Telematics

Telematics data can drive results for business operations, but only when you can collect and analyze it efficiently. Get the insights that can benefit your bottom line.

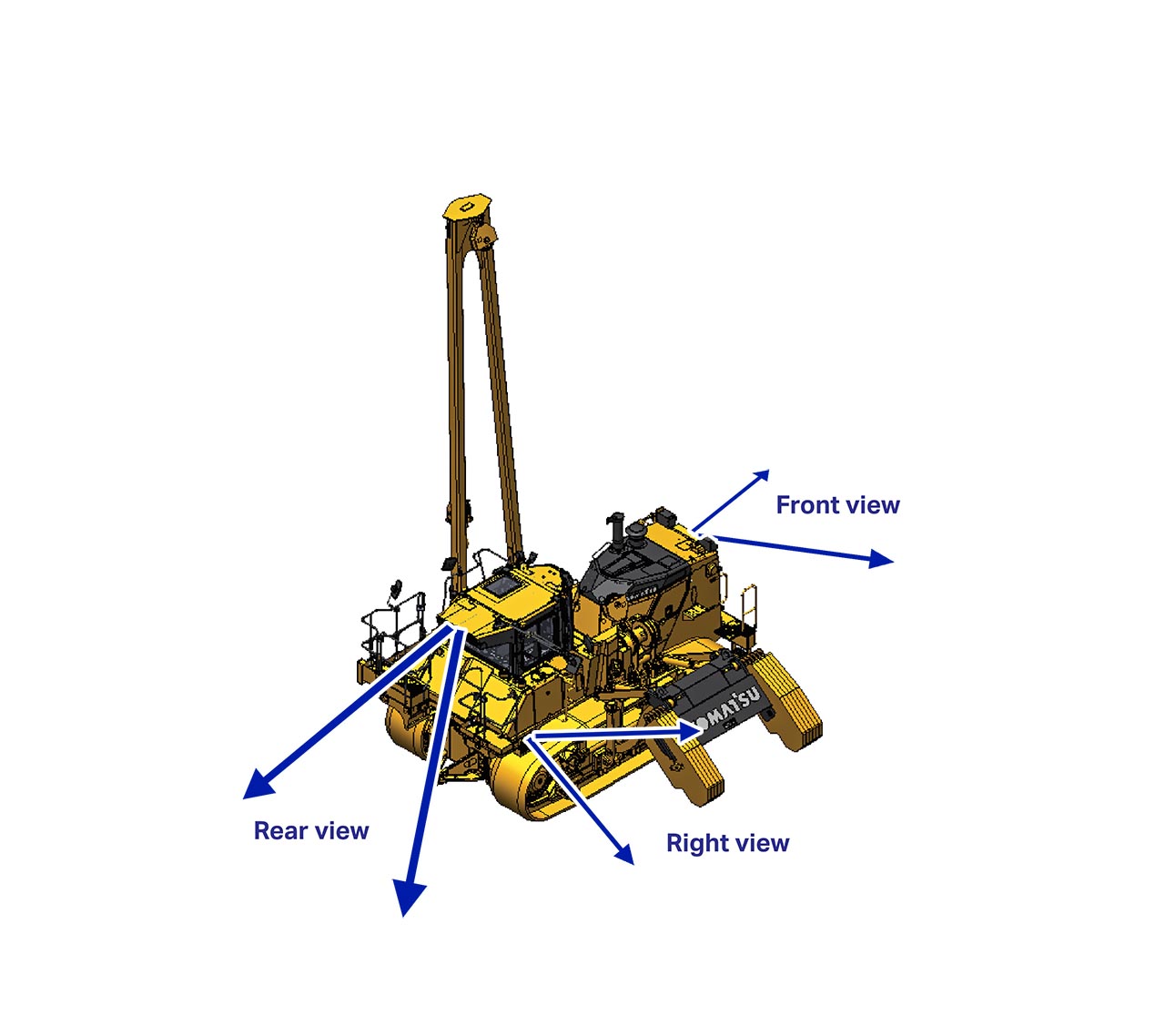

Developed and designed in conjunction with pipeline companies, the D155CX-8 has a 170,000-pound lift capacity and traditional oval track design to deliver the stability and performance required on large pipeline jobs. The draw works package and boom options have been specifically designed for handling up to 36-inch steel pipe, making it ideal for gas and oil projects.

Extended track roller frames and wider track gauge over previous models provide a solid foundation for pipe lifting. Large 9-inch track pitch undercarriage is built for pipelayer applications.

Exceptional structural strength with a new front bumper and integrated towing pin designed to accept a standard winch rope terminator. An extended main frame with a non-oscillating hard bar has all drawworks mounts factory integrated.

