Motor graders

GD655-7

- Horsepower (HP) 218 HP @ 2,100 rpm

- Horsepower (kW) 163 kW @ 2100 rpm

- Operating weight (kg) 17 350

- Operating weight (lbs) 38,250

- Moldboard (ft) 14

- Moldboard (m) 4

Designed for precision

Designed for smooth, powerful accuracy at your operator’s fingertips. A unique dual mode transmission with a torque converter and innovative stall prevention technology makes this motor grader easier to operate for operators of varying skill levels.

- Exceptional visibility

- Smooth power and optimized control

- High flow hydraulics with on-demand CLSS valves for operator efficiency

- Up to 15% increased fuel efficiency*

Note: *compared to GD655-5

Features and benefits

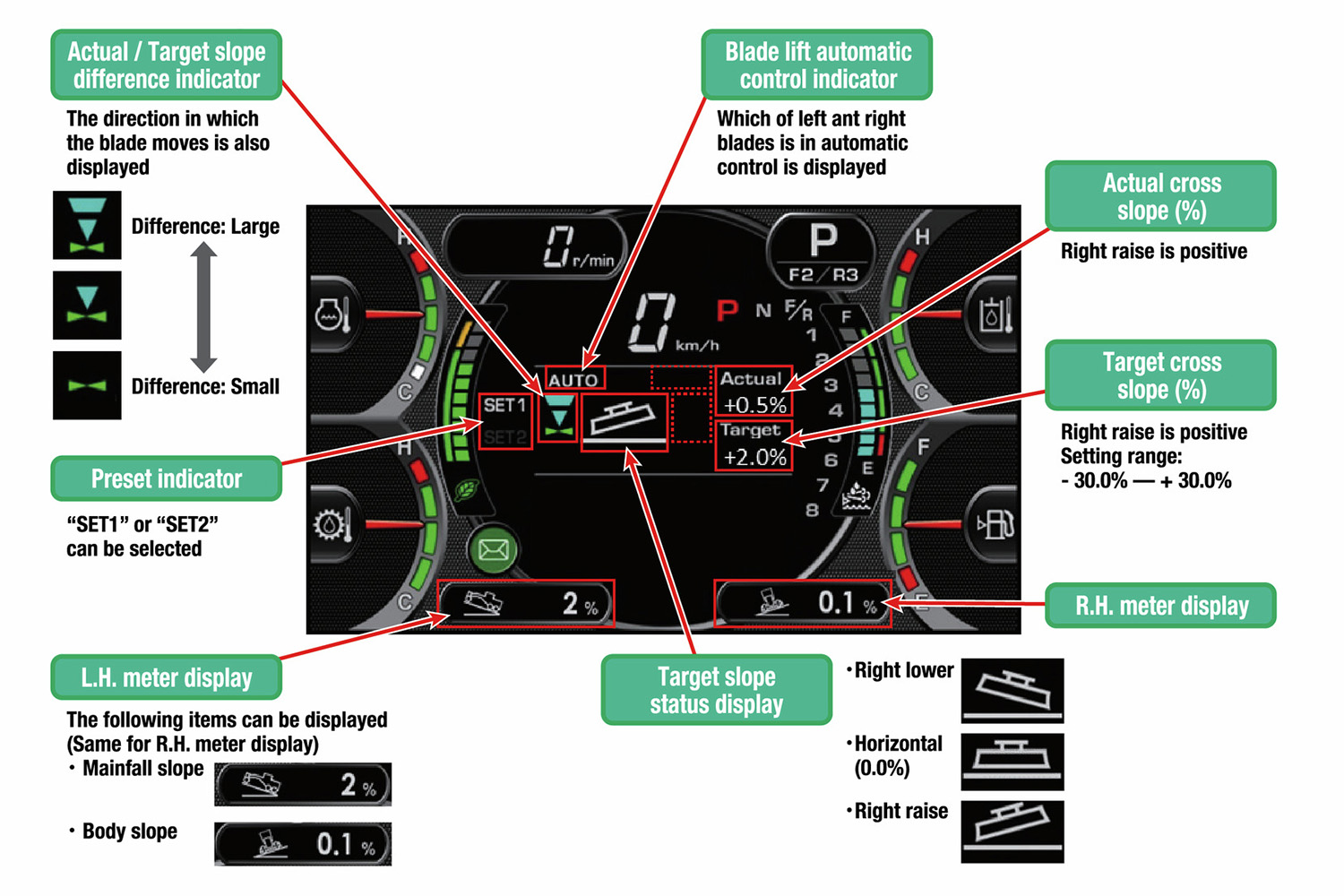

2D cross slope standard

Simplify road maintenance and easily maintain a desired cross slope angle when adjusting the blade cutting height. The main display and integrated control levers allow the operator to quickly select a predetermined slope angle.

