Wheel loaders

WA485-11

Large wheel loaders

- Horsepower (HP) 362 HP @ 1,600 rpm

- Horsepower (kW) 270 kW @ 1 600 rpm

- Bucket capacity (m^3) 4.9 - 5.5

- Bucket capacity (yd^3) 6.4 - 7.2

- Operating weight (kg) 27 865 - 28 575

- Operating weight (lbs) 61,432 - 64,997

Engineered for high productivity and low total cost of ownership

If you are looking for a versatile loader to help drive efficiency in your fleet, Komatsu’s WA485-11 is the right solution. Redesigned and engineered for increased productivity, lower fuel consumption and longer maintenance intervals.* An available WA485-11 yard loader (YL) configuration provides an ideal three-pass match with on-highway trucks.

- Up to 12% lower fuel consumption*

- 21% more engine power*

- 13% greater climbing speed*

*Compared to the WA480-8

Features and benefits

Increased engine power and efficiency

Komatsu DBA127 engine is compliant with U.S. EPA Tier 4 Final emissions. Redesigned and optimized with many advancements, such as proprietary technology to eliminate exhaust gas recirculation (EGR). This engine is designed for lower fuel consumption, and more power and torque at lower engine speeds.

Newly designed cab

A pressurized, large, four-pillar cab is designed to provide a quiet operator environment and features a new intuitive console design. Visibility was increased by 21% compared to the previous model by adding a lower glass area and eliminating the two rear pillars.

