Forklifts

FG40ZTU-10

IC pneumatic

- Tire type Pneumatic

- Power type LPG/Dual fuel

- Capacity (kg) 3 500 - 5 000

- Capacity (lbs) 8,000 - 11,000

Fast, clean and powerful

Who would have thought moving 8,000- to 11,000-pound loads in high volume could be effortless? The CX50’s fusion of advanced engine technologies and a unique hydraulic system was engineered to deliver outstanding performance while reducing cost and Carbon Dioxide emissions, compared to previous models.

- Designed for low costs of operation

- Engineered for reliability in a variety of conditions

- Helps operators work efficiently

Features and benefits

Hydraulics that do more than lift

To minimize hydraulic loss and reduce the engine load, the CX50 Series uses the CLSS hydraulic system, technology proven in Komatsu’s rugged construction machines. Reducing the engine’s load means it uses less fuel than typical gear pump-driven hydraulic trucks.

Reduces costs from the ground up

The CX50’s sealed wet disc brake system is warranted to go 10,000 hours without maintenance, eliminating the downtime and added cost of frequent shoe replacements. The engine oil needs replacing only every 500 hours, helping to further reduce operating costs.

Clean burning engine

The CX50’s electronically controlled engine uses a 3-way catalytic system and clean burning LPG. All models meet applicable EPA emission standards.

Brakes built for a variety of conditions

Smooth, stable braking and fade resistance in a variety of conditions. Unlike conventional drum and shoe braking systems, the CX50 Series features a wet disc brake system sealed with oil to block dust and water-resistant components.

Robust hydraulic and electrical systems

Separate hydraulic and electrical systems improve reliability and service accessibility. O-ring face seals on critical hydraulic connections reduce the potential for leaks. Water- and dust-resistant connectors join the main harnesses and the system controller.

