Crushing

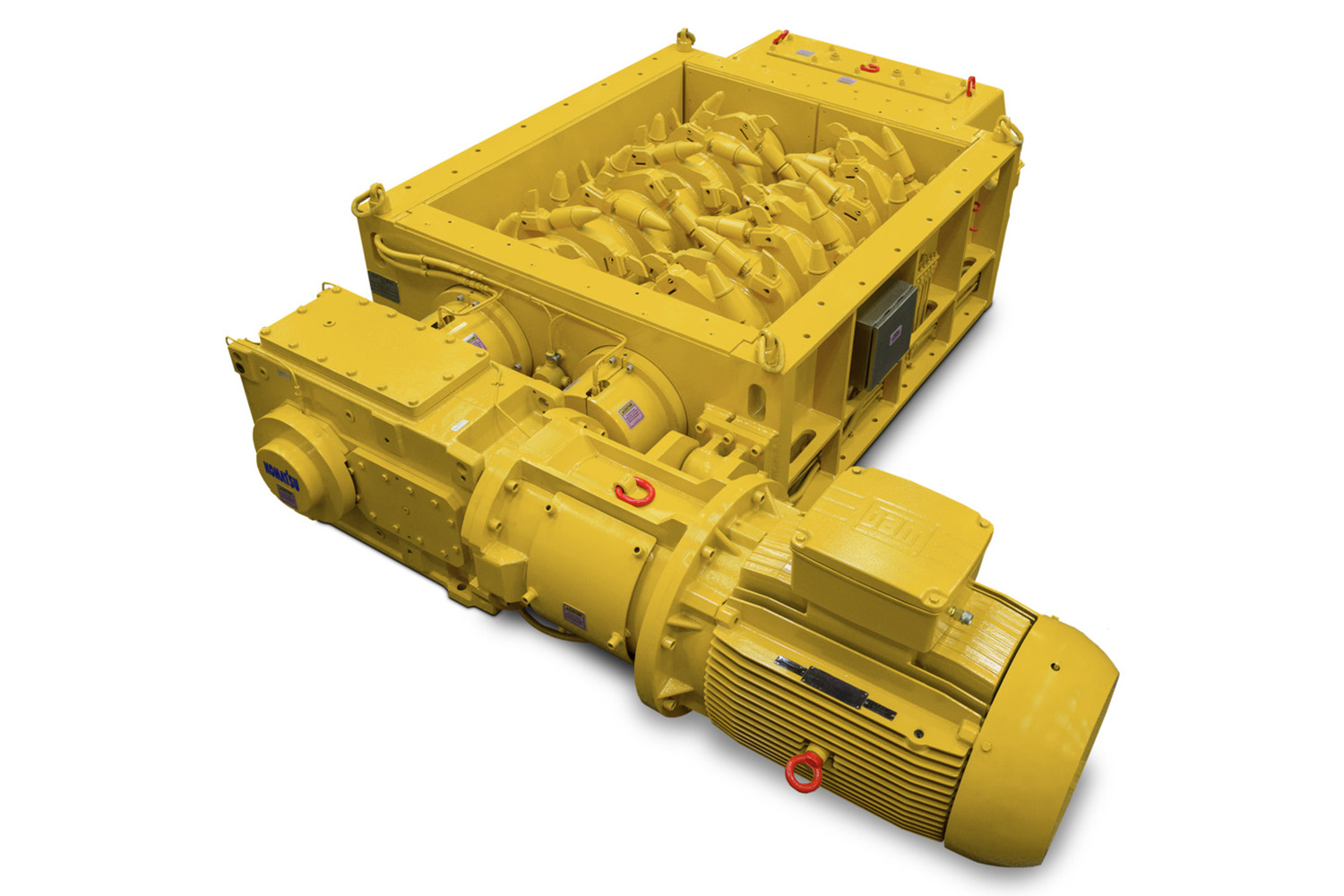

XRS 600

Sizers

- Capacity (MTPH) Up to 1 800

- Capacity (TPH) Up to 1,984

- Standard output product sizes (in) 6 or 8

