Smart Construction Retrofit

Optional Smart Construction 3D guidance and payload monitoring system to help optimize loads, promote improved accuracy and reduce rework, and prevent overloading/underloading.

The PC900LC-11 is built for tough jobs that require high performance. This excavator is an easy-to-transport, versatile machine with exceptional power and digging capabilities. Excellent for construction, mass excavation, material handling, deep sewer and water installations, and mining/quarry environments. The PC900LC-11 is a perfect four-pass match for the HM400-5 truck.

Note: *versus the PC800LC-8 model

When your operators need to meet demanding production targets, they will appreciate this excavator's improved engine power, crowd-digging force, swing torque, lift capacity and increased bucket size options.

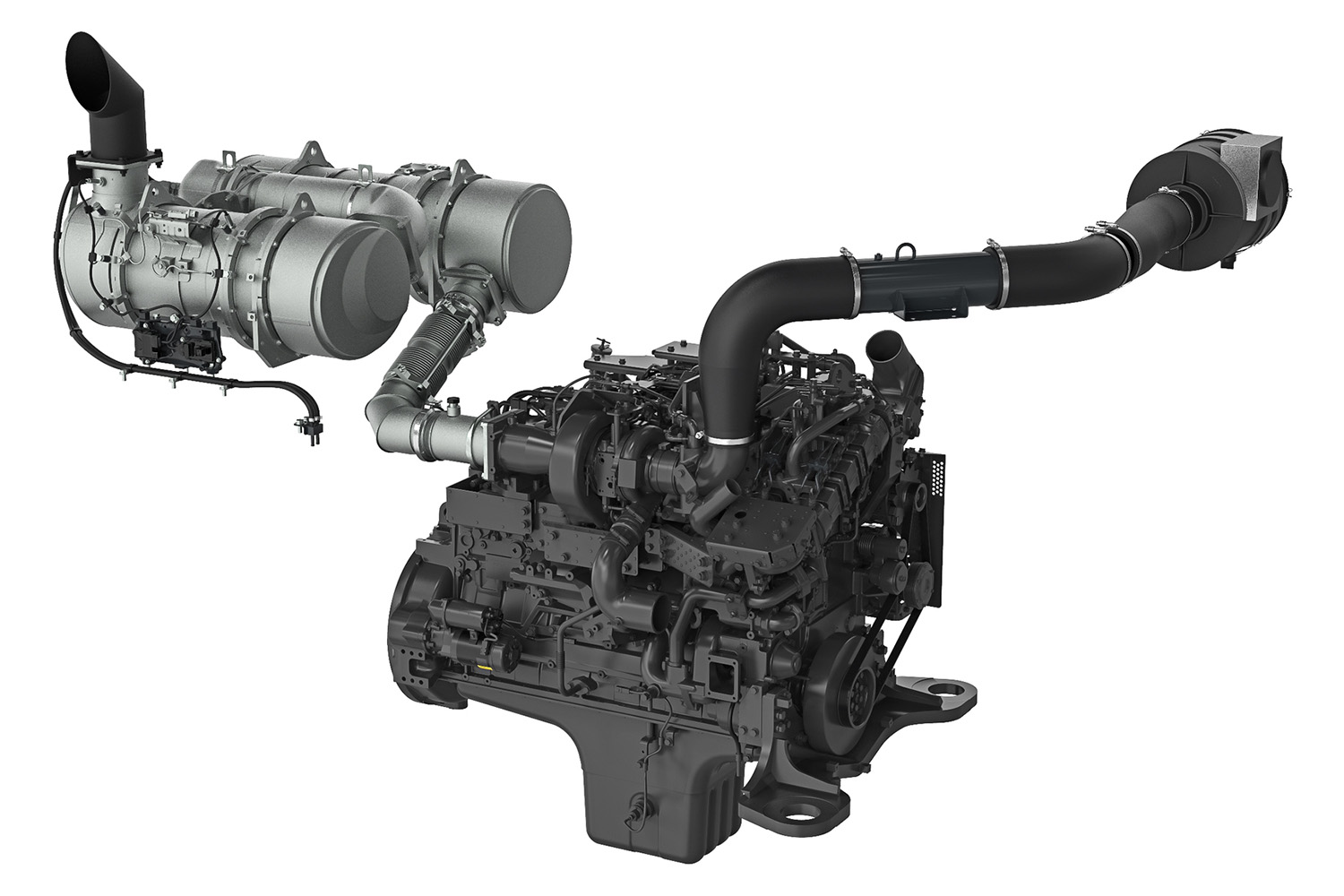

Get a high-performance engine and enhanced hydraulics technology with this versatile excavator that handles high-production demands in large-scale operations while promoting machine reliability.

Operators can promote safety and streamline their performance with technology like the KomVision camera system's real-time view of immediate surroundings and optional Smart Construction 3D guidance and payload monitoring.

Make maintenance easy and help minimize downtime with convenient access to all filters, oil level checks, sample ports and engine maintenance service areas with top, left and right walkways.

The new counterweight removal system makes the excavator easier to transport on trailers and move between job sites, simplifying logistics and helping reduce transportation costs.

Make those long shifts comfortable with a spacious, quiet cab and an adjustable seat. The short joystick control levers provide a convenient, ergonomic workspace that promotes operator productivity.

Hydraulic cylinders

Main pump

Relief valve setting

Hydraulic motors

Triple grouser shoes

Horsepower

Maximum travel speed

Optional Smart Construction 3D guidance and payload monitoring system to help optimize loads, promote improved accuracy and reduce rework, and prevent overloading/underloading.

KomVision camera system to help enhance visibility, mitigate blind spots, promote job site safety and enable operators to maneuver the equipment with confidence.

Smart Quarry Site is a digital fleet tracking and visualization solution providing information to help you unlock productivity from your machines, operators, site design and more. Imagine a near-real time animated overview of every movement of production machines and dashboards showing their effectiveness.

Find what works for you