Smart payload management, bucket by bucket

Argus delivers real-time feedback, peer benchmarking and in-seat coaching to help operators sharpen their technique and stay aligned with payload targets. Each bucket is weighed as it’s loaded, keeping production on track and reducing guesswork.

Built on an open API platform, Argus works across any OEM machine and is available for electric rope shovels, hydraulic excavators and wheel loaders.

- Argus WL – Optimize payload measurement and operator productivity for wheel loaders

- Argus E – Boost electric rope shovel productivity with real-time payload optimization

- Argus Hydraulic 2 – Improve compliance, reliability and accuracy for hydraulic excavators with plug-and-play CANBUS hardware

By optimizing truck loading and payload management, Argus helps you move material efficiently and consistently with every pass.

**These results are based on documented Komatsu MTS customer case studies and reflect performance improvements compared to the customer's prior system or manual operations. Individual customer results are not guaranteed and will vary by mine site and operating conditions.

Argus Payload Management System – Key features and benefits

| Feature | Benefit |

| Payload optimization | Track every bucket in real time for precise payload control |

| Position awareness | See live shovel and bucket positions for accurate loading |

| KPI scorecards and reporting | Benchmark operators and help boost performance with clear insights |

| Remote monitoring | Stay connected with live equipment data through mRoc Desktop |