- Standard output product sizes (mm) 150 or 200

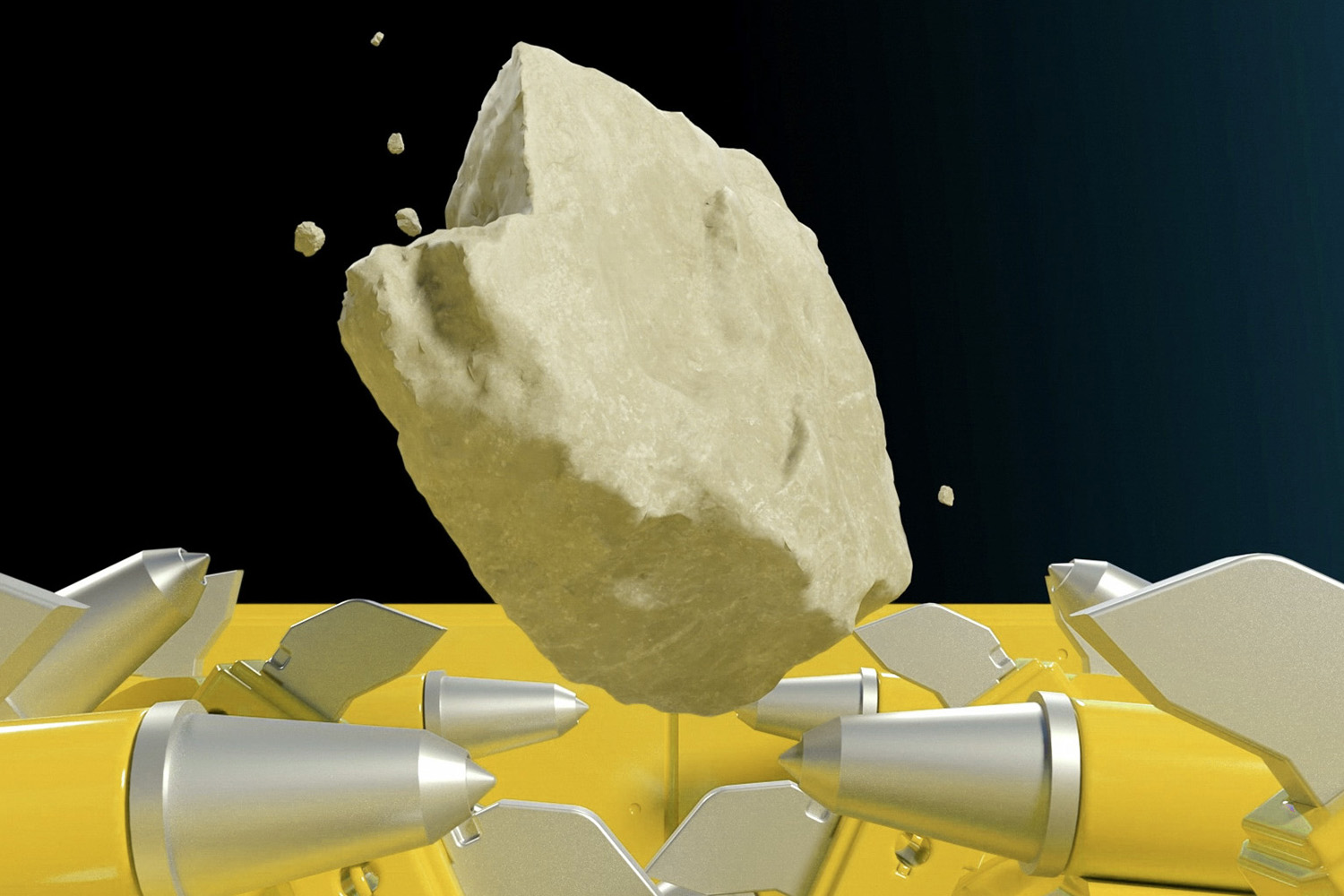

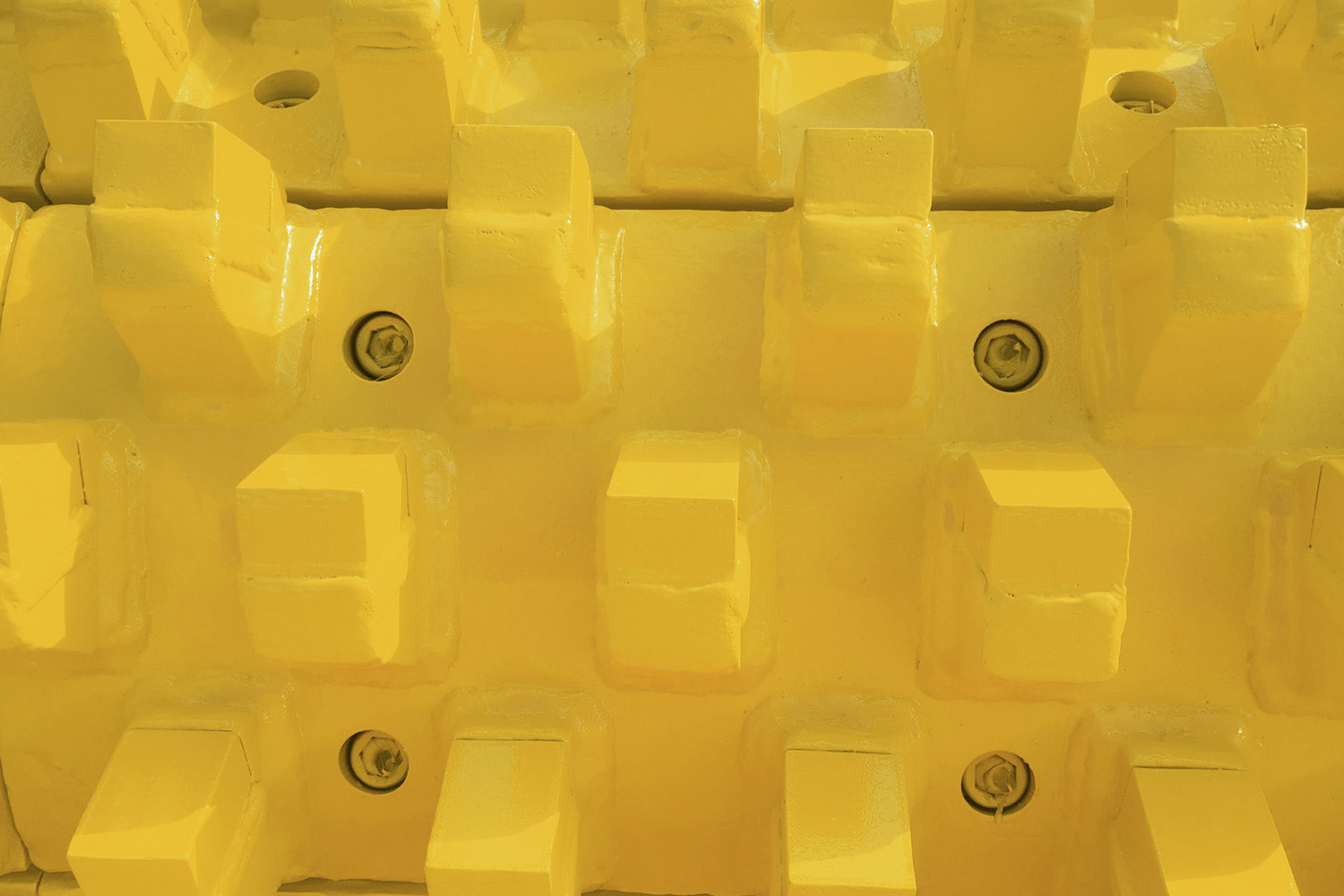

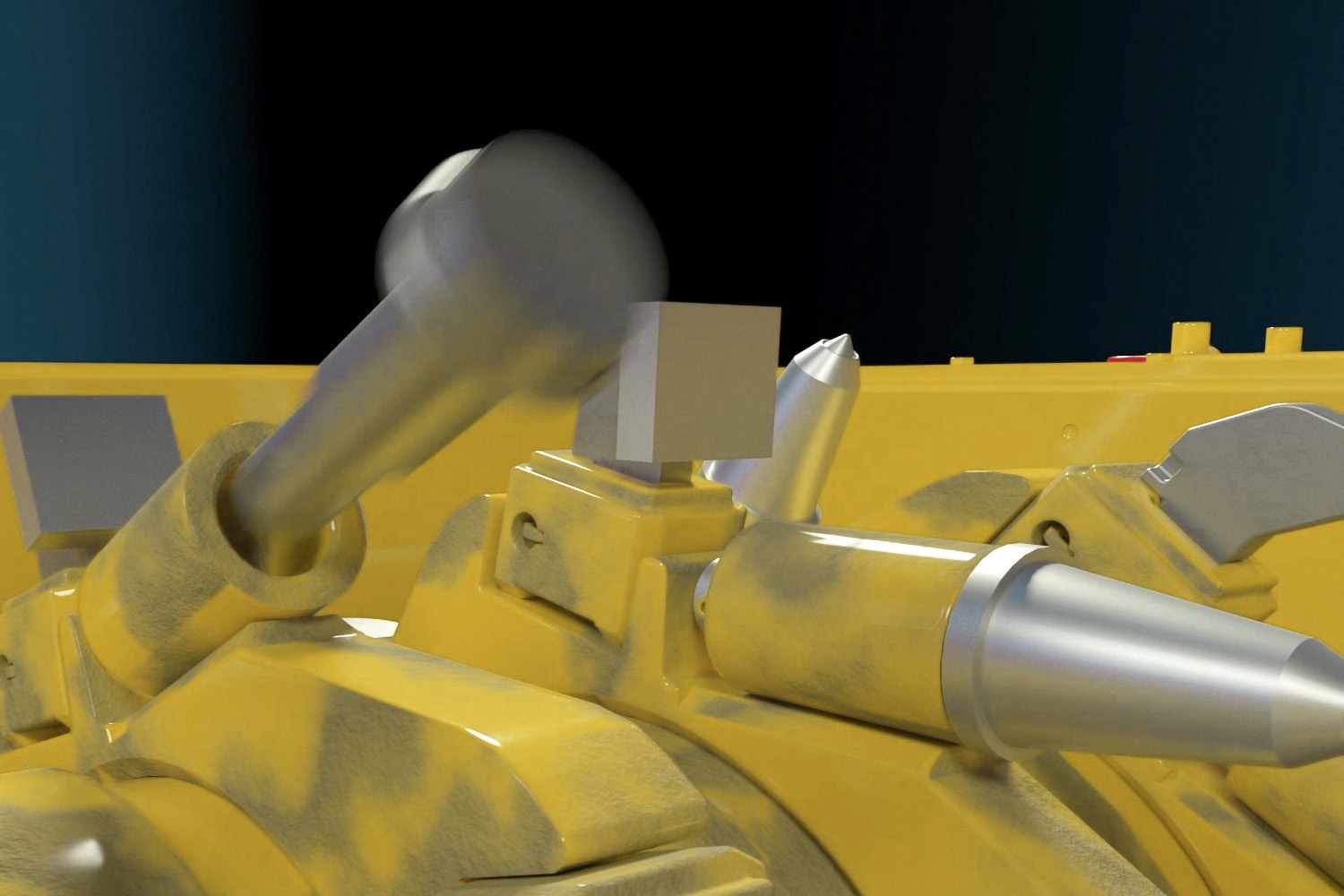

Wear-resistant pick technology

Primary sizers use wear-resistant pick technology developed from shearers, continuous miners and more than 3,500 feeder breakers. Several pick designs available to match your application - hard, abrasive or sticky. Control product sizing with adjustable, removable breaker bars and pick selection.

