Excavators

PC1250SP-11

Large excavators

- Horsepower (HP) 758 HP @ 1,800 rpm

- Horsepower (kW) 565 kW @ 1 800 rpm

- Operating weight (kg) 117 916 - 120 610

- Operating weight (lbs) 259,960 - 265,900

- Bucket Capacity (m^3) 3.1 - 9.1

- Bucket Capacity (yd^3) 4.1 - 11.9

High-capacity excavation.

Ideal for mass excavation jobs, this large excavator comes with a Super Performance arrangement that includes a short undercarriage, short mass excavation boom and larger buckets for high production truck loading.

- 13% more HP and up to 8% increase in performance*

- Versatility with two application configurations

- Exceptional operator awareness

- Designed for serviceability

Features and benefits

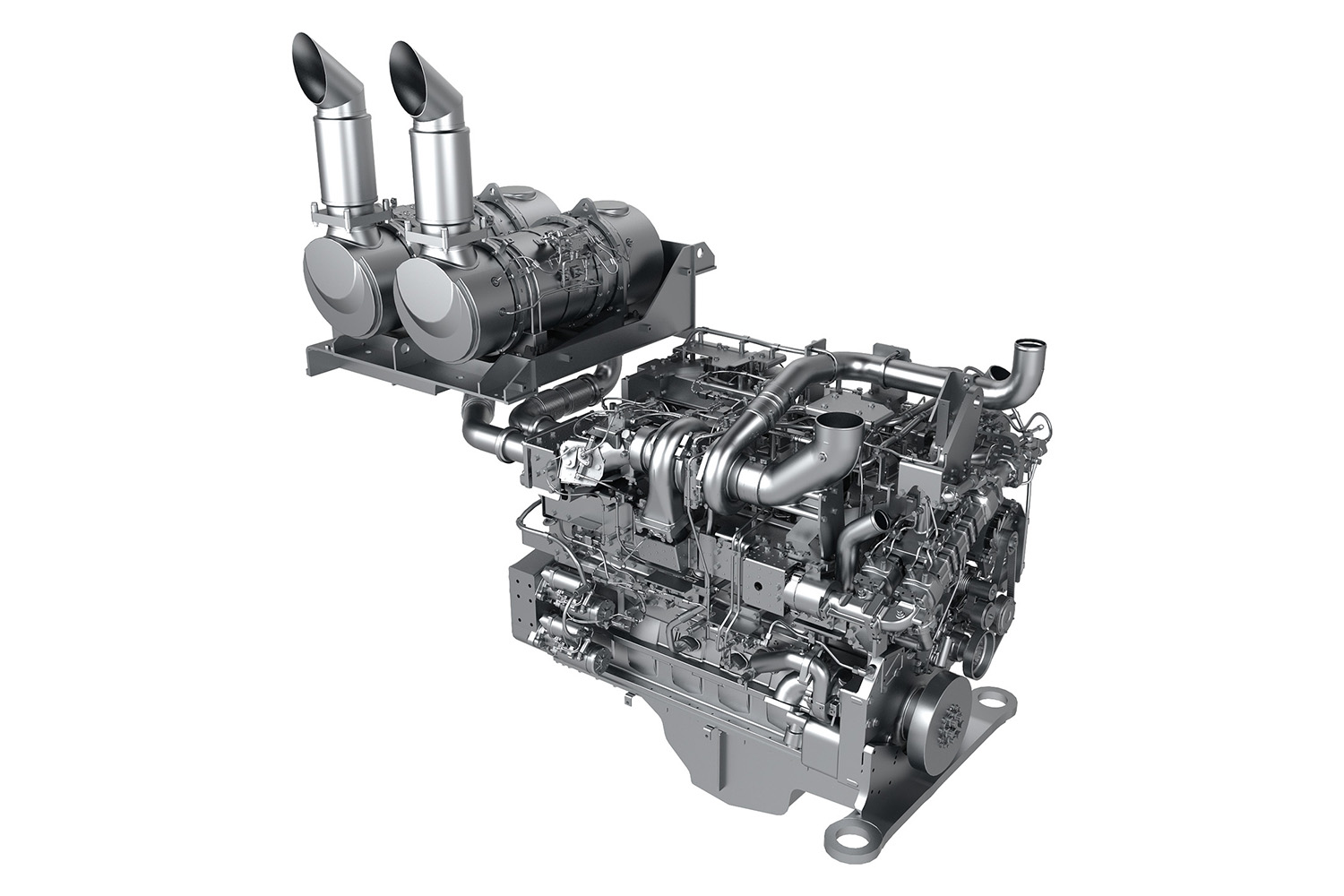

Powerful engine

13% more HP and up to 8% greater productivity*. A Tier 4 Final-compliant engine without requiring diesel exhaust fluid or a selective catalytic converter. Auto idle shutdown timer and thermostatically controlled variable speed cooling fan.

