Underground hard rock haulage

HX16

Underground mining trucks

- Tramming capacity (kg) 16 000

- Tramming capacity (lbs) 35,300

- Standard box volume (m^3) 8

- Standard box volume (yd^3) 10.5

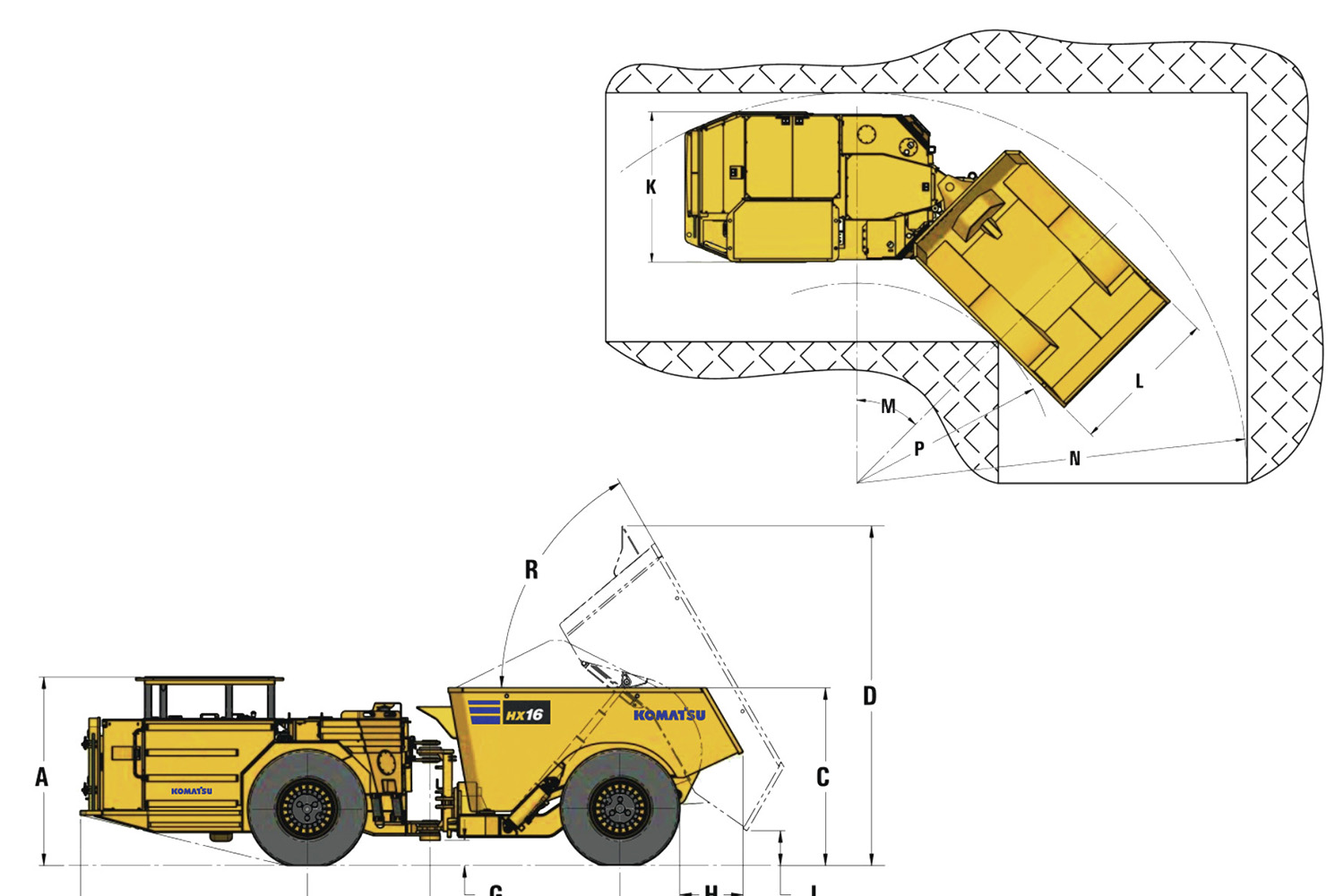

- Dimensions (in) 304 x 91 x 83

- Dimensions (mm) 7 728 x 2 318 x 2 114

Purchase options

Request a quoteTrucks you can rely on to drive productivity and performance

The HX16 is a reliable 16-tonne truck with high-strength steel frame design and heavy-duty, all-mechanical powertrain that can help you hit your production targets while keeping your costs down.

- 6% more capacity than market competitors*

- Faster ramp speeds* - 15% incline in 2nd gear (8.7 km/h)

- Frame oscillation +/- 10 degrees - keeps four wheels on the ground**

Note: *compared to competitors in this size class

Note: **even in most difficult applications

Features and benefits

Operator comfort and care

Designed to deliver exceptional operator visibility. ROPS/FOPS-certified canopies and cabins, fail-safe braking system, operation interlocks, three-point mounting, antislip steps, and hot component isolation promote zero harm.

Ground-level maintenance

Exceptional serviceability with vital maintenance components accessible from the ground level. Ensure fast, efficient repairs with added protection for your service crew.

Customizable

Upgrade to meet your operational needs. Available options include fire suppression system (manual, automatic), centralized auto-lubrication system, fire extinguisher, and spare rim/wheel.