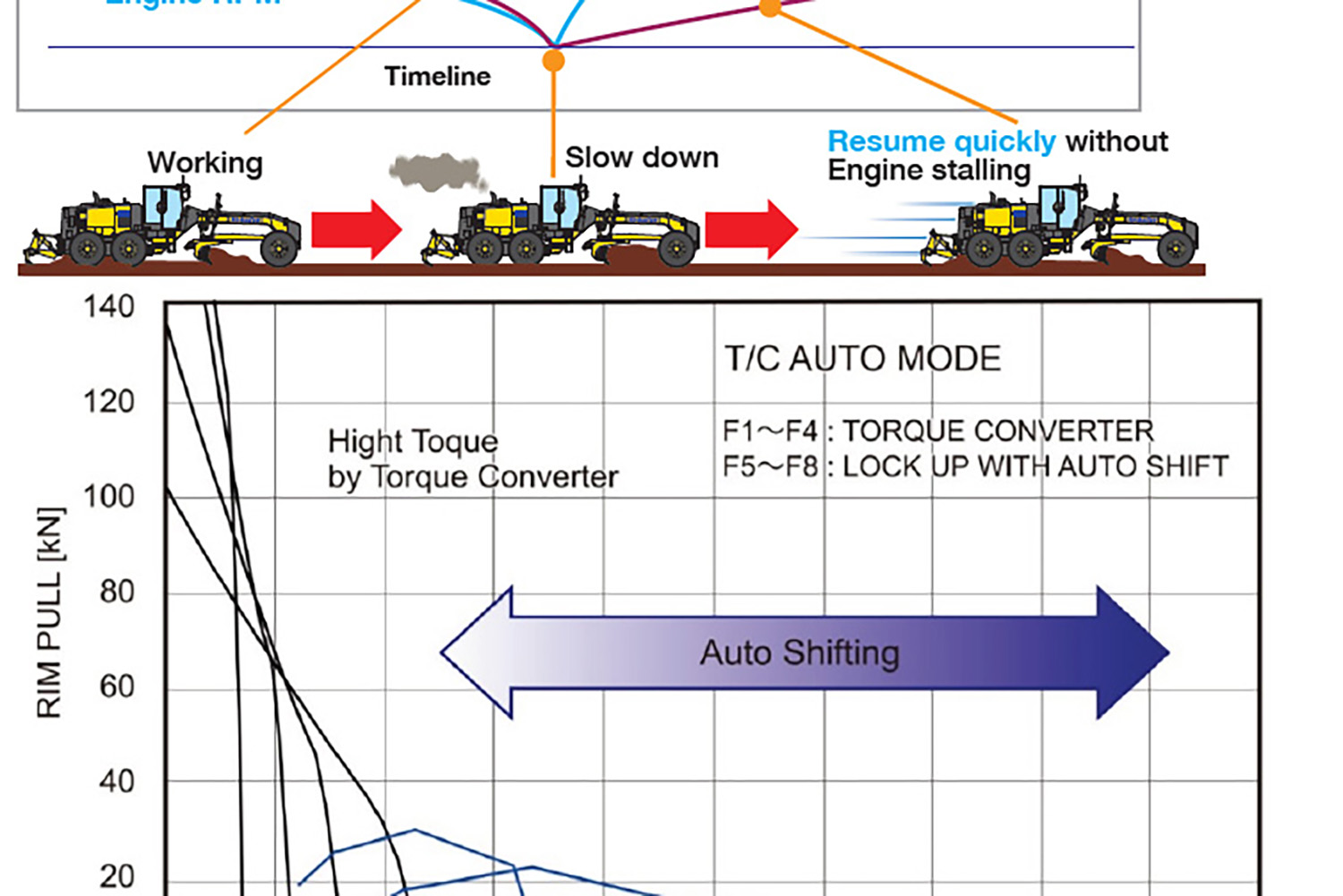

Dual mode powershift transmission

Control, finesse and traction where it is needed — at the ground with our unique dual-mode transmission. Torque converter with stall prevention technology makes it easier to operators of varying skill levels.

