Crushing

SFB-29

Surface feeder breakers

- Pick force (kN) 1 112

- Pick force (lbf) 250,000

- Weight (tonnes) 20 - 30

- Weight (tons) 22 - 33

- Throughput (standard) (MTPH) Up to 1 500

- Throughput (standard) (TPH) Up to 1,655

Single-source crushing and conveying

For streamlined operation, feeder breakers combine the receiving, sizing and conveying of mineral material into a single unit. For additional efficiency, each model features a specially designed surge hopper, helping trucks and other haulage equipment to discharge material at their maximum rate.

Resources

Features and benefits

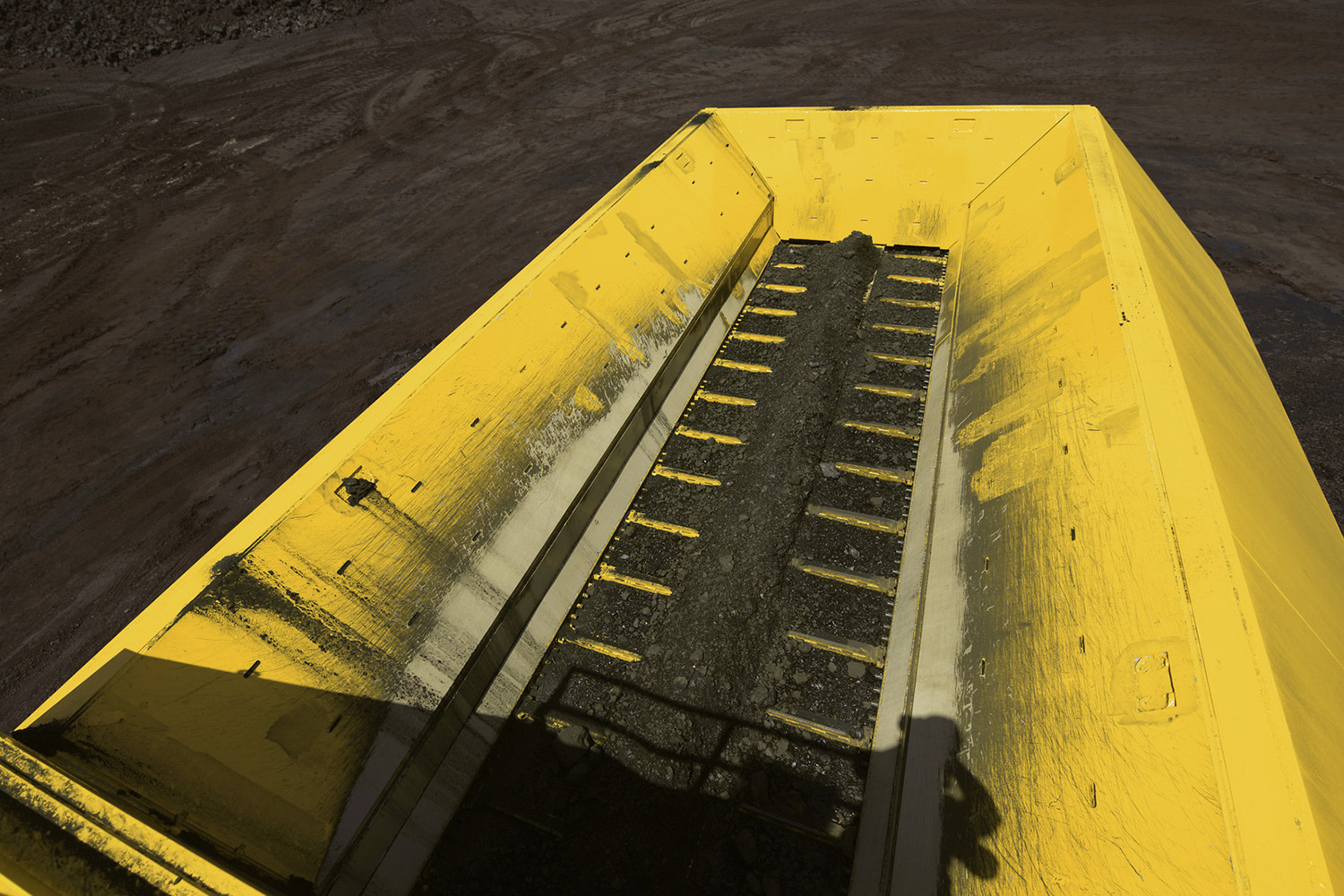

Low profile allows flexibility

You have more loading options with a low horizontal profile feeder breaker ― most haulage equipment can discharge directly into the feeder hopper. If you use trucks, the ramp and foundation can be lower and more economical.

Conveying and crushing in one unit

Simplify your operation with a feeder breaker that combines receiving, feeding and sizing into a single unit.

Managed output

Get the correct material output size for your operation from breaker picks and pick pattern designed for your operation and conveyor flights.

