Excavators

PC650LC-11

Large excavators

- Horsepower (HP) 436 HP @ 1,800 rpm

- Horsepower (kW) 325 kW @ 1 800 rpm

- Operating weight (kg) 63 710 - 65 900

- Operating weight (lbs) 140,456 - 145,284

- Bucket Capacity (m^3) 1.57 - 3.81

- Bucket Capacity (yd^3) 2.05 - 4.98

Versatility and high performance for heavy-duty applications

For high performance, transportability and adaptability to your heavy-duty applications, the PC650LC-11 excavator has a dual swing motor and three arm lengths. Your operator will appreciate the comfortable, climate-controlled cab and your crew will welcome an engine designed for easy access and maintenance.

- Versatile

- High performance

- Built for longevity

- Transportability

Features and benefits

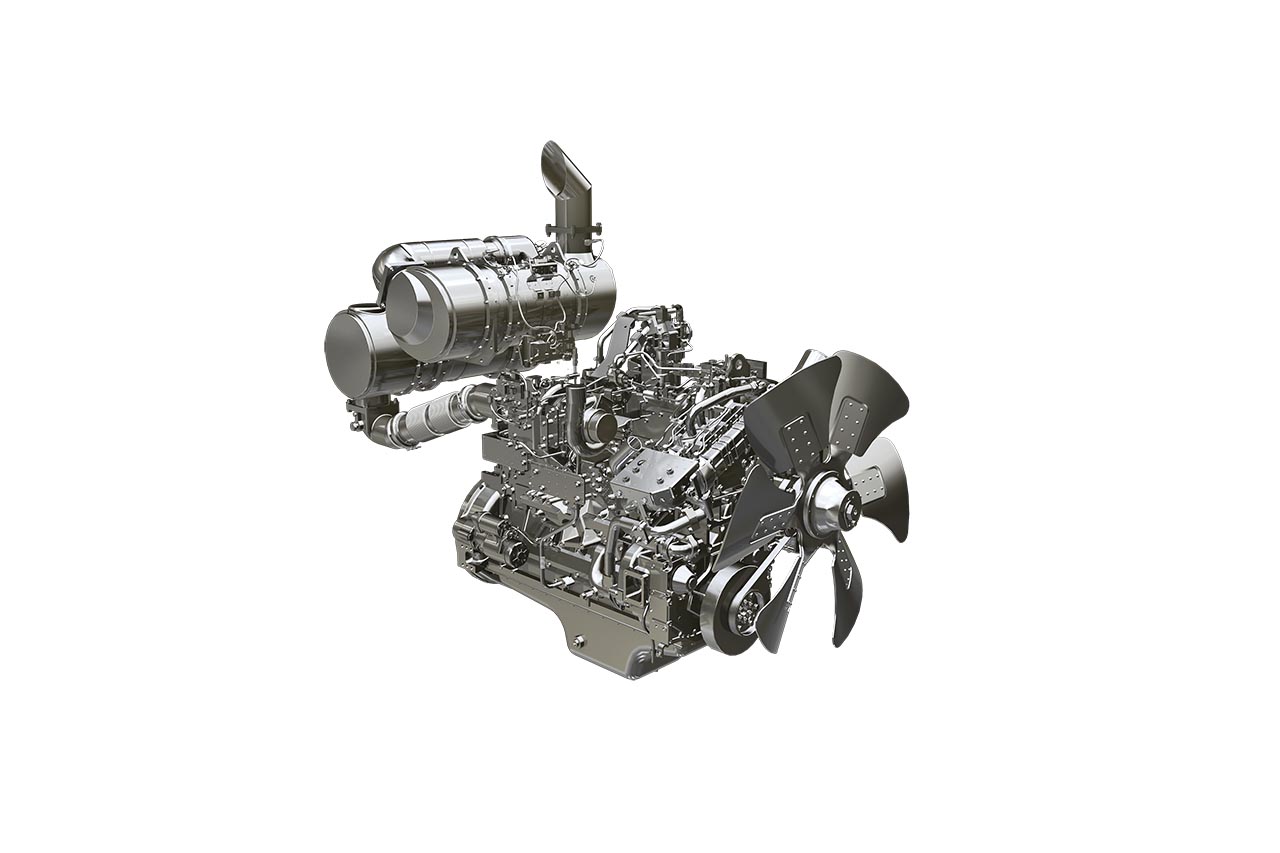

Increased horsepower

You will appreciate the low operating noise, easy serviceability of emissions components and increased horsepower (+7 hp) of the high-performance engine that is EPA Tier 4 Final emissions certified.

