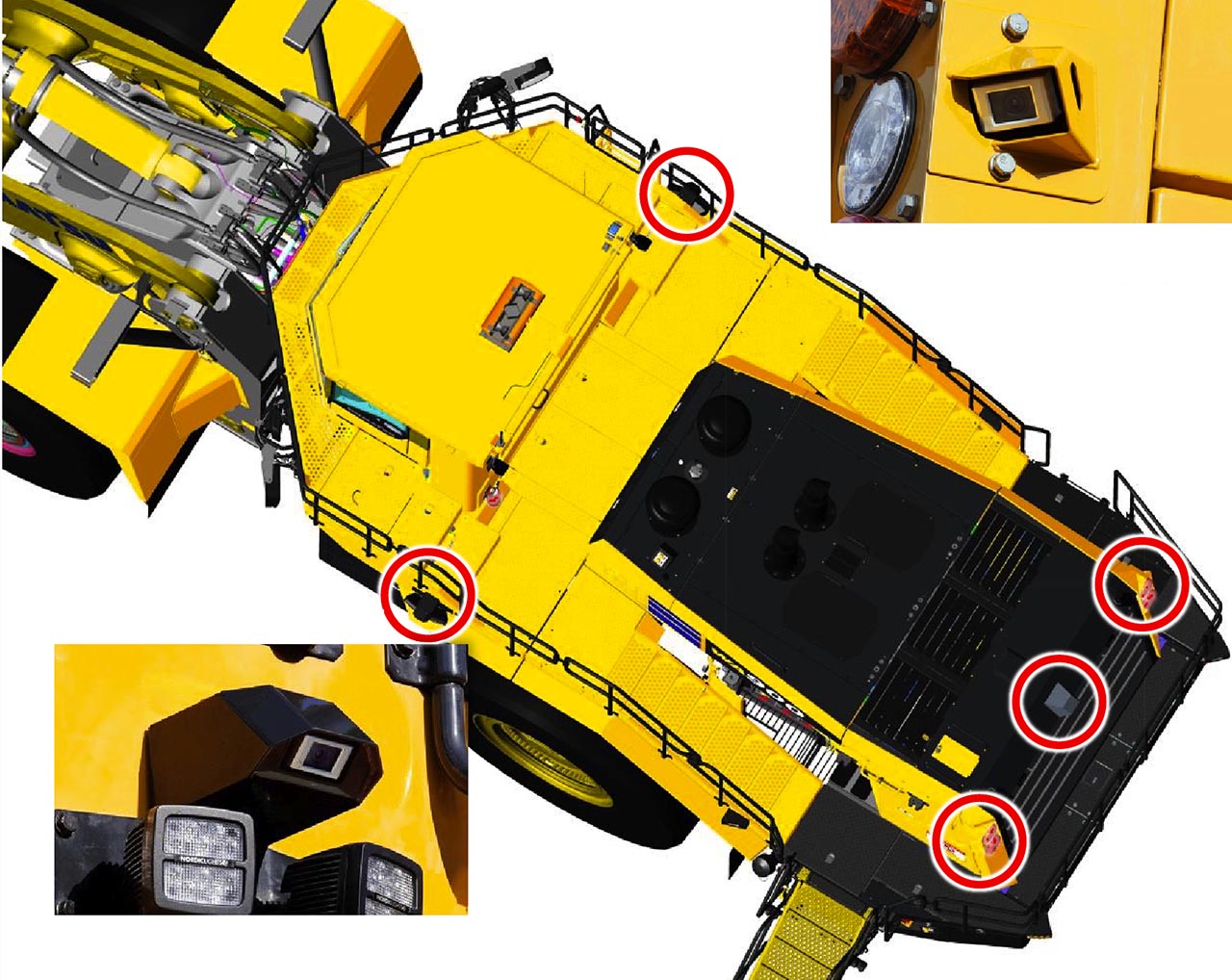

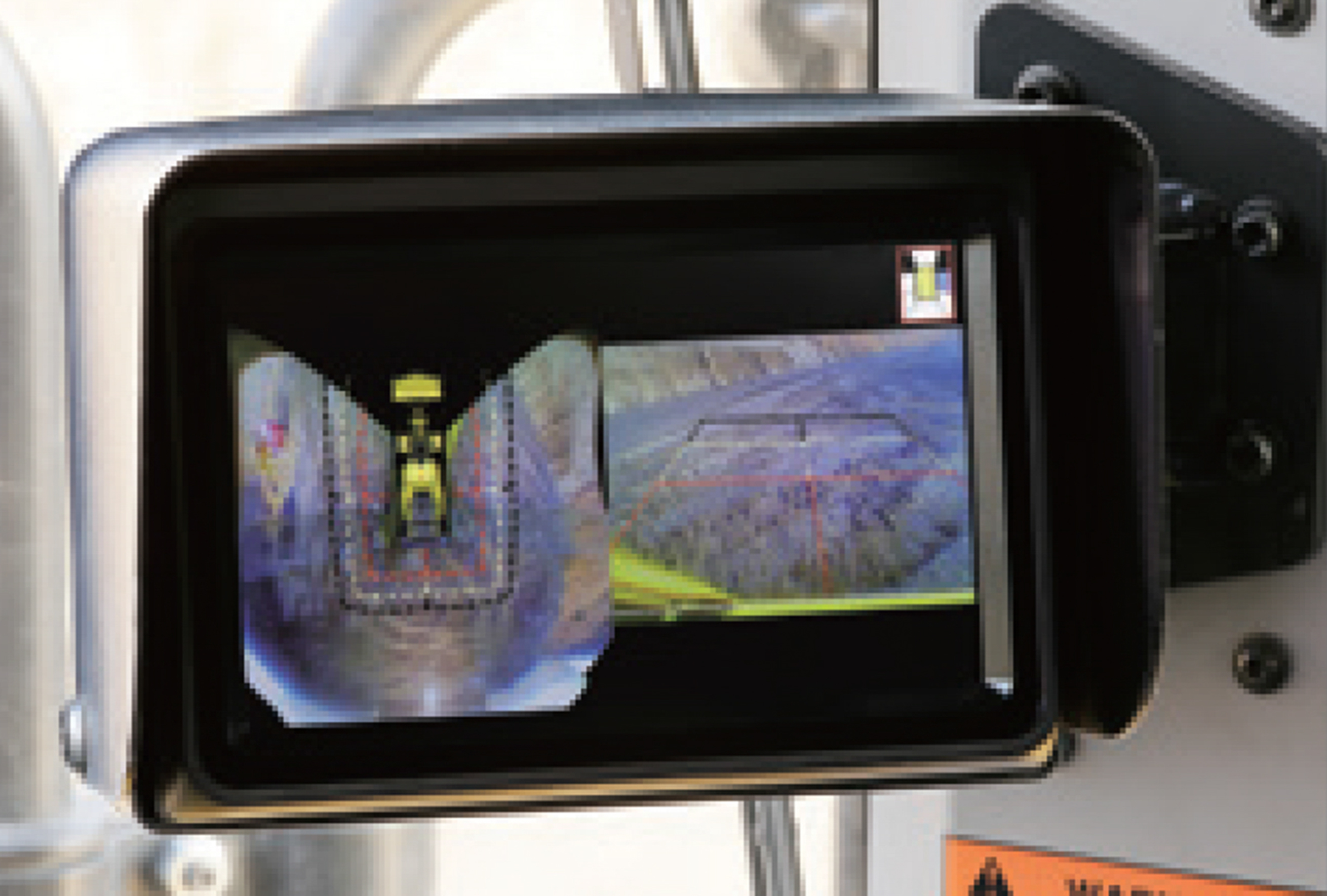

Enhance visibility with KomVision, an all-around monitoring system that uses high-definition cameras to provide operators with a real-time bird’s eye-view of their machines’ immediate working area.