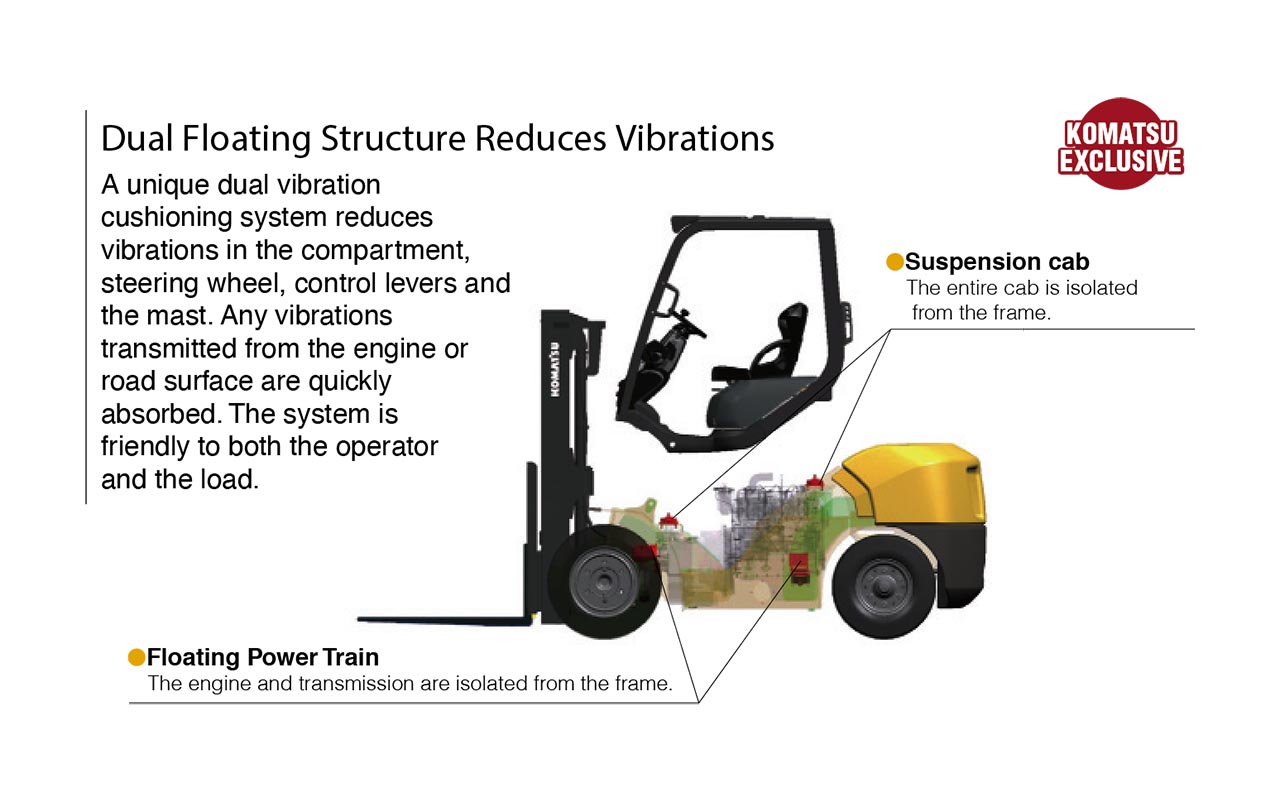

Advanced Ergonomic Design

Designed to improve operator comfort and reduce fatigue, the Komatsu Komfort Zone is a dual floating structure: dampening mounts protect the frame from engine vibration; additional mounts isolate operators from the frame; and the sealed floorboard reduces engine noise and heat.

Specifications

- Full specs

- Standard equipment

- Optional equipment

- Operation type: Sit-Down

- Capacity @ 600 mm load center (kg): 3 500

- Capacity @ 24 in load center (lbs): 8,000

- Wheelbase (mm): 1 800

- Wheelbase (in): 70.9

- Load distance from center axle (2 stage)(in): 21.3

- Load distance from center axle (2 stage)(mm): 540

- Relief pressure, maximum (psi): 2,988

- Relief pressure, maximum (bar): 206

- Transmission: TORQFLOW

- Travel speed, loaded - 1st/ 2nd (mph): 11.2 / NA

- Travel speed, loaded - 1st/ 2nd (kph): 18 / NA

- Travel speed, unloaded - 1st/ 2nd (kph): 19 / NA

- Travel speed, unloaded - 1st/ 2nd (mph): 11.8 / NA

- Lifting speed, loaded/unloaded (fpm): 100.4 / 100.4

- Lifting speed, loaded/unloaded (mm/s): 510 / 510

- Lowering speed, loaded/unloaded (mm/s): 500 / 500

- Lowering speed, loaded/unloaded (fpm): 98.4 / 98.4

- Maximum drawbar pull, loaded (kN): 24

- Maximum drawbar pull, loaded (lbs): 5,395

- Maximum gradeability (%): 28

- Service brake, operation/control: Foot / Hydraulic

- Parking brake, operation/control: Hand / Mechanic

- Steering type: FHPS

- Maximum torque (SaE net)(Nm): 272 Nm @ 1 600 rpm

- Maximum torque (SaE net)(lbs-ft): 201 lbs.-ft. @ 1,600 rpm

- Rated output (SaE Net) (HP): 83.8 HP @ 2,400 rpm

- Rated output (SaE Net) (kW): 62.5 kW @ 2 400 rpm

- Engine manufacturer / model: GCT EBT-TB45-1A

- Fuel tank capacity (L): 76

- Fuel tank capacity (US gal): 20.1

- Number of cylinders / Displacement (cm^3): 6 /4 478

- Number of cylinders / Displacement (in^3): 6 / 273

- Ground clearance, center of wheelbase (mm): 175

- Ground clearance, center of wheelbase (in): 6.9

- Length to fork face (in): 116.3

- Length to fork face (mm): 2 955

- Forks, thickness x width x length (in): 2 x 5.9 x 42.1

- Forks, thickness x width x length (mm): 50 x 150 x 1 070

- Carriage width/ITa class (mm): 1 190 mm / III

- Carriage width/ITa class (in): 46.9 in / III

- Ground clearance under mast (mm): 140

- Ground clearance under mast (in): 5.5

- Tilting angle, forward/backward (deg): 6 / 12

- Free lift height (in): 6.1

- Free lift height (mm): 155

- Height overhead guard (in): 87

- Height overhead guard (mm): 2 210

- Mast height - lowered (in): 82.7

- Mast height - lowered (mm): 2 100

- Mast height - extended (in): 162.6

- Mast height - extended (mm): 4 130

- Turning radius, outside (mm): 2 580

- Turning radius, outside (in): 101.6

- Maximum fork height (mm): 3 000

- Maximum fork height (in): 118.1

- Overall width at drive tires (in): 53.1

- Overall width at drive tires (mm): 1 350

- Right angle stacking aisle (mm): 3 120

- Right angle stacking aisle (in): 122.9

- Length, with standard forks (in): 158.5

- Length, with standard forks (mm): 4 025

- Tire type details: Pneumatic

- Number of wheels, front/rear: 2x / 2

- Tire size - front: 250 - 15 - 16PR (I)