Reinforced structures

Withstand tough applications with strengthened revolving, center and crawler frames. Large cross-section structures use high-tensile-strength steel to increase durability and resistance to bending and torsional stresses.

Improved serviceability

Gain easy access to engine, hydraulic system and maintenance service areas with center and large left side walkways. Engine air cleaners have been relocated outside the engine compartment for easy access.

Enhanced cab

Keep your operators comfortable with a large pressurized cab that comes with a 7-inch color monitor and fully adjustable, heated air-suspension seat. Optional 45° hydraulic access ladder for ease of operator entry and exit.

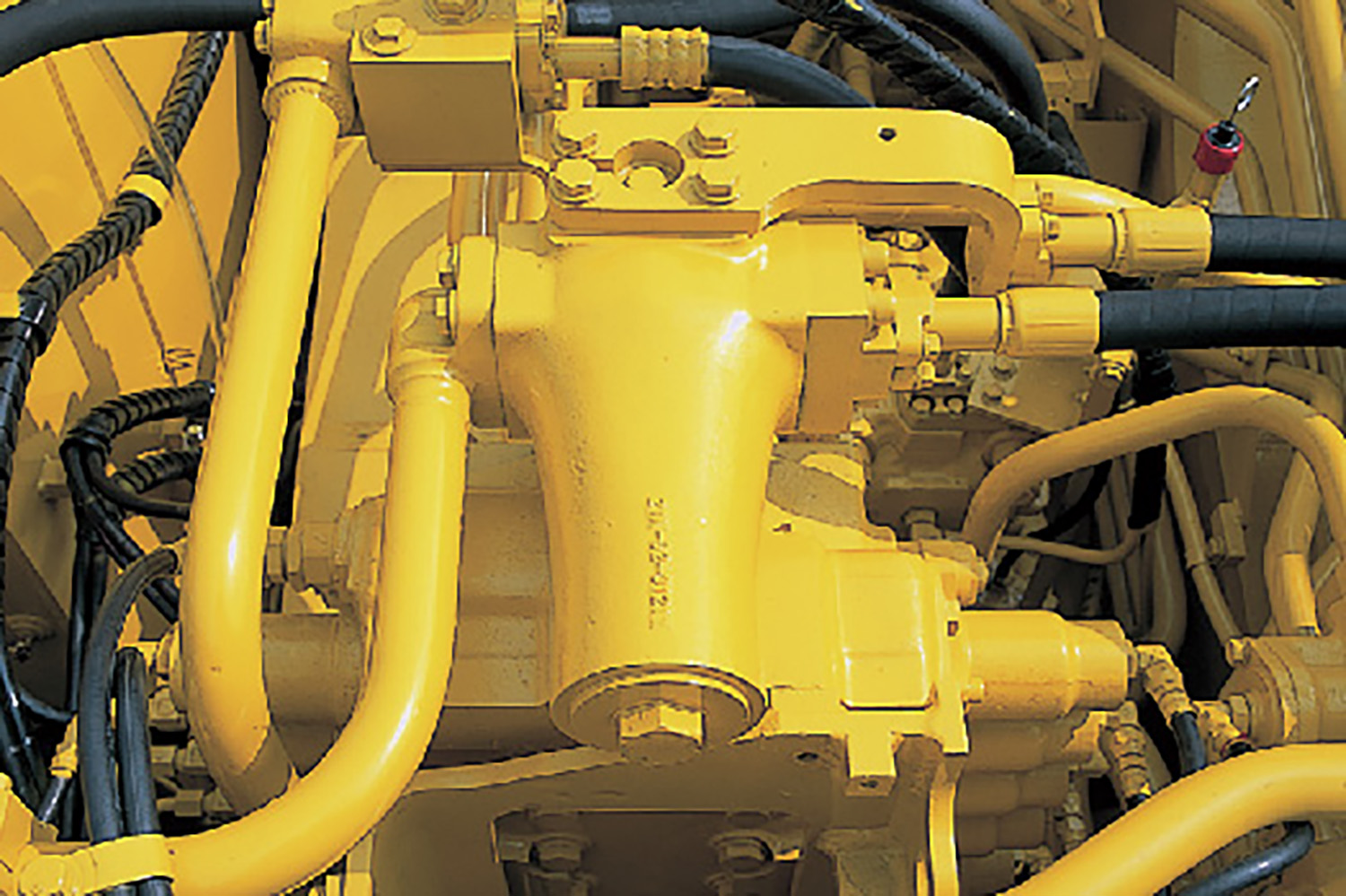

Enhanced hydraulic system

Smarter hydraulics with increased flow at higher pressures and new EPC valves improve machine logic to match working loads.* New filter by-pass sensors monitor system health and alert operators if clogging conditions exist.

Improved operator awareness

Standard KomVision -camera system provides a bird’s-eye view of the surrounding area for improved operator situational awareness.* Komtrax Plus enables expanded monitoring of the fleet via satellite and wireless LAN.

Specifications

- Full specs

- Standard equipment

- Optional equipment

- Drive method: 2 x hydraulic motors

- Swing reduction: Planetary gear

- Service brake: Oil disc brake

- Holding brake/Swing lock: Mechanical disc brake

- Swing speed (rpm): 5.8

- Swing torque (kN-m): 406.1

- HydrauMind Type: Open-center load sensing system, 1 selectable working mode

-

Hydraulic cylinders

- Boom (Number of cylinders – bore x stroke x rod diameter)(in): 8.9 x 94.1 x 6.3

- Boom (Number of cylinders – bore x stroke x rod diameter)(mm): 225 x 2 390 x 160

