Excavators

HB365LC-3

Large excavators

- Horsepower (HP) 269 HP @ 1,950 rpm

- Horsepower (kW) 201 kW @ 1 950 rpm

- Operating weight (kg) 37 180 - 38 780

- Operating weight (lbs) 81,791 - 85,495

- Bucket Capacity (m^3) 0.68 - 1.96

- Bucket Capacity (yd^3) 0.89 - 2.56

Environment-friendly performance

Get power and efficiency in a big package with a hybrid excavator designed to reduce fuel consumption while driving performance. When swinging, all available hydraulic power is sent to the boom, arm and bucket for improved cycle time and increased production. All hybrid components are covered by a 7-year/15,000 hour fully transferable warranty.

- Up to 20% fuel savings *

- Improved cycle time

- Fast, responsive swing

- 15% increase in productivity*

Note: *compared to the non-hybrid excavator design

Features and benefits

High-performing swing

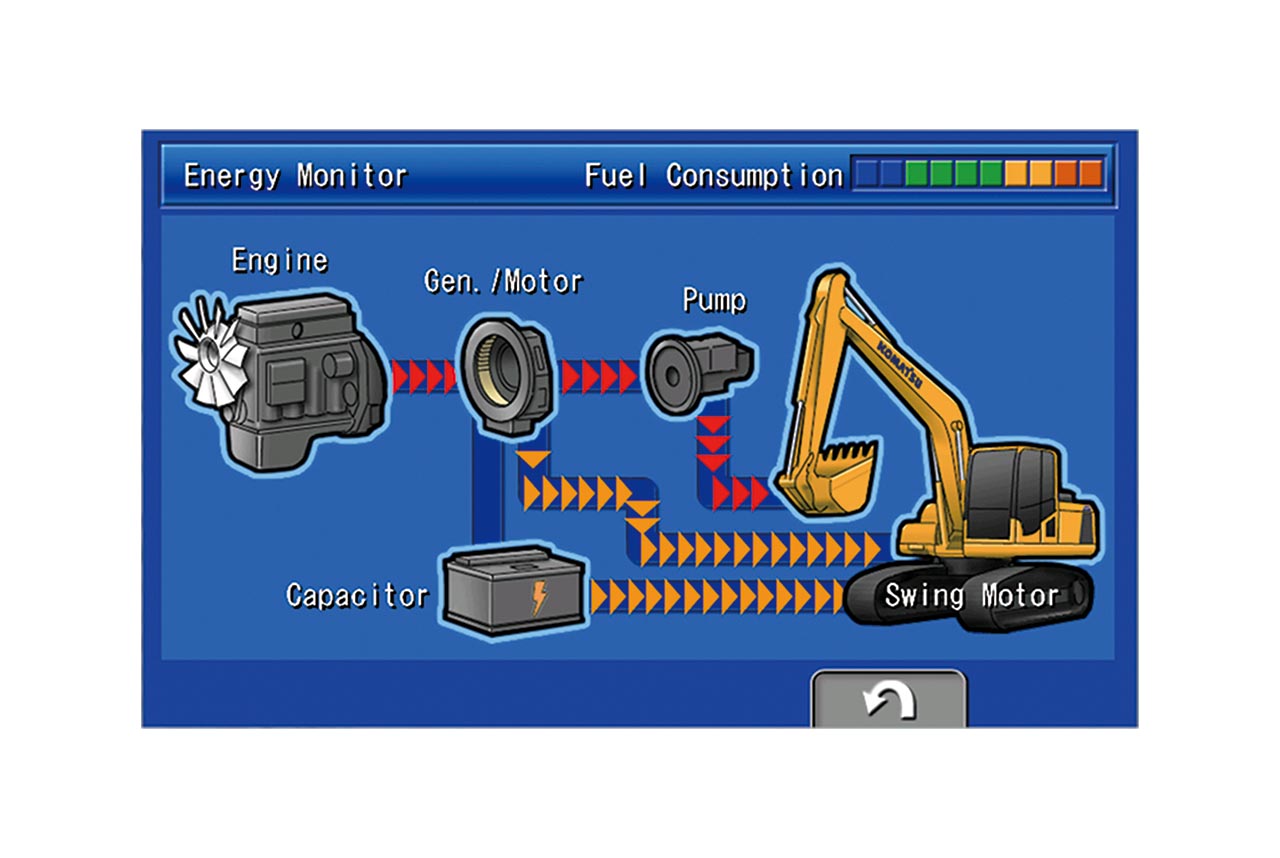

Superb swing power and speed with an ultra-capacitor that captures energy then charges and discharges rapidly to power the electric swing motor.