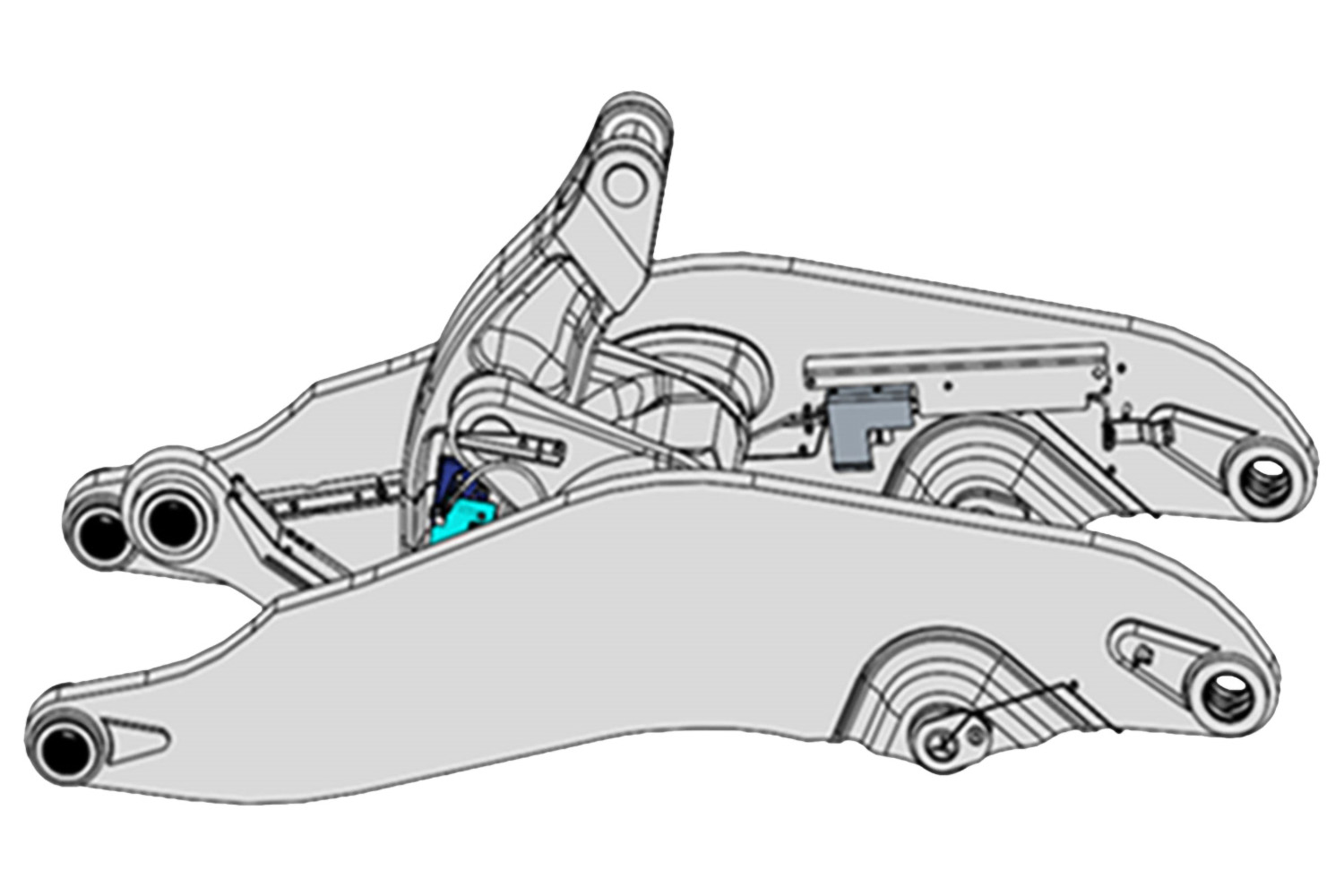

Help surmount the most rugged conditions with a wheel loader that's built for power. The WA800-8 features a z-bar loader linkage that provides excellent breakout force for tough digging applications. You can also help keep your operators productive and comfortable with an ergonomically designed cab.

Note: *all comparisons and claims of improved performance made herein are made with respect to the prior Komatsu model unless otherwise specifically stated. Materials and specifications are subject to change without notice.

If you need to improve your digging performance, this wheel loader will help provide excellent breakout force for tough digging applications with a reinforced z-bar loader linkage.

Help your operators stay safe with an audible or visual alert when an obstacle is detected in the working area. KomVision with radar obstacle detection features six cameras and four radar panels to provide an all-around monitoring system for operators.