- Arm (Number of cylinders – bore x stroke x rod diameter)(in): 9.8 x 95.9 x 6.7

- Arm (Number of cylinders – bore x stroke x rod diameter)(mm): 250 x 2 435 x 170

-

Main pump

- Variable Type: Variable capacity piston

- Maximum flow implement and travel (L/min): 2 x 494

- Maximum flow implement and travel (gpm): 2 x 130.5

- Maximum flow swing (gpm): 1 x 158.5

- Maximum flow swing (L/min): 1 x 600

- Sub-pump for control circuit: Gear type

-

Relief valve setting

- Implement circuits (psi): 4,550

- Travel circuit (psi): 4,980

- Implement circuits (MPa): 31.4

- Swing circuit (psi): 4,267

- Pilot circuit (psi): 455

- Implement circuits (kgf/cm^2): 320

- Pilot circuit (kgf/cm^2): 33

- Pilot circuit (MPa): 3.1

- Swing circuit (kgf/cm^2): 300

- Swing circuit (MPa): 29.4

- Travel circuit (kgf/cm^2): 350

- Travel circuit (MPa): 34.3

-

Bucket

- SP / 2 (in): 6.3 x 76.8 x 4.5

- SP / 2 (mm): 160 x 1 950 x 115

- Standard / 2 (mm): 160 x 1 825 x 115

- Standard / 2 (in): 6.3 x 71.8 x 4.5

-

Hydraulic motors

- Travel: 2 x axial piston motors with parking brake

- Swing: 2 x axial piston motors with swing holding brake

- Fuel tank (US gal): 359.3

- Coolant (US gal): 37.5

- Engine (US gal): 22.7

- Final drive (US gal): 5.5

- Swing drive (L): 2 x 20

- Swing drive (US gal): 2 x 5.3

- Hydraulic tank (L): 670

- Hydraulic tank (US gal): 177

- Engine (L): 86

- Fuel tank (L): 1 360

- Final drive (L): 21

- Coolant (L): 142

- Operating weight features (mm): PC1250SP-11: Operating weight, including 7 800 mm boom, 3 400 mm arm, 6.7 m³ bucket, track roller guard, operator, lubricant, coolant, full fuel tank, and standard equipment.

- Operating weight features (ft): PC1250SP-11: Operating weight, including 25 ft. 7 in boom, 11 ft. 2 in arm, 8.8 yd³ bucket, track roller guard, operator, lubricant, coolant, full fuel tank, and standard equipment.

