Excavators

PC290LC-11

Mid-size excavators

- Horsepower (HP) 196 HP @ 2,000 rpm

- Horsepower (kW) 147 kW @ 2 000 rpm

- Operating weight (kg) 32 070 - 32 700

- Operating weight (lbs) 70,702 - 72,091

- Bucket Capacity (m^3) 0.58 - 1.63

- Bucket Capacity (yd^3) 0.76 - 2.13

High production earthmoving from an excavator designed to be easily transportable.

The PC290LC-11 is a mid-size hydraulic excavator designed for long reach arm and boom combined with a heavy-duty undercarriage provide extended reach with a stable platform.

- Large high-strength steel castings on the boom, arm and bucket link

- Closed-center load-sensing hydraulics for precise, fine control

- Large displacement high-efficiency pumps provide optimal attachment flow

- Large, spacious, quiet cab featuring standard air suspension seat

Features and benefits

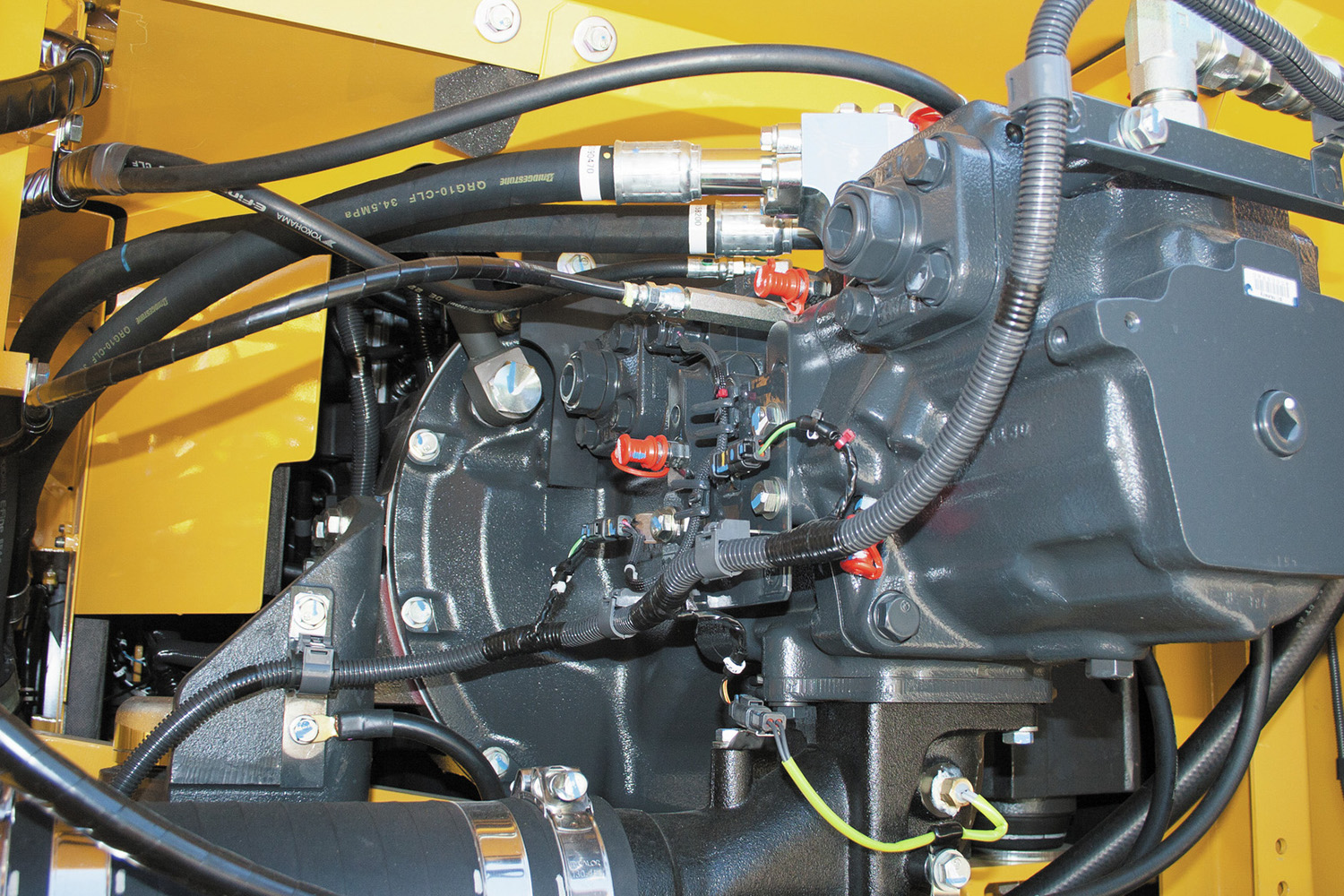

Large displacement high efficiency pump

Large displacement hydraulic implement pumps provide high flow output at lower engine RPM, operation at the most efficient engine speed.

Closed-center load-sensing hydraulic system

Smooth operation, quick cycle times, great multi-function, while lowering fuel consumption from closed-center load-sensing hydraulic system.

Built for strength

Equipment designed for long-term durability with high resistance to bending and torsional stress. Booms and arms are constructed with thick plates of high tensile strength streel and designed with large cross-sectional areas.