| Machine guidance | Dig to plan with centimeter-level precision |

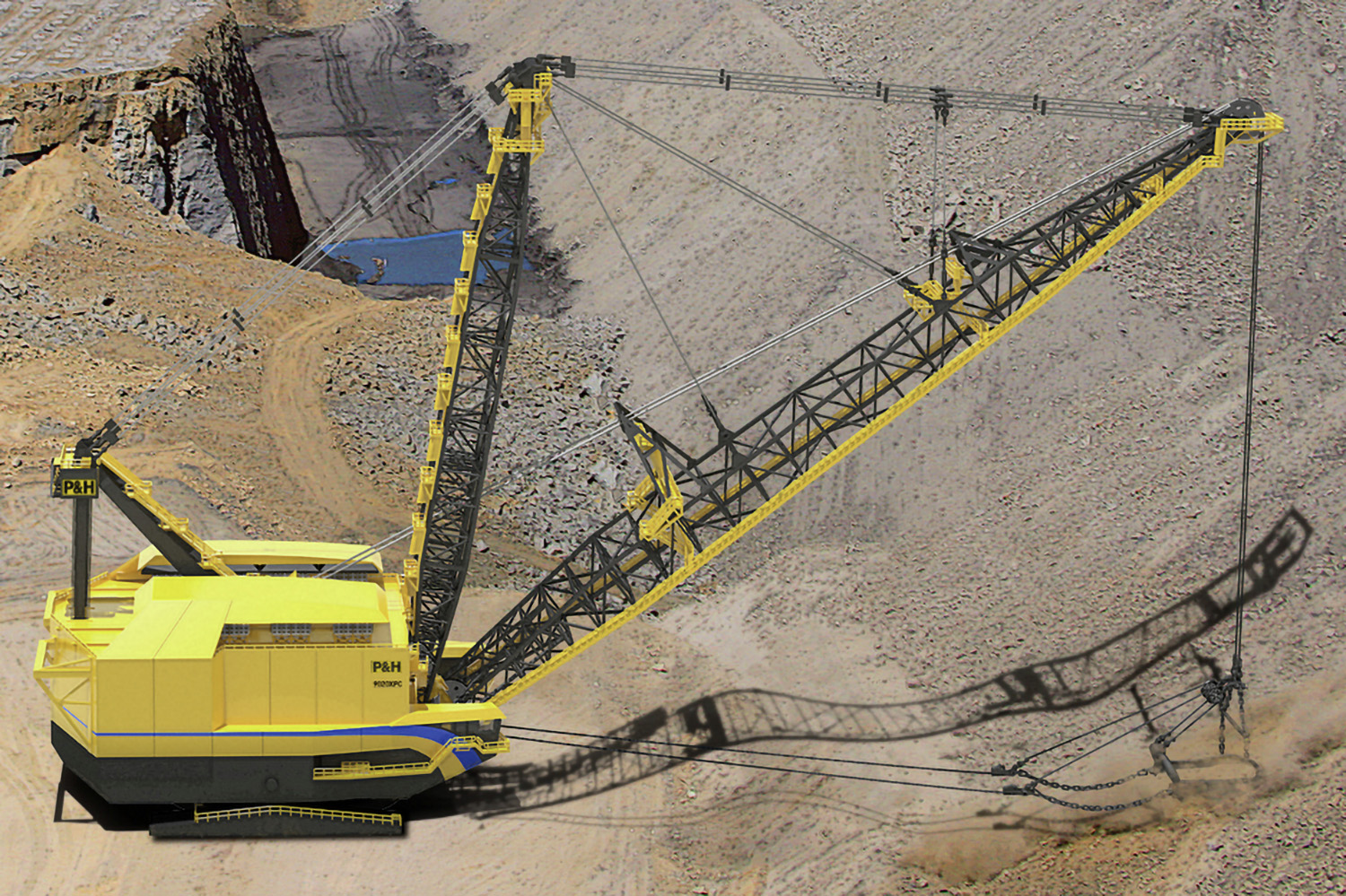

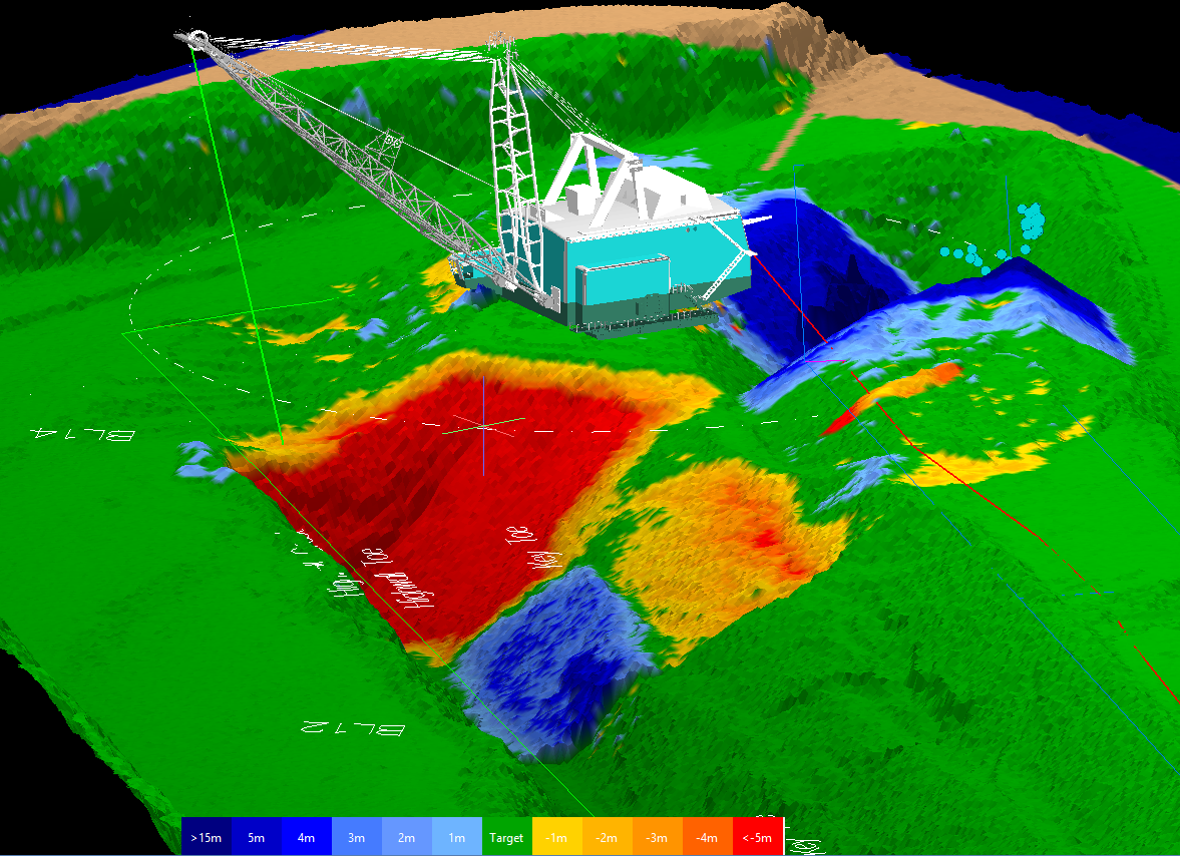

Pegasys Dragline Monitoring System

Payload precision for draglines

Pegasys is the industry’s leading system for dragline payload and compliance monitoring — engineered to help boost efficiency, safety, and productivity. By combining real-time payload data, visual guidance and operator feedback, Pegasys helps your team work with greater accuracy and control.

With boom-mounted laser scanners, GPS sensors and strategically placed strain gauges, it continuously maps terrain, tracks stress and monitors structural health to keep your dragline performing at its best.

The Pegasys Dragline Monitoring system has the potential to:

**These results are based on documented Komatsu MTS customer case studies and reflect performance improvements compared to the customer's prior system or manual operations. Individual customer results are not guaranteed and will vary by mine site and operating conditions.

Pegasys Dragline Monitoring System – Key features and benefits

| Feature | Benefit |

| Payload optimization | Track payload, time use and delays bucket by bucket for maximum efficiency |

| Digital terrain mapping | Dig to design with precision guidance and compliance feedback |

| Structural monitoring | Monitor stress and duty every cycle with alerts for proactive maintenance |

| Operator guidance | Real-time, in-cab guidance to keep operators on plan |

| Enhanced visibility | Improve safety and operator awareness with live video and Pegasys data overlays |