Motor graders

GD955-7

- Horsepower (HP) 426 HP @1,900 rpm

- Horsepower (kW) 318 kW at 1,900 rpm

- Operating weight (kg) 47 320

- Operating weight (lbs) 104,323

- Moldboard (ft) 18 (standard), 20 (optional)

Get smooth, efficient performance for all your grading tasks

When you need increased efficiency when maintaining your quarry or mine site, choose the powerful capabilities of Komatsu's GD955-7 motor grader to help clear the way. With best-in-class blade downforce pressure for efficient grading performance and plenty of horsepower to boost productivity, this motor grader will help you build and maintain stable, efficient roads for your haulage operation.

- 50% more operating weight for increased blade downforce pressure and stability

- Up to 33% increase in productivity with 18-foot moldboard*

- Up to 46% increase in productivity with 20-foot moldboard*

- Up to 21% reduction in total maintenance time with circle bearing system and auto-lubrication*

Note: *compared to the previous model

Features and benefits

Get consistent, reliable grades

A long wheelbase and heavy operating weight allow the GD955-7 to achieve high blade downforce pressures at more aggressive moldboard angles for improved penetration and material flow in hard-packed road surface applications.

Work effectively in confined areas

The large 27-degree articulation angle allows a tight turning radius and provides maneuverability for narrow haul road applications in confined spaces and around obstacles.

Strong and durable structure

Redesigned front and rear frames help withstand bending forces and torsional loads, promoting reduced life-cycle costs and a longer service life.

