Joy Connect

Actionable insights to help solve your toughest challenges. JoyConnect uses data-driven intelligence gathered from electronics installed on Joy, Komatsu and third-party equipment.

Designed for maximum production in low-seam applications with a robust drive system and reduced maintenance with a Joy OptiDrive AC variable frequency drive, due to no commutator brushes to inspect or replace.

Designed for reliability with heavy-duty conveyor reducers and abrasion-resistant decking and chassis and rolling gears designed for optimal balance of volumetric load, vehicle dimensions, load-carrying ability and fatigue life.

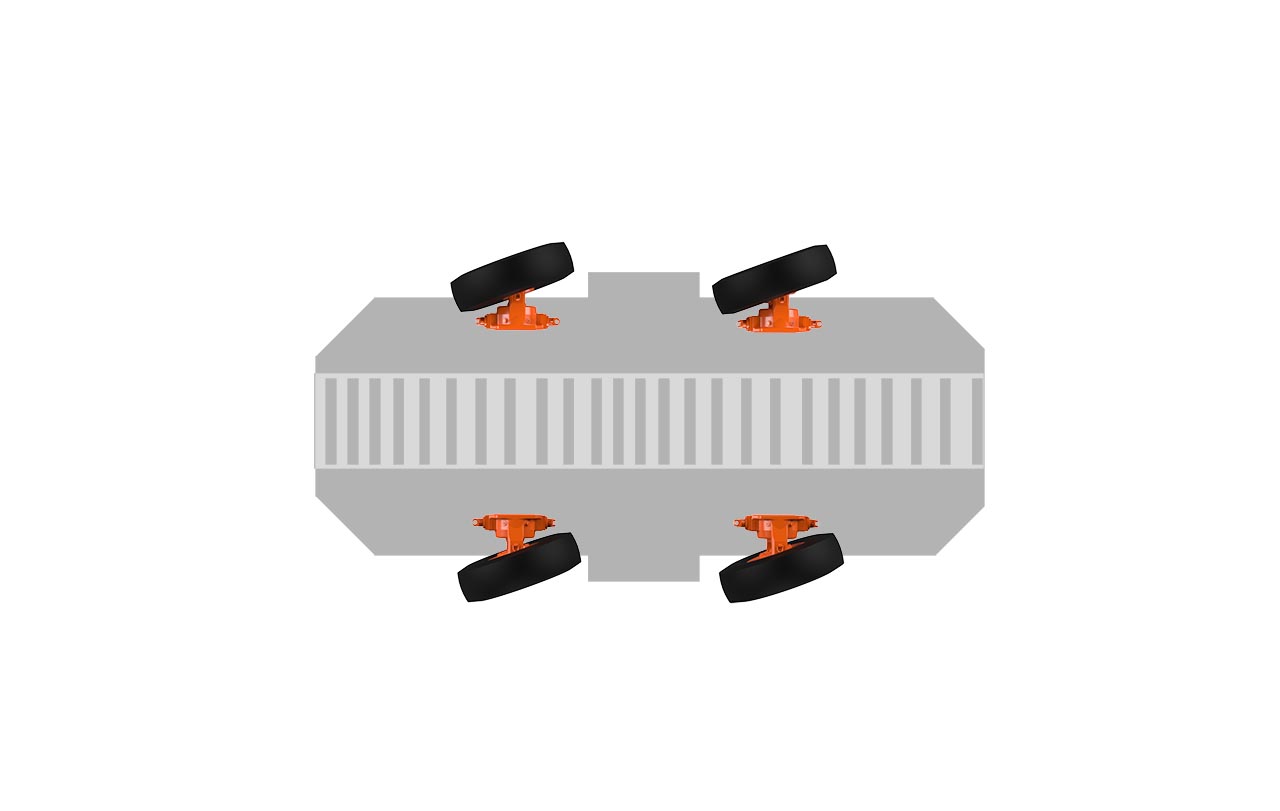

For uneven or broken roadways, Joy shuttle cars’ four-wheel independent suspension mitigates energy transferred to the chassis, designed for longer machine life and to help reduce operator fatigue.

With a swing-out controller and swing-out pump compartment, easy access to hose and cables helps reduce maintenance time. Lighting options and zoned-out difficult-to-access grease points further facilitate maintenance.

Variable frequency drive (VFD) conveyor reduces the shock loading of all key conveyor drive components to help ensure the reliability and availability of the conveyor system. Operators can adjust discharge rates to match the mine belt infrastructure.

All-time four-wheel drive system helps performance on soft bottoms and grades. Powered by two 85kW VFD AC traction motors (50 kW in lower seam models).

Four-wheel steering provides deft operation in narrow roadways. Non-suspension shuttle cars have crab steering, enabling an operator to turn all four wheels in the same direction for additional maneuverability.

Exceptional visibility using infrared or black-and-white cameras. One forward and one rearward-looking monitor are mounted in the operator’s compartment.

To help supply clean air for your operators, positive pressure is maintained by a hydraulically powered motor operating both blower and air conditioner in the operator compartment. Filter improves air quality. Available as an OE option on new cars, or a kit for existing cars.

An optional remote-control system can increase productivity of your room and pillar operations. An unmanned shuttle car can follow a continuous miner under an unsupported roof section, allowing for deeper cuts.

Actionable insights to help solve your toughest challenges. JoyConnect uses data-driven intelligence gathered from electronics installed on Joy, Komatsu and third-party equipment.

Variable frequency drive (VFD) conveyor reduces the shock loading of all key conveyor drive components to help ensure the reliability and availability of the conveyor system. Operators can adjust discharge rates to match the mine belt infrastructure.

Operators can perform more quickly and safely when they can easily see what’s in front of and behind the hauler. Optional forward and rearward FLIR cameras, mated to monitors in operator compartment, help operators be sure of their surroundings.