Telematics

Telematics data can drive results for business operations, but only when you can collect and analyze it efficiently. Get the insights that can benefit your bottom line.

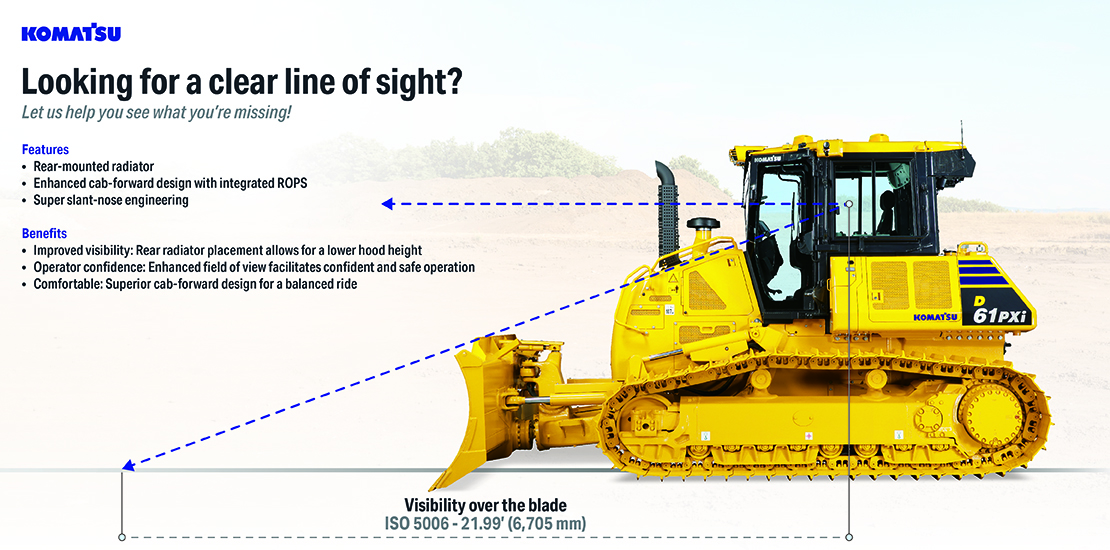

Efficient fuel consumption in a mid-size dozer with the updated D61PX-24. This mid-size dozer provides your operator exceptional blade visibility and comes with a parallel link undercarriage system for long undercarriage life.

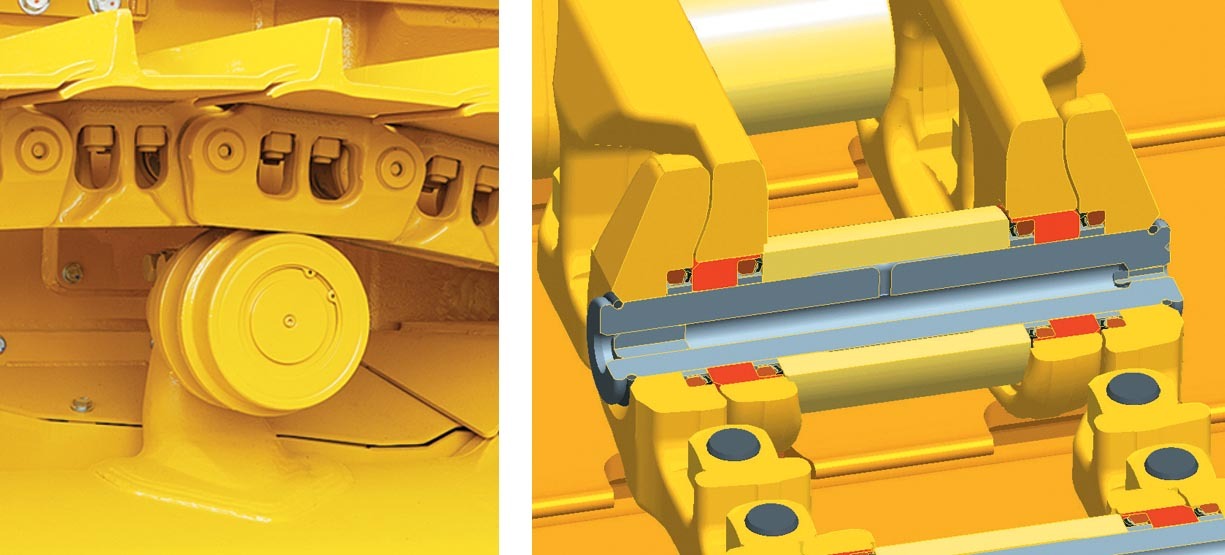

Designed to wear evenly so the machine provides close to 100% usage of undercarriage components, Komatsu PLUS undercarriage lowers undercarriage maintenance costs by up to 40% over a conventional undercarriage. Strengthened rollers and links increase wear life up to two times.

Expand your productivity and gain more versatility in a variety of applications with a power angle tilt (PAT) dozer blade with adjustable blade pitch system.

An innovative super-slant nose design provides excellent blade visibility for improved machine control and increased efficiency and productivity.

Fully electronic control provides complete automatic shifting and enables smooth control. Equipped with Komatsu-designed HST, this machine allows for Quick-Shift or variable speed selection.

A swing-up fan with a gas strut-assisted lift system provides easy access to the radiator, oil cooler and charge air cooler. The hydraulic fan has a reversing fan for cleaning any objects that are restricting air flow.

Designed for your operator’s comfort and ease of use, the ergonomic, low-effort palm command control system (PCCS) joystick controls all directional movements, including machine travel speed, as well as counter-rotation.

Reverse

Forward

Hydraulic oil capacity (refill)

Number of cylinders

Positions

Hydraulic cylinders

Horsepower

Lubrication system

Tractor weight

Operating weight

* Dozer assembly and rear mounted equipment are not included in base machine standard equipment

** Cab meets ROPS and FOPS Level 2 standards

* Dozer assembly and rear mounted equipment are not included in base machine standard equipment

** Cab meets ROPS and FOPS Level 2 standards

Multi-shank ripper

Multi-shank ripper

Telematics data can drive results for business operations, but only when you can collect and analyze it efficiently. Get the insights that can benefit your bottom line.

D61PXi-24 Slant Nose Dozer Infographic

D61PXi-24 Slant Nose Dozer Infographic

Find what works for you