-

Triple grouser shoes

- Ground pressure with triple-grouser shoes 700 mm (kg/cm^2): 1.54

- Ground pressure with triple-grouser shoes 28 in (psi): 21.85

- Operating weight with triple-grouser shoes 28 in (lbs): 259,960

- Operating weight with triple-grouser shoes 700 mm (kg): 118 164

-

Double grouser shoes

- Ground pressure with double-grouser shoes 1 000 mm (kg/cm^2): 1.1

- Ground pressure with double-grouser shoes 39.4 in (psi): 15.64

- Operating weight with double-grouser shoes 39.4 in (lbs): 265,900

- Operating weight with double-grouser shoes 1 000 mm (kg): 120 864

- Engine Model: Komatsu SAA6D170E-7*

- Cooling Type: Water-cooled, 4-cycle, direct injection

- Aspiration: Turbocharged, aftercooled, cooled, EGR

- Number of cylinders: 6

- Bore (mm): 170

- Bore (in): 6.69

- Stroke (in): 6.69

- Stroke (mm): 170

- Piston displacement (L): 23.15

- Piston displacement (in^3): 1,413

- Engine Rated (rpm): 1,800

- Governor: All-speed control, electronic

- Fan drive method for radiator cooling: Hydraulic

-

Horsepower

- SAEJ1995 - Gross (kW): 578

- SAEJ1995 - Gross (HP): 775

- ISO 9249 / SAE J1349 - Net (kW): 565

- ISO 9249 / SAE J1349 - Net (HP): 758

- Fan at maximum speed - Net (HP): 696

- Fan at maximum speed - Net (kW): 519

- Drive method type: Fully hydrostatic

- Maximum drawbar pull (lbf): 154,320

- Service brake type: Hydraulic lock

- Parking brake: Oil disc brake

- Gradeability: 70%, 35°

- Travel motor: Axial piston motor, in-shoe design

-

Maximum travel speed

- High (mph): 2

- High (kph): 3.3

- Low (mph): 1.5

- Low (kph): 2.3

- Center frame: H-leg frame

- Track frame: Box-section

- Track adjuster: Hydraulic

- Number of shoes (each side): 48

- Number of carrier rollers (each side): 3

- Number of track rollers (each side): 8

- Seal of track: Sealed

- Exterior – ISO 6395 (dB(A)): 109.9

- Operator – ISO 6396 (dB(A)): 68.5

- Number of Long Undercarriage shoes (each side): 55

- Number of Long Undercarriage track rollers (each side): 10

- Automatic Engine warm-up system

- Dry type air cleaner, double element

- Engine, Komatsu SAA6D170E-7

- Fuel pre-filter with water separator

- Variable speed cooling fan, hydraulic drive, reversible

- Alternator, 24 V/90 A

- Auto idle shutdown (programmable)

- Auto-decelerator

- Batteries, 2 x 12 V/220 Ah

- Battery disconnect switch w/lock out - tag out

- Circuit breaker

- Lever lock auto-lock

- Power supply, 12 V

- Starting motor, 2 x 24 V/11k

- Step light with timer

- Service isle light

- Working lights, 2 boom, 2 Cab roof front, 1 right front, 2 LED rear facing

- Cab guards

-Bolt-on top guard, OPG Level 2 (ISO 10262) - Strengthened revolving frame underguards

- Revolving frame swivel guard

- Track guiding guards, ends and center

- Travel motor guard

- Radiator and oil cooler dustproof net

- 2 speed travel with auto shift

- Power+ work mode

- Automatic swing holding brake

- Fully hydraulic, with Open-Center Load-Sensing and Engine speed sensing

(Pump and Engine mutual control system) - Heavy lift mode

- In-line high pressure pump outlet filters

- Pressure Proportional Control (PPC) hydraulic control system

- Shockless control system for boom

- Two-mode setting for boom

- 2 x 12V power ports in Cab

- Auto climate control, A/C with defroster

- AM/FM radio

- Auxiliary input (3.5 mm jack)

- Cab with opening front window

- Engine shut down secondary switch

- High back air suspension seat, heated

- KomVision, 4 camera system

- Large high resolution LCD color monitor

- Lock lever

- Mirrors (RH,LH)