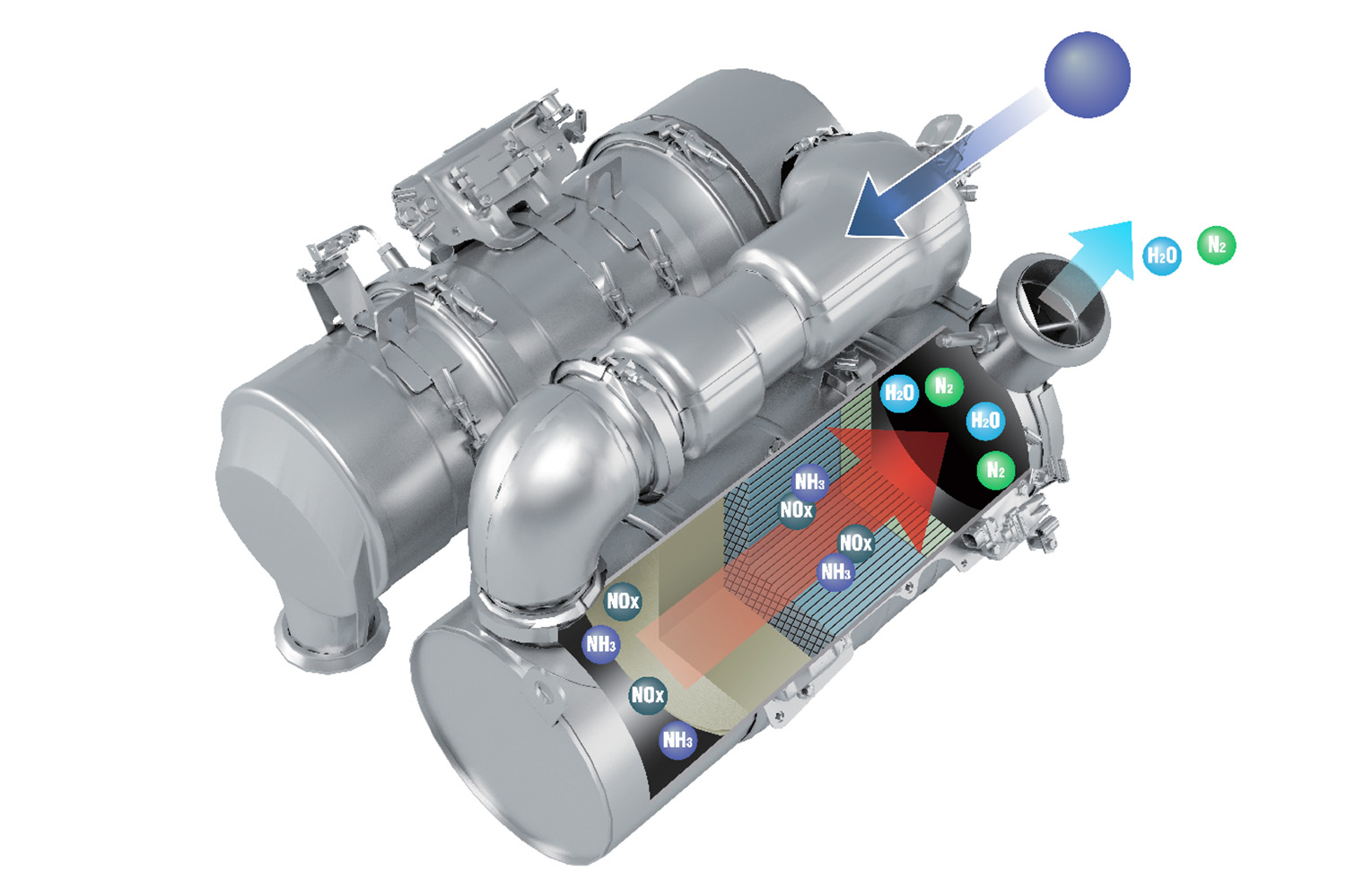

Cleaner emissions

A heavy-duty aftertreatment system that combines a Komatsu Diesel Particulate Filter (KDPF) and selective catalytic reduction (SCR). The system injects the correct amount of diesel exhaust fluid at the proper rate, decomposing nitrogen oxide.