Convenient control

The all-new, low-effort fingertip control levers provide quick response and precision, for new and experienced operators. Located on the powered armrests for ultimate comfort, arm movement is reduced up to 92%.

Designed for ease of operation

Put your operator in control. Equipped with both a right-sized steering wheel and steering lever to match operator preference and to reduce fatigue.

Fuel efficiency

Efficient operation with two selectable power settings. For fine finish grading or light-duty road maintenance, eco mode helps provide fuel efficiency, while heavy pushing or high-demand tasks are tackled in power mode.

Reliability

Protect the moldboard, drawbar and blade circle from damage with two selectable function blade accumulators. Blade lift cylinders absorb impacts if the blade edge hits an immobile object such as a manhole, boulder or railroad crossing.

Operator comfort

Long days on the job are more comfortable with the new standard air suspension seat. The seat adjusts to the operator’s weight and dampens vibrations from the machine, reducing fatigue.

Smooth, efficient operation

High-performance hydraulic system provides responsive control and smooth, constant speed. The closed center load sensing system allows for multiple circuits to operate simultaneously, independent of engine speed.

Ergonomic cab

Increase visibility to the moldboard heel and toe with the new hexagonal cab. The comfortable cab has enhanced ergonomics with adjustable seat, consoles, arm rests and controls.

Specifications

- Full specs

- Standard equipment

- Optional equipment

- Maximum lift above ground (ft): 1 ft 7 in

- Maximum lift above ground (mm): 480

- Maximum cutting depth (mm): 615

- Maximum cutting depth (ft): 2 ft 0 in

- Maximum blade angle, right or left (degrees): 90

- Blade tip angle forward (degrees): 40

- Blade tip angle reverse (degrees): 5

-

Moldboard side shift

- Blade range: right (moldboard)(ft): 2 ft 8 in

- Blade range: right (moldboard)(mm): 820

- Blade range: left (moldboard)(mm): 820

- Blade range: left (moldboard)(ft): 3 ft 8 in

-

Maximum shoulder reach outside rear tires (frame straight)

- Blade range: right (maximum shoulder reach)(mm): 2 000

- Blade range: right (maximum shoulder reach)(ft): 6 ft 7 in

- Blade range: left (maximum shoulder reach)(mm): 2 000

- Blade range: left (maximum shoulder reach)(ft): 6 ft 7 in

-

With rear mounted ripper and front push plate

- Total operating weight with rear mounted ripper and front push plate(lbs): 41,667

- Total operating weight with rear mounted ripper and front push plate(k): 19 260

-

- Total operating weight with 5.5 m blade (lbs): 38140

- Total operating weight with 5.5 m blade (kg): 17 300

*5.5 m blade, L3 tire, ripper (three shanks) and pusher

- Engine Model: SAA6D107E-3*

- Engine type: Water-cooled, 4-cycle, direct injection

- Aspiration: Turbocharged, aftercooled, cooled EGR

- Number_of_cylinders: 6

- Bore (in): 4.21

- Bore (mm): 107

- Stroke (in): 4.88

- Stroke (mm): 124

- Piston displacement (in^3): 408

- Piston displacement (L): 6.69

- Max.torque @ 1,450 rpm (kg/m): 96

- Max.torque @ 1,450 rpm (lbs/ft): 694

- Max.torque @ 1,450 rpm (nm): 941

- Torque rise (%): 30

- Fan speed (Max rpm): 1,450

- Air cleaner: 2-stage, dry-type

- Engine footnote: * EPA Tier 4 Final emissions certified.

- Net horsepower footnote: ** Net horsepower output for standard (SAE J1349) including air cleaner, alternator (not charging), water pump, lubricating oil, fuel pump, muffler and fan running at minimum speed.

