Intelligent Machine Control

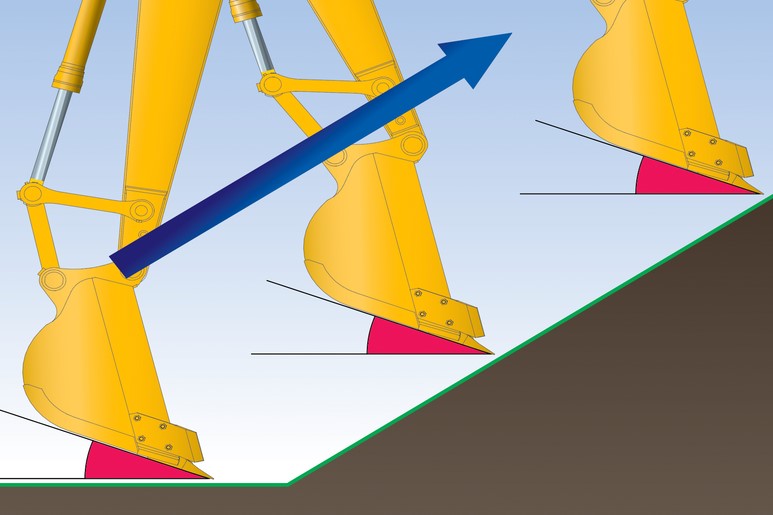

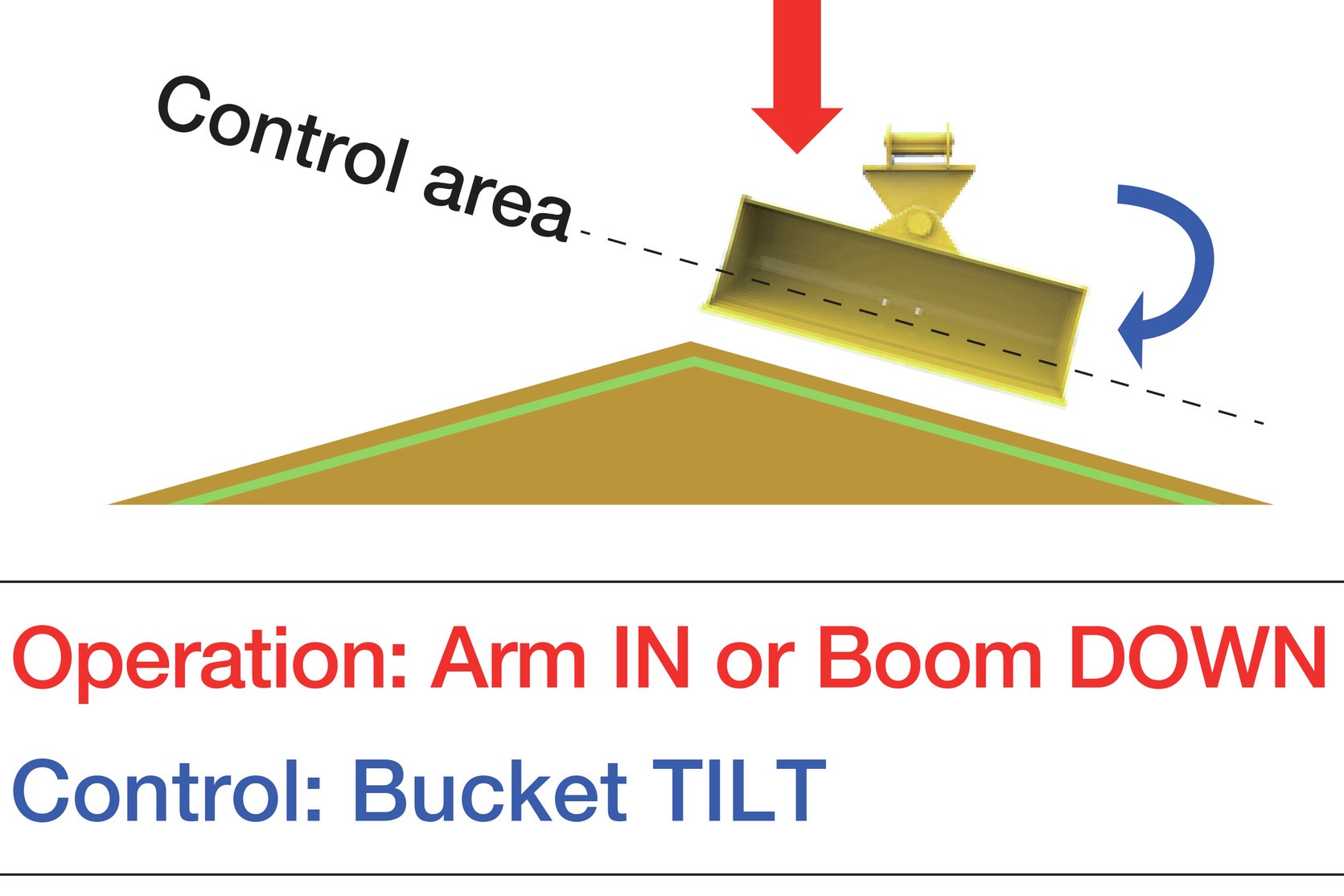

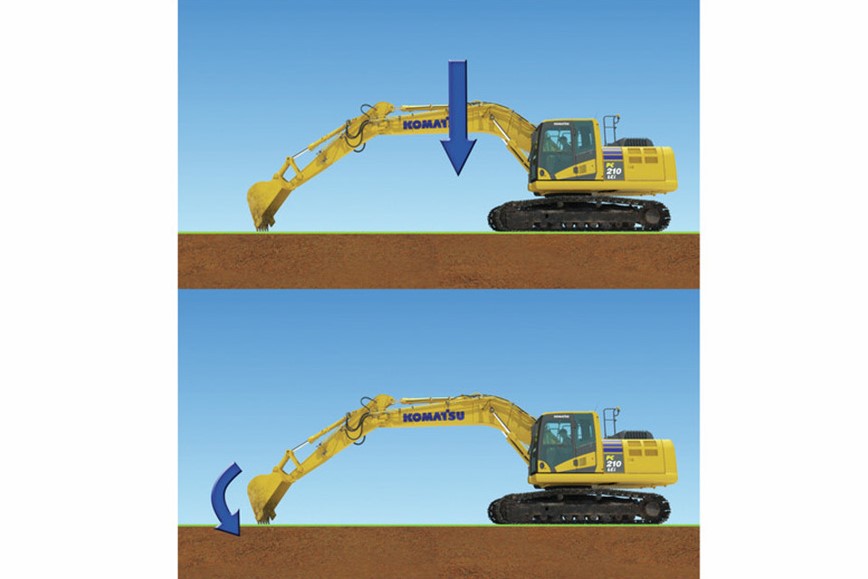

Productivity is the key to success on your job site, and the faster your crew can reach a state of maximum productivity, the better. Now you have a powerful tool to help make that happen with Komatsu’s Intelligent Machine Control (IMC). Incorporating a host of advanced, proprietary machine technology, IMC gives you the opportunity to take advantage of sophisticated, productivity-enhancing automation and cutting-edge job site design.