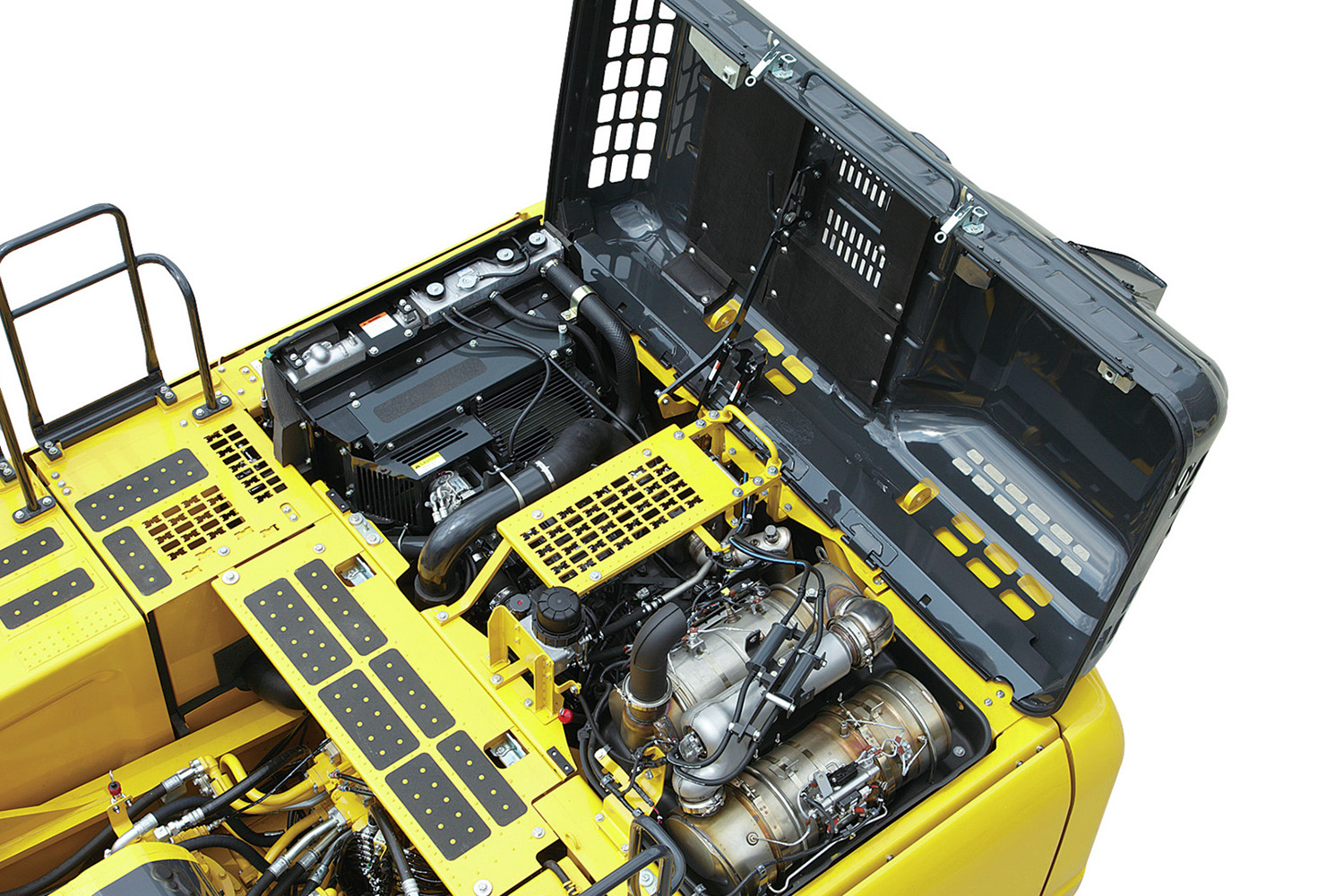

Easy access

Engine oil check and filter locations integrated into one side to allow easier maintenance access.

Advanced ergonomic design

Wide spacious cab includes a heated air suspension seat with reclining backrest. Seat height and position are easily adjusted using a pull-up lever. Armrest position easily adjusted with the console.

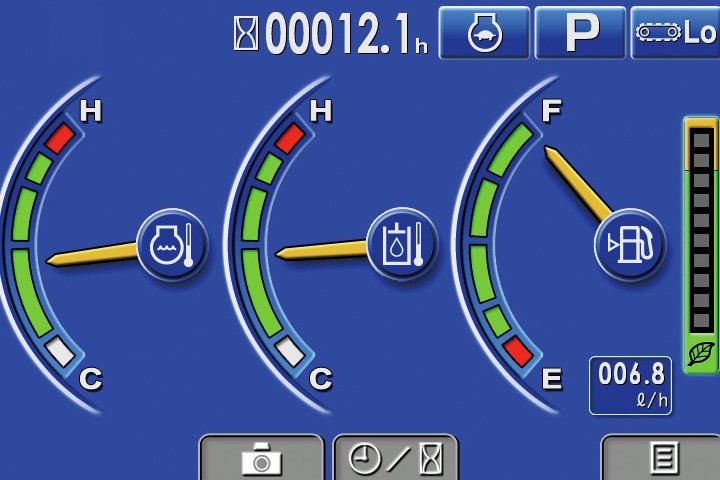

Information at your fingertips

Updated, large, high-resolution LCD color monitor to ease accurate and smooth work. Key machine information displayed in user-friendly interface, rearview camera and DEF level gauge display added to default main screen.

Rollover protection

A ROPS cab that conforms to ISO 12117-2 comes as standard equipment. It also satisfies requirements for level 1 operator protective guard (OPG) and top guard (ISO 10262).

