Telematics

Telematics data can drive results for business operations, but only when you can collect and analyze it efficiently. Get the insights that can benefit your bottom line.

Need a powerful, economical dozer with outstanding floatation? You'll appreciate the D85PX-18's 11-liter engine, 14' 4” straight tilt blade, fuel-efficient automatic transmission and expansive footprint for soft ground conditions. Optional extended wear life undercarriage with 36” wide PLUS (Parallel Link Undercarriage System) rotating bushing track shoes is available.

All the dozers in the D65/85/155 family offer you outstanding power, economy and reliability. Customize yours with the blade (straight, Semi-U, Sigmadozer and Full U (D155 only)), track shoe width and horsepower combo best suited to your particular application.

An advanced Tier 4 engine offers you a potent combo of power and fuel efficiency. An auto idle shutdown, adjustable from 5-60 minutes, also helps cut fuel use and emissions.

Operators will enjoy the palm command electronic control joysticks that fit the natural relaxed shape of their hands. Auto-shift or manual-shift modes are easily selected with one push of a button for precision with less fatigue over the course of a shift.

Your operators can execute smooth powerful turns with the hydrostatic steering system. It transmits engine power to both tracks without power interruption and minimizes turning radius with counter-rotation while in neutral.

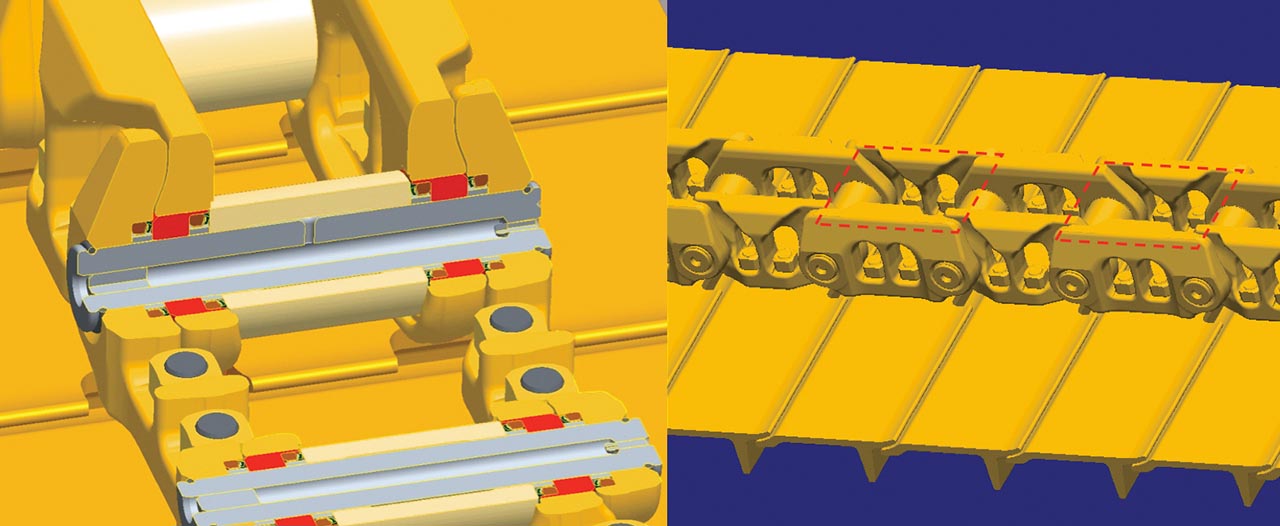

Get the most from your dozer. The Parallel Link Undercarriage System (PLUS) with rotating bushings delivers up to twice the life of our conventional undercarriage with no pin and bushing turn required. Parts wear evenly and last longer before needing replacement.