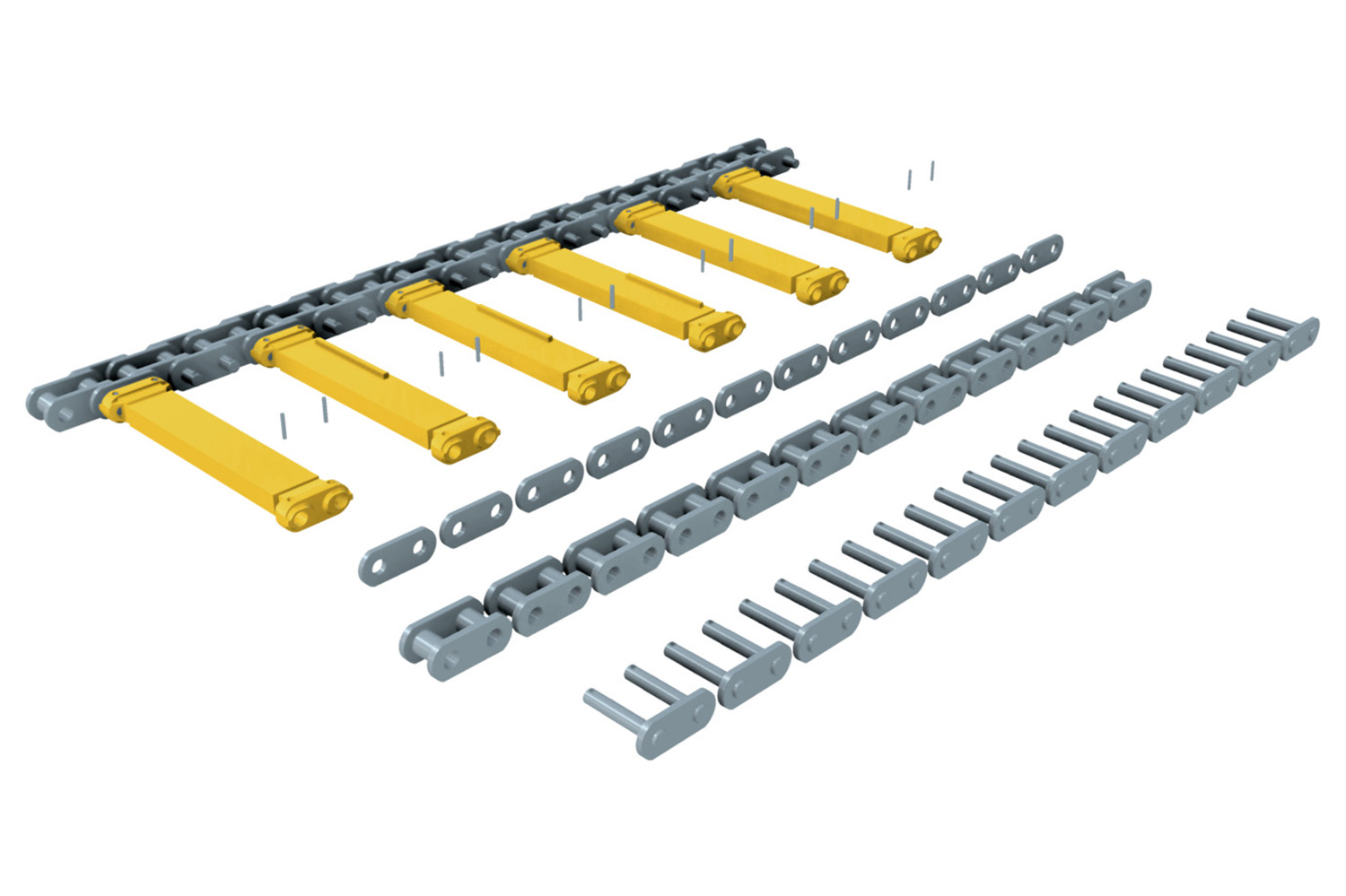

Long-life, low-maintenance conveyor chain

To keep the feeder breaker running, the conveyor uses a high strength engineered chain with hardened link pins.

