Underground hard rock haulage

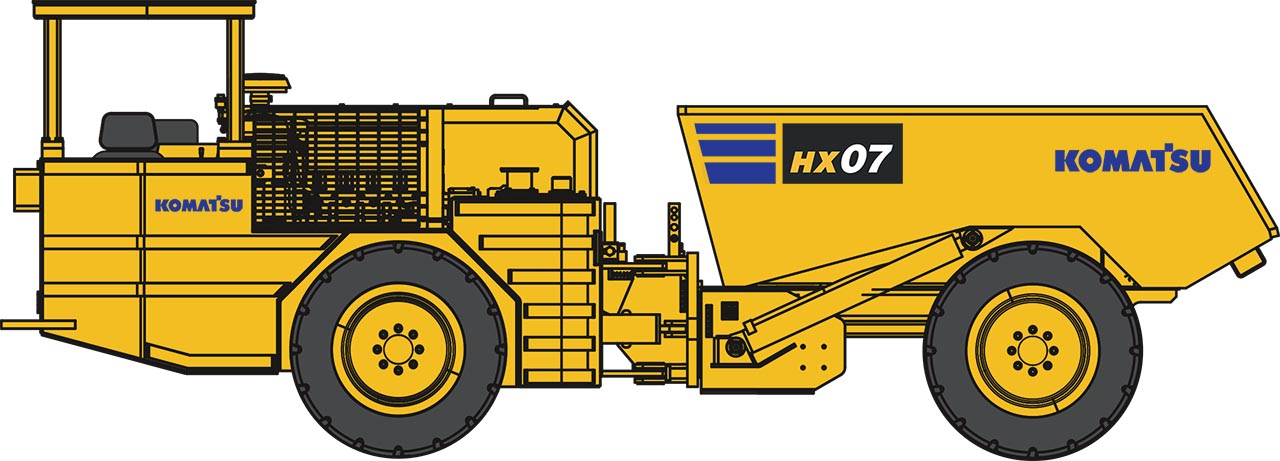

HX07

Underground mining trucks

- Tramming capacity (kg) 6 600

- Tramming capacity (lbs) 14,520

- Standard box volume (m^3) 3.3

- Standard box volume (yd^3) 4.3

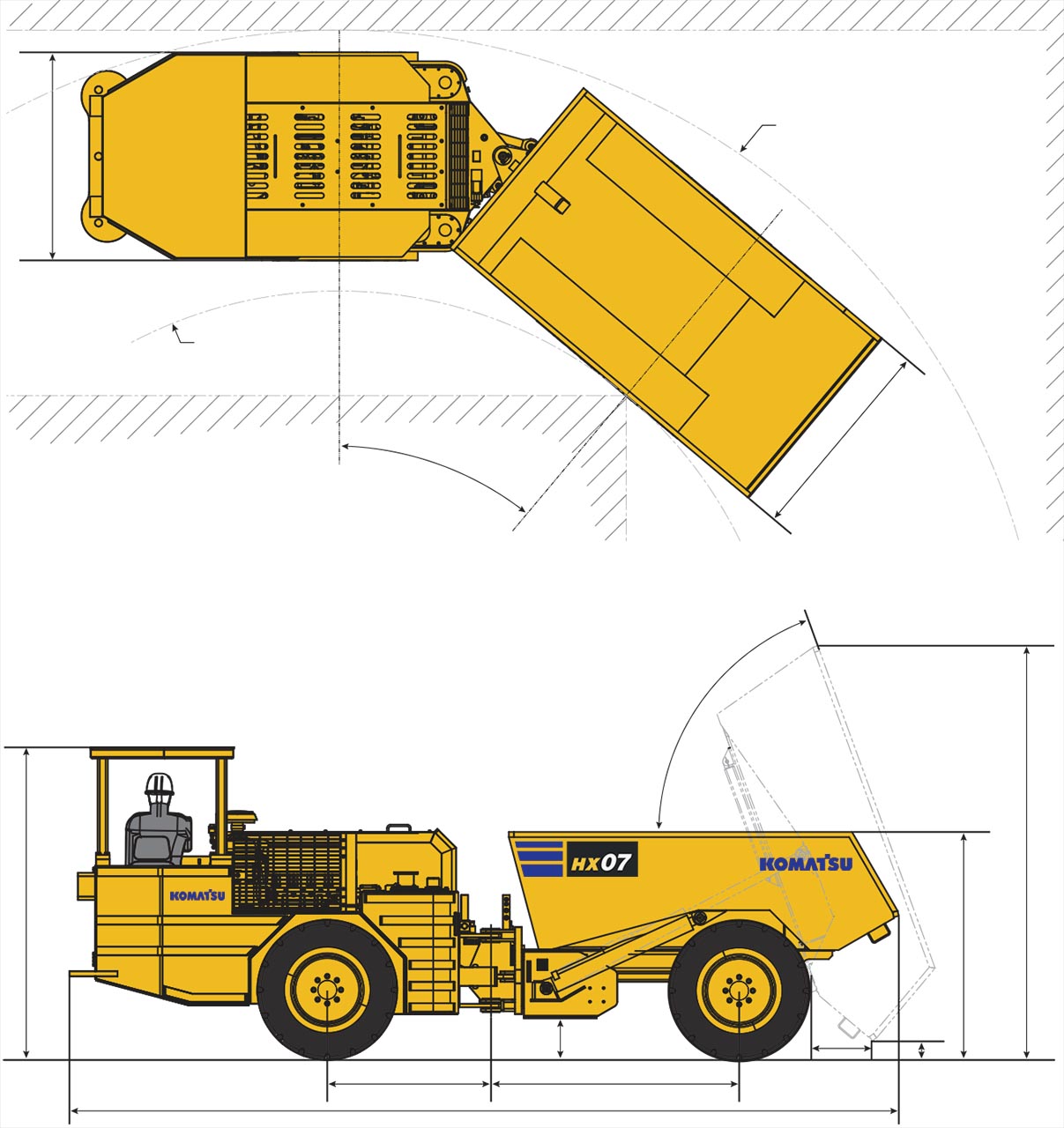

- Dimensions (in) 245 x 61 x 82

- Dimensions (mm) 6 217 x 1 549 x 2 084

- Payload capacity (kg) 6 600

- Payload capacity (lbs) 14,520

Purchase options

Request a quoteA small haulage truck engineered for big performance

The HX07 is a reliable 7-tonne truck for narrow vein applications. This workhorse features a large operator cabin and simple operation controls. With a rugged long-life structure, the HX07 is engineered for reliability and longevity.

- 6 600 kg (14,520 lbs.) rated load capacity for more mineral hauling per cycle

- 4-minute fixed cycle time - loading, dumping, turning, accelerating

- Efficient power to the ground and maximized tractive effort with heavy duty powertrain

Features and benefits

Operator-focused design

Engineered for operator care. ROPS/FOPS-certified canopies, fail-safe braking system, operation interlocks, hot component isolation, three-point mounting, and slip resistant steps help you drive toward zero harm.

Ground-level maintenance

Ease of serviceability with vital maintenance components accessible from the ground level. The HX07 is engineered for fast, efficient repairs while helping you drive toward zero harm to your service crew.

Engineered for longevity

Designed for reliability and long component life. Heavy-duty all-mechanical powertrain, rugged steel frame, severe-duty electrical system and centralized lubrication help ensure long product life.

Upgrades and options

Customize your HX07 to your operational needs. Available upgrades include a fire suppression system (manual, automatic), centralized auto-lubrication system, fire extinguisher and a spare rim/wheel.

Rugged steel frame

Structural integrity comes from the rugged steel frame structures and the solid design built for the rigors of hard rock mining. Collet-style pins for ease of maintenance and longevity.