- Wear parts designed for long life

- Versatility for multiple applications

- Leverages advanced pick technology

Resources

Features and benefits

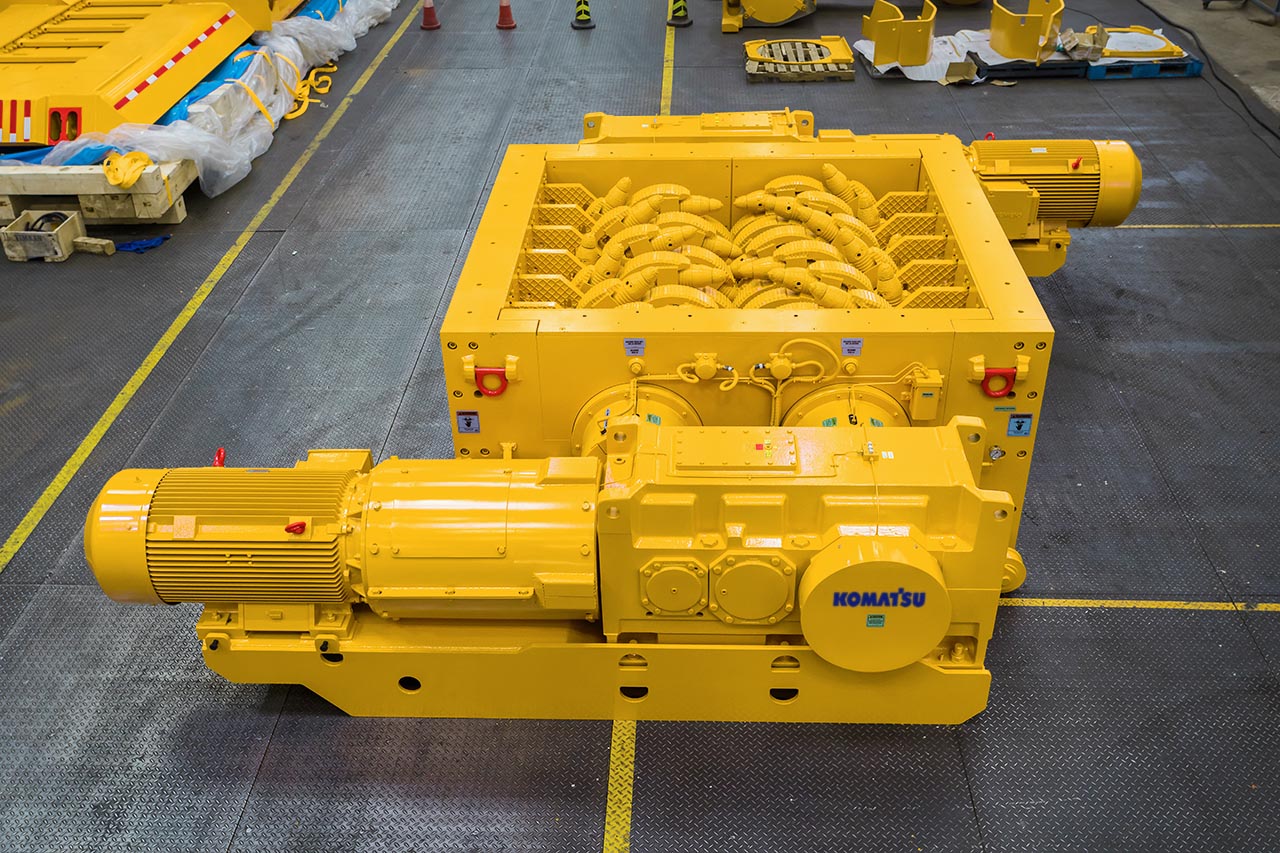

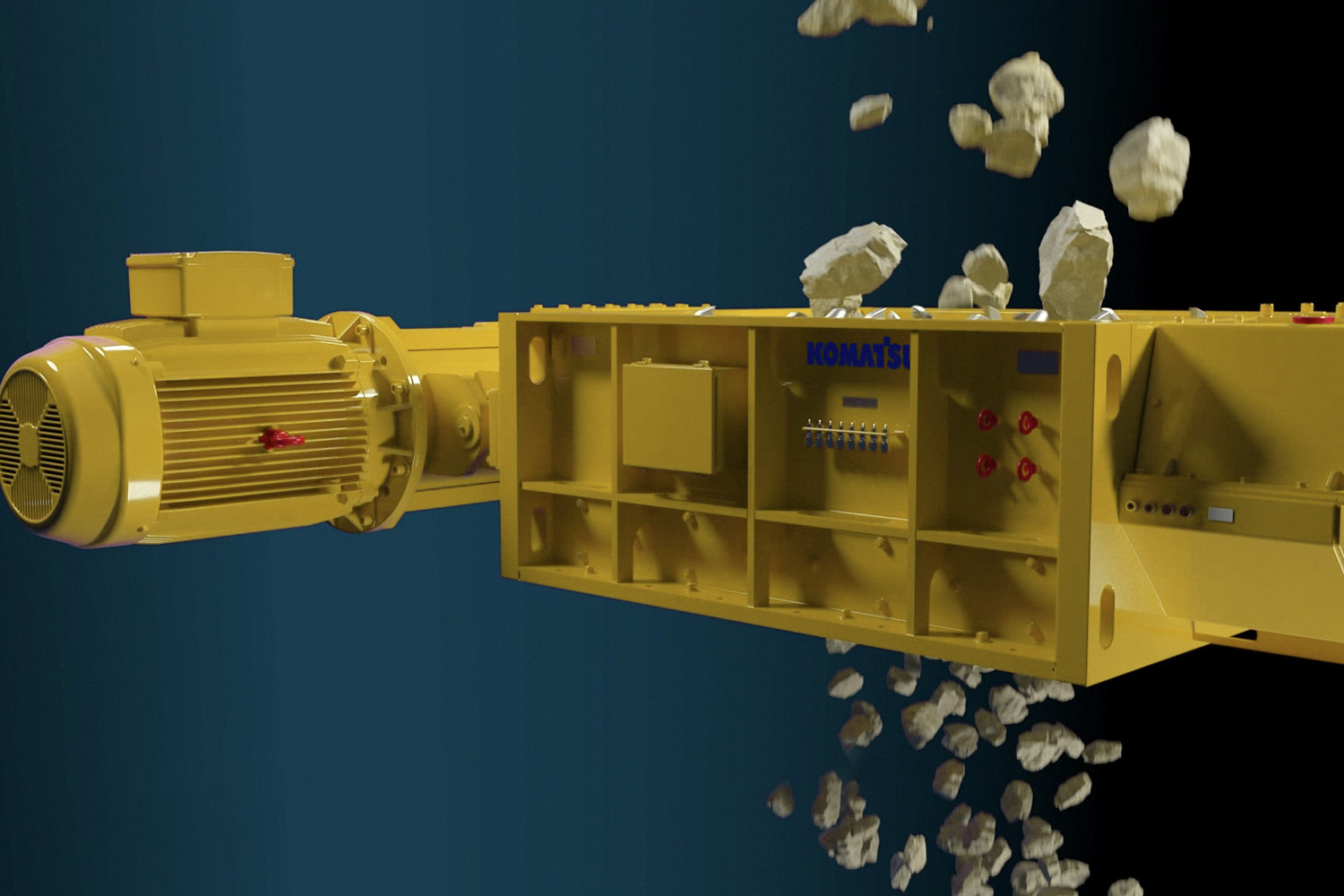

High capacity

High-capacity sizers reduce the number of crushing or dump stations required. Sizers can work with very large lump sizes to increase crushing ratios.

Reduce costs

To lower install costs, sizers can be installed where other crushers would not fit. Ideal for mobile or underground applications with a small machine envelope.

Ability to crush wet, sticky materials

Cleaners in the frame effectively scrape off material accumulation. Sizers work well with wet and sticky materials to include clay, marl and tunnel spoil.

