Telematics

Telematics data can drive results for business operations, but only when you can collect and analyze it efficiently. Get the insights that can benefit your bottom line.

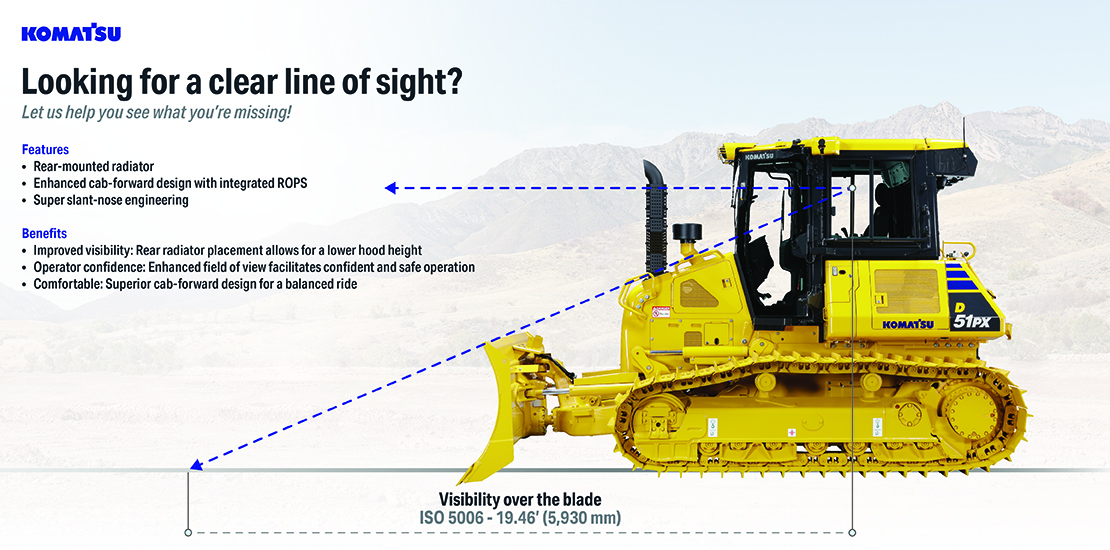

Combine a super slant nose with 3D grade control for a fast and accurate grading system. The D51EX-24 sets the standard for general-purpose construction dozers and provides your operator excellent blade visibility while working any job.

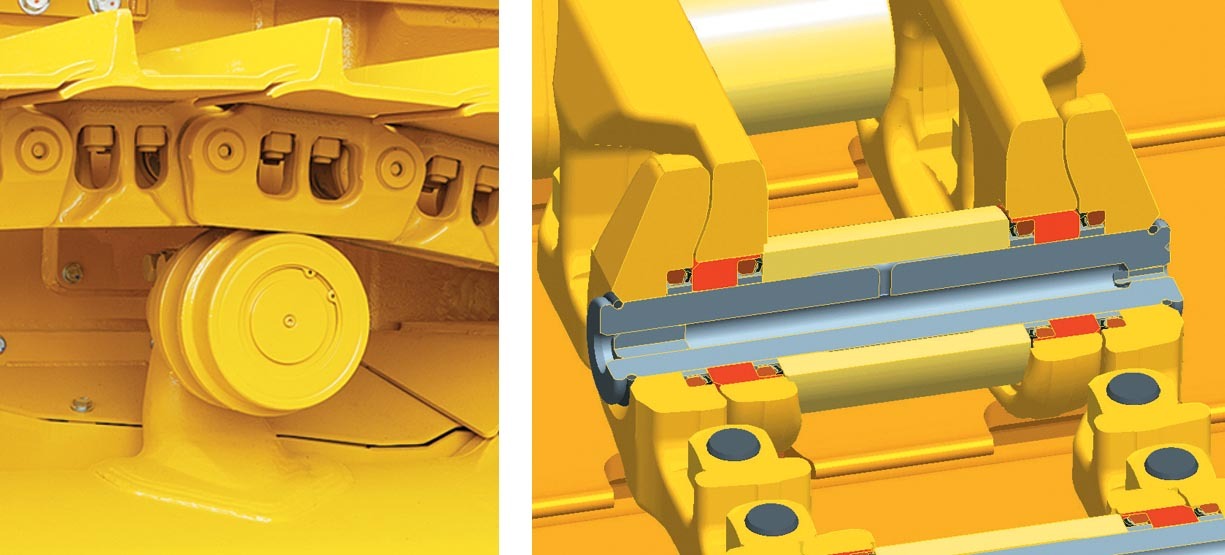

Designed to wear evenly so the machine provides close to 100% usage of undercarriage components, Komatsu PLUS undercarriage lowers undercarriage maintenance costs by up to 40% over a conventional undercarriage. Strengthened rollers and links increase wear life up to two times.

Expand your productivity and gain more versatility in a variety of applications with a power angle tilt (PAT) dozer blade with adjustable blade pitch system.

An innovative super-slant nose design provides excellent blade visibility for improved machine control and increased efficiency and productivity.

Fully electronic control provides complete automatic shifting and enables smooth control. Equipped with Komatsu-designed HST, this machine allows for Quick-Shift or variable speed selection.

A swing-up fan with a gas strut-assisted lift system provides easy access to the radiator, oil cooler and charge air cooler. The hydraulic fan has a reversing fan for cleaning any objects that are restricting air flow.

Designed for your operator’s comfort and ease of use, the ergonomic, low-effort palm command control system (PCCS) joystick controls all directional movements, including machine travel speed, as well as counter-rotation.

Horsepower

Lubrication system

Operating weight

Tractor weight

Travel speed (quick shift mode)*

Forward

Reverse

Hydraulic oil capacity (refill)

Positions

Number of cylinders

Hydraulic cylinders

Multi-shank ripper:

Multi-shank ripper

Telematics data can drive results for business operations, but only when you can collect and analyze it efficiently. Get the insights that can benefit your bottom line.

D51PXi-24 Slant Nose Dozer Infographic

D51PXi-24 Slant Nose Dozer Infographic

Find what works for you