Komtrax monitoring system

Helps manage owning and operating costs by continuously monitoring and recording machine health and operational data such as fuel consumption and utilization. Tracks when maintenance is due so you can plan ahead.

The TimberPro TN785D swing machine was developed to handle various length timber in millyard applications with ease. It started with the proven TimberPro design and components, and then added power, lift, swing and reach capacities. The result is the largest, most powerful and highest capacity TimberPro machine produced.

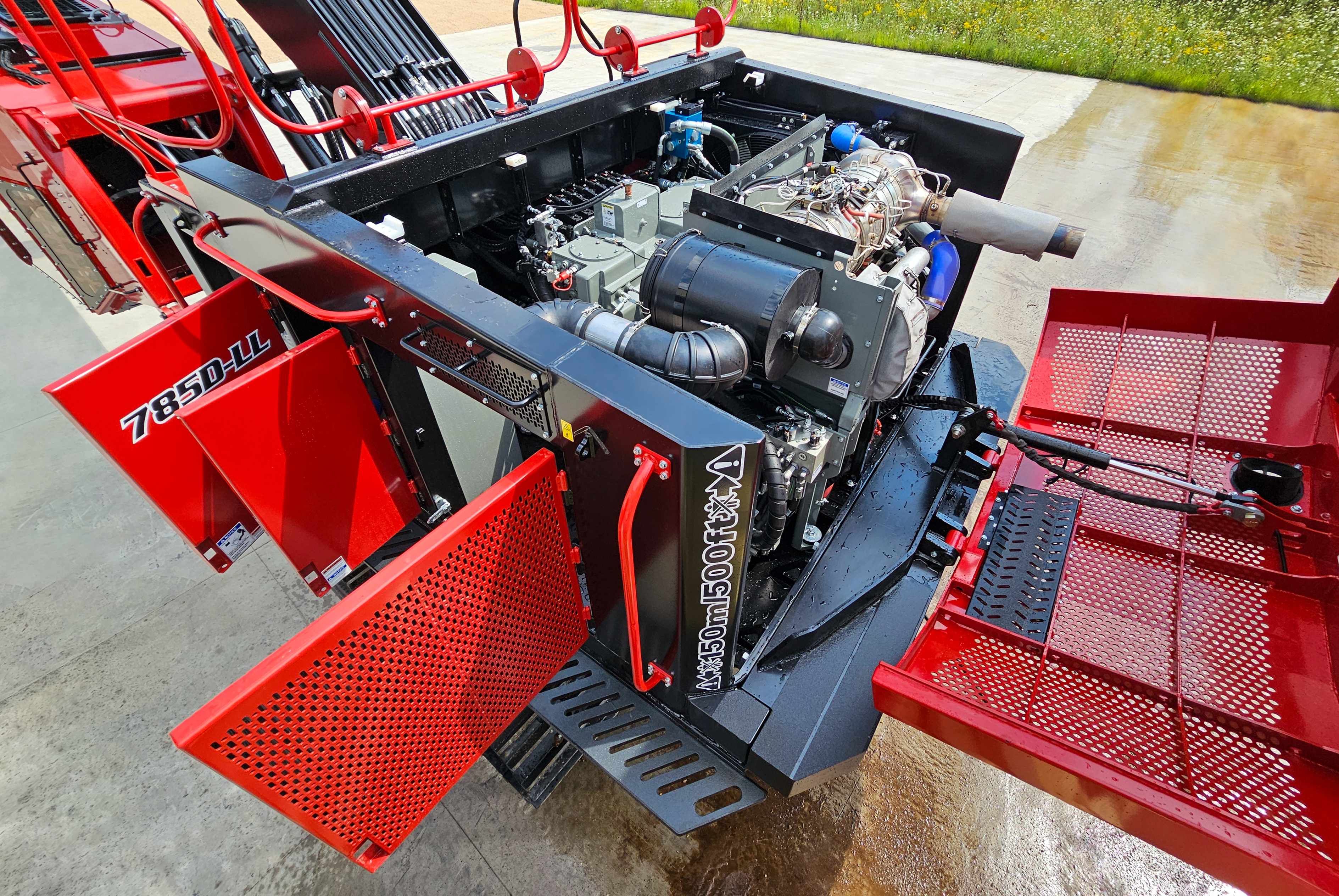

A high output 390HP Cummins engine is among the most powerful in its class and provides the power and hydraulic capacity for brisk yet controlled swing and lift commands. The hydrostatic swing mechanism is redesigned, with dual motors and dedicated circuit for fast precision operation when placing logs.

Redesigned, extended 12 roller track frames provide a long, stable platform for even weight distribution, high traction and low ground pressure while moving heavy loads. More than 2.5 ft [.76 m] of ground clearance helps ensure that the operator can place the machine where it needs to be.

With more than 44 feet of reach [13.4 m] an operator can grab logs at a greater distance without having to reposition the machine — for less effort in loading and unloading trucks and with easy ability to high stack logs. Can be equipped with either grapple or live heel depending on application needs.

A comfortable operator is a productive operator. The TN785D has a plush, ergonomic air ride suspension seat with adjustable armrests for comfort. Electric over hydraulic controls can be custom tuned and configured to each operator and access to the operator station is made easy through a rear facing door. Additionally, there is a roof mounted egress hatch.

To aid the operator in maintaining line of sight to the work equipment and surrounding working area, the cab is raised 51 in [1.3 m] and has large windows on either side with protective guarding, a skylight for upward line of sight and a standard rearview camera system with dedicated display.

Ample walkways and access panels enable easy cleanout of debris buildup and daily service checks. Centralized greasing bank and tilting cab make routine maintenance straightforward. Ground level fueling and a convenient carbody mounted trunk storage allow for simple daily maintenance.

Hydraulic motors

Relief valve setting

Main pump

Hydraulic cylinders (Bore x Stroke x Rod Diameter)

Maximum travel speed (auto-shift)

Horsepower

Helps manage owning and operating costs by continuously monitoring and recording machine health and operational data such as fuel consumption and utilization. Tracks when maintenance is due so you can plan ahead.