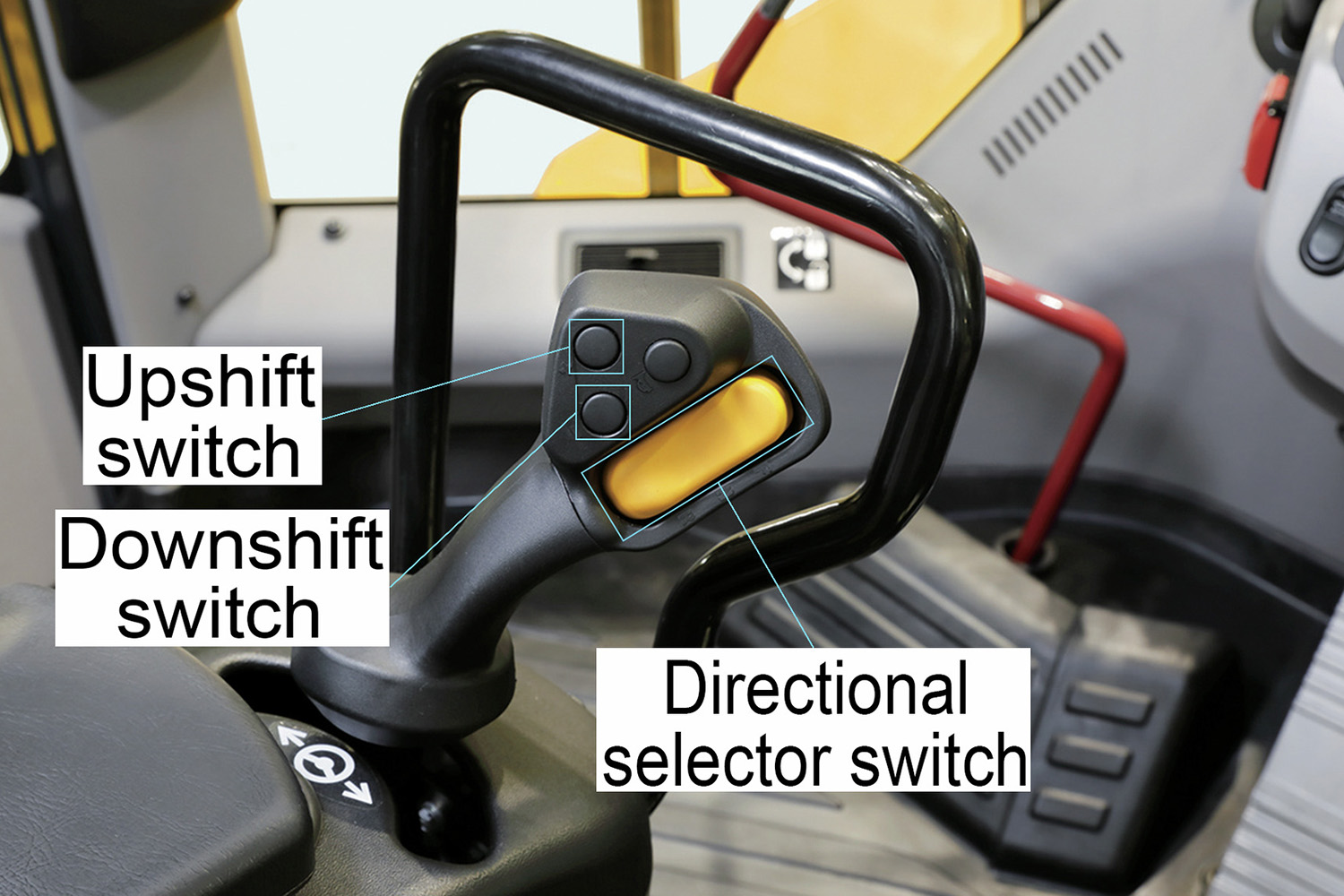

When agility and precision are needed, this wheel loader will provide comfortable, simple operation throughout long shifts with its Advanced Joystick Steering System (AJSS), Electronic Pilot Controls (EPC) levers, a cab featuring a trainer seat, and heated/ventilated operator seats.