Make maintenance easy

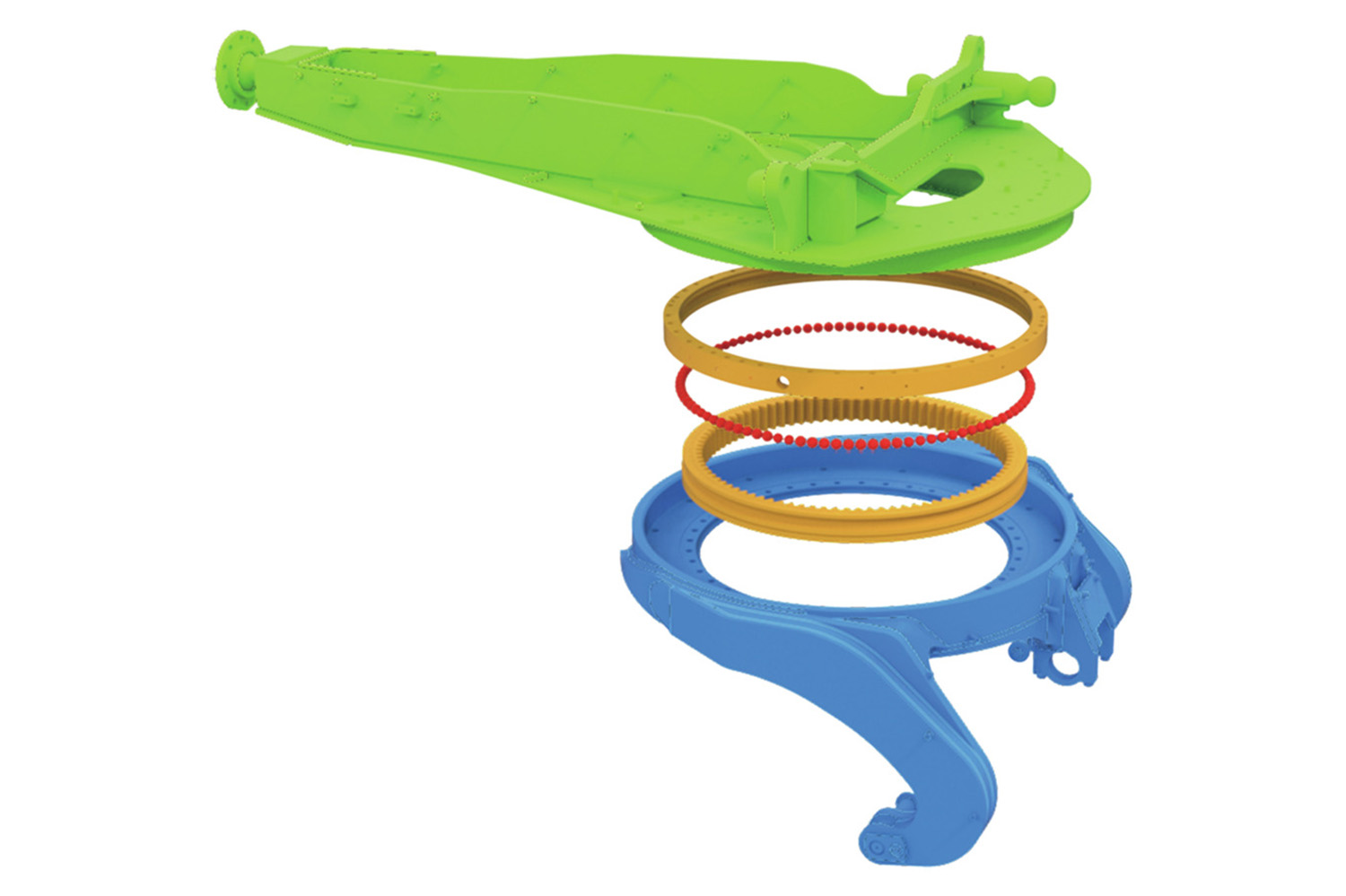

A newly adopted bearing-type circle assembly eliminates wear plates and the need for frequent play adjustments to help minimize downtime. Coupled with an auto-lubrication system, this helps to reduce maintenance times by up to 21%*.

