1 min read

Komatsu enables large Canadian oil sands operation to achieve significant production gains with Argus Payload

- Overview

- Challenge

- Solution

- Results

- Implementation

- Sustained Improvement

- Conclusion

Select continent

This Canadian mine is one of the largest producers of heavy crude oil in Canada, operating nine electric rope shovels and several hydraulic excavators. The site also uses a mixed fleet of haul trucks predominantly within the 360-ton range and moves between 500,000 tonnes and 1,000,000 tonnes of ore and waste per day on their primary shovels.

The large oil sands mine currently leverages Argus on its six P&H shovels to optimize payload performance. This case study details how the Key Account Manager (KAM) team helped the mine implement the Argus Payload Management system on their remaining CAT495 electric rope shovels, which led to substantial improvements in under four months.

The mine sought to move more material while increasing payload compliance on their fleet of three CAT 495 electric shovels. The previous payload system on the shovels relied on the truck onboard scales to relay information to their fleet management system. These onboard scales were often inaccurate due to re-weighing the truck after it had left the pit (resulting in unexpected payload increases or decreases post load), difficult scale maintenance schedules or often did not function at all (blank value).

In addition, the majority of the fleet of CAT 797 trucks is leased to the mine. As part of the leasing agreement, the mine is fined anytime a truck weighs in over 120% of payload capacity. Given the inaccuracies mentioned above, the mine was experiencing 120%+ payload events on a regular basis. This resulted in the operation facing the potential of millions of dollars in fines, as there were no other payload measurements to refute the scales.

To overcome this challenge, the mine sought to increase payload compliance while reducing major overloads and underloads by providing shovel operators with real-time feedback on shovel payload.

The Komatsu Argus Payload Management system helps optimize operator efficiency in loading by providing bucket by bucket payload information to the shovel operator while also providing truck target payload on-board the operator screen.

Underloads remained less than 2% of the total of which some can be attributed to weather events, and major overloads remained suppressed.

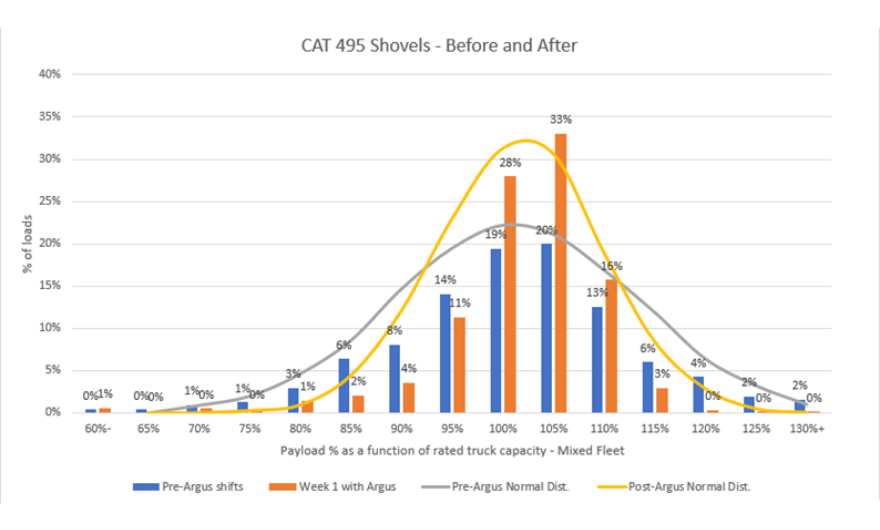

The performance improvement within just the first week of implementation was notable with the payload distribution tightening significantly (Figure 1). There was also a significant reduction in underloads and overloads as trucks were loaded closer to their rated payload capacity.

While the average payload to target capacity before and after increases by less than 1% (98.57% to 99.18%), the biggest gain was how the operators were achieving that average compliance value. The standard deviation between truckloads dropped from 11.87% to 8.09%, confirming that the operators used the Argus system to load more effectively. Major overloads dropped off completely, and underloads shrink significantly.

Prior to Argus, 20% of truckloads left the shovel under 90% capacity, with the average payload for underloaded trucks 81.5%. This equates to 65 tonnes short of a full load. Over a week, with an average of 5,500 truckloads on a predominantly CAT 797 fleet, this would result in an additional 71,500 tonnes moved at no additional cost between the 3 CAT 495 shovels.

On average, a CAT 797 moves 225,000 tonnes of material per month (based on May 2020). The above increase in achieving target on the 20% of underloaded trucks equates to 306,000 additional tonnes moved per month or parking a CAT 797 truck.

Major overloads reduced from 8% to 0.4% in the first week. Given that trucks that leave the pit with major overloads result in a fine, the reduction results in immediate cost savings.

