Crushing

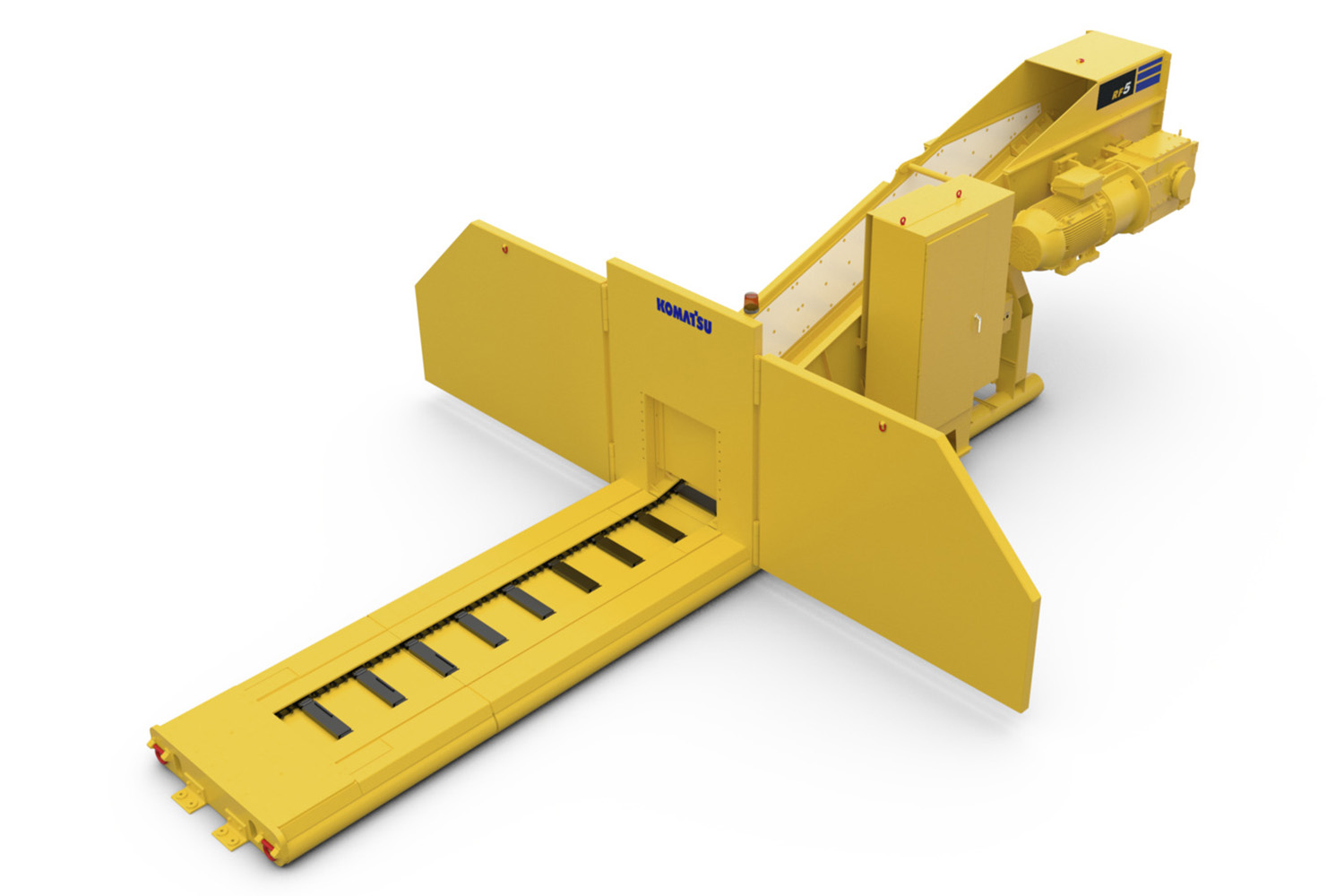

Stamler RF-5

Reclaim Feeders

- Throughput (standard) (MTPH) Up to 3 629

- Throughput (standard) (TPH) Up to 4,000

- Power rating range (HP) Less than or equal to 496

- Power rating range (kW) Less than or equal to 370

Operational flexibility with low total cost of ownership

Promote productivity with a cost-effective feeder that is designed for ease of operation and maintenance. Engineered for flexibility — easy to relocate and fits multiple applications. Start production quickly with this standard unit — 25-30% faster delivery than engineered solutions.

- 25-30% faster than customized OE alternatives

- 15 years average life

- Replacement parts costs as low as $0.01/ton

Resources

Features and benefits

Low total cost of ownership

Demonstrated machine durability delivers long-term value. Control haulage equipment operating costs by using an engineered reclaim feeder integrated with belt conveyors to move material from the pit to the plant.

