Hard rock continuous miners

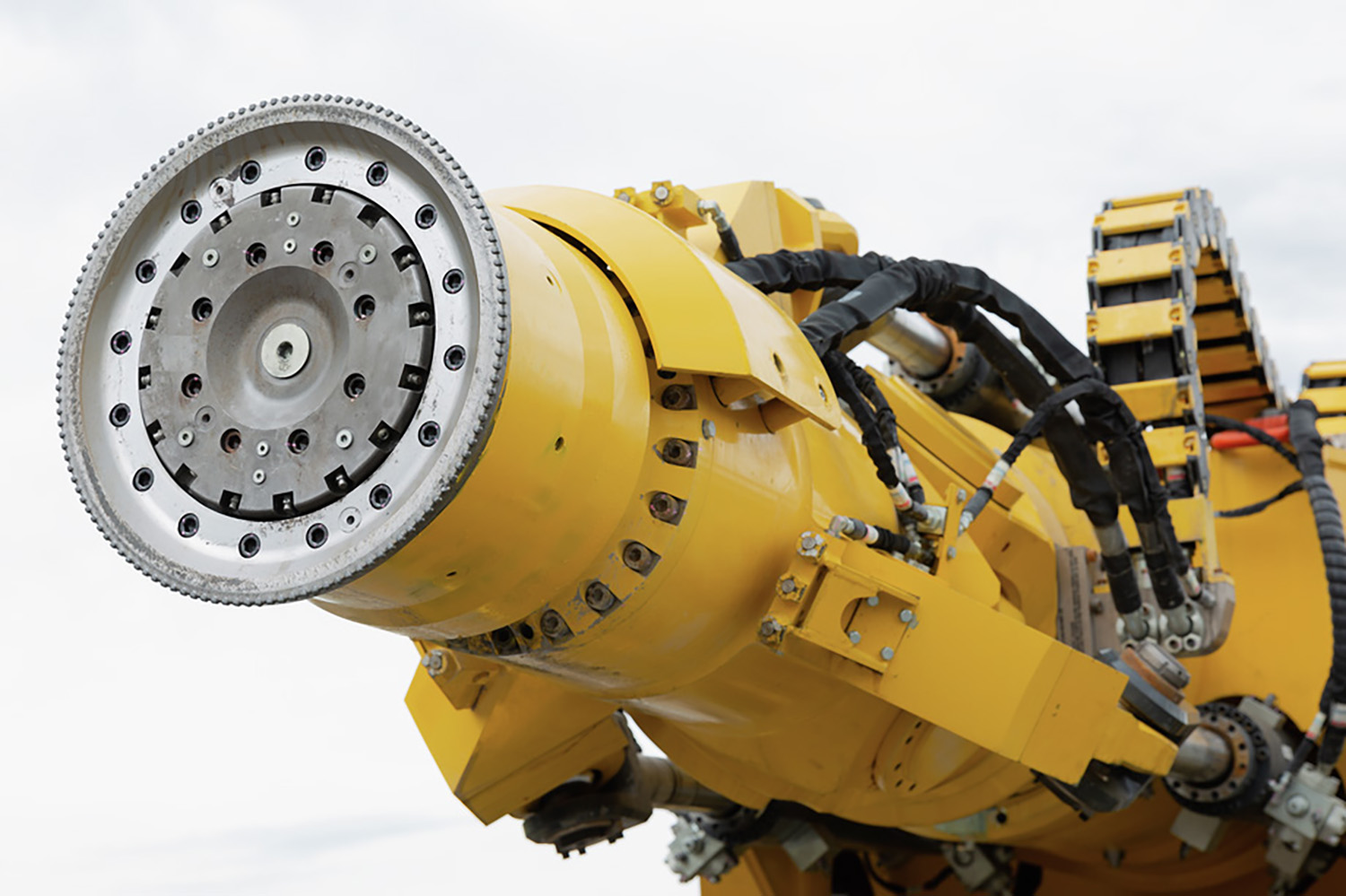

MC51

- L x W x H (ft) 41' x 13'7" x 11'8"

- L x W x H (m) 12.5 x 4.2 x 3.6

- Tunnel size maximum (ft) 17'1" x 17'1"

- Tunnel size maximum (m) 5.2 x 5.2

- Remove cut material up to (m^3/hr) 60

- Remove cut material up to (yd^3/hr) 78

Purchase options

Contact UsAn agile and nimble approach to safer mining

The MC51 is an agile and compact hard rock continuous miner. At only 12.5 m (41 ft.) long, this workhorse can turn on its center axis within approximately 6 m for easy and fast deployment. It also uses Komatsu DynaCut technology that cuts using a dynamic undercutting method for consistent rock size and efficient material handling.

- 100% clean up - no secondary material removal required

- Up to 50% less equipment needed vs. batch process

- Fully electric and remote controlled system

Features and benefits

Fully remote controlled

Help keep your operators out of harm’s way at the cutting face. Machine system uses a series of remote positioning sensors, onboard cameras, and a touch screen tablet device to help navigate the machine into its predetermined position.

Fully electric system

No diesel and less requirement for underground ventilation for a more sustainable mining operation. Low power requirement of only 320 kW – 430 HP (1000V, 50 & 60 Hz). Can fit into most mining operations without major electrical connection changes.

Flexible cutting profile

Designed to cut a tunnel profile of 5 m x 5 m within 50 mm of accuracy over the length of the excavation. It can cut a wide range of rock types and varying profiles around tight corners with a hardness of up to 250 MPa.

Excellent tunnel quality

DynaCut technology helps make the tunnel profile accurate and clean. Reduces roof and ground support quantity and the potential need for tunnel structure rehab. Conveyor system fully captures cut material for proper water drainage — no need for concrete or road fill.

DynaCut technology

Dynamic undercutting method takes advantage of weak tensile rock properties. Ground engagement tools deliver smaller, uniform and consistent rock material size for exceptional material handling productivity and efficiency throughout the entire mining process.

Continuous vs. batch

Employs a continuous mining method versus a more traditional batch cycle. This simplified method using automation brings more control to the process. Requires up to 50% less equipment than normally used for this type of mining operation.