Optimize your machine's performance

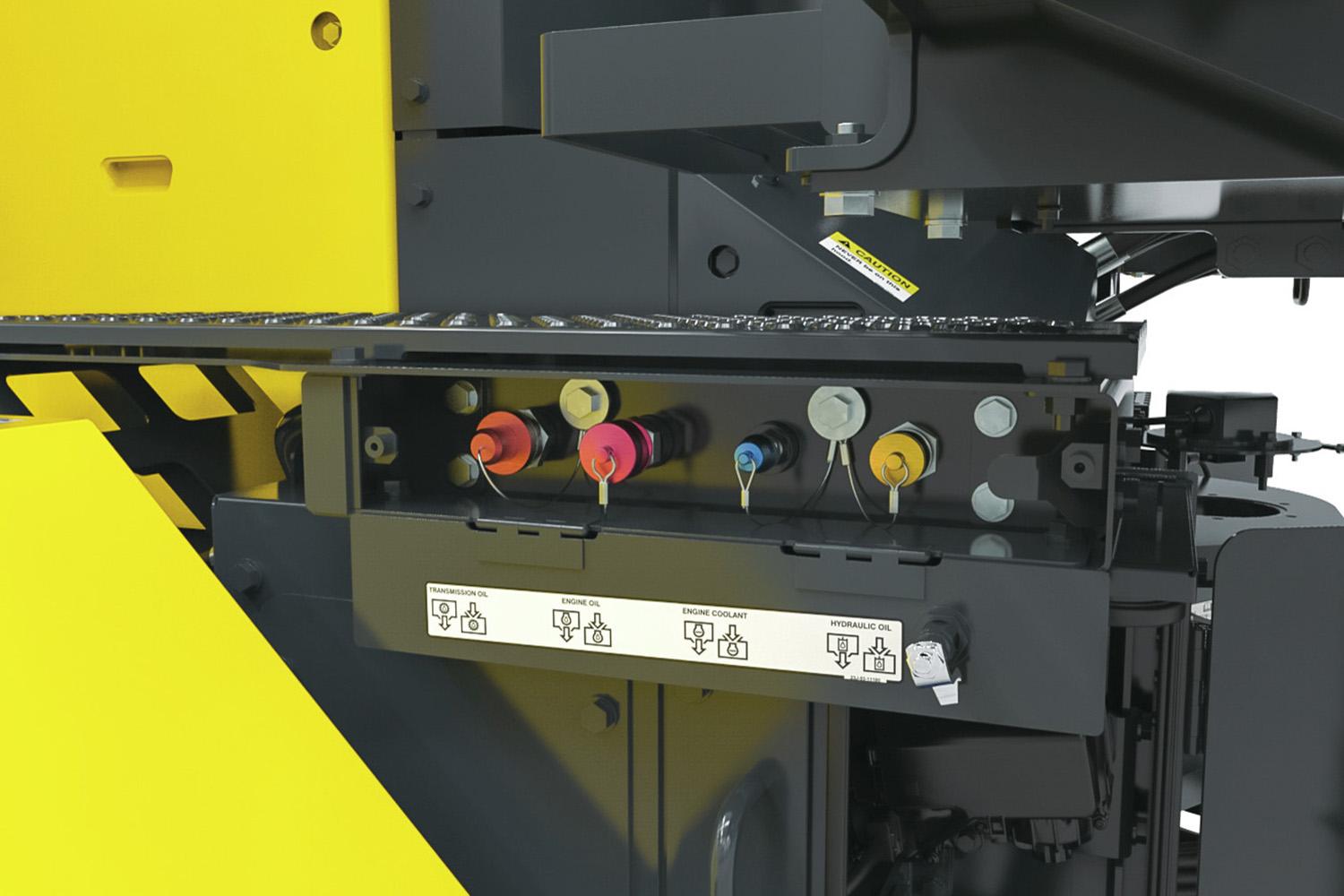

Perform routine checks, inspections and repairs conveniently with a centrally located, ground-level service center. Regular maintenance helps promote your machine's uptime, while easy access streamlines maintenance workflow.

Flexible for all operator levels

Enhance production with the efficiency of a direct-drive transmission and the controllability of a torque converter drive transmission. Perfect for trained operators of all experience levels and applicable to a wide variety of tasks, including maintaining and building haul roads

Stay comfortable while working

Operators can work comfortably in the cab throughout the day with an air-suspension, heated and ventilated seat that helps dampen mechanical vibrations. Operators can also electronically or manually adjust the control lever console height to their preference.

Precise control efficient operation

Controls within easy reach allow operators to quickly adjust to changing grading conditions or terrain. This helps optimize performance, while fingertip controls make for a more ergonomic and comfortable working environment.

Facilitating work site visibility

The hexangular cab and integrated control console layout allow for improved visibility to the moldboard. Strategically placed mirrors enhance visibility, while KomVision provides a bird’s-eye view around the vehicle on an in-cab monitor. *Compared to the previous model

Specifications

- Full specs

- Standard equipment

- Optional equipment

- Maximum lift above ground (ft): 1 ft 8 in

- Maximum lift above ground (mm): 498

- Maximum cutting depth (mm): 542

- Maximum cutting depth (ft): 1 ft 9 in

- Blade tip angle forward (degrees): 49

- Blade tip angle reverse (degrees): 3

-

Moldboard side shift

- Blade range: right (moldboard)(ft): 2 ft 8 in

- Blade range: right (moldboard)(mm): 818

- Blade range: left (moldboard)(mm): 916

- Blade range: left (moldboard)(ft): 3 ft 1 in

-

Maximum shoulder reach outside rear tires (frame straight)

- Blade range: right (maximum shoulder reach)(mm): 2 119

- Blade range: right (maximum shoulder reach)(ft): 6 ft 11 in

- Blade range: left (maximum shoulder reach)(mm): 2 126

- Blade range: left (maximum shoulder reach)(ft): 7 ft

-

Includes lubricants, coolant, full fuel tank *6.1 m blade, L4 tire, ripper (five shanks), pusher and access