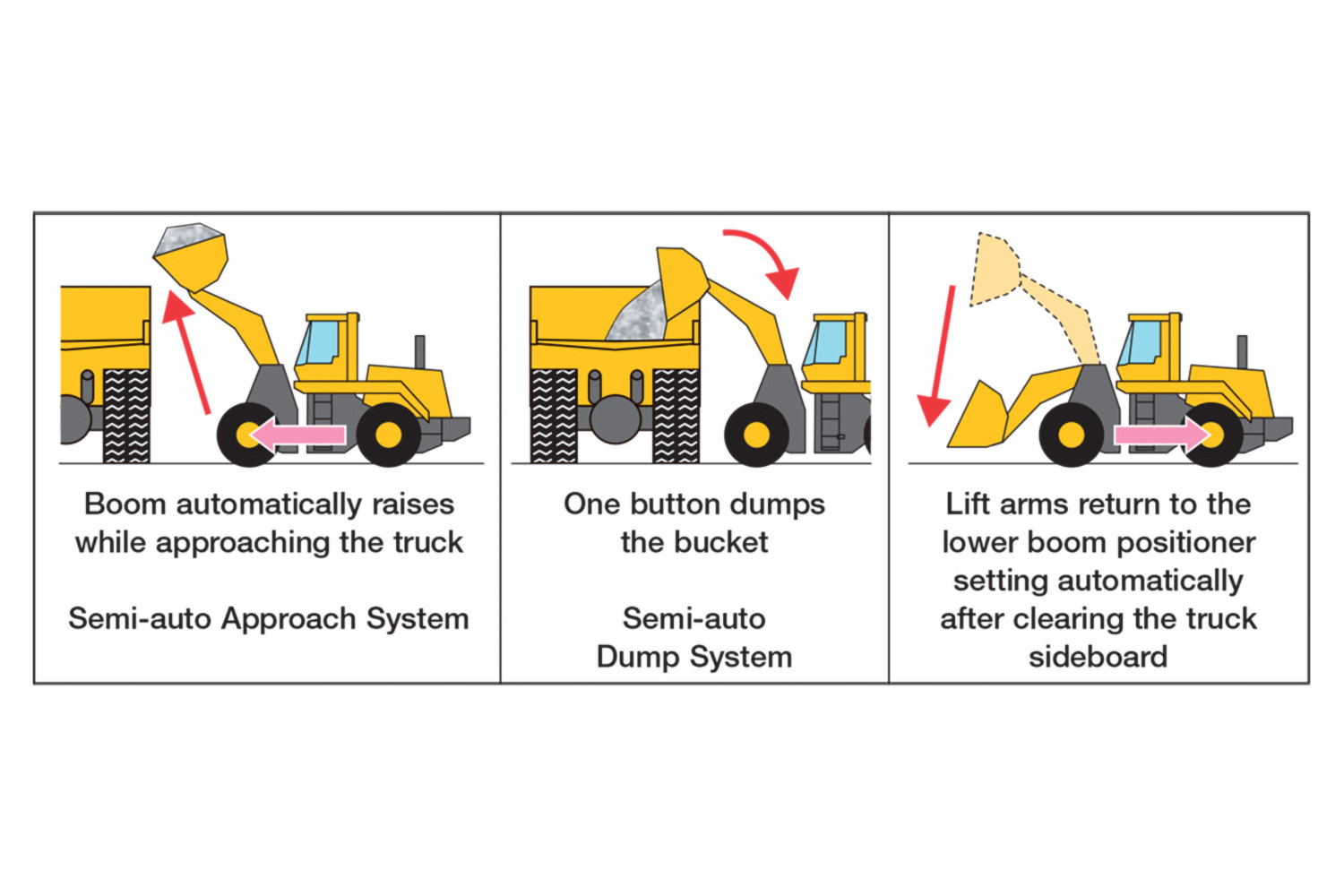

Help maintain productivity, especially when V-cycle loading haul trucks, with three automated features: automatic dig, semi-auto approach and semi-auto dump systems. These features help alleviate operator fatigue and improve efficiency.

Help prevent tire slippage for increased tire life with this wheel loader's variable traction control system. Designed to help operators maintain traction in slippery or wet conditions, machine rim pull can be adjusted between 100% and 20% tractive effort depending on conditions.

Engine RPM can be set to a constant speed in the cab for fast work equipment speeds and quick cycle times. Auto-deceleration automatically reduces engine RPM to 680 if no operator command is sensed after 10 seconds for additional fuel savings.

A smooth approach for your operators when loading haul trucks, as well as simple control of tire slippage and shock reduction when shifting from forward to reverse. Modulation clutch adjusts the tractive effort using the left brake pedal from 100% to 20% of the torque converter output.