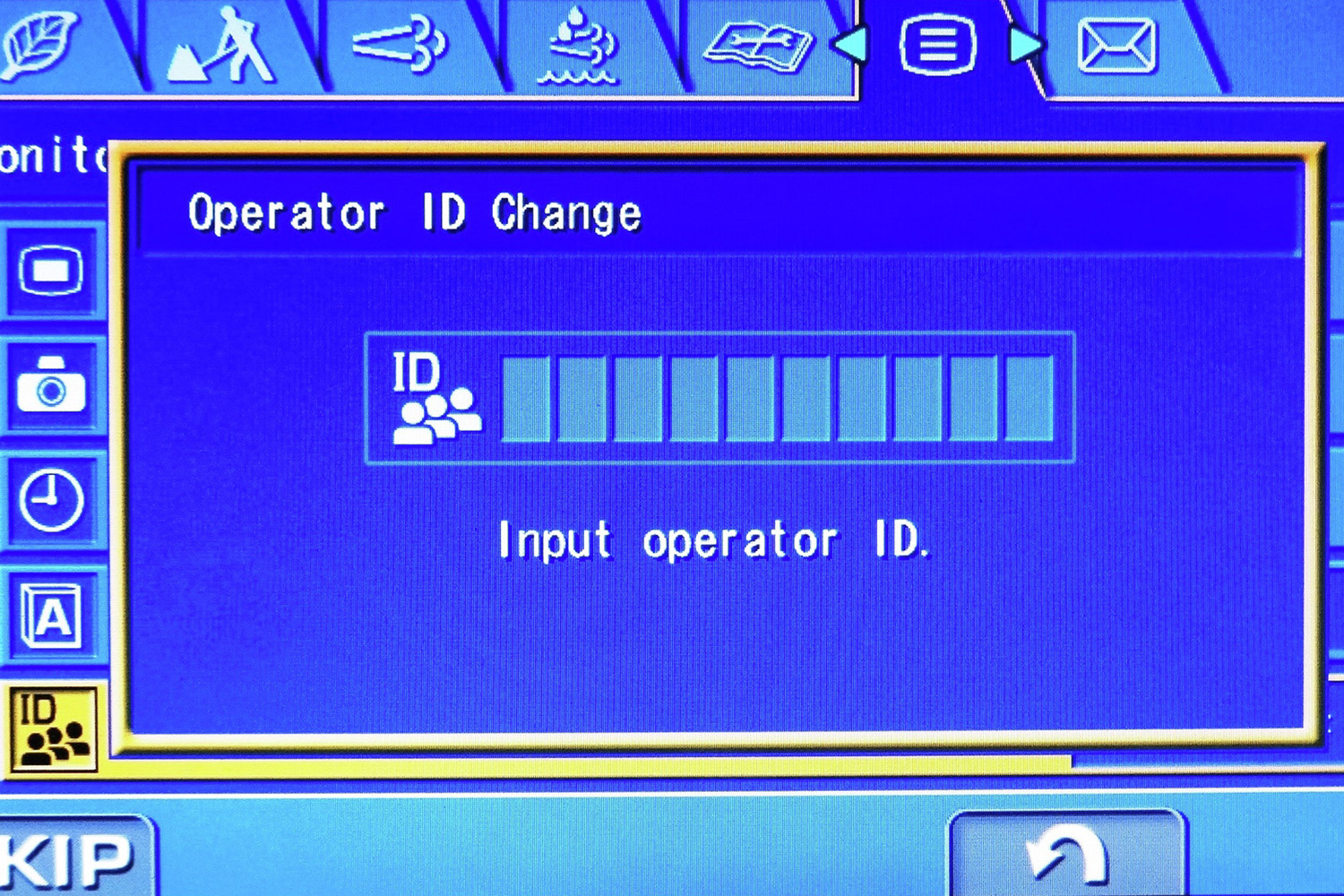

Multi-operator productivity

An operator identification ID can be set up for each operator and used to manage operation information of individual machines using Komtrax data. Data can analyze operation status by operator and by machine.

Reduce fuel consumption

Auto idle shutdown automatically shuts the engine down after idling for a set period to reduce unnecessary fuel consumption and exhaust emissions. Time before engine is shutdown can be programmed from 5 to 60 minutes.

Designed for durability

Large heavy-duty revolving frame guards and swivel guard help protect vital components from damage and debris build-up.

Ease of maintenance and serviceability

Provide a convenient and more secure work area in front of the engine. A new step provides easier access for filling the AdBlue/DEF tank.

Specifications

- Full specs

- Standard equipment

- Optional equipment

- Swing reduction: Planetary gear

- Holding brake/Swing lock: Mechanical disc brake

- Swing speed (rpm): 10.5

- Swing torque (kg-m): 8 889

- Swing torque (ft-lbs): 64,292

- HydrauMind Type: HydrauMind (Hydraulic Mechanical Intelligence New Design) system, closed-center system with load sensing valves and pressure compensated valves

- Number of selectable working modes: 6

-

Main pump

- Variable Type: Variable displacement piston type

- Maximum flow (L/min): 479

- Maximum flow (US gpm): 126.5

- Supply for control circuit: Self-reducing valve

- Main pumps for: Boom, arm, bucket, swing, and travel circuits

-

Relief valve setting

- Implement circuits (psi): 5,400

- Travel circuit (psi): 5,400

- Swing circuit (psi): 4,190

- Implement circuits (MPa): 37.3

- Pilot circuit (psi): 470

- Implement circuits (kgf/cm^2): 380

- Pilot circuit (kgf/cm^2): 33

- Pilot circuit (MPa): 3.2

- Swing circuit (kgf/cm^2): 295

- Swing circuit (MPa): 28.9

- Travel circuit (kgf/cm^2): 380

- Travel circuit (MPa): 37.3

-

Hydraulic cylinders

- Boom (Number of cylinders – bore x stroke x rod diameter)(mm): 140 x 1 300 x 100