- Total operating weight with 6.1 m blade (kg): 48 570

- Total operating weight with 6.1 m blade (lbs): 107,079

- Operating weight on front wheels with 6.1 m blade (lbs): 31,019

- Operating weight on front wheels with 6.1 m blade (kg): 14 070

- Operating weight on rear wheels with 6.1 m blade (lbs): 76,059

- Operating weight on rear wheels with 6.1 m blade (kg): 34 500

-

- Total operating weight with 5.5 m blade (lbs): 104,323

- Total operating weight with 5.5 m blade (kg): 47 320

- Operating weight on front wheels with 5.5 m blade (kg): 13 800

- Operating weight on front wheels with 5.5 m blade (lbs): 30,424

- Operating weight on rear wheels with 5.5 m blade (kg): 33 520

- Operating weight on rear wheels with 5.5 m blade (lbs): 73,899

*5.5 m blade, L3 tire, ripper (three shanks) and pusher

- Engine Model: Komatsu SAA6D140E-7

- Engine type: Water-cooled, 4-cycle, direct injection

- Aspiration: Turbocharged and air-to-air aftercooled

- Number of cylinders: 6

- Bore (in): 5.6

- Bore (mm): 140

- Stroke (in): 6.5

- Stroke (mm): 165

- Piston displacement (L): 15.24

- Torque rise (%): 37

- Fan speed (Max rpm): 1 300

- Air cleaner: 2-stage, dry-type

- Engine footnote: U.S. EPA Tier 4 Final emissions certified.

-

Engine power (manual mode)

- SAEJ1995 - Gross (HP): 426 HP at 1,900 rpm

- SAEJ1995 - Gross (kW): 318 kW at 1,900 rpm

- ISO 14396 (HP): 426 HP at 1,900 rpm

- ISO 14396 (kW): 318 kW at 1,900 rpm

- ISO 9249 (net engine power)(kW): 311 kW at 1,900 rpm

- ISO 9249 (net engine power)(HP): 417 HP at 1,900 rpm

- Maximum torque (ft-lbs): 1,586 @ 1,350 rpm

- Maximum torque (kgf-m): 219 @ 1,350 rpm

- Maximum torque (N-m): 2 150 @ 1,350 rpm

- Moldboard details: Hydraulic power shift fabricated from high tensile steel. Includes replaceable metal wear inserts, cutting edge and end bits. Cutting edge and end bits are hardened.

- Dimensions (in): 18 ft x 3 ft 2 in x 1 in

- Dimensions (mm): 5 489 x 960 x 25

- Arc radius (ft): 1 ft 4 in

- Arc radius (mm): 414

- Cutting edge (mm): 254 x 25

- Cutting edge (in): 10 x 1

- Replaceable/Reversible side edges (mm): 204 x 490 x 19

- Replaceable/Reversible side edges (in): 8 in x 1 ft 7 in x .75 in

- Blade pull (kgf): 26 816

- Blade pull (lbf): 59,119

-

Blade down pressure

- Blade pressure down - base GVW (lbs): 49,009

- Blade pressure down - base GVW (kg): 22 230

- Fuel tank (L): 717

- Fuel tank (US gal): 189

- Cooling system (US gal): 21

- Cooling system (L): 80

- Crank case (L): 50

- Crank case (US gal): 13

- Transmission (US gal): 23

- Transmission (L): 85

- Final drive (L): 56

- Final drive (US gal): 15

- Tandem housing (each)(US gal): 53

- Tandem housing (each)(L): 199

- Hydraulic system (L): 147

- Circle reverse housing (US gal): 7

- Hydraulic system (US gal): 39

- Circle reverse housing (L): 28

- DEF tank (L): 36

- DEF tank (US gal): 10

- Minimum turning radius details: Hydraulic power steering providing stopped engine steering meeting ISO 5010.

- Maximum steering range, right or left (degrees): 50

- Articulation, right or left (degrees): 70

- Hydraulic power steering: Providing stopped engine steering meeting ISO 5010.

- Minimum turning radius for steering (ft) (in): 30 ft. 6 in

- Minimum turning radius for steering (m): 9 300

- Front axle type: Solid bar construction welded steel sections

- Ground clearance at pivot (mm): 710

- Ground clearance at pivot (in): 2 ft 4 in

- Wheel lean angle, right or left (degrees): 14

- Oscillation, total (degrees): 32

-

Speeds (at rated engine speed)