-

Gross Horsepower (Manual mode)

- P-Mode Gear 1-3 @ 2,000 rpm (kW): 136

- P-Mode Gear 1-3 @ 2,000 rpm (HP): 183

- P-Mode Gear 4-6 @ 2,000 rpm (kW): 151

- P-Mode Gear 4-6 @ 2,000 rpm (HP): 203

- P-Mode Gear 7-8 @ 2,000 rpm (kW): 165

- P-Mode Gear 7-8 @ 2,000 rpm (HP): 221

- E-Mode (manual) Gear 1-6 @ 2,000 rpm (kW): 136

- E-Mode (manual) Gear 1-6 @ 2,000 rpm (HP): 183

- E-Mode (manual) Gear 7-8 @ 2,000 rpm (kW): 165

- E-Mode (manual) Gear 7-8 @ 2,000 rpm (HP): 221

-

Net horsepower** (Manual Mode)

- P-Mode (manual) Gear 1-3 @ 2,000 rpm (HP): 180

- P-Mode (manual) Gear 1-3 @ 2,000 rpm (kW): 134

- P-Mode (manual) Gear 4-6 @ 2,000 rpm (kW): 149

- P-Mode (manual) Gear 4-6 @ 2,000 rpm (HP): 200

- P-Mode (manual) Gear 7-8 @ 2,100 rpm (HP): 218

- P-Mode (manual) Gear 7-8 @ 2,100 rpm (kW): 163

-

Net horsepower**(Manual Mode)

- E-Mode Gear 1-6 @ 2,000 rpm (HP): 180

- E-Mode Gear 1-6 @ 2,000 rpm (kW): 134

- E-Mode Gear 7-8 @ 2,000 rpm (kW): 163

- E-Mode Gear 7-8 @ 2,000 rpm (HP): 218

- Moldboard details: Hydraulic power shift fabricated from high tensile steel. Includes replaceable metal wear inserts, cutting edge and end bits. Cutting edge and end bits are hardened.

- Dimensions (in): 14 ft x 26 in x .87 in

- Dimensions (mm): 4 320 x 660 x 22

- Arc radius (ft): 1 ft 5 in

- Arc radius (mm): 432

- Cutting edge (mm): 152 x 16

- Cutting edge (in): 6 x 0.63

- Replaceable/Reversible side edges (mm): 156 x 16 x 456

- Replaceable/Reversible side edges (in): 6 ft x 0.63 in x 1 ft 6 in

-

Blade pull

- Blade pull - base GVW (lbs): 22,267

- Blade pull - base GVW (kg): 10 100

- With ripper GVW Blade pull (lbs): 24,207

- With ripper GVW Blade pull (kg): 10 980

-

Blade down pressure

- Blade pressure down - base GVW (lbs): 15,300

- Blade pressure down - base GVW (kg): 6 940

- With ripper GVW Blade down (kg): 8 400

- With ripper GVW Blade down( lbs): 18,519

- Fuel tank (L): 390

- Fuel tank (US gal): 103

- Cooling system (US gal): 7.9

- Cooling system (L): 30

- Crank case (L): 23

- Crank case (US gal): 6.1

- Transmission (US gal): 11.9

- Transmission (L): 45

- Final drive (L): 17

- Final drive (US gal): 4.5

- Tandem housing (each)(US gal): 15.1

- Tandem housing (each)(L): 57

- Hydraulic system (L): 69

- Circle reverse housing (US gal): 1.8

- Hydraulic system (US gal): 18.2

- Circle reverse housing (L): 7

- Maximum steering range, right or left (degrees): 49

- Articulation, right or left (degrees): 25

- Hydraulic power steering: Providing stopped engine steering meeting ISO 5010.

- Minimum turning radius for steering (ft) (in): 24 ft. 3 in

- Minimum turning radius for steering (m): 7.4

- Front axle type: Solid bar construction welded steel sections

- Ground clearance at pivot (mm): 620

- Ground clearance at pivot (in): 2 ft 0 in

- Wheel lean angle, right or left (degrees): 16

- Oscillation, total (degrees): 32

-

Speeds (at rated engine speed)

