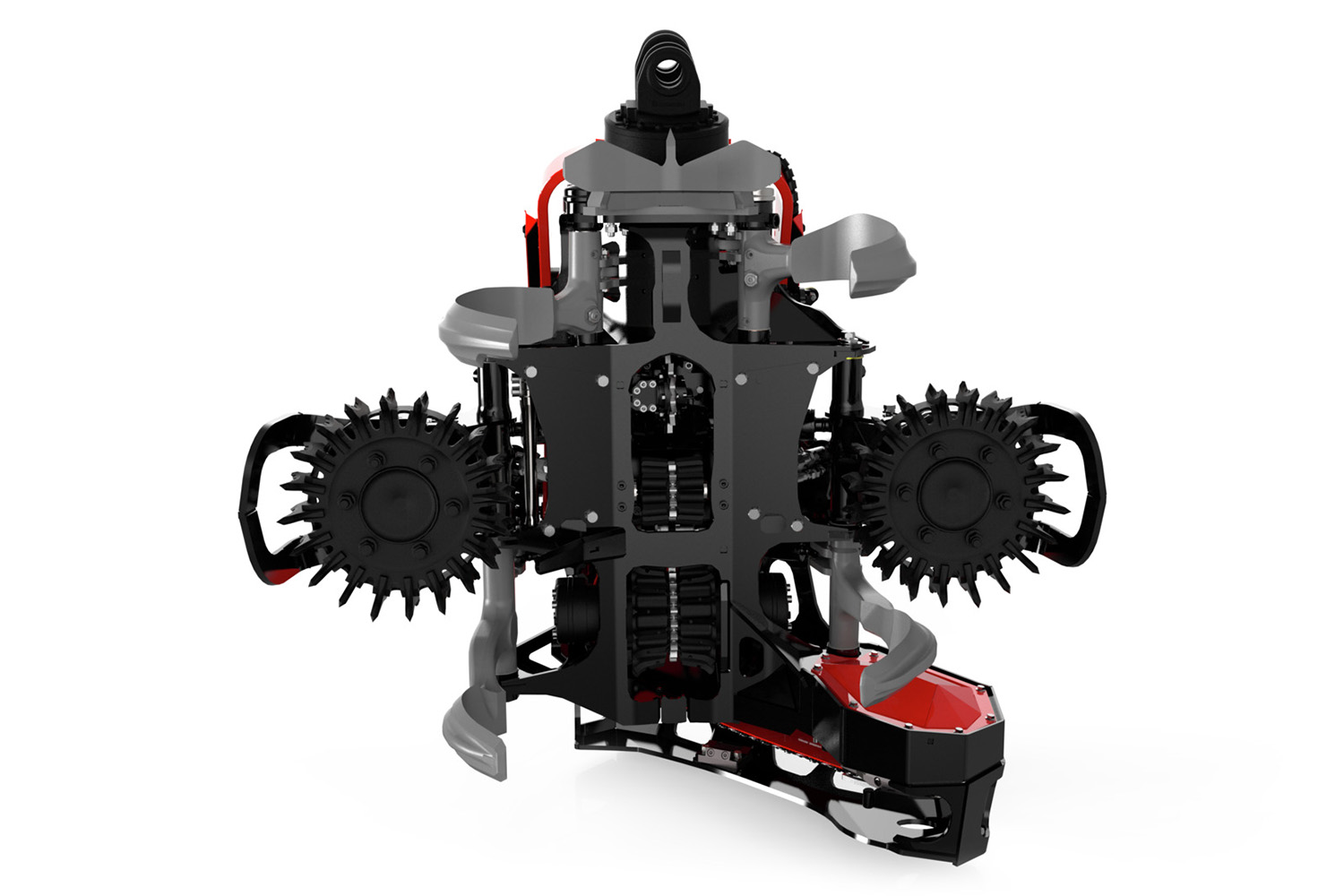

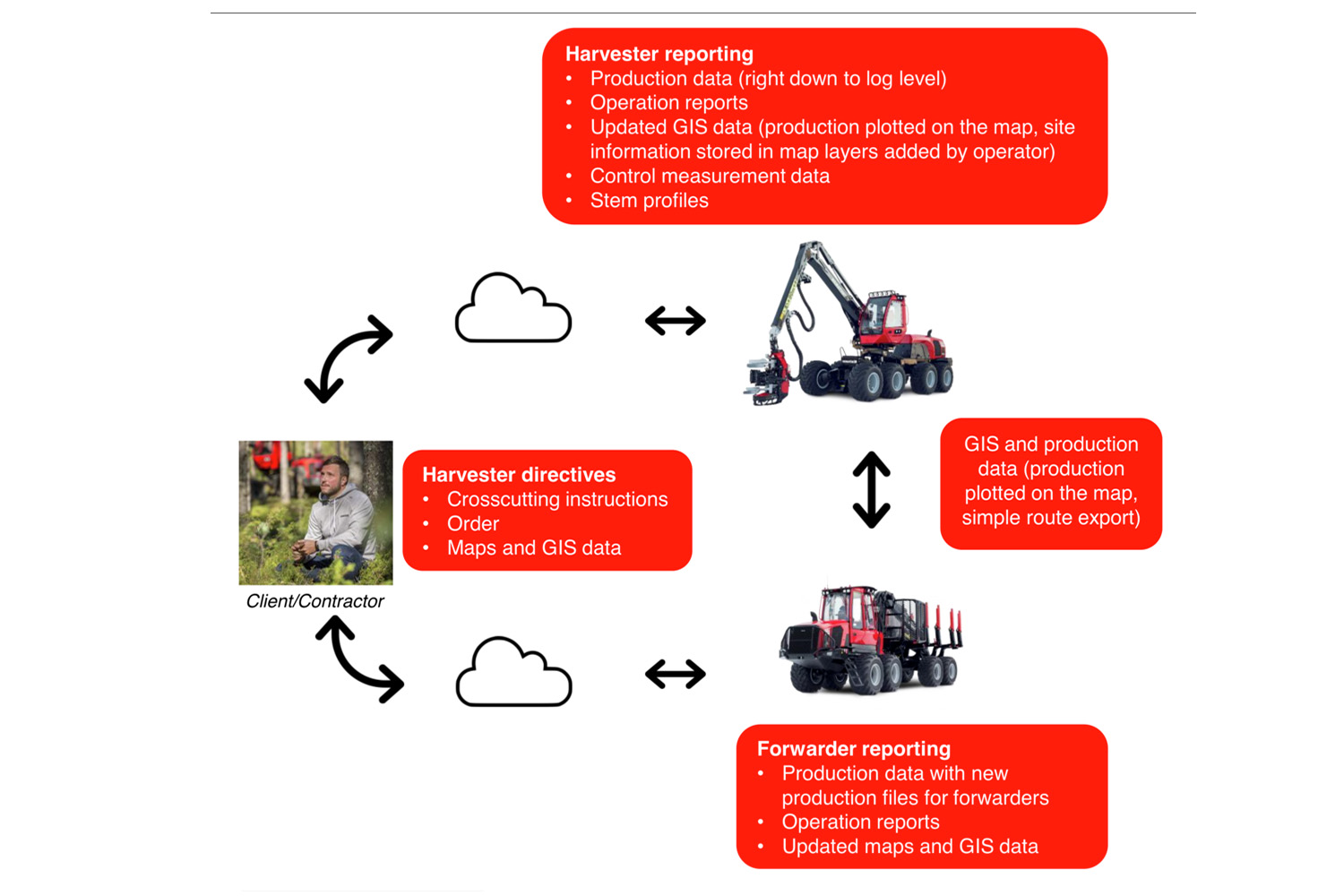

MaxiXT smart control system

