Parts

Maintain functionality, extend life, and minimize downtime with top-of-the-line service products and consumables that meet increasing industry demands.

Product support

Remanufactured components

When you invest in equipment, you need to know how to care for your machines across all phases of the lifecycle. From initial machine assembly to service and rebuild work, Komatsu can help you to keep your machines running at peak performance.

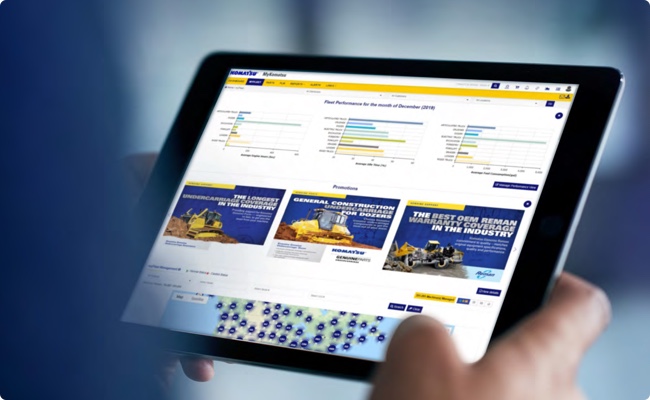

My Komatsu

If you’ve ever wanted a comprehensive digital hub that allows 24/7 access to machine telematics data, parts manuals, service manuals, software and parts ordering — all in a single place — we’ll partner with you to make sure that My Komatsu delivers exactly what you need.