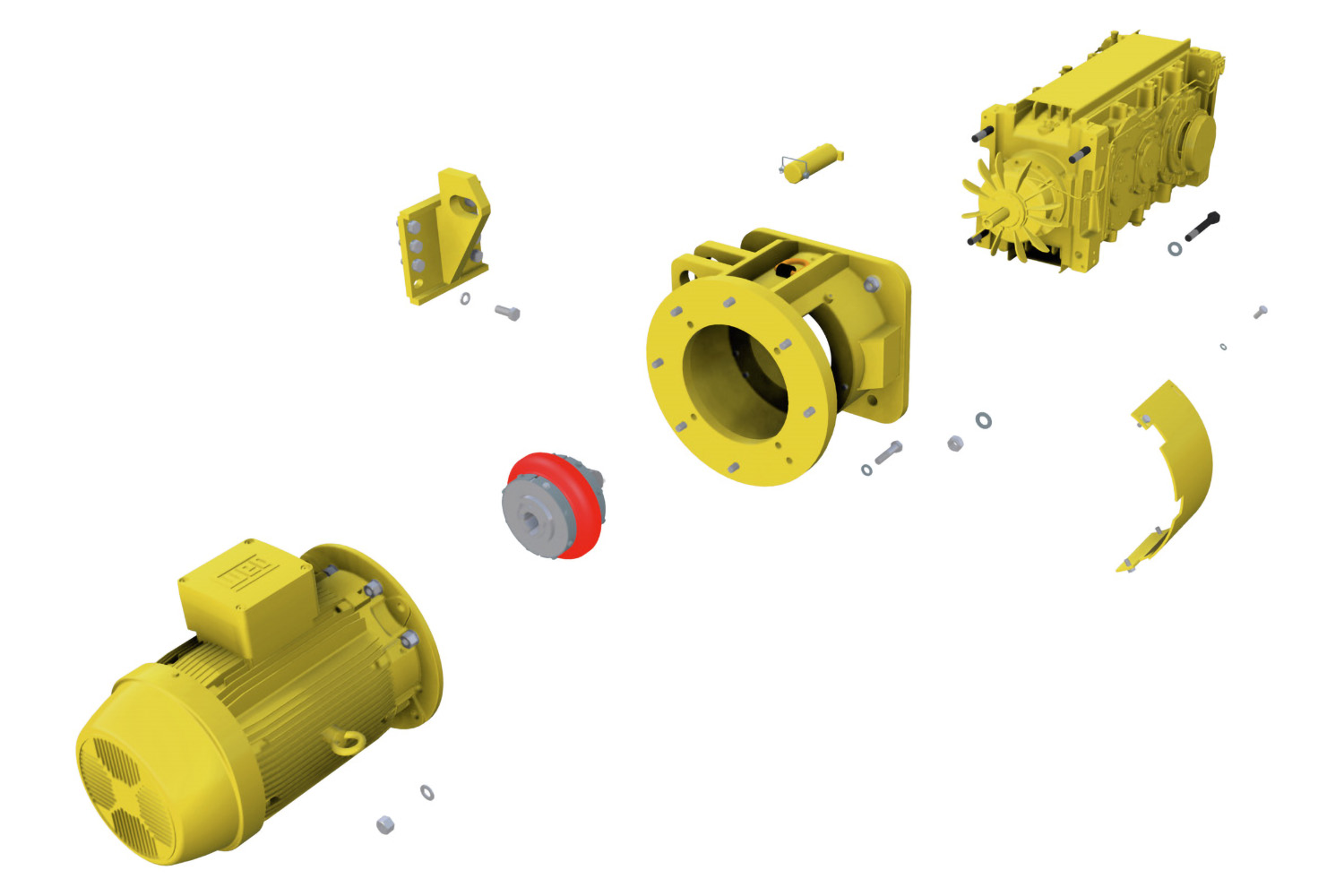

Choose Electro-mechanical or hydraulic conveyor drive

Depending on the needs of your site, choose from a electro-mechanical or hydraulic drive.

Mobility options to match your operation

All feeder breakers can be fitted with skids, wheels or self-propelled crawler tracks – so you can get exactly the configuration that meets your operation.

Hydraulic conveyor chain tensioning system

Yes, chain tensioning can improve your cycle and uptimes. More accurate tensioning can increase performance and component life. Adjusting take-up without shims or removing covers reduces adjustment time from two hours to two minutes.* (*Based on internal testing)

Surge capacity control for no waiting

Our unique hopper design helps haulage equipment to discharge material at the maximum rate — eliminating the need for a loader to wait and meter. This can improve cycle times and productivity

Reduced fines, increased consistency

You can move a variety of material consistencies — wet, dry, sticky or a combination — through a single piece of equipment, as feeder breakers break, instead of crush, materials, reducing fines.

Specifications

- Full specs

- Capacity (MTPH): Up to 1 500 (*The rated capacity, maximum mineral compressive strength, and feed size of a Feeder breaker are interdependant.)

- Capacity (TPH): Up to 1,655 (*The rated capacity, maximum mineral compressive strength, and feed size of a Feeder breaker are interdependant.)

- Weight (tonnes): 20 - 30

- Weight (tons): 22 - 33

- Chain pitch (in): 3.5

- Chain pitch (mm): 89

- Mineral hardness: Soft and medium

- Typical Applications*: Coal, salt, gypsum, potash, lignite and hard rock materials including copper, gold, pyrite, limestone, and polymetallic materials. (*Larger Surface Feeder breakers are often used to crush softer minerals due to required capacity or feed size.)

- Capacity** (TPH): Up to 1,655 (**The rated capacity, maximum mineral compressive strength, and feed size of a Feeder breaker are interdependant.)

- Capacity** (MTPH): Up to 1 500 (**The rated capacity, maximum mineral compressive strength, and feed size of a Feeder breaker are interdependant.)

- Maximum feed size (in): 31.5 (**The rated capacity, maximum mineral compressive strength, and feed size of a Feeder breaker are interdependant.)

- Maximum feed size (mm): 800 (**The rated capacity, maximum mineral compressive strength, and feed size of a Feeder breaker are interdependant.)

Support you can count on

Find what works for you