1 min read

Komatsu helps an African iron ore mine increase overall equipment effectiveness and productivity through haul cycle automation

Case Study

- Overview

- Challenge

- Solution

- Results

Select continent

Komatsu’s Performance Assurance (PA) program is a next-level support initiative designed to ensure that each customer receives maximum sustained value over the life of their Komatsu technologies. With each PA engagement, a dedicated team of experts collaborates with a cross section of mine personnel to develop tailored, flexible, and proactive solutions to address each operation’s specific challenges. Participating mines have seen numerous benefits, including enhanced truck productivity, shorter queue times, reduced equipment maintenance costs, and more.

This case study details how the PA team helped the mine make the transition from manual to automated haul cycle tracking, which led to substantial improvements in just three months.

Recently, a large open-pit iron ore mine in South Africa—a long-time Komatsu customer and DISPATCH Fleet Management System (FMS) user—reached out to Komatsu PA for assistance. The mine sought to further leverage the DISPATCH System’s optimization algorithms and OEM interfaces to automate haul cycle tracking reduce their reliance on manual tracking methods.

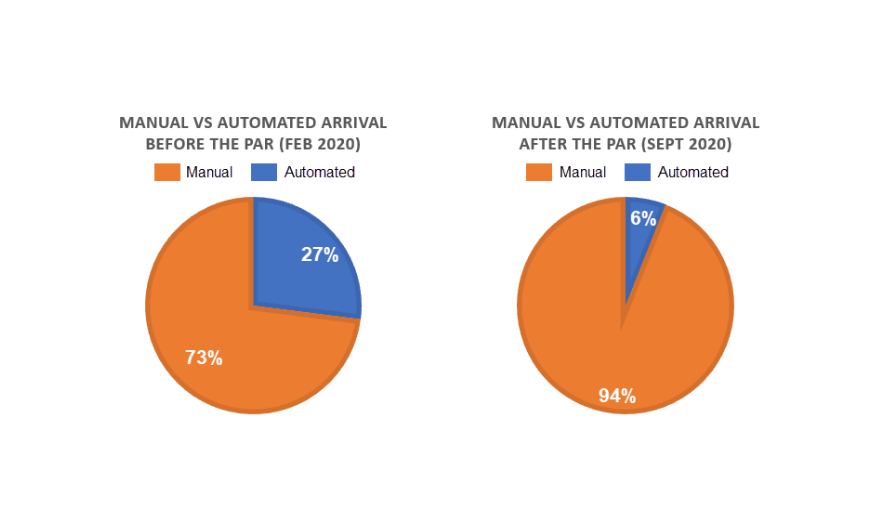

Working with mine leadership, the PA team conducted a thorough evaluation of continuous haul cycle data from the DISPATCH FMS and report inspections. From the results, the PA team identified that the haulage fleet operators were, on average, manually entering haul cycle arrivals at loading units 27% of the time, as shown in Figure 1:

Factors such as network connectivity, hardware maintenance, changes in roads and paths, placement of mobile access points, and system configuration, can all impact the operator’s need to manually input arrivals. However, as with any manual process, data accuracy can be comprised, therefore, fewer manual interactions is the goal. Reducing the occurrence of manual processes also presents an opportunity for the mine to improve their operations.

Factors such as network connectivity, hardware maintenance, changes in roads and paths, placement of mobile access points, and system configuration, can all impact the operator’s need to manually input arrivals. However, as with any manual process, data accuracy can be comprised, therefore, fewer manual interactions is the goal. Reducing the occurrence of manual processes also presents an opportunity for the mine to improve their operations.

As in this case, the accuracy of captured cycle times was negatively affected, and the number of haul cycle exceptions that had to be managed by the control room, increased. The overall effect of this was limiting the mine’s ability to further optimize their haul cycle.

Once the PA team and mine personnel uncovered the opportunity to improve and automate haul cycle arrives, the team focused on enhancing the DISPATCH FMS’ haul cycle automation (HCA) functionality to address the mine’s challenges. The main objective of HCA is to automate the initiation of the haul cycle actions captured in the DISPATCH FMS, such as:

- The assignment to the loading unit whilst at the dumping location

- The arrival at endpoint locations (loading units, benches, dumps, crushers and stockpiles)

- The start of loading at the loading unit

- The end of loading at the loading unit and assignment to dump location.

The HCA functionality combines location, time, and equipment information to create a comprehensive picture of the haulage cycle. Each destination, such as loading units, benches, dumps, crushers, and stockpiles, is assigned a virtual GPS beacon consisting of a reference location and a radius. When the truck detects that it is within range of the beacon and the truck’s velocity is below a specific threshold, the truck automatically sends the ARRIVE action to the DISPATCH System’s central server via the truck’s on-board hardware.

The central server then records the ARRIVE equipment and location and automatically advances the equipment to the next stage in the haulage cycle. The system can be configured to leverage onboard equipment sensors for cycle state automation.

The HCA functionality is the driving force in haulage optimization with the primary objective to reduce the need for the operator to interact with the in-cab mobile field computer. The benefits of this include:

- Improved the accuracy of captured cycle times

- Improved optimization levels

- Fewer exceptions that need to be handled by dispatchers in the central control room

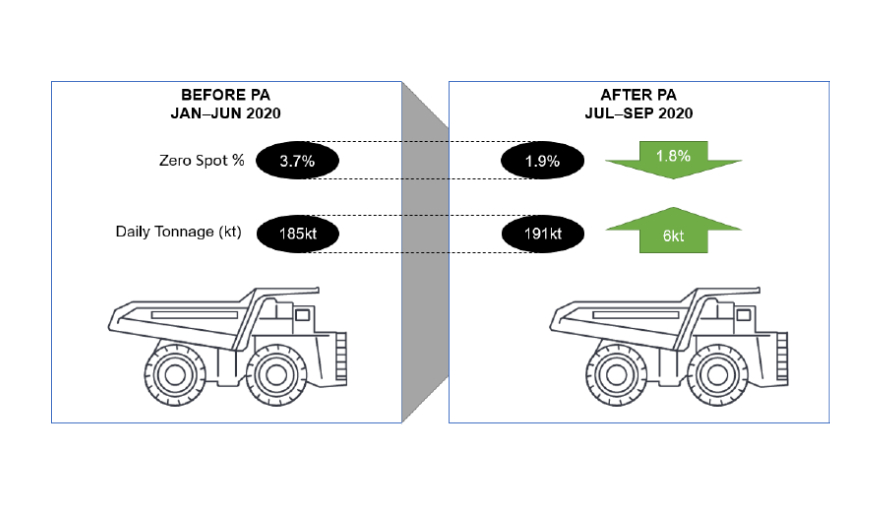

The PA team worked with the mine to enhance the current HCA functionality to meet their specific challenges. In July 2020, the PA team implemented the enhanced HCA functionality, and within three months, it had reduced manual cycle usage which, in turn, increased the data quality and accuracy used in fleet optimization.

As a result, the occurrence of zero spots reduced from 3.7% to 1.9%, for an improvement of 1.6 %. This ultimately led to a 6 ktonne increase in production per day, as shown in Figure 2. The PA team anticipates the improvement could equate to approximately 2 million additional ktonnes, per annum.

By leveraging the PA team’s expertise, the mine successfully improved its overall equipment effectiveness and data quality, and reduced the workload of personnel in the control room. This enabled the mine to take a significant step towards meeting their strategic goals defined at their corporate level.

Haul Cycle Automation pie chart

Haul Cycle Automation pie chart

HCA Before and After

HCA Before and After