Engineered for long life

Your excavator is designed to be part of your fleet for a long time with its sturdy undercarriage, robust under guards and the use of thick, high-tensile-strength steel plates throughout the boom and arm structures.

Quick cycle times

For your heavy-duty projects, the dual swing motors and arm quick return circuit provide fast cycle times under heavy loads.

Easy to move

You will enjoy how easy it is to transport the PC650LC-11 between job sites and the less disassembly required to meet transportation weight requirements. Plus, you don’t need to rent a crane to remove the counterweight during movement, which can help lower your transportation costs.

Simplified maintenance

Ease of serviceability with latched service access doors and grouped service points. Designed to save time and money on repairs, Tier 4 Final emission system diagnostics monitor up to 167 vehicle parameters and notifies you when and where maintenance is required.

Cost-saving hydraulic efficiency

You will appreciate this machine’s increased hydraulic efficiency and reduced fuel consumption with its larger bucket return piping size that reduces hydraulic back pressure in the bucket circuit in order to match the machine load to hydraulic pump output.

Operator comfort

Your operator will enjoy the quiet cab with less vibration, auto climate control, adjustable arm rests, and a rearview camera monitoring system combined with mounted work lights and skylight that helps improve visibility upward and in low light working conditions.

Advanced telematics technology

Keep track of your machines and their productivity with free, state-of-the-art remote monitoring services.

Service and support

Protect your investment with complimentary factory-scheduled Komatsu Care maintenance for the first three years or 2,000 hours, whichever occurs first.

Specifications

- Full specs

- Standard equipment

- Optional equipment

- Drive method: 2 x hydraulic motors

- Swing reduction: Planetary gear

- Service brake: Oil disc brake

- Holding brake/Swing lock: Mechanical disc brake

- Swing speed (rpm): 8.3

- Swing torque (kg-m): 21 369

- Swing torque (ft-lbs): 154,481

- HydrauMind Type: Open-center load sensing system, 3 selectable working modes

-

Hydraulic cylinders

- Boom (Number of cylinders – bore x stroke x rod diameter)(in): 7.3 x 67.9 x 4.7

- Boom (Number of cylinders – bore x stroke x rod diameter)(mm): 185 x 1 725 x 120

- Arm (Number of cylinders – bore x stroke x rod diameter)(in): 7.9 x 80.5 x 5.5

- Arm (Number of cylinders – bore x stroke x rod diameter)(mm): 200 x 2 045 x 140

- Bucket (Number of cylinders – bore x stroke x rod diameter)(in): 7.3 x 56.1 x 5.1

- Bucket (Number of cylinders – bore x stroke x rod diameter)(mm): 185 x 1 425 x 130

-

Main pump

- Variable Type: Variable capacity piston

- Maximum flow (US gpm): 2 x 108

- Maximum flow (L/min): 2 x 410

- Gear Type: Variable capacity piston

- Main pumps for: Boom, arm, bucket, swing, and travel circuits

- Sub-pump for control circuit: Gear type

-

Relief valve setting

- Implement circuits (psi): 4,700

- Travel circuit (psi): 4,980

- Implement circuits (MPa): 32.4

- Swing circuit (psi): 3,700

- Pilot circuit (psi): 430

- Implement circuits (kgf/cm^2): 330

- Pilot circuit (kgf/cm^2): 30

- Pilot circuit (MPa): 2.9

- Swing circuit (kgf/cm^2): 260

- Swing circuit (MPa): 25.5

- Travel circuit (kgf/cm^2): 350

- Travel circuit (MPa): 34.3

-

Hydraulic motors

- Travel: 2 x axial piston motors with parking brake

- Swing: 2 x axial piston motors with swing holding brake

- Fuel tank (US gal): 232.5

- Coolant (US gal): 20.1

- Engine (US gal): 12.7

- Final drive (US gal): 2.65

- Swing drive (L): 2 x 13

- Swing drive (US gal): 2 x 3.4

- Hydraulic tank (L): 360

- Hydraulic tank (US gal): 95

- DEF tank (US gal): 16.4

- Engine (L): 48

- DEF tank (L): 62.2

- Fuel tank (L): 880

- Final drive (L): 10

- Coolant (L): 76

- Operating weight features (mm): Operating weight includes 7 660 mm one-piece boom, 3 500 mm arm, ISO 7451 heaped 2.70 m3 bucket, rated capacity of lubricants, coolant, full fuel tank, operator, and standard equipment.