High-response engine

Great engine response, performance and efficiency with an engine-mounted motor/generator powered by the capacitor, which provides up to a 70 hp boost to the engine.

Reduced fuel consumption

Control costs and reduce your carbon footprint with a hybrid energy conservation system that combines with Tier 4 Final technology for up to 20% fuel savings compared to the non-hybrid excavator design.

Complete jobs quicker

Get fast cycle times and boost productivity with a powerful electric swing motor and a closed-center load sensing system (CLSS). The CLSS delivers hydraulic power to the excavator for an immediate high performance, smooth and precise operation.

Standard telematics technology

Track valuable machine data with the KomtraxTM remote equipment monitoring and management system, standard and with no subscription fees. KomtraxTM also provides advanced machine troubleshooting capabilities by continuously monitoring machine health.

Improved stability

The HB365LC-3 excavator features a 6% increase in operating weight* designed to help its stability so operators can dig, lift, and handle heavy materials confidently and effectively, especially when working on uneven or challenging terrain. *Compared to a traditional Komatsu 36-ton diesel engine excavator

Specifications

- Full specs

- Standard equipment

- Optional equipment

- Drive method: Electric drive

- Swing reduction: Planetary gear

- Service brake: Electric brake

- Holding brake/Swing lock: Mechanical disc brake

- Swing speed (rpm): 9.5

- Swing torque (kg-m): 11 386

- Swing torque (ft-lbs): 82,313

- HydrauMind Type: HydrauMind (Hydraulic Mechanical Intelligence) system, closed-center system with load sensing valves and pressure compensated valves

- Number of selectable working modes: 6

-

Hydraulic cylinders

- Boom (Number of cylinders – bore x stroke x rod diameter)(in): 5.5 x 58.3 x 3.9

- Boom (Number of cylinders – bore x stroke x rod diameter)(mm): 140 x 1 480 x 100

- Arm (Number of cylinders – bore x stroke x rod diameter)(in): 6.3 x 71.9 x 4.3

- Arm (Number of cylinders – bore x stroke x rod diameter)(mm): 160 x 1 825 x 110

- Bucket / 1 - for 10'5" and 13'2" Arms (in): 5.5 x 50.6 x 3.9

- Bucket / 1 - for 3.2 m and 4.0 m Arms (mm): 140 x 1 285 x 100

-

Main pump

- Variable Type: Variable displacement piston type

- Maximum flow (US gpm): 141.3

- Maximum flow (L/min): 535

- Supply for control circuit: Self-reducing valve

- Gear Type: Variable displacement piston type

- Main pumps for: Boom, arm, bucket, swing, and travel circuits

-

Relief valve setting

- Implement circuits (psi): 5,540

- Travel circuit (psi): 5,540

- Implement circuits (MPa): 38.2

- Pilot circuit (psi): 470

- Implement circuits (kgf/cm^2): 390

- Pilot circuit (kgf/cm^2): 33

- Pilot circuit (MPa): 3.2

- Travel circuit (kgf/cm^2): 390

- Travel circuit (MPa): 38.2

-

Hydraulic motors

- Travel: 2 x axial piston motors with parking brake

- Swing: 1 x axial piston motor with swing holding brake

- Fuel tank (US gal): 159.8

- Coolant (US gal): 11.1

- Engine (US gal): 10.2

- Final drive (US gal): 2.4

- Swing drive (L): 15.6

- Swing drive (US gal): 4.12

- Hydraulic tank (L): 188

- Hydraulic tank (US gal): 49.7

- DEF tank (US gal): 10.3

- Motor-generator (US gal): 2.25

- Motor-generator (L): 8.5

- Swing motor - generator (US gal): 0.95

- Swing motor - generator (L): 3.6

- Ultra capacitor cooling system (L): 11.7

- Ultra capacitor cooling system (US gal): 3

- Engine (L): 38.5

- DEF tank (L): 39.2

- Fuel tank (L): 605

- Final drive (L): 9

- Coolant (L): 42

- Operating weight features (mm): Operating weight including 6 500 mm one-piece HD boom, 3 185 mm arm, 850 mm track shoes, SAE heaped 1.96 m3 bucket, rated capacity of lubricants, coolant, full fuel tank, operator, and standard equipment.