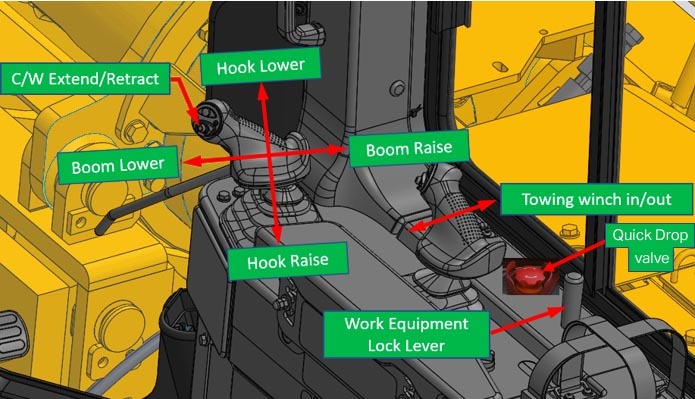

The drawworks package uses custom-designed winches built to Komatsu specifications. Excellent hook speed, boom and counterweight control make precision pipework or handling large loads easy and efficient.

Easily access your machine with integrated left/right front steps, left access ladder and left/right rear walkways.

Integrated load block transport storage bracket makes disassembly and assembly easier for shipping.

Standard enclosed ROPS cab with auto climate control, large cab windows and skylight viewing area provides a comfortable operator environment in hot and cold climates.

Improve your operator confidence with standard front, rear and right-side cameras that provide improved situational awareness around the machine.

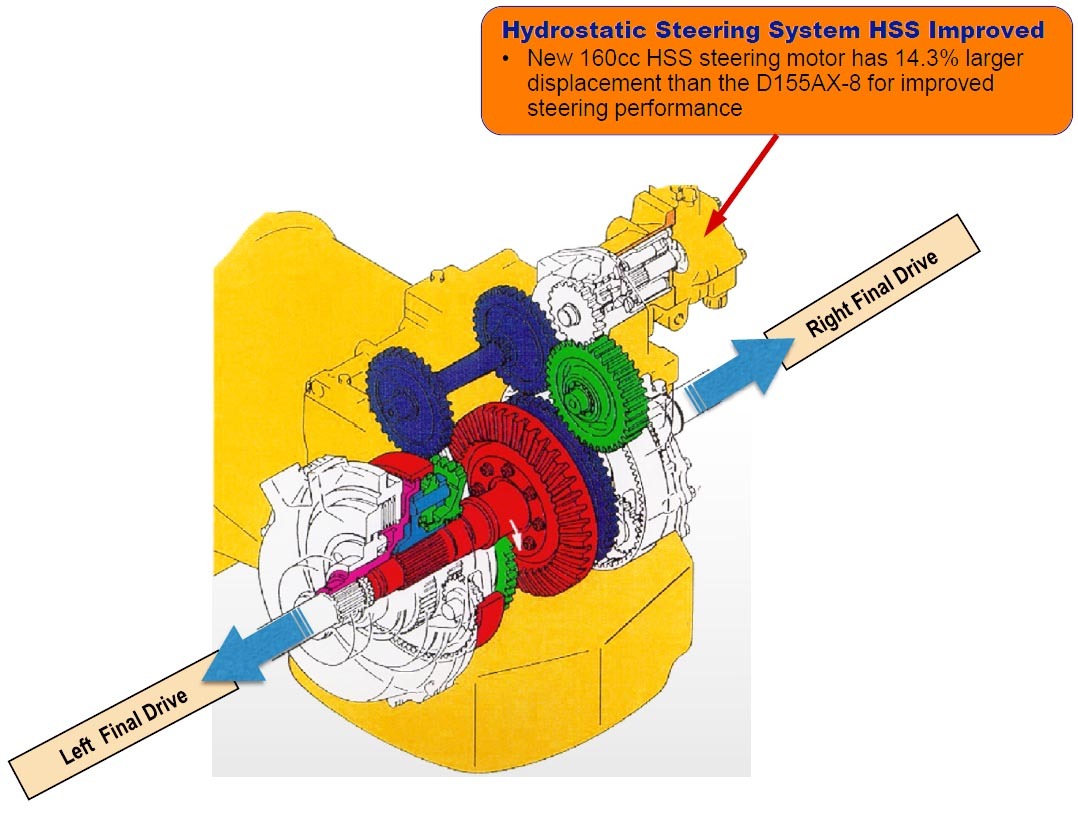

The Hydrostatic Steering System (HSS) with all-directional Palm Command Control System lever controls provide smooth, quick and powerful steering control in various ground conditions. A new 14% larger steering motor than the D155AX-8 base model improves steering power and maneuverability.

