Actionable insights to help solve your toughest challenges. JoyConnect uses data-driven intelligence gathered from electronics installed on Joy, Komatsu and third-party equipment.

Leave the constraints of cables behind with Joy battery-powered haulage carts. Agile and versatile, particularly in low seam conditions, they offer you plenty of power to get the job done. Add the lithium-ion option for even more routing flexibility.

Brushless AC-traction motors drive each wheel independently and are designed to deliver maximum torque. Your operators enjoy excellent steering, smooth operation and strong performance on steep inclines. Regenerative braking enhances control on descents.

When conditions require extra traction, operators can hold down a button on the joystick to engage the trailer wheels for all-wheel-drive. No need to worry about problems with complex drive shafts, chains or sprockets.

Electronically activated steering assist for smooth-and-easy steering while relieving stress on motors, drivetrain and suspension assemblies.

The first lithium-Ion battery in soft rock mining is designed to boost productivity with 75% faster charge time, and much lower maintenance versus traditional lead acid technology. Contact your Komatsu representative for availability.

Pursue higher productivity with the Joy lithium battery charging option. Two hours from discharged to full charge. No cool down period. A partial charge still provides significant haulage ability. No ventilation required.

A gauge in the cab helps your operators monitor battery capacity. In the event of low remaining capacity, the system reduces features to conserve energy, so the operator can return to the charging area.

After off-loading, the ejector bed retract sequence is completely automated and takes place while your operators tram back to the miner. This simultaneous tram and retract can save significant time and allow more trips during a shift.

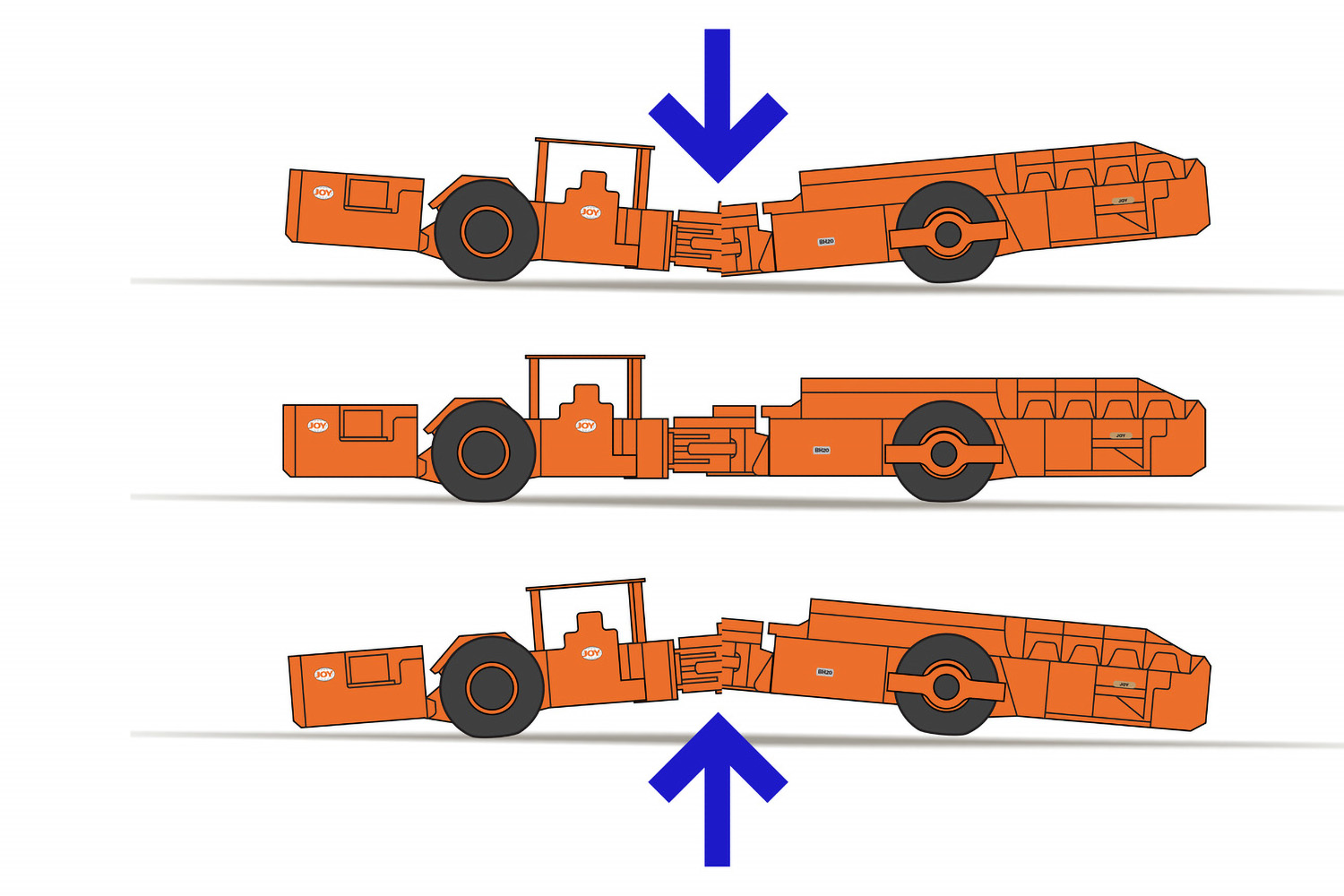

Your operators will appreciate the Joy battery hauler’s 25 degrees total full-up to full-down vertical articulation between the midsection and the trailer assembly. They’ll maintain excellent maneuverability and comfort, even in rugged conditions.

Operators can perform more quickly and safely when they can easily see what’s in front of and behind the hauler. Optional forward and rearward FLIR cameras, mated to monitors in operator compartment, help operators be sure of their surroundings.

Low-seam applications (AC or DC model availalble)

Motors

Low-seam applications (AC or DC model available)

Actionable insights to help solve your toughest challenges. JoyConnect uses data-driven intelligence gathered from electronics installed on Joy, Komatsu and third-party equipment.

The first lithium-ion battery in soft rock mining is designed to boost productivity with 75% faster charge time, and much lower maintenance versus traditional lead acid technology.

The Optidrive variable frequency drive system is the result of a holistic approach to transmission design that provides you with an adaptable, rugged and reliable solution for shearer traction systems. The medium voltage (MV, 3300 or 4160 V) OptiDrive system integrates the variable speed drive with the motor to achieve outstanding speed and torque control for soft starts and stops and fast acceleration. The variable chain speeds allow your operators to adapt to production conditions, giving you an opportunity to increase capacity, improve cutting cycles, and achieve remarkable efficiency with your longwall system.