Flexibility optimizes valuable resources

Helps reduce wear and tear on haul trucks when used in high-production operations. Designed to effectively handle a wide range of applications, including coal, industrial minerals, heavy ores and other wet, sticky materials

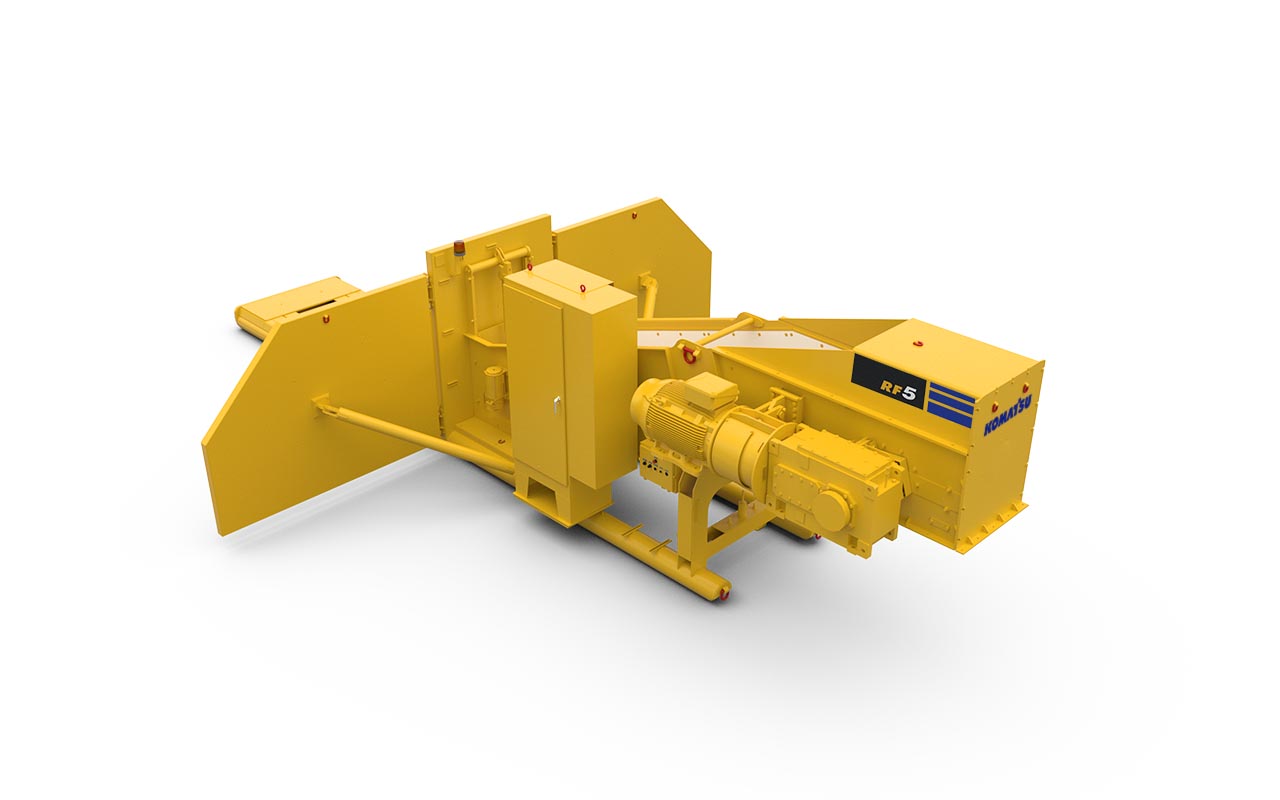

Delivering reliability

Average in-service life of more than 20 years. Simple design with steel components provides you with a reliable, durable machine to enhance production.

Controllability and job site integration

Connecting to an engineered reclaim feeder from Machine Control Center (MCC) helps deliver efficient operational adjustment and production. Remote connectivity and the Komatsu-engineered onboard VFD integrates with greenfield operations and existing work sites.

Reduce downtime

Take manual component lubrication out of the maintenance equation with electric automatic lubrication. Set the component greasing schedule and let the electric automatic lubrication system do the work for you, even with the machine operating.