- 1st Gear - forward (kph): 5.3 / 5.7*

- 1st Gear - forward (mph): 3.3 / 3.5*

- 2nd Gear - forward (kph): 7.2 / 7.8*

- 2nd Gear - forward (mph): 4.5 / 4.8*

- 3rd gear - forward (mph): 6.3 / 6.8*

- 3rd gear - forward (kph): 10.2 /11*

- 4th gear - forward (mph): 8.5 / 9.1*

- 4th gear - forward (kph): 13.7 / 14.6*

- 5th gear - forward (mph): 10.4 / 11.1*

- 5th gear - forward (kph): 16.8 / 17.9*

- 6th gear - forward (mph): 14.3 / 15*

- 6th gear - forward (kph): 23.0 / 24.2*

- 7th gear - forward (mph): 20.2 / 20.9*

- 7th gear - forward (kph): 32.5 / 33.7*

- 8th gear - forward (mph): 27.1 / 27.6*

- 8th gear - forward (kph): 43.6 / 44.4*

- 1st Gear - reverse (kph): 4.5 / 4.9*

- 1st Gear - reverse (mph): 2.8 / 3*

- 2nd Gear - reverse (mph): 3.8 / 4.1*

- 2nd Gear - reverse (kph): 6.1 / 6.6*

- 3rd gear - reverse (kph): 8.7 / 9.4*

- 3rd gear - reverse (mph): 5.4 / 5.8*

- 4th gear - reverse (mph): 7.3 / 7.8*

- 4th gear - reverse (kph): 11.7 / 12.6*

- 5th gear - reverse (mph): 9.9 / 10.6*

- 5th gear - reverse (kph): 15.9 / 17*

- 6th gear - reverse (mph): 13.5 / 14.5*

- 6th gear - reverse (kph): 21.8 / 23*

- 7th gear - reverse (mph): 19.1 / 19.9*

- 7th gear - reverse (kph): 30.8 / 32.1*

- 8th gear - reverse (kph): 41.4 / 42.3*

- 8th gear - reverse (mph): 25.7 / 26.3*

- Circle engineering details: Lubricated bearing type circle; Circle and pinion require no adjustment

- Diameter (outside) (mm): 1 822

- Diameter (outside) (ft): 6

- Circle reversing control hydraulic rotation (degrees): 130

- Oscillating welded box section (mm): 739 x 296

- Oscillating welded box section (in): 2 ft 5 in x 12 in

- Side wall thickness - inner (mm): 25

- Side wall thickness - inner (in): 1

- Side wall thickness - outer (mm): 25

- Side wall thickness - outer (in): 1

- Wheel axle spacing (ft/ in): 6 ft 6 in

- Wheel axle spacing (mm): 1 981

- Ripping depth, maximum (ft): 1 ft 9 in

- Ripping depth, maximum (mm): 537

- Ripper shank holders: 7

- Ripper shank holder spacing (ft): 1 ft 8 in

- Ripper shank holder spacing (mm): 501

- Penetration force (kN): 232

- Penetration force (lbs): 52,156

- Pryout force (lbs): 54,404

- Pryout force (kN): 242

- Details of hydraulics system: Load-sensing closed center hydraulics with variable displacement piston pump. Short stroke/low effort direct acting control valves with preselected maximum flow setting to each function. Double acting anti-drift check valves on blade lift, tip, circle shift, articulation, and leaning wheels.

- Output (at engine rated rpm)(L/min): 315.2

- Output (at engine rated rpm)(gpm): 83.3

- Maximum system pressure(psi): 3,989

- Maximum system pressure(kg/cm^2): 280

- Maximum system pressure(MPa): 27.5

- Frame height (in): 20

- Frame height (mm): 504

- Frame width (in): 19

- Frame width (mm): 470

- Upper, Lower (mm): 28 / 32

- Upper, Lower (in): 1.1 / 1.3

- Front frame structure, side(mm): 25 / 32

- Front frame structure, side (in): 1 / 1.3

- Drawbar details: A-shaped, u-shaped press formed and welded construction for maximum strength with a replaceable drawbar ball

- Drawbar frame(in): 12 x 1.25

- Drawbar frame(mm): 310 x 32

- Gauges: Electric monitoring system with diagnostics.