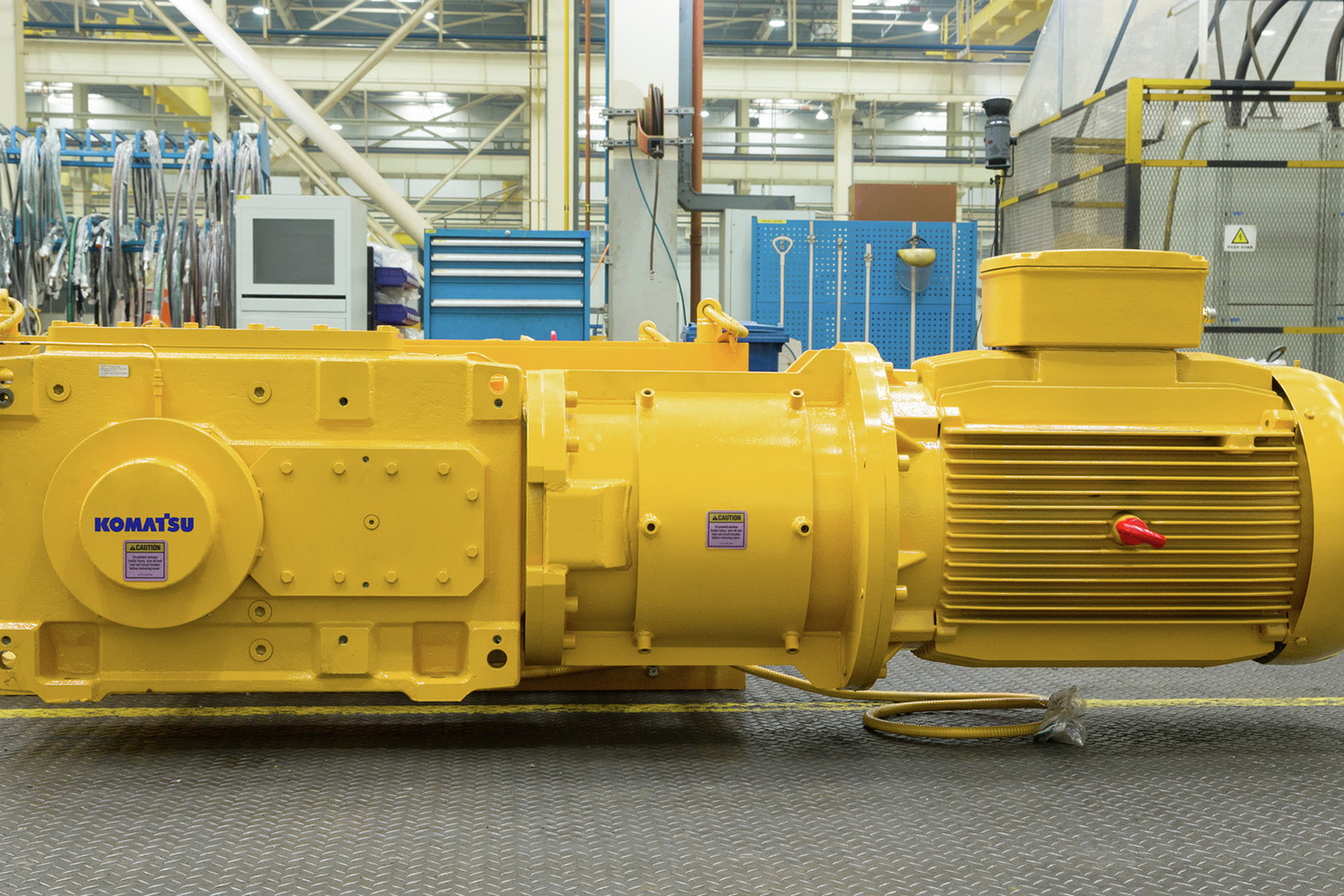

Efficient and cost-effective

Cost-effective design includes energy-efficient helical gear reducers, robust power transmission components, automatic lubrication system, extended life one- and two-piece picks. Smart machine technology to monitor operation and predict maintenance requirements.

Minimizes water and dust ingression

Many sites use water spray in the sizer to suppress dust and wash the mineral being crushed. Our sizers incorporate an outboard bearing design with a custom seal arrangement to minimize water and dust ingress.

Variety of pick designs

Choose from pick designs for hard, abrasive and sticky applications developed from experience with building thousands of feeder breakers, continuous miners and shearers.

Replaceable picks

Sizer shafts have replaceable picks that allow you to renew them compared to disposable competitive offerings.

Control product size

Control product size with adjustable, removable breaker bars and pick selection. Minimize transfer issues to chutes, transfer points and conveyor belts.

Instrumentation to increase reliability

Bearing temperature and vibration is monitored. Locked rotor detection alarms notify the operator to help minimize damage from tramp metal.

Specifications

- Full specs

- Application: Bauxite, phosphate, shale, coal, limestone, nickel, coke, borax, polyhalite, gypsum

- Capacity (TPH): Up to 1,984

- Capacity (MTPH): Up to 1 800

- Mass (tons): 11 - 15.4

- Mass (tonnes): 10 - 14

- Roll spacing (in): 23.6

- Roll spacing (mm): 600

- Feed size (in): Less than 23.6

- Feed size (mm): Less than 600

- Standard output product sizes (mm): 150 or 200

- Standard output product sizes (in): 6 or 8

- Roll length range (in): 39.4 - 98.4

- Roll length range (mm): 1 000 - 2 500

Support you can count on

Find what works for you