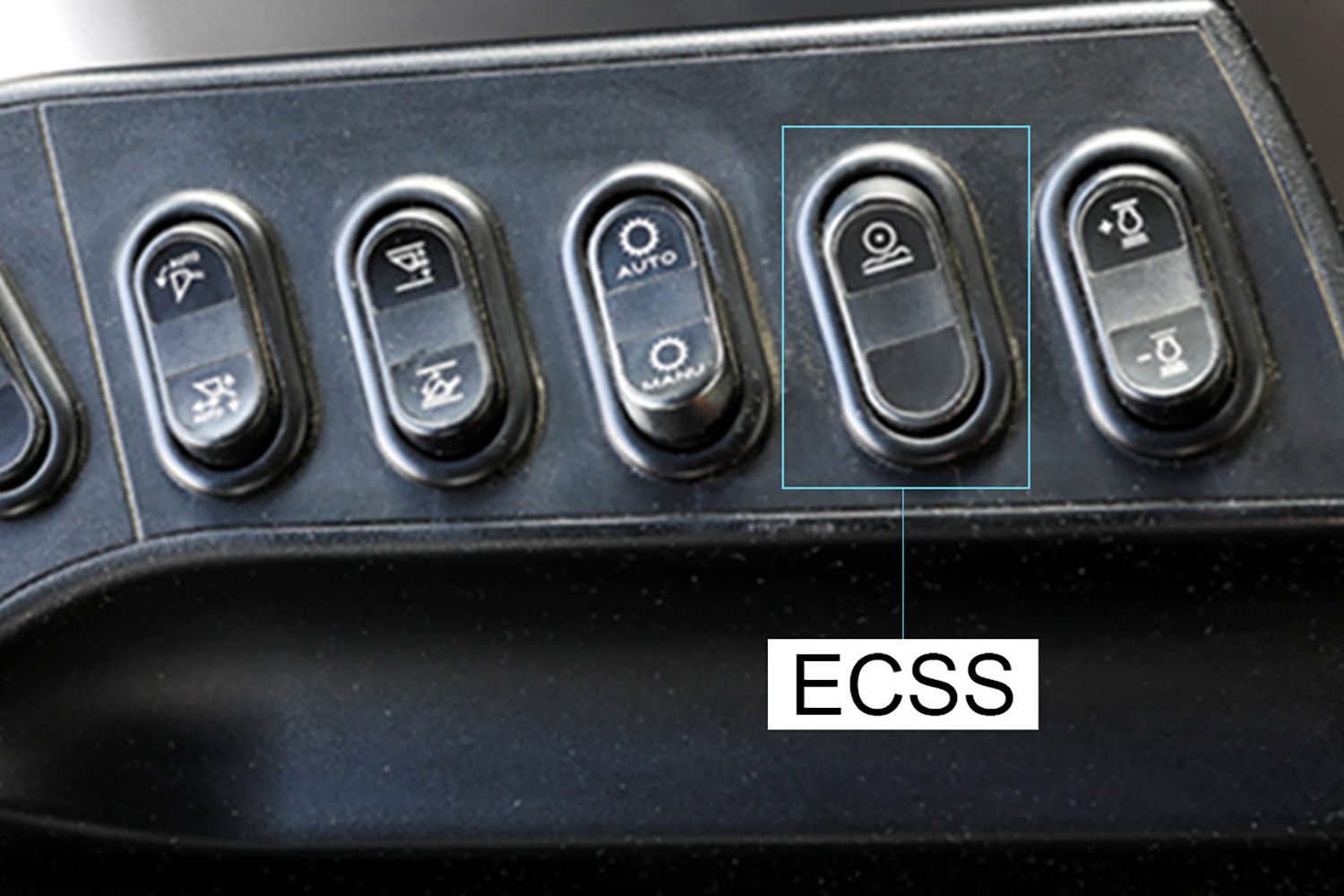

Help manage operator fatigue and material spillage with this wheel loader’s electronically controlled suspension system (ECSS) accumulators. This feature helps absorb the shock from the boom when in load-and-carry applications or tramming around the site.

Help improve awareness around the mine by providing your operators the visibility they need. With 22 LED lamps, your operators will have enough bright lighting to help them perform their best, even in the toughest and darkest working conditions.