- Operating weight features (ft): Operating weight includes 25 ft. 2 in one-piece boom, 11 ft. 6 in arm, ISO 7451 heaped 3.53 yd3 bucket, rated capacity of lubricants, coolant, full fuel tank, operator, and standard equipment.

-

Triple grouser shoes

- Ground pressure with triple-grouser shoes 24 in (psi): 15.16

- Ground pressure with triple-grouser shoes 600 mm (kg/cm^2): 1.07

- Ground pressure with triple-grouser shoes 30 in (psi): 12.3

- Ground pressure with triple-grouser shoes 750 mm (kg/cm^2): 0.86

- Ground pressure with triple-grouser shoes 35.5 in (psi): 10.3

- Ground pressure with triple-grouser shoes 900 mm (kg/cm^2): 0.73

- Operating weight with triple-grouser shoes 24 in (lbs): 140,456

- Operating weight with triple-grouser shoes 30 in (lbs): 142,396

- Operating weight with triple-grouser shoes 35.5 in (lbs): 144,292

- Operating weight with triple-grouser shoes 600 mm (kg): 63 710

- Operating weight with triple-grouser shoes 750 mm (kg): 64 590

- Operating weight with triple-grouser shoes 900 mm (kg): 65 480

- Engine Model: Komatsu SAA6D140E-7*

- Cooling Type: Water-cooled, 4-cycle, direct injection

- Aspiration: Turbocharged, aftercooled, cooled, EGR

- Number of cylinders: 6

- Bore (mm): 140

- Bore (in): 5.51

- Stroke (in): 6.50

- Stroke (mm): 165

- Piston displacement (L): 15.24

- Piston displacement (in^3): 930

- Engine Rated (rpm): 1,800

- Governor: All-speed control, electronic

- Fan drive method for radiator cooling: Hydraulic

-

Horsepower

- SAEJ1995 - Gross (kW): 327

- SAEJ1995 - Gross (HP): 439

- ISO 9249 / SAE J1349 - Net (kW): 325

- ISO 9249 / SAE J1349 - Net (HP): 436

- Fan at maximum speed - Net (HP): 392

- Fan at maximum speed - Net (kW): 293

- Drive method type: Fully hydrostatic

- Maximum drawbar pull (kgf): 42 300

- Maximum drawbar pull (lbs): 93,250

- Service brake type: Hydraulic lock

- Parking brake: Oil disc brake

- Gradeability: 70%, 35°

-

Maximum travel speed

- High (mph): 3

- High (kph): 4.9

- Low (mph): 1.9

- Low (kph): 3

- Center frame: H-leg

- Track frame: Box-section

- Track adjuster: Hydraulic

- Number of shoes (each side): 52

- Number of carrier rollers (each side): 3

- Number of track rollers (each side): 9

- Seal of track: Sealed

- Exterior – ISO 6395 (dB(A)): 104

- Operator – ISO 6396 (dB(A)): 73

- Alternator & A/C compressor auto-tensioner

- Automatic Engine warm-up system

- Dry type air cleaner, double element

- Engine, Komatsu SAA6D140E-7

- Fuel pre-filter with water separator

- Variable speed cooling fan, hydraulic drive, reversible

- Alternator, 24 V/90 A

- Auto-decelerator

- Batteries, 2 x 12 V/170 Ah

- Battery disconnect switch

- Circuit breaker

- Horn, electric

- Horn interconnected with warning light

- Power supply, 12 V

- Starting motor, 24 V/11 kW

- Step light with timer

- Working light, 2 (Boom and RH)

- Working lights, 2 on Cab

- 3-mode system (Power, Economy, Lifting)

- Arm holding valve

- Boom holding valve

- Fully hydraulic, with Open-Center Load-Sensing and Engine speed sensing (Pump and Engine control system)

- In-line high pressure filters

- Power maximizing system

- Pressure Proportional Control (PPC) hydraulic control system

- Shockless control system for boom

- Two-mode setting for boom

- Fan guard structure

- Strengthened revolving frame underguard

- Track frame undercover (Center)

