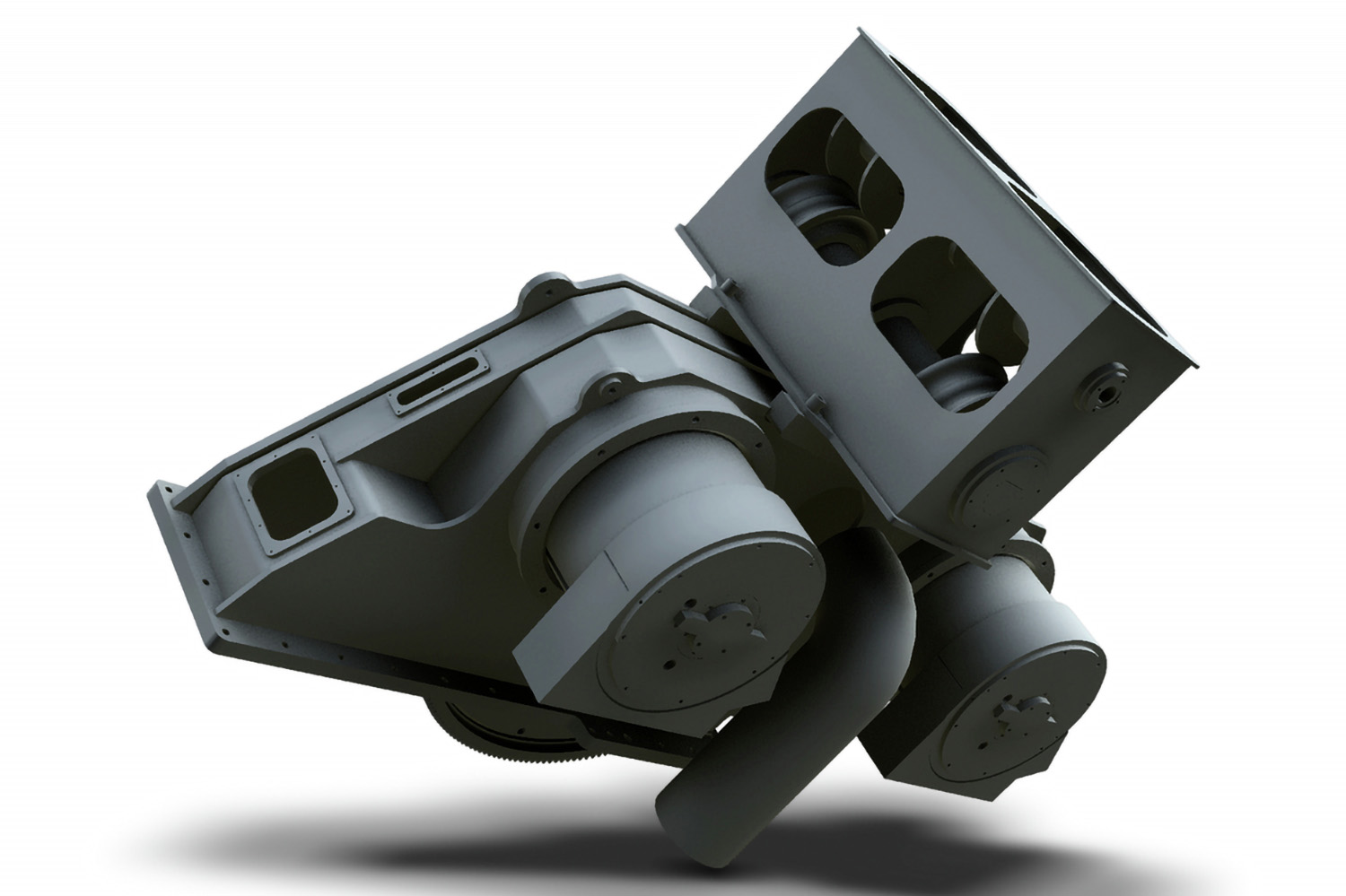

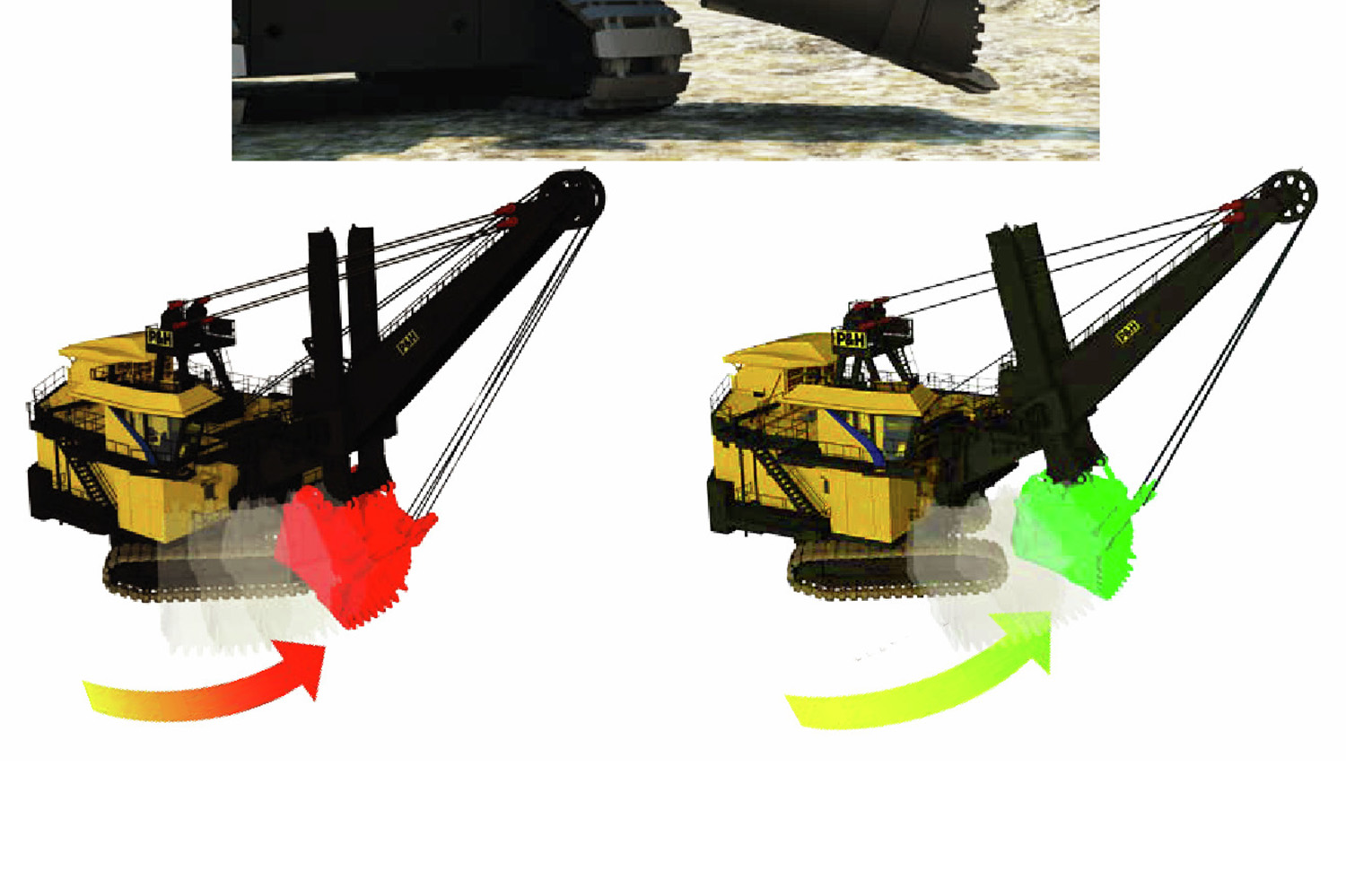

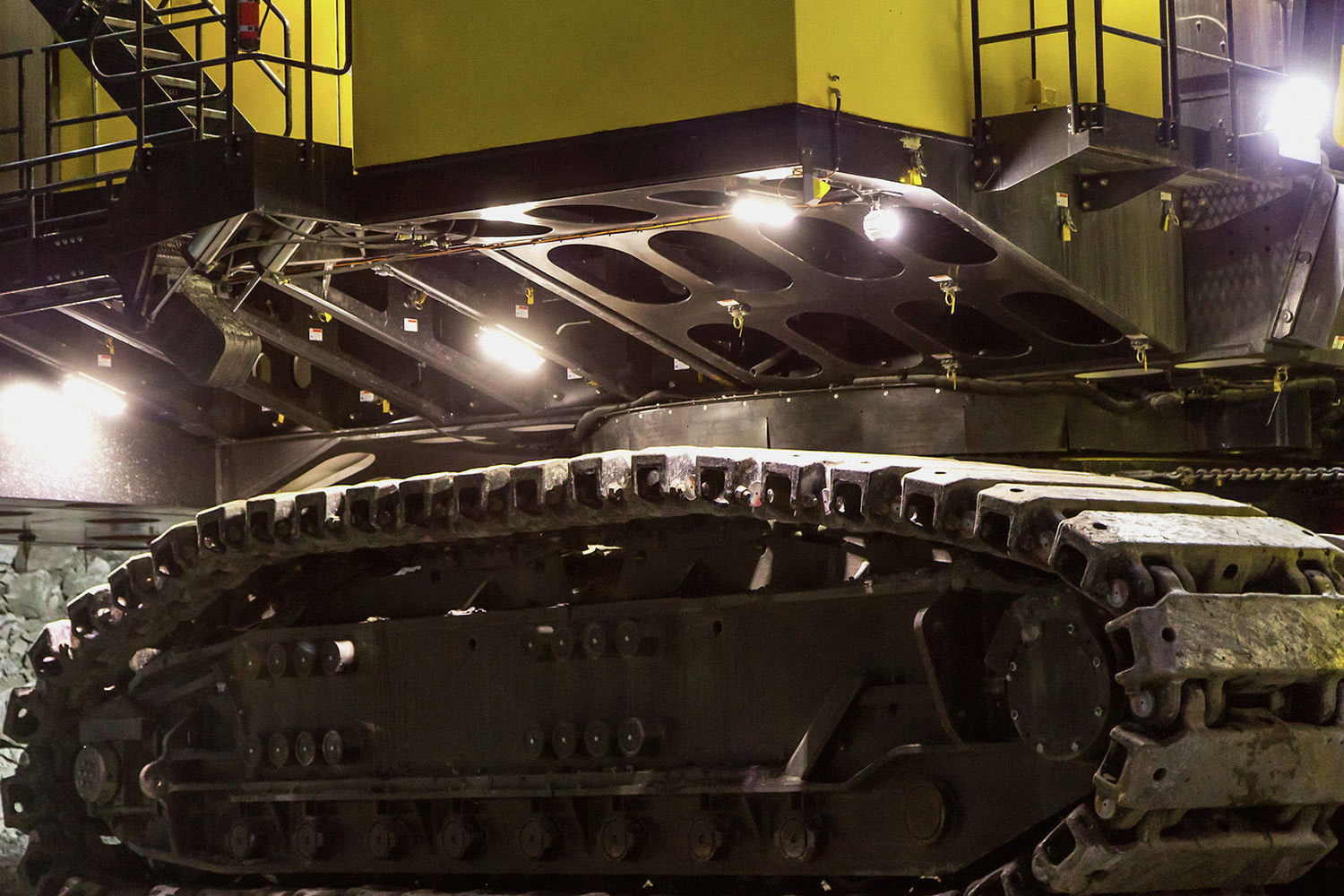

Argus

The Argus Payload Monitoring System weighs each bucket in real-time, which helps eliminate the need to stop and calculate payload before loading the truck. Immediate feedback promotes loading accuracy, while peer benchmarking works to reinforce best practices to improve operator performance.