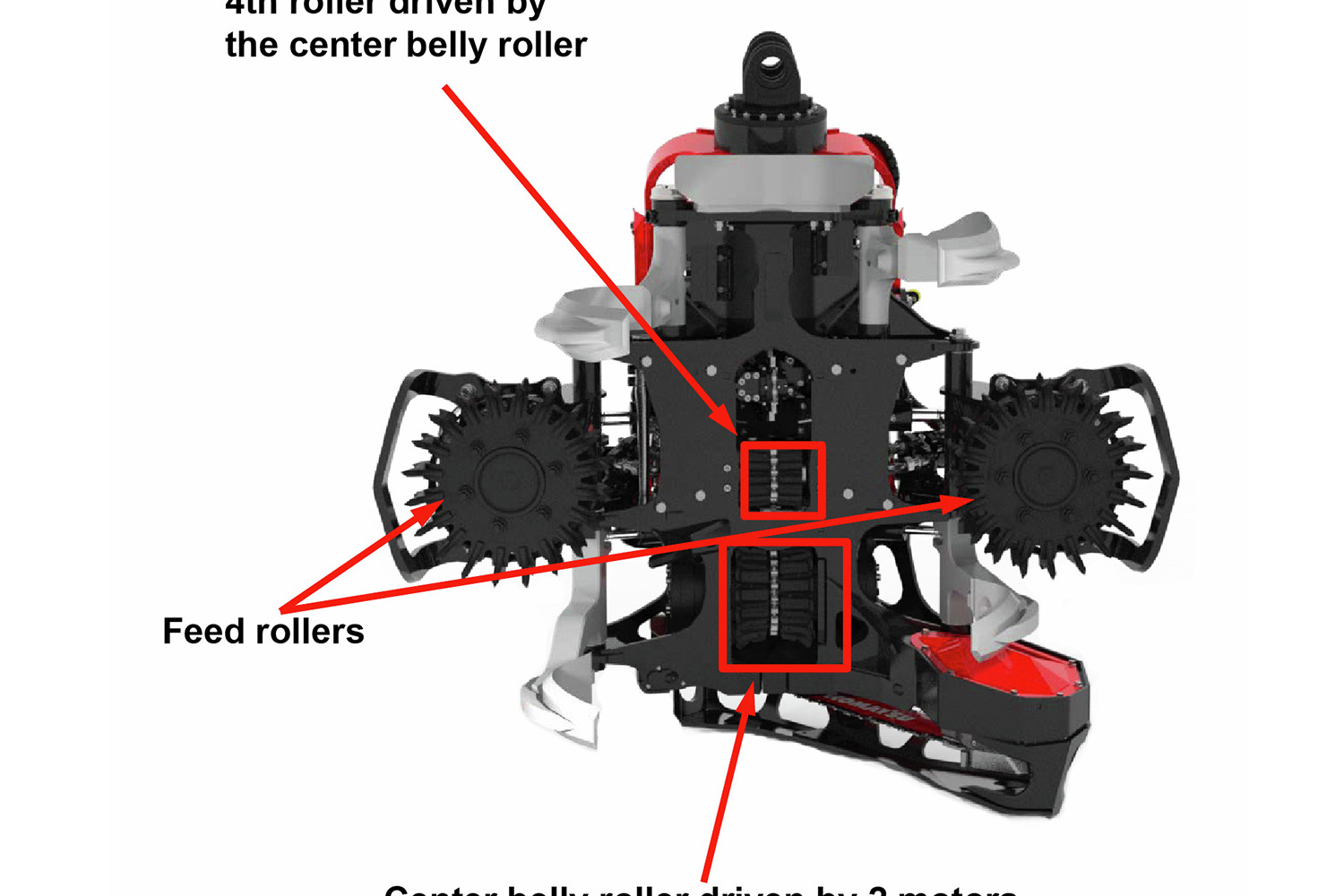

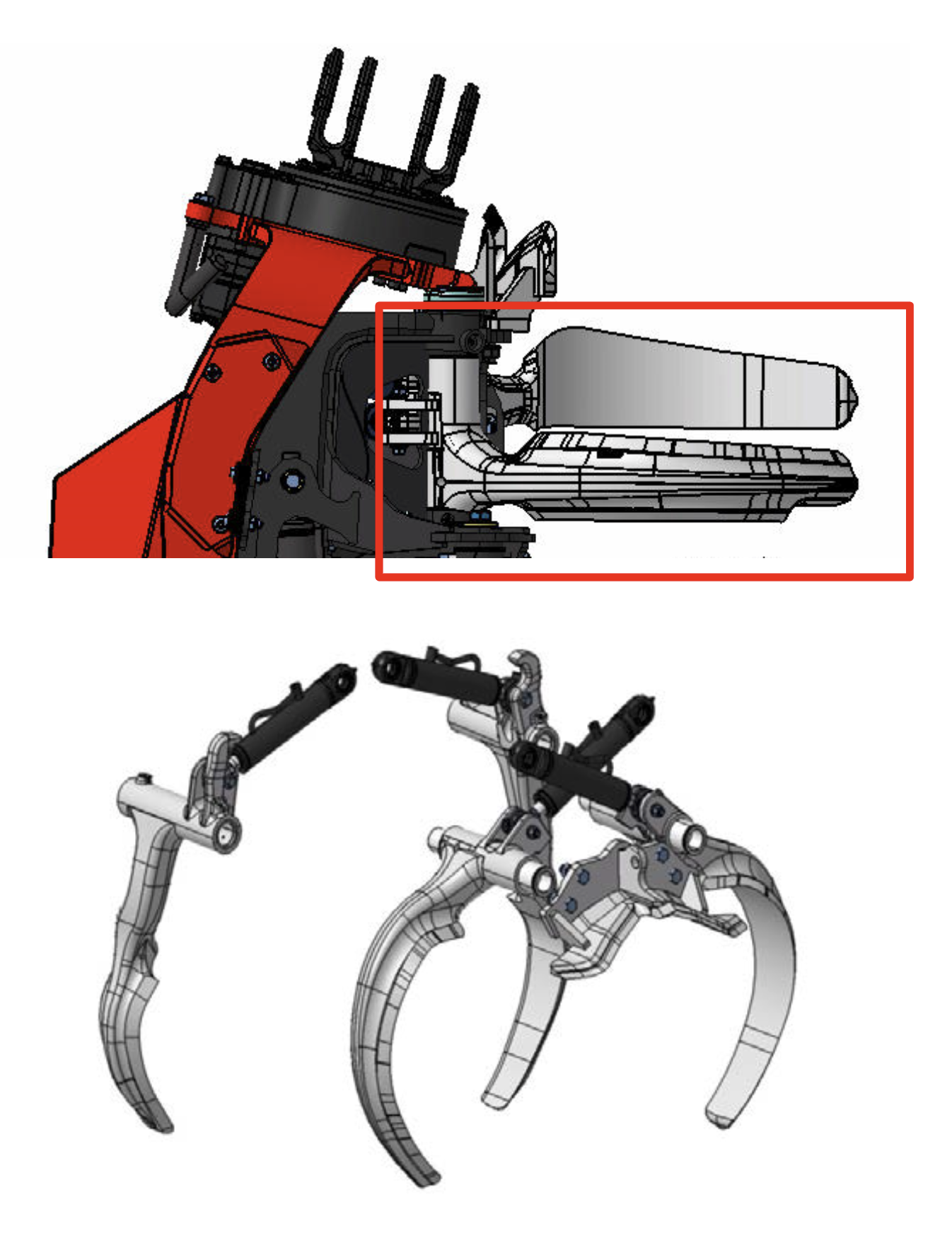