- 1st Gear - forward (kph): 3.4

- 1st Gear - forward (mph): 2.1

- 2nd Gear - forward (kph): 5

- 2nd Gear - forward (mph): 3.1

- 3rd gear - forward (mph): 4.3

- 3rd gear - forward (kph): 7

- 4th gear - forward (mph): 6.3

- 4th gear - forward (kph): 10.2

- 5th gear - forward (mph): 9.6

- 5th gear - forward (kph): 15.4

- 6th gear - forward (mph): 13.9

- 6th gear - forward (kph): 22.3

- 7th gear - forward (mph): 19

- 7th gear - forward (kph): 30.6

- 8th gear - forward (mph): 27.5

- 8th gear - forward (kph): 44.3

- 1st Gear - reverse (kph): 4.5

- 1st Gear - reverse (mph): 2.8

- 2nd Gear - reverse (mph): 5.7

- 2nd Gear - reverse (kph): 9.2

- 3rd gear - reverse (kph): 20.3

- 3rd gear - reverse (mph): 12.6

- 4th gear - reverse (mph): 25

- 4th gear - reverse (kph): 40.3

-

Middle, V-type

- Middle scarifier, V-type working width (ft): 4 ft 8 in

- Middle scarifier, V-type working width (mm): 1 430

- Middle scarifier, V-type scarifying depth, maximum (in): 7.5

- Middle scarifier, V-type scarifying depth, maximum (mm): 190

- Middle scarifier, V-type scarifier shank holders spacing (mm): 138

- Middle scarifier, V-type scarifier shank holders spacing (in): 5.4

- Middle scarifier, V-type scarifier shank holders (in): 11

- Middle scarifier, V-type scarifier shank holders (mm): 11

-

Rear

- Rear scarifier working width (mm): 2 186

- Rear scarifier working width (ft): 7 ft 2 in

- Rear scarifier scarifying depth, maximum (in): 6.5

- Rear scarifier scarifying depth, maximum (mm): 165

- Rear scarifier scarifying shank holders: 9

- Rear scarifier scarifying shank holders spacing (in): 10.5

- Rear scarifier scarifying shank holders spacing (mm): 267

- Circle engineering details: Single piece rolled ring forging. Six circle support shoes with replaceable wear surface. Circle teeth hardened on front 180 degree of circle.

- Diameter (outside) (mm): 1 530

- Diameter (outside) (ft): 5

- Circle reversing control hydraulic rotation (degrees): 360

- Oscillating welded box section (mm): 520 x 202

- Oscillating welded box section (in): 1 ft 8 in x 8 in

- Side wall thickness - inner (mm): 22

- Side wall thickness - inner (in): 0.87

- Side wall thickness - outer (mm): 19

- Side wall thickness - outer (in): 0.75

- Wheel axle spacing (ft/ in): 5 ft 0 in

- Wheel axle spacing (mm): 1 525

- Tandem oscillation reverse (degrees): 13

- Tandem oscillation forward (degrees): 11

- Tank (L): 7

- Tank (US gal): 1.8

- Ripping depth, maximum (ft): 1 ft 5 in

- Ripping depth, maximum (mm): 425

- Ripper shank holders: 5

- Ripper shank holder spacing (ft): 1 ft 9 in

- Ripper shank holder spacing (mm): 534

- Penetration force (kg): 9 390

- Penetration force (lbs): 20,701

- Pryout force (lbs): 38,801

- Pryout force (kg): 17 600

- Machine length increase, beam raised (ft): 2 ft 5 in

- Machine length increase, beam raised (mm): 690

- Details of hydraulics system: Load-sensing closed center hydraulics with variable displacement piston pump. Short stroke/low effort direct acting control valves with preselected maximum flow setting to each function. Double acting anti-drift check valves on blade lift, tip, circle shift, articulation, and leaning wheels.

- Output (at engine rated rpm)(L/min): 200

- Output (at engine rated rpm)(gpm): 52.8

- Standby pressure(psi): 500

- Standby pressure(MPa): 3.4

- Standby pressure(kg/cm^2): 35

- Maximum system pressure(psi): 3,000

- Maximum system pressure(kg/cm^2): 210

- Maximum system pressure(MPa): 20.6

- Frame height (in): 11.8

- Frame height (mm): 300

- Frame width (in): 11.8

- Frame width (mm): 300

- Upper, Lower (mm): 25

- Upper, Lower (in): 1.0 in

- Drawbar details: A-shaped, u-shaped press formed and welded construction for maximum strength with a replaceable drawbar ball

- Drawbar frame(in): 8.3 x 0.87

- Drawbar frame(mm): 210 x 22

- Bearings: Tapered roller

- Tires: 17.5R25

- Tire rims (demountable): 13 in one-piece rims

- Gauges: Electric monitoring system with diagnostics.