- Boom (Number of cylinders – bore x stroke x rod diameter)(in): 5.5 x 51.2 x 3.9

- Arm (Number of cylinders – bore x stroke x rod diameter)(mm): 150 x 1 635 x 110

- Arm (Number of cylinders – bore x stroke x rod diameter)(in): 5.9 x 64.3 x 4.3

- Bucket (Number of cylinders – bore x stroke x rod diameter)(in): 5.5 x 39.7 x 3.9

- Bucket (Number of cylinders – bore x stroke x rod diameter)(mm): 140 x 1 009 x 100

-

Hydraulic motors

- Travel: 2 x axial piston motor with parking brake

- Swing: 1 x axial piston motor with swing holding brake

- Operating weight features (mm): Operating weight, including 6 150 mm one-piece boom, 3 200 mm arm, SAE heaped 1.41 m³ backhoe bucket*, rated capacity of lubricants, coolant, full fuel tank, operator, and standard equipment.

- Operating weight features (ft): Operating weight, including 20 ft. 2 in one-piece boom, 10 ft. 6 in arm, SAE heaped 1.85 yd³ backhoe bucket*, rated capacity of lubricants, coolant, full fuel tank, operator, and standard equipment.

-

Component Weights

- Component weight of 1.42 m^3 bucket - 48 in width (kg): 1 088

- Component weight of 1.85 yd^3 bucket - 48 in width (lbs): 2,399

- Component weight of 3 046 mm HD arm assembly (kg): 3 316

- Component weight of 10 ft 6 in arm assembly (lbs): 3,157

- Component weight of 3 200 mm arm assembly (kg): 1 432

- Component weight of 11 ft 6 in arm assembly (lbs): 1,504

- Component weight of 6 150 mm HD boom assembly (kg): 2 448

- Component weight of 20 ft 2 in HD boom assembly (lbs): 5,397

- Component weight of boom cylinders x 2 (kg): 231

- Component weight of boom cylinders x 2 (lbs): 509

- Counterweight (lbs): 12,148

- Counterweight (kg): 5 510

-

Triple grouser shoes

- Ground pressure with triple-grouser shoes 700 mm (kg/cm^2): 0.54

- Ground pressure with triple-grouser shoes 28 in (psi): 7.71

- Ground pressure with triple-grouser shoes 31.5 in (psi): 6.83

- Ground pressure with triple-grouser shoes 33.5 in (psi): 6.47

- Ground pressure with triple-grouser shoes 800 mm (kg/cm^2): 0.45

- Ground pressure with triple-grouser shoes 850 mm (kg/cm^2): 0.45

- Operating weight with triple-grouser shoes 28 in (lbs): 67,395

- Operating weight with triple-grouser shoes 31.5 in (lbs): 68,233

- Operating weight with triple-grouser shoes 33.5 in (lbs): 68,654

- Operating weight with triple-grouser shoes 700 mm (kg): 30 570

- Operating weight with triple-grouser shoes 800 mm (kg): 30 950

- Operating weight with triple-grouser shoes 850 mm (kg): 31 141

- Engine Model: Komatsu SAA6D107E-3*

- Cooling Type: Water-cooled, 4-cycle, direct injection

- Aspiration: Komatsu variable geometry turbocharged, aftercooled, cooled EGR

- Number of cylinders: 6

- Bore (mm): 107

- Bore (in): 4.21

- Stroke (mm): 125

- Stroke (in): 4.88

- Piston displacement (in^3): 408

- Piston displacement (L): 6.69

- Engine Rated (rpm): 2,050

- Governor: All-speed control, electronic.