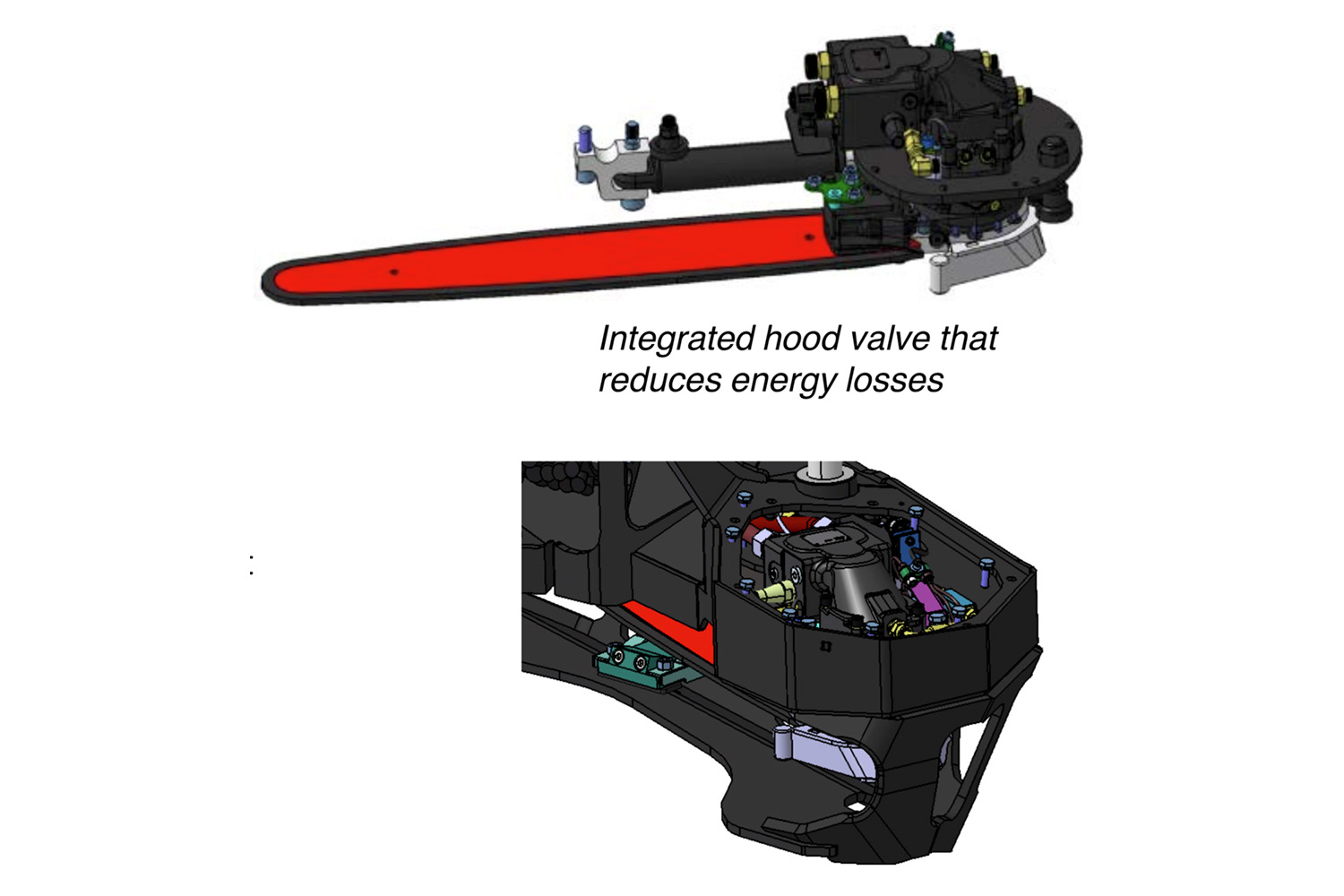

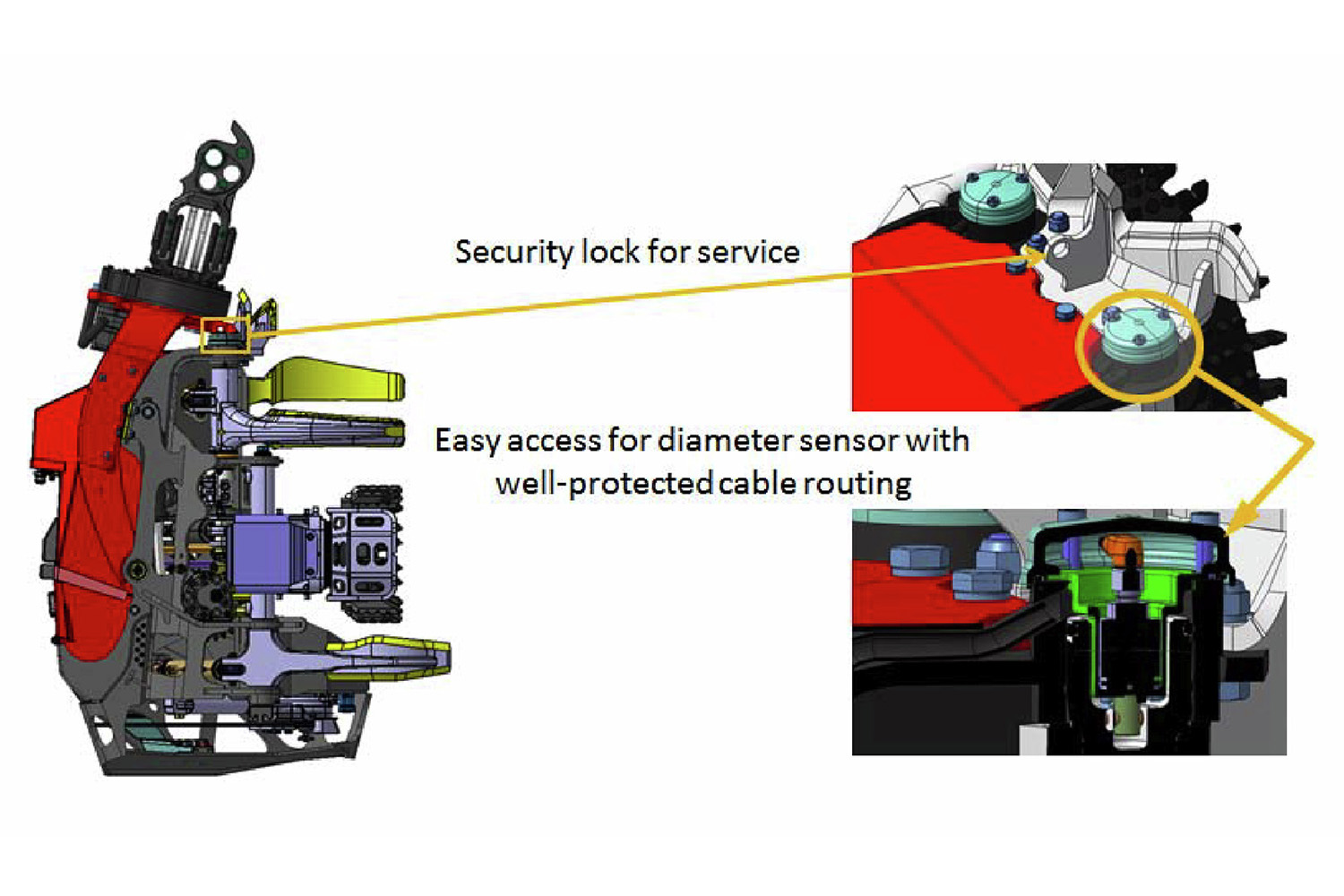

The MaxiXT smart control system is designed to enable fast, accurate execution of even the narrowest of cutting windows. The power of the knives, feed rollers and tilt down function are determined by stem diameter and tree species, and are easily adjusted using a graph. This helps optimize your productivity, measurement accuracy and time savings.