Telematics

Telematics data can drive results for business operations, but only when you can collect and analyze it efficiently. Get the insights that can benefit your bottom line.

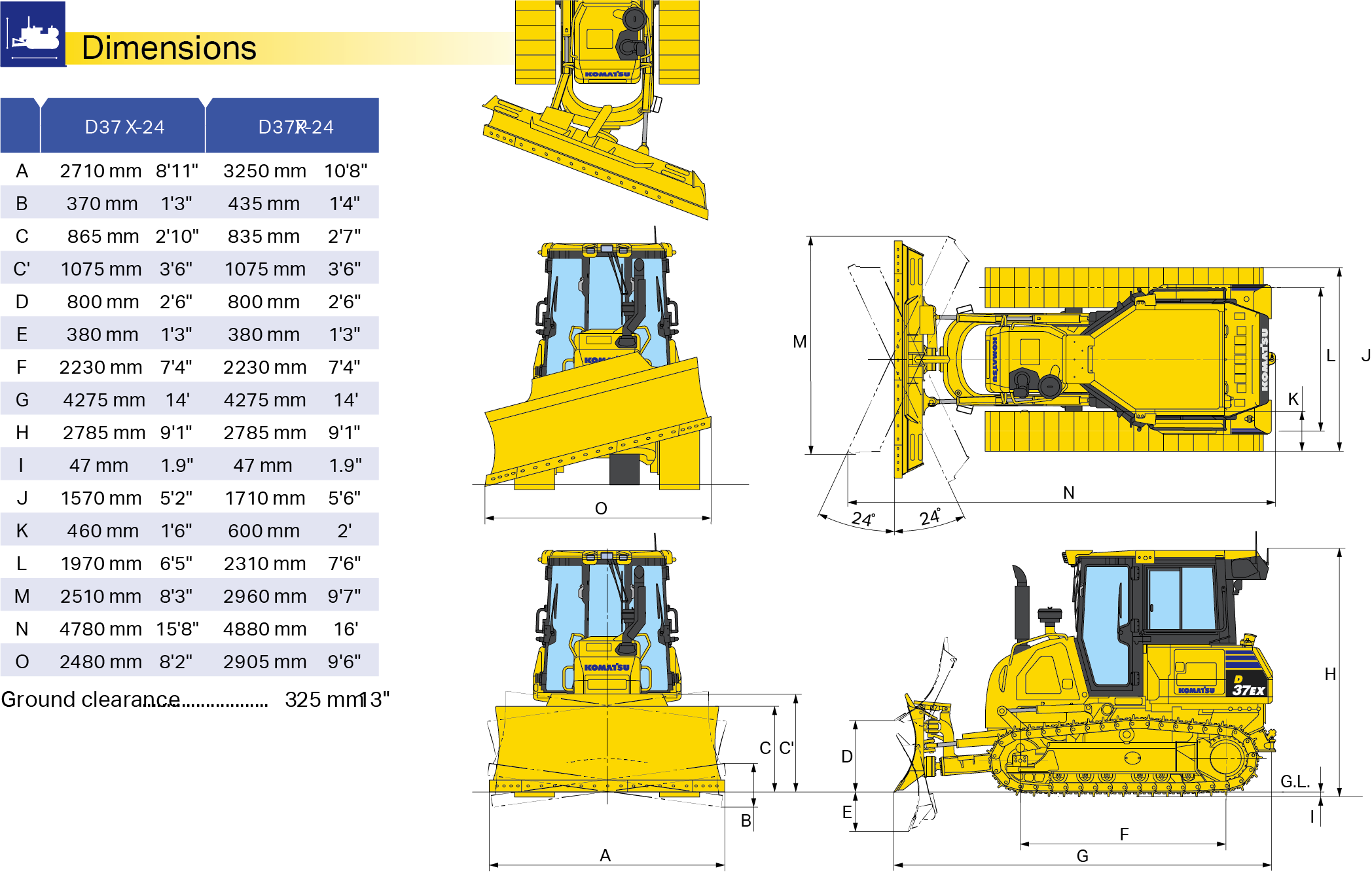

When your job demands a transportable dozer that delivers power plus precise grading, the D37 may be the answer. Your operators enjoy excellent blade visibility, agility and comfort. You get versatility for construction site work, high-speed grading and more.

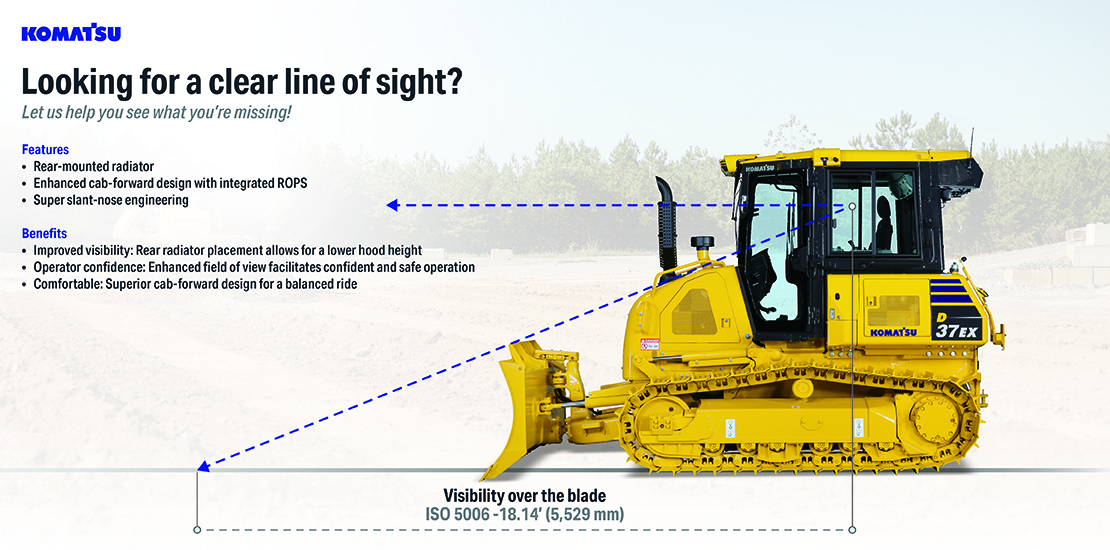

Your operators will love the dozer’s super-slant nose, cab-forward design that provides outstanding visibility to the cutting edges, plus excellent balance and maneuverability.

You don’t need to fret about debris coming off the blade and damaging the engine cooling system. The D37’s rear-mounted cooler keeps vital engine cooling components away from the blade and is easy for your crews to maintain from ground level.

Need an agile dozer able to maneuver in tight areas and grade quickly? The D37 is designed to deliver, with variable speed option or three presets. Hydrostatic transmission eliminates steering clutches and brakes for smooth power and performance.

Horsepower

Lubrication system

Operating weight

Tractor weight

Travel speed (quick shift mode)*

Forward

Reverse

Telematics data can drive results for business operations, but only when you can collect and analyze it efficiently. Get the insights that can benefit your bottom line.

D37EX-24 Slant Nose Dozer Infographic

D37EX-24 Slant Nose Dozer Infographic

Find what works for you