- Hydraulic track adjusters (Each side)

- Track roller, 9 (Each side)

- Track shoe, 35.5" triple grouser

- Variable track gauge

- A/C with defroster

- AM/FM radio

- Auxiliary input (3.5 mm jack)

- Cab with pull-up type front window

- Engine shut down secondary switch

- High-back suspension seat, heated

- Large high resolution LCD monitor

- Lock lever

- Mirrors (RH, LH)

- Operator protective top guard (OPG), level 1 (ISO 12117-2)

- Rear view monitor system

- Seat belt, retractable, 78 mm

- Washable Cab floor mat

- Counterweight, 26,358 lbs

- Electric priming pump for fuel

- Equipment Management Monitoring System

- Grease gun, electric pump type

- Hand rails & guard rails

- KOMTRAX

- One-touch Engine oil drainage

- Preventive Maintenance (PM) tune-up service connector

- Rear reflector

- Slip-resistant plates

- Travel alarm

- Wide walkway

- Alternator & A/C compressor auto-tensioner

- Automatic Engine warm-up system

- Dry type air cleaner, double element

- Engine, Komatsu SAA6D140E-7

- Fuel pre-filter with water separator

- Variable speed cooling fan, hydraulic drive, reversible

- Alternator, 24 V/90 A

- Auto-decelerator

- Batteries, 2 x 12 V/170 Ah

- Battery disconnect switch

- Circuit breaker

- Horn, electric

- Horn interconnected with warning light

- Power supply, 12 V

- Starting motor, 24 V/11 kW

- Step light with timer

- Working light, 2 (Boom and RH)

- Working lights, 2 on Cab

- 3-mode system (Power, Economy, Lifting)

- Arm holding valve

- Boom holding valve

- Fully hydraulic, with Open-Center Load-Sensing and Engine speed sensing (Pump and Engine control system)

- In-line high pressure filters

- Power maximizing system

- Pressure Proportional Control (PPC) hydraulic control system

- Shockless control system for boom

- Two-mode setting for boom

- Fan guard structure

- Strengthened revolving frame underguard

- Track frame undercover (Center)

- Hydraulic track adjusters (Each side)

- Track roller, 9 (Each side)

- Track shoe, 900 mm triple grouser

- Variable track gauge

- A/C with defroster

- AM/FM radio

- Auxiliary input (3.5 mm jack)

- Cab with pull-up type front window

- Engine shut down secondary switch

- High-back suspension seat, heated

- Large high resolution LCD monitor

- Lock lever

- Mirrors (RH, LH)

- Operator protective top guard (OPG), level 1 (ISO 12117-2)

- Rear view monitor system

- Seat belt, retractable, 78 mm

- Washable Cab floor mat

- Counterweight, 11955 kg

- Electric priming pump for fuel

- Equipment Management Monitoring System

- Grease gun, electric pump type

- Hand rails & guard rails

- KOMTRAX

- One-touch Engine oil drainage

- Preventive Maintenance (PM) tune-up service connector

- Rear reflector

- Slip-resistant plates

- Travel alarm

- Wide walkway

Guards and covers

- Cab guards

- Bolt-on top guard, OPG Level 2 (ISO 10262)

- Full front guard, OPG Level 2 (ISO 10262) - Track roller guard (Full length)

Operator environment

- Cab accessories

- Rain visor

- Sun visor - KomVision

Other equipment

- Counterweight removal device with 10657 kg 23,496 lb counterweight

Work equipment

- Arms

- 11'6" arm assembly

- 14'1" arm assembly

- 17'1" arm assembly - Boom

- 25'1 boom assembly

- boom cylinders only

Guards and covers

- Cab guards

- Bolt-on top guard, OPG Level 2 (ISO 10262)

- Full front guard, OPG Level 2 (ISO 10262) - Track roller guard (Full length)

Operator environment

- Cab accessories

- Rain visor

- Sun visor - KomVision

Other equipment

- Counterweight removal device with 10657 kg 23,496 lb counterweight

Work equipment

- Arms

- 3500 mm arm assembly

- 4300 mm arm assembly

- 5200 mm arm assembly - Boom

- 7660 mm boom assembly

- boom cylinders only

Support you can count on

Videos

- Video

- Video

- Video

- Video

Find what works for you