Built for hauling productivity

Designed from the ground up for exceptional productivity. Efficient power to the ground and maximized tractive effort delivers faster hauls. Robust design means fewer failures and more uptime.

Specifications

- Full specs

- Optional equipment

- Engine: Deutz BF4L914

- Engine displacement (L): 4.3

- Output (HP): 96 HP @ 1,600 rpm

- Output (kW): 72 kW @ 1 600 rpm

- Maximum torque (N-m): 355 N-m @ 1 600 rpm

- Maximum torque (ft-lbs): 264 ft.-lbs. @ 1,600 rpm

- Number of cylinders in engine: 4

- Engine cooling type: Air cooled

- Induction type for engine: Turbo charged

- Governor for engine: Mechanical

- Engine certification (standard): EPA Tier 2

- Cooling Type: Air cooled

- Operating weight (kg): 8 545

- Operating weight (lbs): 19,000

- Total loaded weight (kg): 15 145

- Total loaded weight (lbs): 33,320

-

Axle weight with load

- Front axle (kg): 6 873

- Front axle (lbs): 15,120

- Rear axle (kg): 8 273

- Rear axle (lbs): 18,200

-

Axle weight without load

- Front axle (lbs): 13,300

- Front axle (kg): 6 045

- Rear axle (lbs): 5,700

- Rear axle (kg): 2 591

- Raising motion time (s): 8

- Lowering motion time (s): 6

- 1st gear (kph): 3.4 (0% grade), 3.4 (10% grade), 3.4 (15% grade)

- 1st gear (mph): 2.1 (0% grade), 2.1 (10% grade), 2.1 (15% grade)

- 2nd gear (kph): 7.7 (0% grade), 7.5 (10% grade), 7.3 (15% grade)

- 2nd gear (mph): 4.8 (0% grade), 4.7 (10% grade), 4.5 (15% grade)

- 3rd gear (mph): 14.3 (0% grade), 3.5 (10% grade)

- 3rd gear (kph): 23 (0% grade), 5.62 (10% grade)

- Standard payload (kg): 6 600

- Standard payload (lbs): 14520

- Standard box (m^3): 3.3

- Standard box (y^3): 4.29

- Tramming capacity (lbs): 14,520

- Tramming capacity (kg): 6 600

- Alternator: 24 V / 100 A

- Batteries: 2 x 24 V

- Starter: 24 V heavy duty

- Driving and working lights: 2 front / 2 rear

-

Axles

- Front and rear: Dana 113 series

- Differential, front: Open

- Differential, rear: Open

- Brakes: Hydraulic apply, inboard disk

- Oscillation angle (deg): +/- 10 deg (frame)

- Tires: Radial lugged

- Size (in): 9.00 x 20

-

General

- Air filtration: Donaldson (dry type)

- Powertrain exhaust system: Diesel oxidation catalyzer

- Fuel tank capacity (US gal): 31

- Fuel tank capacity (L): 117

- Converter: Integral

- Transmission: Dana HR20000 series

- Shifting: Powershift c/w modulation

- Speeds: 3 forward / 3 rear

- Turning time: left (s): 2.4

- Turning time: right (s): 2.5

- Front and rear frames: Welded steel box construction

- Material: ASTM A572 GR50

- Hoist cylinder: Two, double acting, single stage

- Steer cylinder: Two, double acting, single stage

- Operating weight (kg): 8 545

- Operating weight (lbs): 19,000

- Brake system: Service brakes are enclosed hydraulic apply, spring release disk brakes, located inboard. The emergency and park brakes are spring apply. Brakes will apply upon loss of hydraulic pressure or electrical power.

- Centralized auto lubrication system

- Fire extinguisher

- Fire suppression system (manual, automatic)

- Spare rim/wheel

- Centralized auto lubrication system

- Fire extinguisher

- Fire suppression system (manual, automatic)

- Spare rim/wheel

Support you can count on

Find what works for you