- Operating weight features (ft): Operating weight including 21 ft. 3 in one-piece HD boom, 10 ft. 5 in arm, 33.5 in track shoes, SAE heaped 2.56 yd3 bucket, rated capacity of lubricants, coolant, full fuel tank, operator, and standard equipment.

-

Triple grouser shoes

- Ground pressure with triple-grouser shoes 700 mm (kg/cm^2): 0.62

- Ground pressure with triple-grouser shoes 28 in (psi): 8.79

- Ground pressure with triple-grouser shoes 31.5 in (psi): 7.77

- Ground pressure with triple-grouser shoes 800 mm (kg/cm^2): 0.55

- Ground pressure with triple-grouser shoes 33.5 in (psi): 7.35

- Ground pressure with triple-grouser shoes 850 mm (kg/cm^2): 0.52

- Operating weight with triple-grouser shoes 28 in (lbs): 83,012

- Operating weight with triple-grouser shoes 31.5 in (lbs): 83,894

- Operating weight with triple-grouser shoes 33.5 in (lbs): 84,335

- Operating weight with triple-grouser shoes 700 mm (kg): 37 654

- Operating weight with triple-grouser shoes 800 mm (kg): 38 054

- Operating weight with triple-grouser shoes 850 mm (kg): 38 254

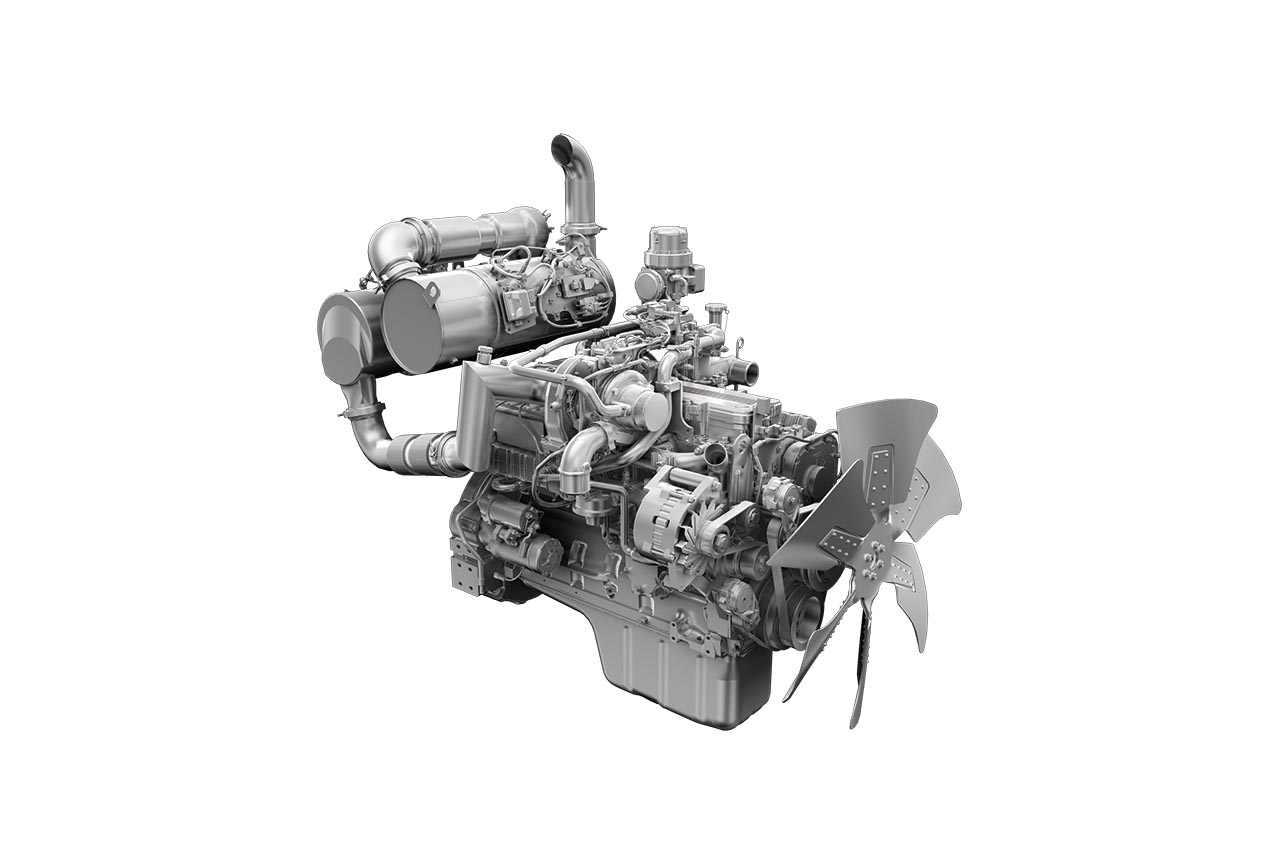

- Engine Model: Komatsu SAA6D114E-6*

- Cooling Type: Water-cooled, 4-cycle, direct injection

- Aspiration: Turbocharged, aftercooled, cooled EGR

- Number of cylinders: 6

- Bore (mm): 114

- Bore (in): 4.49

- Stroke (in): 5.69

- Stroke (mm): 144.5

- Piston displacement (L): 8.85

- Piston displacement (in^3): 540

- Engine Rated (rpm): 1950

- Governor: All-speed control, electronic.

- Fan drive method for radiator cooling: Mechanical with viscous fan clutch

-

Horsepower

- SAEJ1995 - Gross (kW): 202

- SAEJ1995 - Gross (HP): 271

- ISO 9249 / SAE J1349 - Net (kW): 201

- ISO 9249 / SAE J1349 - Net (HP): 269

- Fan at maximum speed - Net (HP): 251

- Fan at maximum speed - Net (kW): 197

- Drive method type: Fully hydrostatic

- Maximum drawbar pull (kgf): 290 kN / 29 570 kg

- Maximum drawbar pull (lbs): 65,191

- Service brake type: Hydraulic lock