- Standard gauges details: Standard - articulation, engine coolant temperature, fuel level, speed meter, transmission shift indicator, engine tachometer, torque converter oil temperature

- Warning lights/ Indicator: Standard-battery charge, brake oil pressure, blade float, brake oil pressure, inching temperature, directional indicator, engine oil pressure, hydraulic oil temperature, heater signal, lift arm lock, parking brake, differential lock, torque converter oil, temperature, ecology, P mode, fan reverse, rpm set, high beam, working lights

- Rear axle construction: Alloy steel, heat treated, full floating axle with lock/unlock differential

- Service brake details: Foot operated, sealed oil disc brakes, hydraulically actuated on four tandem wheels

- Parking brake details: Manually actuated, spring applied, hydraulically released caliper

- Accelerator and electric throttle control

- Air cleaner, double element with dust indicator

- Air intake extension

- Antifreeze -22 F(-30C)

- Auto-idle Shutdown

- Hydraulic driven, reversing, cooling fan,blower type, plastic blade, with fan guard

- Engine, Komatsu SAA6D107E-3, 145 to 218 VHP EPA Tier 4 Final certified, turbocharged and air-air after cooled

- Fuel line pre-filter

- KDPF - After-Treatment Assembly Consisting of KDOC and KCSF

- Secondary Engine Shutdown Switch

- Selective Catalytic Reduction (SCR) System

- Alarm, backup

- Alternator, 140 Ampere, (24V)

- Batteries, Extreme duty, 2 x 12V, 1146 cca each

- Battery, disconnect switch

- Dome light Cab

- Headlights,(2) halogen type, front bar mounted

- Horn, electric

- Indicator lights:

- Battery charge

- Blade float

- Brake oil pressure

- Cooling fan reverse mod

- Differential lock

- Differential oil temperature

- Dual power mode, economy and power

- Engine oil pressure

- Engine RPM set

- Lift arm lock

- Lights, high beam

- Parking brake

- Transmission system electrical circuit - Lights, backup, stop, directional

- Starter 5.5kW

- Working light, front(4) and rear(2)

- Working light ,(4)Cab mounted flood type

- 12V (10A) power port

- Adjustable air suspension seat

- Adjustable tilt/telescopic steering wheel

- Air conditioner (R134a) with heater

- AM/FM radio with Aux input and USB port

- Cab: low profile with ROPS/FOPS Level II (SAE J1040, J2311)

- Console, adjustable with instrument panel monitoring system

- Electric defroster rear window

- Electronic height adjustable LH and RH consoles

- Mirrors: interior Cab, right and left exterior mirrors

- Multi-monitor with 7" LCD Display

- Rearview Camera and Monitor

- Sound suppression, 72 Dba at operators ear with floor mat with tinted windows, front, rear and door intermittent wiper/washers

- Dual mode transmission (8F-4R) power shift direct drive and torque converter with auto shift

- Electronic gear shift lever

- Axle, rear full floating, planetary type reduction

- Service brakes, fully hydraulic wet disc

- Parking brake, spring apply, hydraulic release dry disc

- Differential, manual lock/unlock

- Tires and rims: 17.5R25 radials on one-piece 13" rims (6)

- Blade accumulators

- Blade lift float, detent type, LH and RH

- Circle, drawbar mounted, 360° rotation with blade lift and circle side shift with anti-drift check valves

- Circle slip clutch

- Low-effort electronic proportional control levers (joysticks)

- Greaseless circle wear plates

- Hydraulic control valve, 2-5 valve sections

- Hydraulic system, closed center, load sensing

- Steering, full hydraulic with tilt steering wheel plus leaning front wheels and frame articulation with anti-drift check valves. Steering lever/joystick provided

- Komtrax - Level 5

- Precleaner, Turbo II

- Provision for Grade Control, TOPCON

- Rear hitch

- Ripper, provision for battery cover and Engine side covers

- Steps and handrails, right, left and rear

- Toolbox with lock

- Vandalism protection, lockable fuel tank, hydraulic tank

- Accelerator and electric throttle control

- Air cleaner, double element with dust indicator

- Air intake extension

- Antifreeze -22 F(-30C)