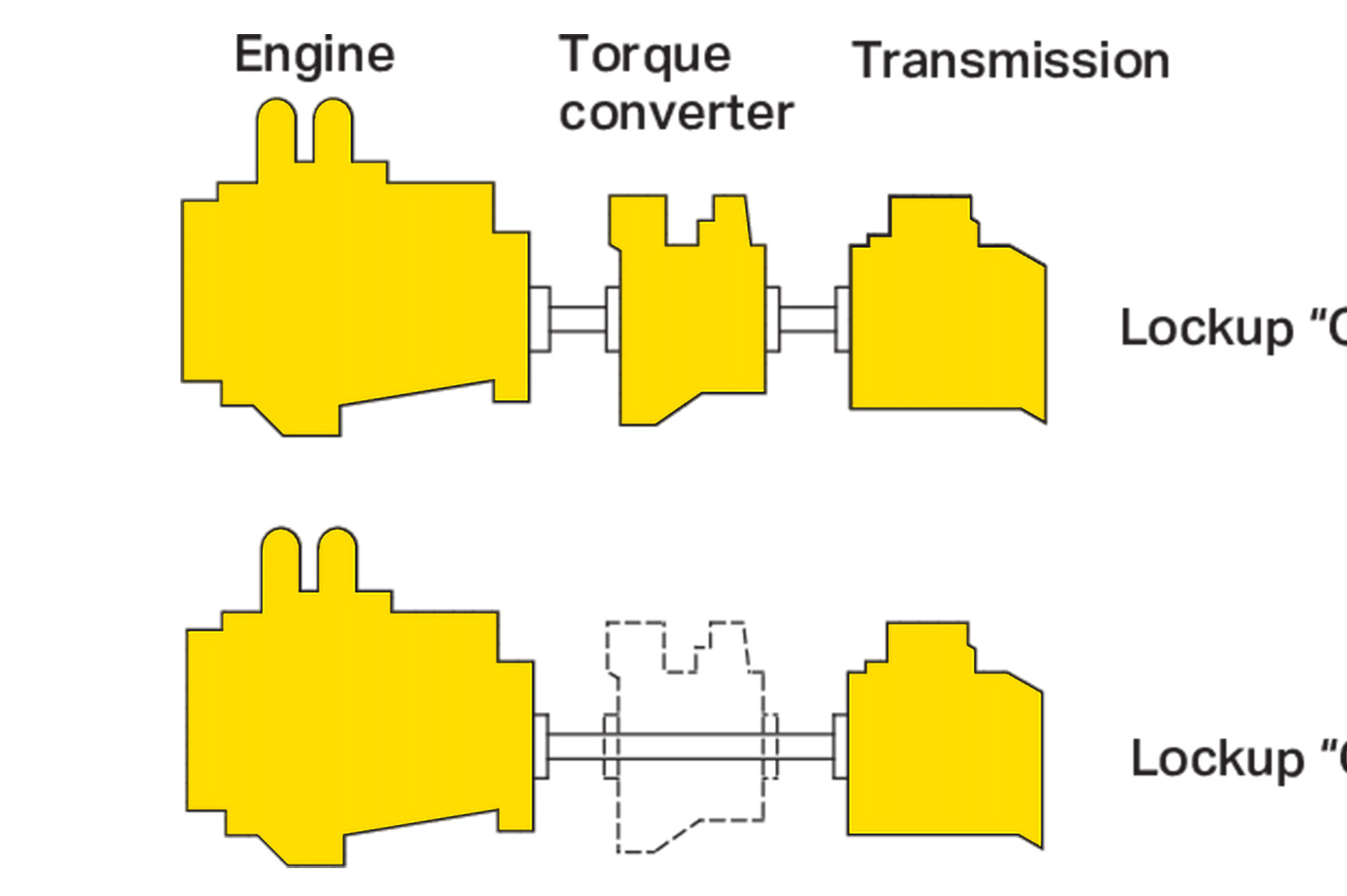

Seek maximum work efficiency with a lock-up torque converter. It determines the appropriate gear based on load and conditions. The lockup mechanism then automatically transfers engine power directly to the transmission, helping boost drive train efficiency.

With automatic dozing, rough cut to finish grade, iMC-equipped machines make every pass count. Dozers “learn” operator blade input. In select situations, operators can opt for near-100% auto control. And, iMC helps new operators get up to speed quickly.

Your operators perform best when they’re comfortable. That’s why they’ll love the air suspension seat with lumbar support and tilt. It’s easy for them to adjust to suit their needs, and electric heat helps them stay comfortable in the cold.

A standard rear camera monitoring system displays the view behind the dozer on the large color monitor in the cab.