- Rear & Side view monitor system

- Seat belt, retractable, 3"

- Washable Cab floor mat

- Counterweight, 36,640 lb

- Electric priming pump for fuel system

- Equipment Management Monitoring System

- Grease gun, with hose reel and air power pump

- Hand rails & guard rails

- Horn, air

- KOMTRAX 5.0 with KOMTRAX Plus

- One-touch Engine oil drainage

- Preventive Maintenance (PM) service connector

- Tie off points on boom & arm

- Rear reflector

- Seat belt indicator

- Slip-resistant plates

- Travel alarm

- Vandalism protection locks

- Wide walkways

- Carrier rollers, 3 (Each side)

- Hydraulic track adjusters (Each side)

- Track rollers, 8 (Each side)

- Track shoes, 27.6"double grouser

- Automatic Engine warm-up system

- Dry type air cleaner, double element

- Engine, Komatsu SAA6D170E-7

- Fuel pre-filter with water separator

- Variable speed cooling fan, hydraulic drive, reversible

- Alternator, 24 V/90 A

- Auto idle shutdown (programmable)

- Auto-decelerator

- Batteries, 2 x 12 V/220 Ah

- Battery disconnect switch w/lock out - tag out

- Circuit breaker

- Lever lock auto-lock

- Power supply, 12 V

- Starting motor, 2 x 24 V/11k

- Step light with timer

- Service isle light

- Working lights, 2 boom, 2 Cab roof front, 1 right front, 2 LED rear facing

- Cab guards

-Bolt-on top guard, OPG Level 2 (ISO 10262) - Strengthened revolving frame underguards

- Revolving frame swivel guard

- Track guiding guards, ends and center

- Travel motor guard

- Radiator and oil cooler dustproof net

- 2 speed travel with auto shift

- Power+ work mode

- Automatic swing holding brake

- Fully hydraulic, with Open-Center Load-Sensing and Engine speed sensing

(Pump and Engine mutual control system) - Heavy lift mode

- In-line high pressure pump outlet filters

- Pressure Proportional Control (PPC) hydraulic control system

- Shockless control system for boom

- Two-mode setting for boom

- 2 x 12V power ports in Cab

- Auto climate control, A/C with defroster

- AM/FM radio

- Auxiliary input (3.5 mm jack)

- Cab with opening front window

- Engine shut down secondary switch

- High back air suspension seat, heated

- KomVision, 4 camera system

- Large high resolution LCD color monitor

- Lock lever

- Mirrors (RH,LH)

- Rear & Side view monitor system

- Seat belt, retractable, 75 mm

- Washable Cab floor mat

- Counterweight, 16620 kg

- Electric priming pump for fuel system

- Equipment Management Monitoring System

- Grease gun, with hose reel and air power pump

- Hand rails & guard rails

- Horn, air

- KOMTRAX 5.0 with KOMTRAX Plus

- One-touch Engine oil drainage

- Preventive Maintenance (PM) service connector

- Tie off points on boom & arm

- Rear reflector

- Seat belt indicator

- Slip-resistant plates

- Travel alarm

- Vandalism protection locks

- Wide walkways

- Carrier rollers, 3 (Each side)

- Hydraulic track adjusters (Each side)

- Track rollers, 8 (Each side)

- Track shoes, 700 mm double grouser

Guards and covers

- Cab guards -Full front guard, OPG Level 2 (ISO 10262)

Operator environment

- Hydraulically operated access stairway

- Hydraulic operated access stairway Field Installation Kit

Undercarriage

- PC1250SP-11 -39.4" double grouser track shoes Track roller guard (Full length)

Other

- Boom cylinders only

Work equipment

- Booms PC1250SP-11 -25'7"SP boom assembly

- Arms PC1250SP-11 -11'2" SP arm assembly

Guards and covers

- Cab guards -Full front guard, OPG Level 2 (ISO 10262)

Operator environment

- Hydraulically operated access stairway

- Hydraulic operated access stairway Field Installation Kit

Undercarriage

- PC1250SP-11 -1000 mm double grouser track shoes Track roller guard (Full length)

Other

- Boom cylinders only

Work equipment

- Booms PC1250SP-11 -7800 mm SP boom assembly

- Arms PC1250SP-11 -3400 mm SP arm assembly

Support you can count on

Find what works for you