- Parking brake: Mechanical disc brake

- Gradeability: 70%, 35°

-

Maximum travel speed

- High (mph): 3.4

- High (kph): 5.5

- Mid (kph): 4.5

- Mid (mph): 2.8

- Low (mph): 2

- Low (kph): 3.2

- Center frame: X-frame

- Track frame: Box-section

- Track adjuster: Hydraulic

- Number of shoes (each side): 48

- Number of carrier rollers (each side): 2

- Number of track rollers (each side): 8

- Seal of track: Sealed

- Exterior – ISO 6395 (dB(A)): 101

- Operator – ISO 6396 (dB(A)): 69

- Auto idle

- Auto idle shut down programmable

- Automatic Engine warm-up system

- Dry type air cleaner, double element

- Engine, Komatsu SAA6D114E-6

- Engine coolant to -25°C -13°F

- Engine overheat prevention system

- Fuel pre-filter (10 micron, with water separator)

- Fuel priming pump

- Viscous fan clutch, temperature controlled

- Ultra capacitor with inverter

- Electric swing motor/generator

- Engine mounted motor/generator

- Hybrid component cooling system

- Alternator, 24 V/90 A

- Batteries, large capacity (2 x 12V)

- Battery master disconnect switch

- Electric horn

- Power ports (2) 24V to 12V

- Starting motor, 24 V/11 kW

- Working lights, 2 (Boom and RH front)

- Arm holding valve

- Boom holding valve

- Power maximizing system

- PPC hydraulic control system

- Service valve, one additional function

- Two-mode setting for boom

- Working mode selection system

- CarBody swivel guard

- Pump/Engine compartment partition

- Revolving frame deck guards

- Revolving frame under covers

- Slip resistant plates

- Thermal and fan guards

- Track roller guards (center section)

- 3 speed travel with auto shift

- Carrier roller (2 each side)

- Hydraulic track adjusters (Each side)

- Track roller, 8 each side

- Track shoe, triple grouser, 33.5"

- Auxiliary input (3.5 mm jack)

- Automatic climate control/air conditioner/heater/defroster

- High back air suspension seat with heat

- Large high resolution 7" LCD monitor

- Lock lever, work equipment

- Mirrors (RH and LH)