- Fan drive method for radiator cooling: Mechanical

-

Horsepower

- SAEJ1995 - Gross (HP): 213

- SAEJ1995 - Gross (kW): 159

- ISO 9249 / SAE J1349 - Net (HP): 196

- ISO 9249 / SAE J1349 - Net (kW): 147

- Fuel tank (US gal): 105.7

- Coolant (US gal): 9.5

- Engine (US gal): 6.1

- Final drive (US gal): 2.1

- Swing drive (US gal): 1.9

- Swing drive (L): 7.2

- Hydraulic tank (L): 132

- Hydraulic tank (US gal): 34.9

- DEF tank (US gal): 6.1

- Hydraulic system (L): 253

- Hydraulic system (US gal): 66.8

- Fuel tank (L): 400

- Coolant (L): 36

- Engine (L): 23.1

- Final drive (L): 8

- DEF tank (L): 23.1

- Drive method type: Hydrostatic

- Maximum drawbar pull (kg): 25 400

- Maximum drawbar pull (lbs): 56,000

- Service brake type: Hydraulic lock

- Parking brake: Mechanical disc brake

- Gradeability: 70%, 35°

-

Maximum travel speed

- High (kph): 5.5

- High (mph): 3.4

- Mid (mph): 2.5

- Mid (kph): 4.1

- Low (mph): 1.9

- Low (kph): 3

- Center frame: X-frame

- Track frame: Box-section

- Track adjuster: Hydraulic

- Number of shoes (each side): 48

- Number of carrier rollers (each side): 2

- Number of track rollers (each side): 8

- Seal of track: Sealed

- Exterior – ISO 6395 (dB(A)): 104

- Operator – ISO 6396 (dB(A)): 70

- ROPS Cab (ISO12117-2)

- High back air suspension seat, with heat

- Operator Protective Guard (OPG) Level 1 top guard

- Large LCD high resolution color monitor

- Automatic climate control

- Retractable seat belt (76 mm width) with indicator

- Two 12V accessory outlets

- Rearview mirrors, right hand and left hand side

- Rearview monitoring system (1 camera)

- Travel alarm

- Operator identification system

- Hydraulic lock lever

- Skylight

- Komatsu SAA6D107E-3 Tier 4 Final

- Dry type air cleaner, double element

- Fuel pre-filter with water separator

- Fuel high efficiency filter

- Automatic Engine warm up system

- Programmable auto-idle shut down

- Overheat prevention system

- Turbocharger protection system

- Pattern change control valve (ISO to BH control)

- Working mode selection system (6 Modes)

- Dual pump, Closed Center Load Sensing System (CLSS)

- Auto-deceleration system

- Power max system

- Boom and arm holding valves

- Arm quick return valve

- Komtrax level 5.0

- Batteries, large capacity (2 x 12Volt)

- Battery master disconnect switch with lockout tagout

- Alternator (90Amp, 24Volt)

- Starter motor (5.5 kW)

- Secondary Engine shut off switch

- Working lights (1 front RH side / 1 boom LH side)

- 6150 mm (20'2") boom assembly

- 3200 mm (10'6") arm assembly

- Boom foot, boom nose, & arm end steel castings

- 800 mm (31.5") triple grouser track shoes

- 8 track / 2 carrier rollers (each side)

- Hydraulic track adjusters (each side)

- Track guiding guards, center section (each side)

- Counterweight, 5200 kg (11,464 lbs.)

- Object handling H-link

- Tie off points (ISO 14567) - Work eq. and upper structure

- Revolving frame deck guards

- Revolving frame undercovers - standard

- Track frame swivel guard

- Pump / Engine room partition

- Turbocharger exhaust manifold cover

- Dust net for radiator and hydraulic oil cooler

- Slip resistant foot plates

- Tool free access to Engine and aftertreatment

- Left and right side hand rails

- Three speed travel with auto shift

- Double reduction type final drive

- Triple labyrinth final drive seals

- ROPS Cab (ISO12117-2)

- High back air suspension seat, with heat

- Operator Protective Guard (OPG) Level 1 top guard

- Large LCD high resolution color monitor

- Automatic climate control

- Retractable seat belt (76 mm width) with indicator

- Two 12V accessory outlets

- Rearview mirrors, right hand and left hand side

- Rearview monitoring system (1 camera)