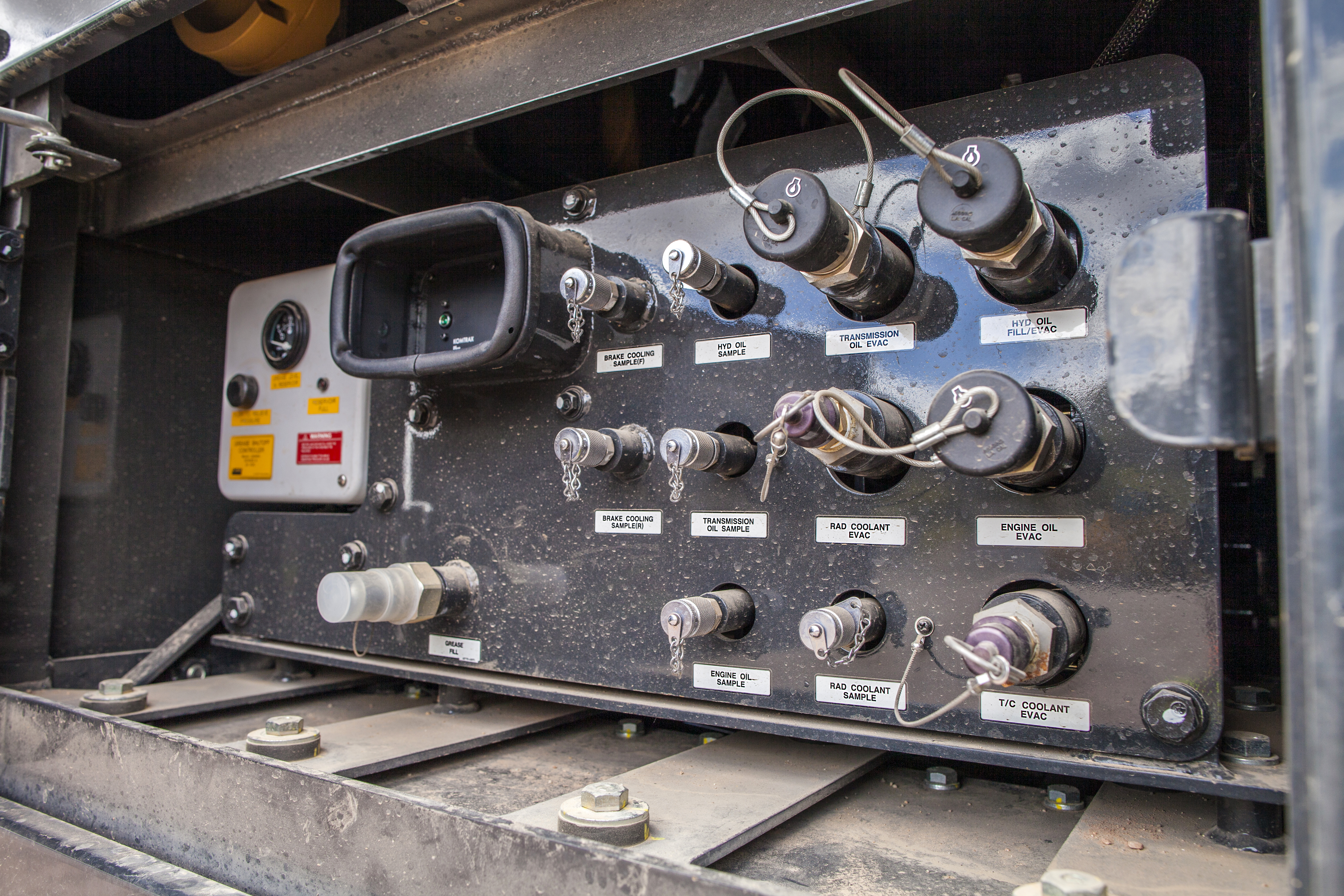

Help save time with easily accessible maintenance at the ground level service center. Drain and fill the transmission oil, hydraulic oil, engine oil and coolant on the spot to avoid lengthy preventative maintenance services.

Help reduce fuel consumption while maintaining you machine’s performance with Komatsu's SmartLoader Logic. This engine control system senses the power requirement of each work phase and automatically changes between 'Economy' and 'Power' mode based on the application's demand.

Make informed decisions to help manage your fleet with Komtrax, Komatsu’s remote equipment monitoring and management system. Additional vital information at your fingertips with Komtrax Plus can help you further reduce operational costs.

Lubrication system

Horsepower

Travel speed

Cylinders

Loader control

Steering System

Control positions

Hydraulic cycle time (rated load in bucket)

Engine and related components

Elecrical system

Power train and controls

Operator environment

Maintenance

Hydraulics and work equipment

Other standard equipment

Vandalism protection

Engine and related components

Elecrical system

Power train and controls

Operator environment

Maintenance

Hydraulics and work equipment

Other standard equipment

Vandalism protection

Enhance visibility with KomVision, an all-around monitoring system that uses high-definition cameras to provide operators with a real-time bird’s eye-view of their machines’ immediate working area.

Manage your machines and their productivity with Komtrax, a free, state-of-the-art remote monitoring service designed to track your assets and help ensure cost control.

Find what works for you