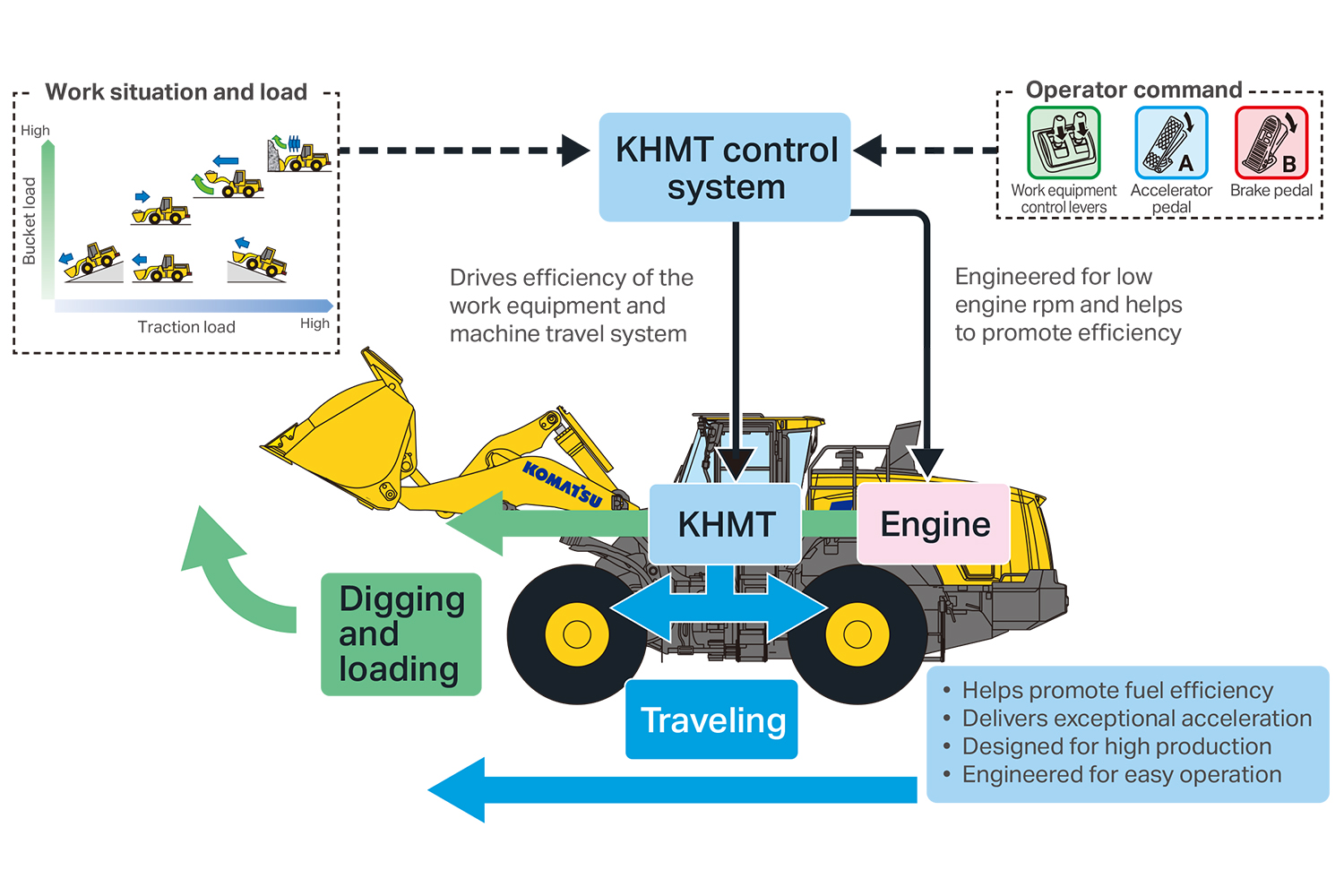

Komatsu Hydraulic Mechanical Transmission (KHMT)

Continuously variable transmission designed for high efficiency. Combining HST and the mechanical transmission in a dual power path allows excellent controllability and high transmission efficiency while promoting low fuel consumption. Dynamic braking of the transmission eliminates a separate brake cooling system.

Available yard loader (YL) configuration

Built for quarry and aggregate applications, the YL configuration is designed as a 3-pass match option for loading aggregate and other materials into on-highway trucks. The package includes a heavier counterweight, wide low-profile tires and rims, reinforced frame and optimized bucket size of 7.2 yd3 (5.5 m3).

Lower maintenance cost

Compared to WA480-8, this machine can help reduce maintenance costs by up to 21% due to an extended change interval for hydraulic oil and oil filters from 2,000 to 6,000 hours and an extended KDPF cleaning interval from 4,500 to 8,000 hours. Also, oil drain intervals can be extended up to 1000 hours.

Angle feedback joystick steering

AFJS articulates the vehicle body according to the tilt angle of the joystick. The joystick operation is converted into electrical signals for a smooth steering feel with less operating force, which may reduce wrist strain. Operators can adjust this low-effort drive-by-wire system. A steering wheel option is still available.

Independent work equipment control

Work equipment speed can be controlled with levers. Engine speed is automatically optimized based on lever operation without pressing an accelerator pedal. This separates the transmission control from work equipment, simplifies operation and reduces brake wear during hopper or truck loading.

Rear object detection system

Two rear-side radars are designed to detect objects and working machines approaching in the direction of travel while reversing the machine. A warning buzzer and indicator light alert the operator of a potential collision. False detection reduction functions help maintain uptime while promoting zero harm.

High-performance bucket

The optimized cross-sectional shape is designed for digging efficiency. The material is scooped and rolled up along the inclined floor of the bucket. Combining this redesigned bucket and the auto digging system can help boost productivity, especially for newer operators.

Specifications

- Full specs

-

Steering System

- Hydraulic pump for steering system: Piston pump

- Capacity for steering system (at rated rpm) (US gpm): 41.7

- Capacity for steering system (at rated rpm) (L/min): 157.7

- Hydraulic cylinders type for steering system: Double-acting, piston type

- Number of cylinders in hydraulic cylinders: 2

- Bore x stroke (in): 3.7 x 1.5

- Bore x stroke (mm): 95 x 441

-

Loader control

- Hydraulic cylinder type for loader control: Double-acting, piston type

- Hydraulic pump: Piston pump

- Relief valve setting (psi): 5,120

- Relief valve setting (Mpa / kgf/cm^2): 35.3 / 360

-

Cylinders

- Lift cylinder - 2 (mm): 150 x 818

- Bucket cylinder - 1 (mm): 180 x 621

- Control valve: 2-spool type

-

Control positions

- Boom: Raise, hold, lower, and float

- Bucket: Tilt-back, hold, and dump

-

Hydraulic cycle time (rated load in bucket)