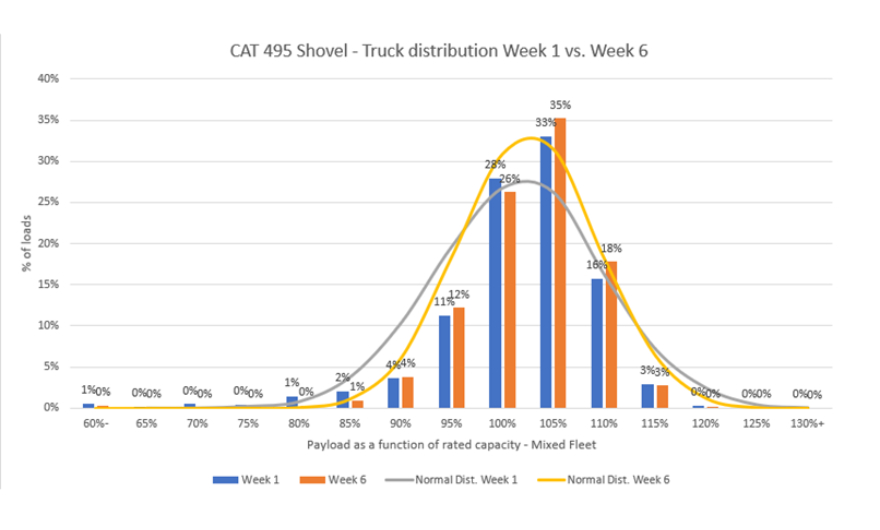

The results in Figure 2 show the first six weeks of operation for the three CAT 495 shovels. The baseline data was collected utilizing the truck scale information.

This reflects an adoption period where the operators continually improved the payload distribution around the target payload. During this period, there is a trend toward moving slightly above target (105% vs 100%) loads, and a complete reduction of overloading.

- Week 1 indicated quick adoption to the system. There were still 23 major overloads (>120%), and 274 loads below target (<90%). 92% of loads were within target (90-110%).

- By week 3, overloads (>120%) were reduced to 2, and underloads (<90%) were reduced to 132 for the week. 97% of loads were within target (90-110%).

- By week six, overloads (>120%) were at 2, underloads (<90%) were at 73, and loads in target (90-110%) were 98% of total.

On a predominantly CAT 797 truck fleet, correctly loading trucks would create an additional 11,100 tons of material moved during the week. This equates to an additional 577,000 tons moved per year on the three CAT 495 shovels, without any additional haulage equipment, effort, or training.

The Komatsu team worked with the mine to install the Argus system hardware on the three CAT 495 shovels during major Planned Maintenance (PM) outages. Once the final Programmable Logic Controller (PLC) work had confirmed the OEM on-board computers were providing data to the Argus system, the project moved into full implementation. The implementation included a weigh-scale study conducted over two weeks to determine the payload calibration required for Argus to produce the most accurate real-time weights.

The data was used to calibrate the Argus systems within a standard deviation of 2% or less between Argus and the ground scale. During this time, the Komatsu KAM trained the shovel operators on how to utilize the in-cab screen, showing them how to leverage the Argus details as a tool to manage their daily operation. Operators were instructed on where to find their KPI’s and benchmark targets, as well as how to reference the performance of the machine with other equipment operators (stress, tph, cycle time, load count, average pass payload). The KAM completed the study results, calibrations, and functional testing, and a meeting was organized to review with the mines management team.

The following results show the sustained improvement at site from week 7 through to week 14 (Figure 3). The operators continued to use Argus to achieve their payload targets post the install and adoption phases.

This indicated that the Argus system had been adopted by the operators and was being used as a payload performance enhancement tool.

The sustained results show a 5% increase in weekly loads (from 100% to 105%). On a predominantly CAT 797 truck fleet (358 ton target), this would equate to an additional 103,375 tons moved per week between the three shovels.

Underloads remained less than 2% of the total of which some can be attributed to weather events, and major overloads remained suppressed.

The collaboration between Komatsu and the mines’ site management is a key component to the success. The mine’s management indicated that the KPI’s set through the Argus Payload system would be used to monitor and measure operator performance.

Through repeatable and demonstrated improvements with all operators, new and experienced, and an engaged management team who check Argus reports daily, the site improved shovel efficiency significantly. Continual refining of targets to tighten the distribution curve further has been identified as part of the mines continuous improvement plan.

The collaboration between Komatsu and the mines’ site management is a key component to the success. The mine’s management indicated that the KPI’s set through the Argus Payload system would be used to monitor and measure operator performance.

Through repeatable and demonstrated improvements with all operators, new and experienced, and an engaged management team who check Argus reports daily, the site improved shovel efficiency significantly. Continual refining of targets to tighten the distribution curve further has been identified as part of the mines continuous improvement plan.

Figure 1 Argus Payload Canadian Oil Sands

Figure 1 Argus Payload Canadian Oil Sands

Figure 2 Argus Payload Canadian Oil Sands

Figure 2 Argus Payload Canadian Oil Sands