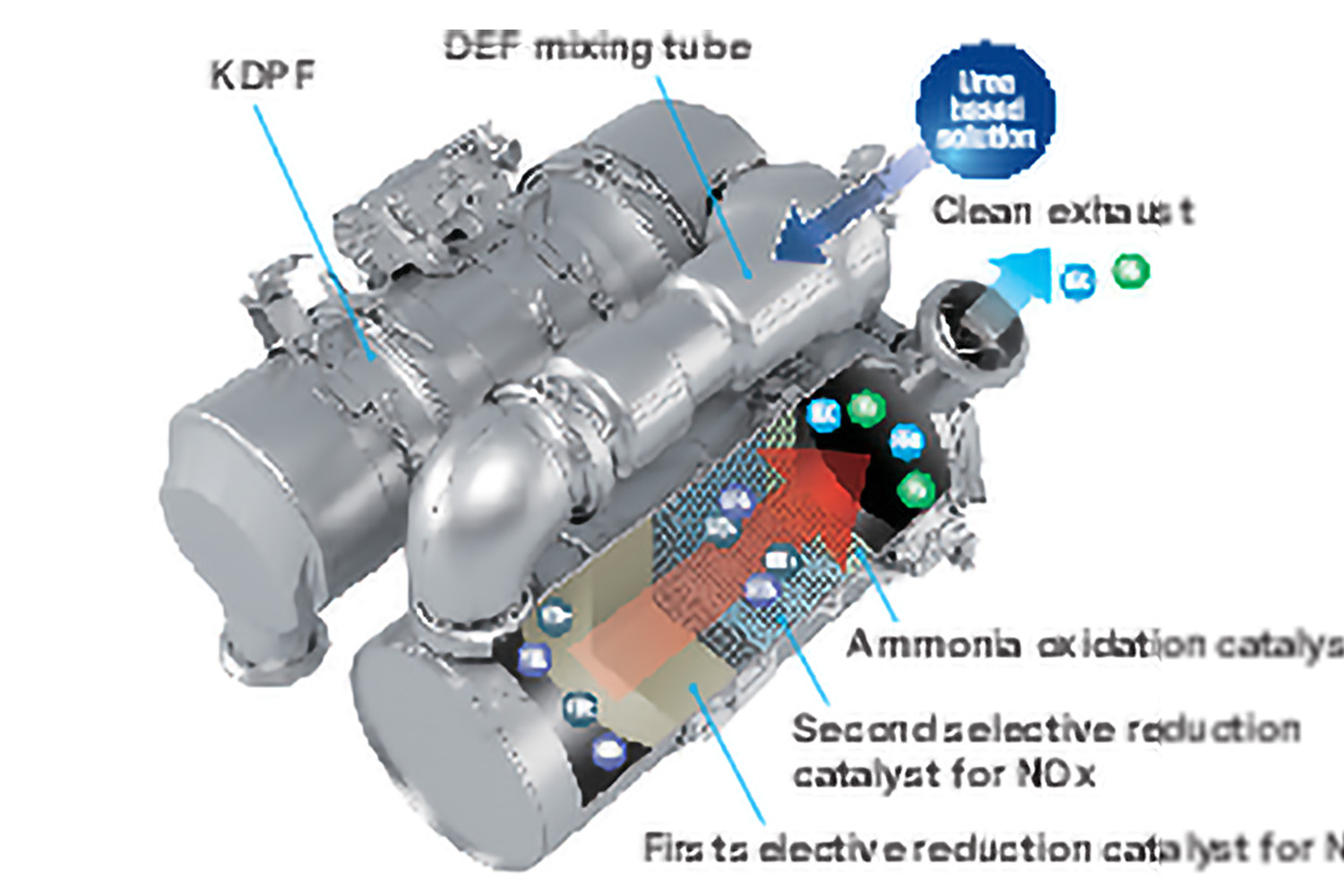

Tier 4 machines use diesel particulate filters to burn off engine soot via regeneration. To help make sure it rarely impacts your operation, all D65/D85/D155 models use continuous passive regeneration, and active regeneration that typically doesn’t require the dozer to stop.

Telematics data can drive results for business operations, but only when you can collect and analyze it efficiently. Get the insights that can benefit your bottom line.

Positions

Horsepower

Lubrication system

Reverse

Forward

Ripper equipment (additional volume)

Tractor weight

Operating weight

* Dozer assembly and rear mounted equipment are not included in base machine standard equipment

** Cab meets OSHA/MSHA ROPS and FOPS Level 2 standards (ROPS standards ISO 3471, SAE J/ISO 3471; FOPS standards ISO 3449)

* Dozer assembly and rear mounted equipment are not included in base machine standard equipment

** Cab meets OSHA/MSHA ROPS and FOPS Level 2 standards (ROPS standards ISO 3471, SAE J/ISO 3471; FOPS standards ISO 3449)

Find what works for you