ProVision

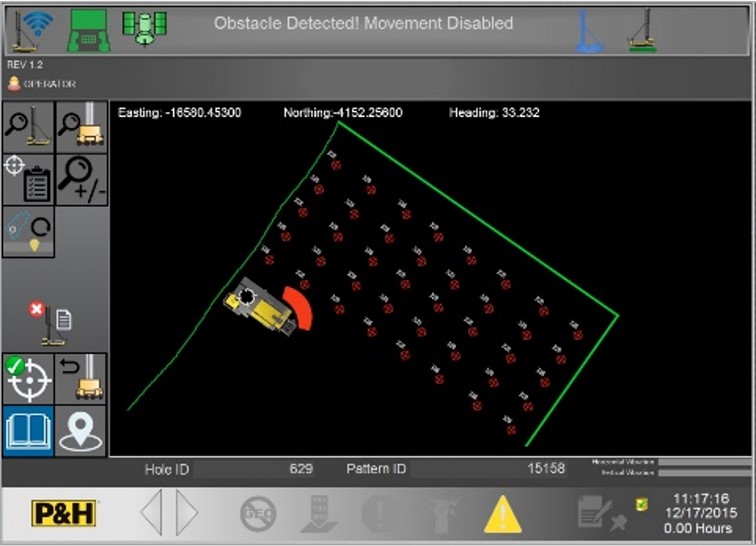

The ProVision Machine Guidance System provides comprehensive blast-hole drill monitoring capabilities and high-precision global navigation satellite system (HP-GNSS) positioning. The ProVision system promotes improved blast-hole drill rig efficiency, better equipment utilization, more precise hole positioning and depth, and greater compliance with final blast design goals.