Designed for long life

Engineered for long component life. Rugged steel frame, heavy-duty all-mechanical powertrain, severe-duty electrical system, and centralized lubrication that gets grease to the right places.

Structural integrity

Rugged steel frame structures built strong for long life. Collet-style pins for ease of maintenance and longevity. Heavy-duty mechanical power train for proven performance underground. Hydraulic systems with piston pumps for cooler operation, longer life.

Engineered to produce

Designed to provide the highest possible productivity in its class. Dana components deliver efficient power to the ground and maximize tractive effort. Robust design means fewer failures and more uptime.

Specifications

- Full specs

- Standard equipment

- Optional equipment

- Output (HP): 220 HP

- Output (kW): 164 kW

- Engine payload (kg): 16 000

- Engine payload (lbs): 35,300

- Engine certification (standard): EPA Tier 3

- Operating weight (kg): 17 900

- Operating weight (lbs): 39,380

- Total loaded weight (kg): 33 900

- Total loaded weight (lbs): 74,580

-

Axle weight with load

- Front axle (kg): 19 200

- Front axle (lbs): 42,240

- Rear axle (kg): 14 700

- Rear axle (lbs): 32,240

-

Axle weight without load

- Front axle (lbs): 29,920

- Front axle (kg): 13 600

- Rear axle (lbs): 9,460

- Rear axle (kg): 4 300

- 1st gear (kph): 5.4 (0% grade), 5.2 (10% grade), 5.1 (15% grade)

- 1st gear (mph): 3.4 (0% grade), 3.2 (10% grade), 3.2 (15% grade)

- 2nd gear (kph): 11.1 (0% grade), 10.9 (10% grade), 8.7 (15% grade)

- 2nd gear (mph): 6.9 (0% grade), 6.8 (10% grade), 5.4 (15% grade)

- 3rd gear (mph): 11.9 (0% grade)

- 3rd gear (kph): 19.2 (0% grade)

- 4th gear (kph): 33.1 (0% grade)

- 4th gear (mph): 20.6 (0% grade)

- Dump box capacity (m^3): 8

- Dump box capacity (yd^3): 10.7

- Haulage capacity (lbs): 35,300

- Haulage capacity (kg): 16 000

- Alternator: 24 V / 100 A

- Batteries: 2 x 24 V

- Starter: 24 V heavy duty

- Driving and working lights: 4 front / 2 rear

- Engine (standard): Cummins QSB 6.7

- Output (standard)(HP): 220 HP @ 2,200 rpm

- Output (standard)(kW): 164 kW @ 2 200 rpm

-

Axles

- Front and rear: Dana 16D2149

- Differential, front: Open

- Differential, rear: Open

- Brakes: Spring applied, hydraulic release

- Tires: Radial lugged

- Size (in): 17.50 R 25

-

General

- Air filtration: Donaldson (dry type)

- Powertrain exhaust system: Diesel oxidation catalyzer

- Fuel tank capacity (US gal): 84

- Fuel tank capacity (L): 317

- Converter: Dana CL320 series with lock-up

- Transmission: Dana 32000 series

- Shifting: Powershift c/w modulation

- Speeds: 4 forward / 4 rear

- Turning time: left (s): 5

- Turning time: right (s): 5

- Raising motion time (s): 12

- Lowering motion time (s): 10

- Frame oscillation angle: +/- 10 deg

- Front and rear frames: Welded steel box construction

- Material: ASTM A572 GR50

- Hoist cylinder: Two, double acting, four stage

- Steer cylinder: Two, double acting, single stage

- Operating weight (kg): 17 900

- Operating weight (lbs): 39,380

- Brake system: Service brakes are enclosed hydraulic apply, spring release disk brakes, located inboard. The emergency and park brakes are spring apply. Brakes will apply upon loss of hydraulic pressure or electrical power.

- FOPS/ROPS open Cabin

- Battery disconnect

- Articulation and dump box locks

- Joystick steering and dump box control

- Side seated operator

- LED working lights

- Central manual lubrication

- Backup alarm

- Manuals: operators, parts, service

- FOPS/ROPS open Cabin

- Battery disconnect

- Articulation and dump box locks

- Joystick steering and dump box control

- Side seated operator

- LED working lights

- Central manual lubrication

- Backup alarm

- Manuals: operators, parts, service

- Reverse camera

- FOPS/ROPS enclosed Cabin with AC and heat

- Fire suppression system: manual or automatic

- Fire extinguisher

- Automatic lubrication system

- Strobe light

- Wheel chocks and holders

- Alternative dump box volumes

- 7.3 m3 for 2.2 mt/m3

- 9.0 m3 for 1.8 mt/m3

- Exhaust blanket

- Cabin pressurizer

- Spare wheel

- Fast fill, Wiggins

- Transmission gear lock-out

- Reverse camera

- FOPS/ROPS enclosed Cabin with AC and heat

- Fire suppression system: manual or automatic

- Fire extinguisher

- Automatic lubrication system

- Strobe light

- Wheel chocks and holders

- Alternative dump box volumes

- 7.3 m3 for 2.2 mt/m3

- 9.0 m3 for 1.8 mt/m3

- Exhaust blanket

- Cabin pressurizer

- Spare wheel

- Fast fill, Wiggins

- Transmission gear lock-out

Support you can count on

Find what works for you