A single joystick for control of load line, boom and counterweight provides your operator precise load control.

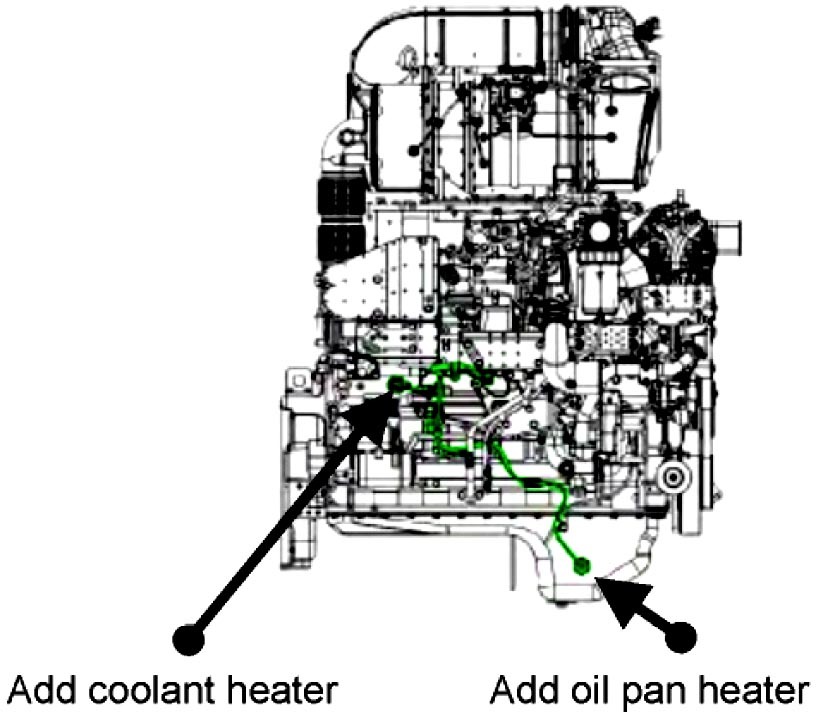

Designed for cold weather operation with large capacity batteries, engine air intake heater grid, and provisions to easily install engine oil and coolant heaters.

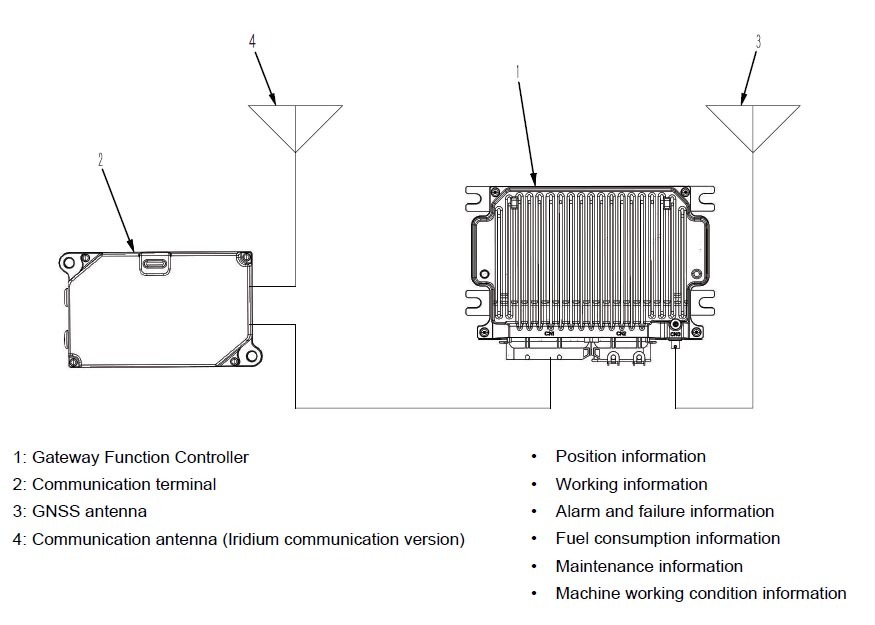

High quality satellite data communications for Komtrax pipelayer telematics in remote areas where cellular communication network coverage is poor or not available. Komtrax data is provided free for life of the machine.

Continuously monitor your machines operation and vital systems to identify machine issues, assist with troubleshooting, and minimize downtime.

Horsepower

Lubrication system

Reverse

Forward

Telematics data can drive results for business operations, but only when you can collect and analyze it efficiently. Get the insights that can benefit your bottom line.

Find what works for you