- Operator protective top guard (OPG), level 1

- Rear view monitor system - one camera

- ROPS Cab (ISO 12117-2)

- Seat belt indicator

- Seat belt, retractable, 3"

- Secondary Engine shut down switch

- Skylight, opening

- AM/FM radio

- Counterweight, 13,933 lb

- Equipment Management Monitoring System (EMMS)

- KOMTRAX® level 5.0

- Operator identification system

- Radiator and oil cooler removable debris screen

- Rear reflector

- Travel alarm

- Auto idle

- Auto idle shut down programmable

- Automatic Engine warm-up system

- Dry type air cleaner, double element

- Engine, Komatsu SAA6D114E-6

- Engine coolant to -25°C -13°F

- Engine overheat prevention system

- Fuel pre-filter (10 micron, with water separator)

- Fuel priming pump

- Viscous fan clutch, temperature controlled

- Ultra capacitor with inverter

- Electric swing motor/generator

- Engine mounted motor/generator

- Hybrid component cooling system

- Alternator, 24 V/90 A

- Batteries, large capacity (2 x 12V)

- Battery master disconnect switch

- Electric horn

- Power ports (2) 24V to 12V

- Starting motor, 24 V/11 kW

- Working lights, 2 (Boom and RH front)

- Arm holding valve

- Boom holding valve

- Power maximizing system

- PPC hydraulic control system

- Service valve, one additional function

- Two-mode setting for boom

- Working mode selection system

- CarBody swivel guard

- Pump/Engine compartment partition

- Revolving frame deck guards

- Revolving frame under covers

- Slip resistant plates

- Thermal and fan guards

- Track roller guards (center section)

- 3 speed travel with auto shift

- Carrier roller (2 each side)

- Hydraulic track adjusters (Each side)

- Track roller, 8 each side

- Track shoe, triple grouser, 850 mm

- Auxiliary input (3.5 mm jack)

- Automatic climate control/air conditioner/heater/defroster

- High back air suspension seat with heat

- Large high resolution 7" LCD monitor

- Lock lever, work equipment

- Mirrors (RH and LH)

- Operator protective top guard (OPG), level 1

- Rear view monitor system - one camera

- ROPS Cab (ISO 12117-2)

- Seat belt indicator

- Seat belt, retractable, 76 mm

- Secondary Engine shut down switch

- Skylight, opening

- AM/FM radio

- Counterweight, 6320 kg

- Equipment Management Monitoring System (EMMS)

- KOMTRAX® level 5.0

- Operator identification system

- Radiator and oil cooler removable debris screen

- Rear reflector

- Travel alarm

Arms

- 10'5" arm assembly

- 10'5" arm assembly with piping

- 13'2" arm assembly

- 13'2" arm assembly with piping

Booms

- 21'3" HD boom assembly

- 21'3" HD boom assembly with piping

Cab guards

- Lower front window guard

- Full front guard, OPG Level 1

- Full front guard, OPG Level 2

- Bolt-on top guard, OPG Level 2

Other

- KomVision surround camera system

- Hydraulic control unit, 1 actuator

- Proportional control handles for auxiliary hydraulics

- Rain visor

- Revolving frame undercovers, heavy duty

- Sun visor

- Track roller guards, full length

- Track shoes, triple grouser, 28"

- Track shoes, single grouser, 31.5"

- Working lights, front, two additional Cab mounted

Arms

- 3185 mm arm assembly

- 3185 mm arm assembly with piping

- 4020 mm arm assembly

- 4020 mm arm assembly with piping

Booms

- 6500 mm HD boom assembly

- 6500 mm HD boom assembly with piping

Cab guards

- Lower front window guard

- Full front guard, OPG Level 1

- Full front guard, OPG Level 2

- Bolt-on top guard, OPG Level 2

Other

- KomVision surround camera system

- Hydraulic control unit, 1 actuator

- Proportional control handles for auxiliary hydraulics

- Rain visor

- Revolving frame undercovers, heavy duty

- Sun visor

- Track roller guards, full length

- Track shoes, triple grouser, 700 mm

- Track shoes, single grouser, 800 mm

- Working lights, front, two additional Cab mounted

Support you can count on

Videos

- Video

- Video

Find what works for you