- Tire size - rear: 7 - 12 - 12PR (I)

- Tread - front (in): 43.9

- Tread - front (mm): 1 115

- Tread - rear (in): 44.1

- Tread - rear (mm): 1 120

- Axle loading - loaded front (kg): 8 530

- Axle loading - loaded front (lbs): 18,766

- Axle loading - loaded rear (lbs): 2,541

- Axle loading - loaded rear (kg): 1 155

- Axle loading - unloaded front (kg): 2 215

- Axle loading - unloaded front (lbs): 4,873

- Axle loading - unloaded rear (kg): 3 470

- Axle loading - unloaded rear (lbs): 7,634

- Service weight (kg): 5 685

- Service weight (lbs): 12,507

- EPA emission-compliant fuel system

- UL-certified

- GK45 LPG Engine with electronic control system

- Anti-restart ignition switch

- Engine protection system

- Enclosed wet disc brakes

- Closed loop exhaust system with 3-way catalytic converter

- Single speed powershift transmission

- Dual floating structure — powertrain and operator compartment

- Komatsu-designed load sensing hydraulic system — CLSS

- Full suspension seat with operator restraint system and orange seat belt

- Small diameter steering wheel

- Tilting steering column

- Paper binder at Engine hood

- Backup alarm

- Rear combination light

- KOPS Plus operator presence system

- Cyclone air cleaner

- Fully hydrostatic power steering

- Overhead guard with front/rear conduits

- Easy-removable floor panel and radiator cover

- EPA emission-compliant fuel system

- UL-certified

- GK45 LPG Engine with electronic control system

- Anti-restart ignition switch

- Engine protection system

- Enclosed wet disc brakes

- Closed loop exhaust system with 3-way catalytic converter

- Single speed powershift transmission

- Dual floating structure — powertrain and operator compartment

- Komatsu-designed load sensing hydraulic system — CLSS

- Full suspension seat with operator restraint system and orange seat belt

- Small diameter steering wheel

- Tilting steering column

- Paper binder at Engine hood

- Backup alarm

- Rear combination light

- KOPS Plus operator presence system

- Cyclone air cleaner

- Fully hydrostatic power steering

- Overhead guard with front/rear conduits

- Easy-removable floor panel and radiator cover

- Wide-angle center mirror

- Rearview mirrors

- Dual fuel system (LPG and gasoline)

- 4-way control valve

- Sideshifter

- Sideshifting fork positioner

- Air intake pre-cleaner

- LPG swing down tank bracket

- LPG lLow fuel warning light

- Steel Cab

- Steel Cab with heater and defroster

- Steel Cab with heater, defroster and air conditioner

- Tilt cylinder boots

- Fire extinguisher

- Overhead guard mounted mirrors

- Anti-static ground strap

- Mast-mounted head lights

- Rear working light

- Amber strobe light

- Fuel level warning lamp

- Solid pneumatic Tires

- Non-marking Tires

- Dual front drive Tires

- Wide-angle center mirror

- Rearview mirrors

- Dual fuel system (LPG and gasoline)

- 4-way control valve

- Sideshifter

- Sideshifting fork positioner

- Air intake pre-cleaner

- LPG swing down tank bracket

- LPG lLow fuel warning light

- Steel Cab

- Steel Cab with heater and defroster

- Steel Cab with heater, defroster and air conditioner

- Tilt cylinder boots

- Fire extinguisher

- Overhead guard mounted mirrors

- Anti-static ground strap

- Mast-mounted head lights

- Rear working light

- Amber strobe light

- Fuel level warning lamp

- Solid pneumatic Tires

- Non-marking Tires

- Dual front drive Tires