Specifications

- Full specs

-

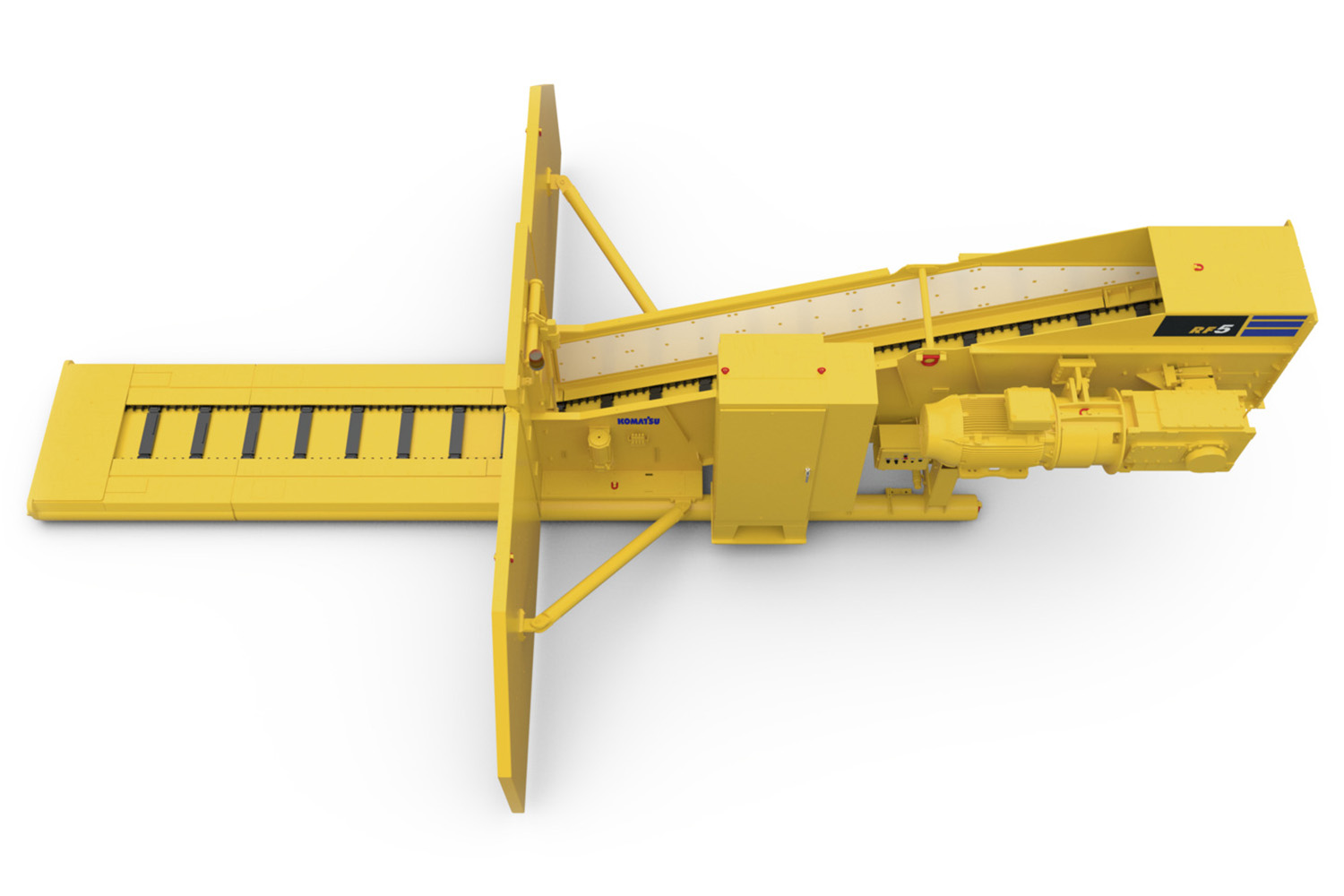

Dimension

- Overall width (mm): 2 304 (RF-5Q), 2 690 (RF-5B) or 3 543 (RF-5E)

- Overall width (ft): 7 ft. 7 in (RF-5Q), 8 ft. 10 in (RF-5B) or 11 ft. 7 in (RF-5E)

- Conveyor width (in): 36 (RF-5Q), 50 (RF-5B) or 66 (RF-5E)

- Conveyor width (mm): 914 (RF-5Q), 1 270 (RF-5B) or 1 676 (RF-5E)

- Overall length (Baseline)(mm): 12 090

- Overall length (Baseline)(ft): 39 ft. 7 in

- Overall height (mm): 3 183 mm

- Intake length (baseline)(ft): 16 ft. 5 in

- Intake length (baseline)(mm): 5 000 mm

- Mass (weight)(kg): 21 000 (RF-5Q), 23 000 (RF-5B) or 31 000 (RF-5E)

- Discharge height (mm): 1 700 mm

- Discharge height (ft): 5 ft. 6 in

- Mass (weight)(lbf): 46,200 (RF-5Q), 50,600 (RF-5B) or 68,200 (RF-5E)

- Overall height (ft): 10 ft. 5 in

- Power rating (baseline)(HP): 200 (RF-5Q and RF-5B) or ≤ 496 (RF-5E)

- Power rating (baseline)(kW): 150 (RF-5Q and RF-5B) or ≤ 370 (RF-5E)

Support you can count on

Find what works for you