- Auto-idle Shutdown

- Hydraulic driven, reversing, cooling fan,blower type, plastic blade, with fan guard

- Engine, Komatsu SAA6D107E-3, 145 to 218 VHP EPA Tier 4 Final certified, turbocharged and air-air after cooled

- Fuel line pre-filter

- KDPF - After-Treatment Assembly Consisting of KDOC and KCSF

- Secondary Engine Shutdown Switch

- Selective Catalytic Reduction (SCR) System

- Alarm, backup

- Alternator, 140 Ampere, (24V)

- Batteries, Extreme duty, 2 x 12V, 1146 cca each

- Battery, disconnect switch

- Dome light Cab

- Headlights,(2) halogen type, front bar mounted

- Horn, electric

- Indicator lights:

- Battery charge

- Blade float

- Brake oil pressure

- Cooling fan reverse mod

- Differential lock

- Differential oil temperature

- Dual power mode, economy and power

- Engine oil pressure

- Engine RPM set

- Lift arm lock

- Lights, high beam

- Parking brake

- Transmission system electrical circuit - Lights, backup, stop, directional

- Starter 5.5kW

- Working light, front(4) and rear(2)

- Working light ,(4)Cab mounted flood type

- 12V (10A) power port

- Adjustable air suspension seat

- Adjustable tilt/telescopic steering wheel

- Air conditioner (R134a) with heater

- AM/FM radio with Aux input and USB port

- Cab: low profile with ROPS/FOPS Level II (SAE J1040, J2311)

- Console, adjustable with instrument panel monitoring system

- Electric defroster rear window

- Electronic height adjustable LH and RH consoles

- Mirrors: interior Cab, right and left exterior mirrors

- Multi-monitor with 7" LCD Display

- Rearview Camera and Monitor

- Sound suppression, 72 Dba at operators ear with floor mat with tinted windows, front, rear and door intermittent wiper/washers

- Dual mode transmission (8F-4R) power shift direct drive and torque converter with auto shift

- Electronic gear shift lever

- Axle, rear full floating, planetary type reduction

- Service brakes, fully hydraulic wet disc

- Parking brake, spring apply, hydraulic release dry disc

- Differential, manual lock/unlock

- Tires and rims: 17.5R25 radials on one-piece 13" rims (6)

- Blade accumulators

- Blade lift float, detent type, LH and RH

- Circle, drawbar mounted, 360° rotation with blade lift and circle side shift with anti-drift check valves

- Circle slip clutch

- Low-effort electronic proportional control levers (joysticks)

- Greaseless circle wear plates

- Hydraulic control valve, 2-5 valve sections

- Hydraulic system, closed center, load sensing

- Steering, full hydraulic with tilt steering wheel plus leaning front wheels and frame articulation with anti-drift check valves. Steering lever/joystick provided

- Komtrax - Level 5

- Precleaner, Turbo II

- Provision for Grade Control, TOPCON

- Rear hitch

- Ripper, provision for battery cover and Engine side covers

- Steps and handrails, right, left and rear

- Toolbox with lock

- Vandalism protection, lockable fuel tank, hydraulic tank

- Moldboard:

-- 12' x 26" x 0.87" with replaceable end bits

-- 6" x 0.63" through-hardened cutting edges and 5/8" hardware - Pusher plate (for use with rear mounted ripper/scarifier assembly)

- Rear-mounted ripper/scarifier assembly includes (3) shanks or (9) scarifier shanks can be inserted into the available slots

- Mid-mounted scarifier assembly (includes 11 shanks and replaceable points)

- Amber colored warning light

- 610 mm 2' LH/RH moldboard extensions

- Kit provision for a single function front attachment

- Winter Tires

- Moldboard:

-- 3710 mm x 660 mm x 22 mm with replaceable end bits

-- 152 mm x 16 mm through-hardened cutting edges and 5/8" hardware - Pusher plate (for use with rear mounted ripper/scarifier assembly)

- Rear-mounted ripper/scarifier assembly includes (3) shanks or (9) scarifier shanks can be inserted into the available slots

- Mid-mounted scarifier assembly (includes 11 shanks and replaceable points)

- Amber colored warning light

- 610 mm 2' LH/RH moldboard extensions

- Kit provision for a single function front attachment

- Winter Tires

Support you can count on

Find what works for you