- Standard gauges details: Articulation, engine coolant temperature, fuel level, speedometer, transmission shift indicator, engine tachometer, torque converter oil temperature, DEF level, hydraulic oil temperature, ECO gauge

- Rear axle construction: Alloy steel, heat treated, full floating axle with lock/unlock differential

- Service brake details: Foot operated, wet multiple-disc brakes, hydraulically actuated on four tandem wheels

- Parking brake details: Manually actuated, spring applied on four tandem wheels, hydraulically released wet disc

Engine and its related items

- Air cleaner, double element with dust indicator

- Alternator, 24V/140 A

- Batteries, maintenance free, 2 x 12V

- Electric priming fuel pump

- Engine, Komatsu SAA6D140E-7, U.S. EPA Tier 4 Final emissions certified

- Engine power mode select (Power, economy and middle speed)

- Fuel line pre-filter

- Hydraulically driven reversible cooling fan

- Komatsu Diesel Particulate Filter

- Selective catalytic reduction

- Starting motor, 11.0 kW

General equipment

- Emergency stop switches (4)

- Alarm, back up

- Anchor point for tie offs

- Disconnect switches, battery and starting motor

- Engine shutdown secondary switch (in Cab)

- Hammer (emergency exit)

- Horn, electric

- KomVision Camera System

- Machine lock out system

- Operator presence monitoring system

- Parking brake, spring applied, hydraulic release, wet disc

- Rearview monitor and camera

- Secondary brake (ISO 3450)

- Secondary steering, automatic, electric

- Service brakes, fully hydraulic wet multiple-disc

Lighting system

- Access lamps, LED

- Backup lamps, LED

- Beacon lamp, LED

- Cab mounted work lamps, LED

- Engine bay lamp, LED

- Front work lamps, LED

- Head lamps, high and low beam, LED

- Rear work lamps, LED

- Stop and tail lamps, LED

- Turn signal lamps, LED

Operator environment

- Air conditioner (R134a) with heater

- Cab mount, viscous

- Defogger glass, rear

- Doors, left and right side with wipers

- Electrical height adjustable consoles, left and right

- Electrical outlets (2 x 12V outlets, 1 x 24V outlet)

- Floor mat

- Instrument panel and monitoring system

- Mirrors, interior Cab, left and left exterior mirrors

- Mirrors, outside heated and power adjustable

- Operator seat with 2-point seat belt, reclining, air suspension type

- Multi-color monitor with 7-inch LCD display

- Radio, AM/FM with AUX input, Bluetooth®

- Room lamp, LED

- ROPS/FOPS (ISO 3471/ISO 3449)

- Operator seat with 3-point seat belt, reclining, air suspension type

- Space for lunch box

- Steering lever, electric, palm control

- Steering wheel, tilt and telescopic

- USB port for charging

- Wipers, front, doors and rear

Power train

- Automatic differential lock

- Axle, rear semi floating, planetary type

- Brake, parking, spring applied, hydraulically released wet disc

- Differential, manual lock/unlock

- Dual mode transmission (8F/8R) power shift direct drive and torque converter with auto shift

- Engine overrun warning and protection

Work equipment and hydraulics

- Accumulators, blade lift

- Articulation, automatic return-to-center

- Clutch, circle drive slip

- Cutting edges, flat, 10" x 1", .75" mounting bolts

- Drawbar, bearing type circle

- End bits, 8" x .75", .75" mounting bolts

- Moldboard, hydraulic side shift and tilt, 18' x 32" x 1"

- Rail guide with backlash adjustment bolts

- Ripper, 7 shankh

Other equipment

- Auto-lube, Graco

- Fast fill coupler for fuel tank

- Externally powered power train heaters, 230V (Engine coolant, Engine oil, transmission oil, differential oil)

- Ground level service center (Engine coolant, Engine oil, transmission oil, hydraulic oil)

- In conformity with lockout/tagout regulation

- Komtrax Plus

- KOWA sampling ports

- Painting, Komatsu standard color scheme

- Pre-cleaner, Turbo II

- Platform, access platfrom with ladders

- Pusher plate

- Tires and rims: 26.5R25 (L-3) with multi-piece rim

- Toolbox with lock

- Transmission under guard

- Vandalism protection, lockable fuel tank, hydraulic tank, battery cover, Engine side covers

- Wheel chocks (2)