- Travel alarm

- Operator identification system

- Hydraulic lock lever

- Skylight

- Komatsu SAA6D107E-3 Tier 4 Final

- Dry type air cleaner, double element

- Fuel pre-filter with water separator

- Fuel high efficiency filter

- Automatic Engine warm up system

- Programmable auto-idle shut down

- Overheat prevention system

- Turbocharger protection system

- Pattern change control valve (ISO to BH control)

- Working mode selection system (6 Modes)

- Dual pump, Closed Center Load Sensing System (CLSS)

- Auto-deceleration system

- Power max system

- Boom and arm holding valves

- Arm quick return valve

- Komtrax level 5.0

- Batteries, large capacity (2 x 12Volt)

- Battery master disconnect switch with lockout tagout

- Alternator (90Amp, 24Volt)

- Starter motor (5.5 kW)

- Secondary Engine shut off switch

- Working lights (1 front RH side / 1 boom LH side)

- 6150 mm (20'2") boom assembly

- 3200 mm (10'6") arm assembly

- Boom foot, boom nose, & arm end steel castings

- 800 mm (31.5") triple grouser track shoes

- 8 track / 2 carrier rollers (each side)

- Hydraulic track adjusters (each side)

- Track guiding guards, center section (each side)

- Counterweight, 5200 kg (11,464 lbs.)

- Object handling H-link

- Tie off points (ISO 14567) - Work eq. and upper structure

- Revolving frame deck guards

- Revolving frame undercovers - standard

- Track frame swivel guard

- Pump / Engine room partition

- Turbocharger exhaust manifold cover

- Dust net for radiator and hydraulic oil cooler

- Slip resistant foot plates

- Tool free access to Engine and aftertreatment

- Left and right side hand rails

- Three speed travel with auto shift

- Double reduction type final drive

- Triple labyrinth final drive seals

Cab

- Proportional joystick control levers

- Sunvisor

- Rainvisor

- Working lights, two additional Cab mounted

- Straight travel pedal

Hydraulic controls

- One way/two way flow hyd control unit Variable flow, return filter, & accumulator

Booms and arms

- 6150 mm (20'2") boom assembly with +1 attach piping

- 3200 mm (10'6") arm assembly with +1 attach piping

- 3500 mm (11'6") arm assembly

- 3500 mm (11'6") arm assembly with +1 attach piping

Undercarriage and work equipment

- 850 mm (33.5") triple grouser track shoes

- 700 mm (28") triple grouser track shoes

- Track roller guards, full length (each side)

- Counterweight, 5500 kg (12,125 lbs.)**

Guards and covers

- Cab full front guard, OPG Level 1

- Cab full front guard, OPG Level 2

- Cab top guard, OPG Level 2

- Revolving frame undercovers - heavy duty

*IMU for auto-tilt control and one way/two way flow hyd control unit required for operation **With revolving frame reinforcements, Only available with super long fronts For a complete list of available attachments, please contact your local Komatsu distributor.

Cab

- Proportional joystick control levers

- Sunvisor

- Rainvisor

- Working lights, two additional Cab mounted

- Straight travel pedal

Hydraulic controls

- One way/two way flow hyd control unit Variable flow, return filter, & accumulator

Booms and arms

- 6150 mm (20'2") boom assembly with +1 attach piping

- 3200 mm (10'6") arm assembly with +1 attach piping

- 3500 mm (11'6") arm assembly

- 3500 mm (11'6") arm assembly with +1 attach piping

Undercarriage and work equipment

- 850 mm (33.5") triple grouser track shoes

- 700 mm (28") triple grouser track shoes

- Track roller guards, full length (each side)

- Counterweight, 5500 kg (12,125 lbs.)**

Guards and covers

- Cab full front guard, OPG Level 1

- Cab full front guard, OPG Level 2

- Cab top guard, OPG Level 2

- Revolving frame undercovers - heavy duty

*IMU for auto-tilt control and one way/two way flow hyd control unit required for operation **With revolving frame reinforcements, Only available with super long fronts For a complete list of available attachments, please contact your local Komatsu distributor.

Support you can count on

Find what works for you