- Raise (s): 6.1

- Dump (s): 2.1

- Lower (Empty) (s): 3.2

- Transmission footnote: Measured with 26.5R25 tires

- Type: Hydraulic Mechanical planetary type

-

Travel speed

- Forward (mph): 1.9 - 23.6

- Forward (kph): 3.0 - 38.0

- Reverse (kph): 3.0 - 28.0

- Reverse (mph): 1.9 - 17.4

- Cooling system (US gal): 17.4

- Cooling system (L): 66

- Fuel tank (L): 359

- Fuel tank (US gal): 94.8

- Engine (L): 41

- Engine (US gal): 10.8

- Hydraulic system (US gal): 34.9

- Hydraulic system (L): 132

- Axle front (L): 56.5

- Axle front (US gal): 14.9

- Axle rear (L): 56.5

- Axle rear (US gal): 14.9

- DEF tank (US gal): 15.9

- DEF tank (L): 60

- Transfer case (US gal): 10.6

- Transfer case (L): 40

- Service brake: Hydraulically actuated, wet multiple-disc brakes actuate on four wheels

- Parking brake: Wet multiple-disc brake

- Secondary brake: One of dual service brake circuits is commonly used

- Engine Model: Komatsu DBA127

- Aspiration: Turbo-charged, after-cooled

- Number of cylinders in engine: 6

- Bore x stroke of engine (in): 5.1 x 6.3

- Bore x stroke of engine (mm): 130 x 160

- Piston displacement (L): 12.74

- Governor: All-speed, electronic

- Model footnote: * Net horsepower at the maximum speed of radiator cooling fan is 347 HP (259 kW). U.S, EPA Tier 4 Final and EU Stage V emissions certified.

-

Lubrication system

- Method: Gear pump, force-lubrication

- Filter: Full-flow type

- Air cleaner: Dry type with double elements and dust evacuator, plus dust indicator

-

Horsepower

- SAEJ1995 - Gross (HP): 363

- SAEJ1995 - Gross (kW): 271

- ISO 9249 / SAE J1349 - Net (HP): 362

- ISO 9249 / SAE J1349 - Net (kW): 270

- Rated RPM: 1,600

- Fan drive method for radiator cooling: Hydraulic

- Fuel system: Direct injection

- Drive System: Four-wheel drive

- Front Axle: Fixed, semi-floating

- Axle Rear: Center-pin support, semi-floating, 26° total oscillation

- Final reduction gear: Planetary gear, single reduction

- Differential gear: Conventional type

- Reduction gear: Spiral bevel gear

- Steering system type: Articulated type, full-hydraulic power steering

- Steering angle: 35° each direction (40° to max end stop)

- Minimum turning radius at the center of outside tire (ft , in): 21 ft. 9 in

- Minimum turning radius at the center of outside tire (mm): 6 630

Support you can count on

Customer testimonials

WA485-11 wheel loader: Big upgrades in comfort, speed and efficiency

Hear it straight from an experienced operator about why the Komatsu WA485-11 wheel loader stands out. Offering more fuel efficiency and a smooth, comfortable cab ride, this machine is a perfect addition to your fleet. Whether you're in the market for a new loader or just curious about the latest tech in heavy equipment, Komatsu has you covered.

How the Komatsu WA485-11 wheel loader improves efficiency and comfort on the job

Hear from an experienced operator in Picayune, Mississippi, as he explains why the Komatsu WA485-11 wheel loader stands out on the job. From fuel efficiency to comfort and control, this machine helps him get the job done right. See what makes the WA485 a trusted part of his daily work.

Efficiency, safety and support: why Gulf Coast Sand chose the Komatsu WA485-11 wheel loader

Gulf Coast Sand shares how the Komatsu WA485-11 wheel loader is helping them tackle workforce challenges while boosting efficiency. From advanced safety features to standout support from Lyle Machinery, see why this machine has made an impact from day one.

WA485-11 wheel loader in action: power, comfort and efficiency at Vulcan Materials

Hear how the WA485-11 wheel loader is making a difference at an operation in Palmdale, CA. From improved operator comfort to powerful performance, Derek Lanier, an operator from Vulcan Materials shares how this machine is built to handle tough jobs with ease. Hear first hand why it stands out and how the WA485 has allowed them to improve efficiencies.

See the Komatsu WA475-11 wheel loader in action

The Komatsu WA475-11 wheel loader is built for efficiency and power. Hear from operators in Chicago about how this machine helps them move material with less fuel and more comfort on the job site. Watch it in action and learn why it’s a valuable addition to their fleet.

- Big upgrades

- Efficiency and comfort

- Gulf Coast Sand

- Vulcan

- WA475

Find what works for you