Engine and its related items

- Air cleaner, double element with dust indicator

- Alternator, 24V/140 A

- Batteries, maintenance free, 2 x 12V

- Electric priming fuel pump

- Engine, Komatsu SAA6D140E-7, U.S. EPA Tier 4 Final emissions certified

- Engine power mode select (Power, economy and middle speed)

- Fuel line pre-filter

- Hydraulically driven reversible cooling fan

- Komatsu Diesel Particulate Filter

- Selective catalytic reduction

- Starting motor, 11.0 kW

General equipment

- Emergency stop switches (4)

- Alarm, back up

- Anchor point for tie offs

- Disconnect switches, battery and starting motor

- Engine shutdown secondary switch (in Cab)

- Hammer (emergency exit)

- Horn, electric

- KomVision Camera System

- Machine lock out system

- Operator presence monitoring system

- Parking brake, spring applied, hydraulic release, wet disc

- Rearview monitor and camera

- Secondary brake (ISO 3450)

- Secondary steering, automatic, electric

- Service brakes, fully hydraulic wet multiple-disc

Lighting system

- Access lamps, LED

- Backup lamps, LED

- Beacon lamp, LED

- Cab mounted work lamps, LED

- Engine bay lamp, LED

- Front work lamps, LED

- Head lamps, high and low beam, LED

- Rear work lamps, LED

- Stop and tail lamps, LED

- Turn signal lamps, LED

Operator environment

- Air conditioner (R134a) with heater

- Cab mount, viscous

- Defogger glass, rear

- Doors, left and right side with wipers

- Electrical height adjustable consoles, left and right

- Electrical outlets (2 x 12V outlets, 1 x 24V outlet)

- Floor mat

- Instrument panel and monitoring system

- Mirrors, interior Cab, left and left exterior mirrors

- Mirrors, outside heated and power adjustable

- Operator seat with 2-point seat belt, reclining, air suspension type

- Multi-color monitor with 7-inch LCD display

- Radio, AM/FM with AUX input, Bluetooth®

- Room lamp, LED

- ROPS/FOPS (ISO 3471/ISO 3449)

- Operator seat with 3-point seat belt, reclining, air suspension type

- Space for lunch box

- Steering lever, electric, palm control

- Steering wheel, tilt and telescopic

- USB port for charging

- Wipers, front, doors and rear

Power train

- Automatic differential lock

- Axle, rear semi floating, planetary type

- Brake, parking, spring applied, hydraulically released wet disc

- Differential, manual lock/unlock

- Dual mode transmission (8F/8R) power shift direct drive and torque converter with auto shift

- Engine overrun warning and protection

Work equipment and hydraulics

- Accumulators, blade lift

- Articulation, automatic return-to-center

- Clutch, circle drive slip

- Cutting edges, flat, 254 mm x 25 mm,19 mm mounting bolts

- Drawbar, bearing type circle

- End bits, 204 mm x 19 mm, 19 mm) mounting bolts

- Moldboard, hydraulic side shift and tilt, 5,500 mm x 810 mm x 25 mm

- Rail guide with backlash adjustment bolts

- Ripper, 7 shankh

Other equipment

- Auto-lube, Graco

- Fast fill coupler for fuel tank

- Externally powered power train heaters, 230V (Engine coolant, Engine oil, transmission oil, differential oil)

- Ground level service center (Engine coolant, Engine oil, transmission oil, hydraulic oil)

- In conformity with lockout/tagout regulation

- Komtrax Plus

- KOWA sampling ports

- Painting, Komatsu standard color scheme

- Pre-cleaner, Turbo II

- Platform, access platfrom with ladders

- Pusher plate

- Tires and rims: 26.5R25 (L-3) with multi-piece rim

- Toolbox with lock

- Transmission under guard

- Vandalism protection, lockable fuel tank, hydraulic tank, battery cover, Engine side covers

- Wheel chocks (2)

Work equipment and hydraulics

- Moldboard, hydraulic side shift and tilt, 20' x 32" x 1"

Other equipment

- Platform, rear entry access platform

- Rear fenders

Work equipment and hydraulics

- Moldboard, hydraulic side shift and tilt, 6,100 mm x 810 mm x 25 mm

Other equipment

- Platform, rear entry access platform

- Rear fenders

Support you can count on

Find what works for you